2

MIS CONTROL Optimize

Swegon reserves the right to alter specifications. 20091207 www.swegon.com

Settings in the GOLD via home page

All settings can also be performed via the home page for

the air handling unit. There are two tabs: [C Optimize],

where you can enable and view readings as well as [Fans]

where you can set limits for pressure regulation.

Supply airflow/pressure/% Extract airflow/pres-

sure/%

This shows the regulated pressure in Pa.

supply air/Extract air controller

Shows the control set point in Pa.

Supply air/Extract air, low speed

Not used by CONTROL Optimize

Supply air/Extract air, max. speed

Not used by CONTROL Optimize

Supply air/Extract air, high speed

These values specify the regulation start pressure for the

air handling unit during the countdown period before

optimisation takes place. This value is appropriately set as

a mean value between min./max.

Supply air/Extract air, C.Optimize min

Is the lowest pressure that applies to the min. airflow for

the entire system. The pressure can be set to 50 Pa at the

lowest.

Supply air/Extract air, C.Optimize max

Is the highest pressure that the system requires in order

to be able to supply the design max. airflow. It is impor-

tant to not set the pressure too high but instead is really

matched to the actual requirement. An excessively high

pressure can create unnecessary noise in the system if

some damper does not operate correctly and CONTROL

Optimize operates as if this damper were fully open.

Settings for optimizing

The basic settings for the damper positions used for opti-

mizing can be changed here. The changes are automati-

cally saved in the CONTROL Optimize.

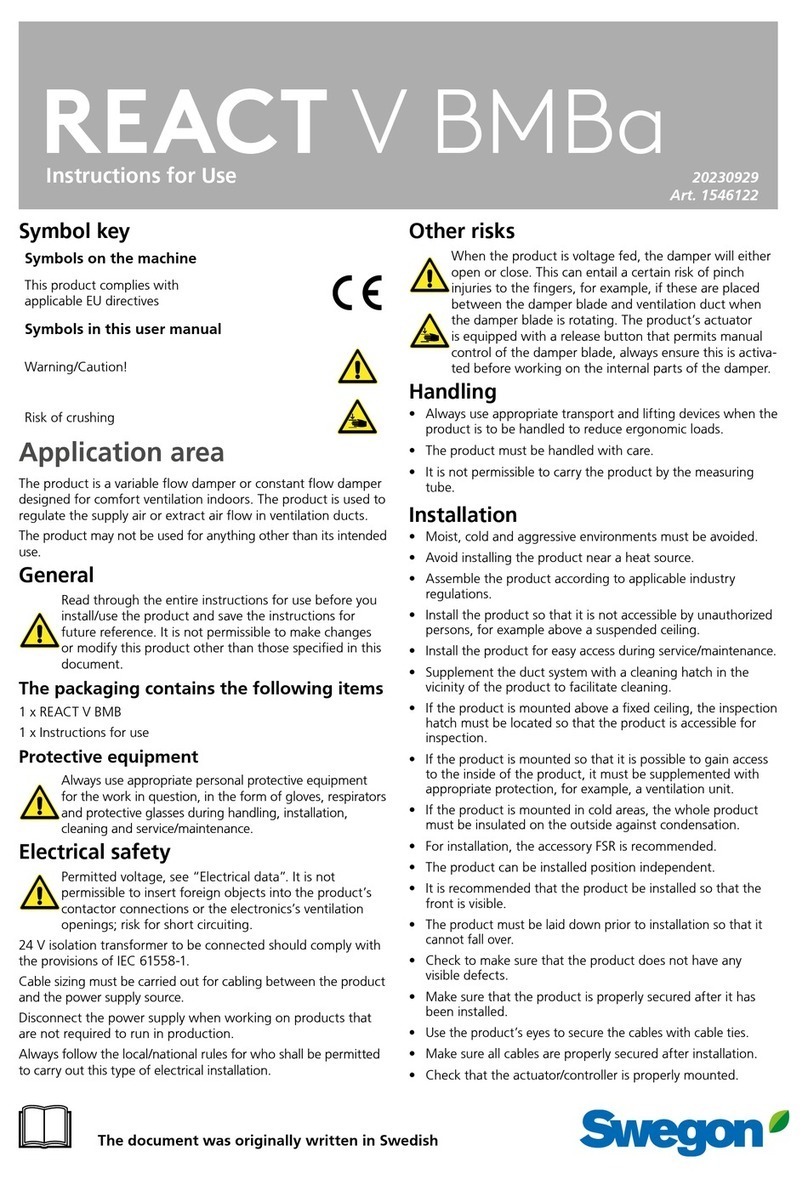

DAMPER LIM.

Value for the limits within which optimising takes place.

If a damper is closed more than to 70%, the system

reduces the pressure set point of the fan and vice-versa

if a damper is open more than 90%, i.e. the system then

increases the pressure set point. These limits are preset to

70/90% and should not be changed.

STEP SIZE

The pre-selected pressure value for the change in set

point of the air handling unit pressure is 10 Pa and

Swegon’s recommendation. The value should not be set

lower than 5 Pa.

INTERVAL

Indicates how often CONTROL Optimize should read the

damper positions in the system. The lowest adjustable

time is 1 minute, which also is pre-selected. In larger

systems with more than 25 dampers, the time should

be lengthened by a minute or two, so as not to create

unnecessarily excessive traffic on the Modbus network.

START UP DELAY

This is the time needed for the system to become stable

before optimisation begins. When the air handling unit

has been shut down, all the zone dampers are fully open

and require time to adjust themselves to their set points.

Optimisation cannot start until the dampers have finished

adjusting themselves.

TIME TO START OPT.

Is the remaining time before optimisation begins the

countdown of the start delay.

* CONTROL Optimize *

FUNCTION ON/OFF

INSTÄLLNINGAR

* CONTROL Optimize *

DAMPER LIM. 70/90 %

STEP SIZE 10 Pa

INTERVAL 1 min

START UP DELAY 10min

TIME TO START OPT. 0s