2

CRM

We reserve the right to alter specifications. 20130522 www.swegon.com

Figure 2.Straight duct length demands, see table below.

Figure 1. Installation.

Technical Description

Design

Circular airflow measurement and commissioning damper.

The CRM consists of a duct section with a damper and

measuring device. The connections are fitted with rubber

seal ring.

The damper has a lockable knob for manual adjustment

and indicators for open and closed damper blade position

are stamped in the damper’s exterior surface.

Inside the damper, there is a measurement unit and a

damper blade. The damper blade is available as a solid blade

with rubber gasket (Ductwork leakage class 4), or as a

perforated blade without rubber gasket (Ductwork lea-

kage class 0). Ductwork leakage classification according

to

SS-EN1751 och VVS AMA 98.

When motorised control is selected, the damper knob shelf

is replaced by a larger actuator support shelf. The motorised

control requires an actuating torque according to the dimen-

sions and weights table on page 7. Standard supporting

shelves are 80 mm high to allow possible duct insulation.

Materials and finish

The entire damper is made of galvanized sheet steel.

Adaptation

The damper can be made of other materials, such as

stainless or epoxy-coated sheet steel. Please contact your

nearest sales representative for further information.

Accessories

Actuator:

Sauter ASM115SF901, ASM124SK001, 24 V AC, standard

actuators depending on size.

Other actuators must be ordered, see actuator table page 7.

Wiring diagrams are available in current Installation -

Commissioning - Maintenance Instructions available at the

Swegon web page.

Knob:

CRTT-1 for manual control.

Quick connection:

FSR. Clamp with quick-acting lock.

Planning

CRM is equipped with components for a differential pressure

method of measurement. In order to meet the specified met-

hodic error, a straight duct length must be arranged upstream

of the damper. See "Methodic Errors" and Figure 2.

When planning for actuator-controlled forcing, the min.

permissible air flow indicated in the diagram must be

taken into account. The methodic error (according to

table) is not applicable to the airflows that are less than

the min. permitted flow.

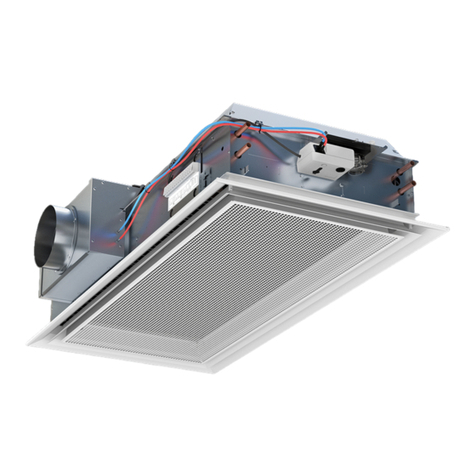

Installation

Damper is Inserted into the connecting duct and fixed in

position by pop rivets or by means of an FSR clamp. See

Figure 1.

Commissioning

Connect hoses from a manometer to the measurement

nipples. Turn and lock the damper blade at the desired

setting angle For particulars of motorised control, we

refer to the actuator supplier’s instructions. K-factors are

shown on the product’s identification label. The K-factor

can also be found in the relevant commissioning instruc-

tions at www.swegon.com.

Maintenance

Clean the damper whenever needed by means of a

vacuum-cleaner or by wiping surfaces with a cloth.

Environment

The Declaration of Construction Materials is available

from www.swegon.com.

Methodic Errors

Type of obstruction

upstream of the CRM

Length of straight duct (L)

upstream of the CRM

For m2= 5% For m2=10%

One 90° bend. 3 x Ød 2 x Ød

Two 90° bends in the same

plane.

4 x Ød 2 x Ød

Two 90° bends in aligment at

right angles to one another.

4 x Ød 2 x Ød

One 45° damper. 6 x Ød 3 x Ød

One T-piece. 4 x Ød 3 x Ød

m2= methodic error. Method for measurement of airflows in

ventilation Installations.