3Rev. 16GB1304

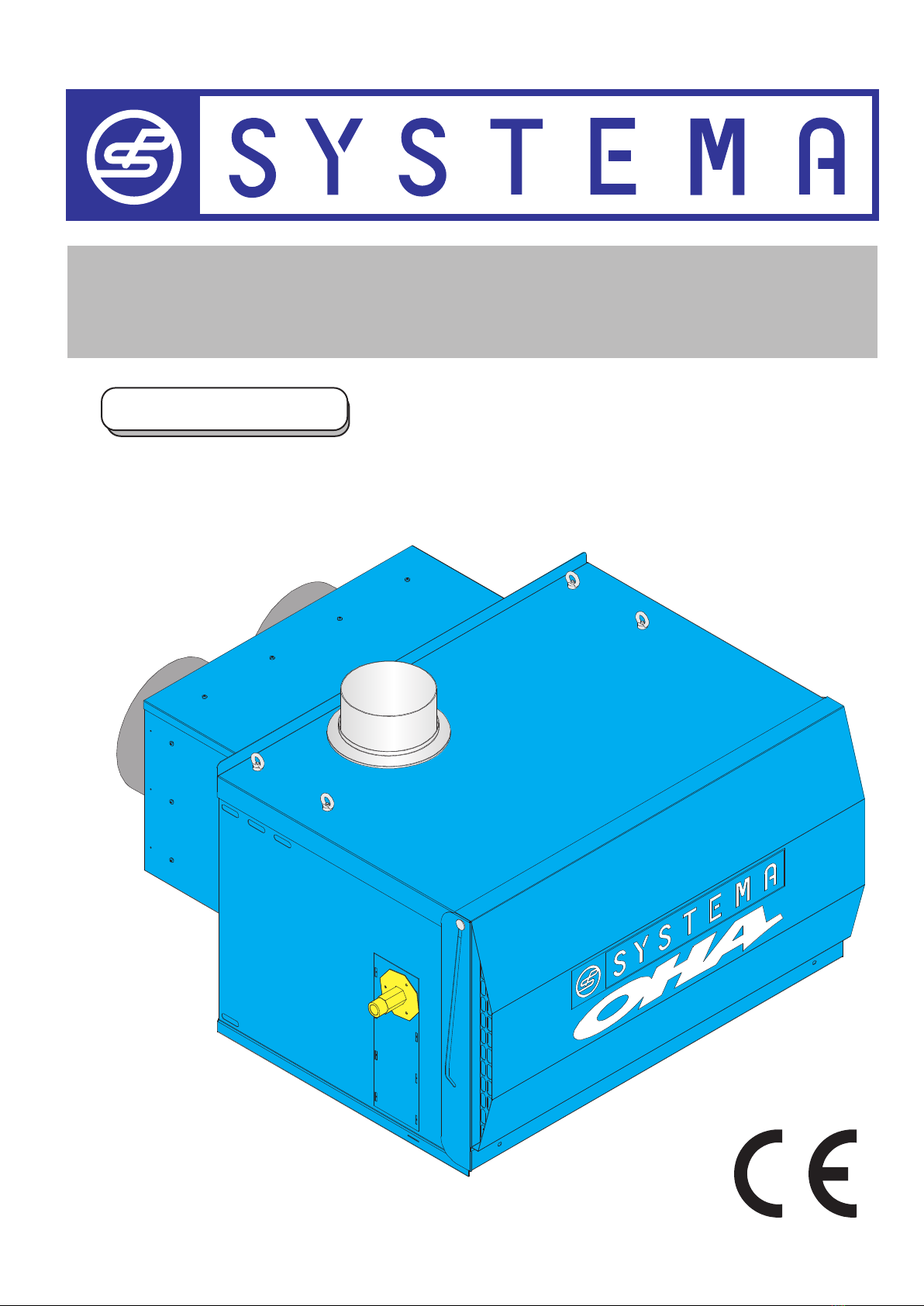

SYSTEMA S.p.A.OHA

SUMMARY

1 GENERAL STANDARDS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

2 PACKING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

2.1 PACKING LIST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

3 TECHNICAL FEATURE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

3.1 OPERATING DESCRIPTION AND FEATURES . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

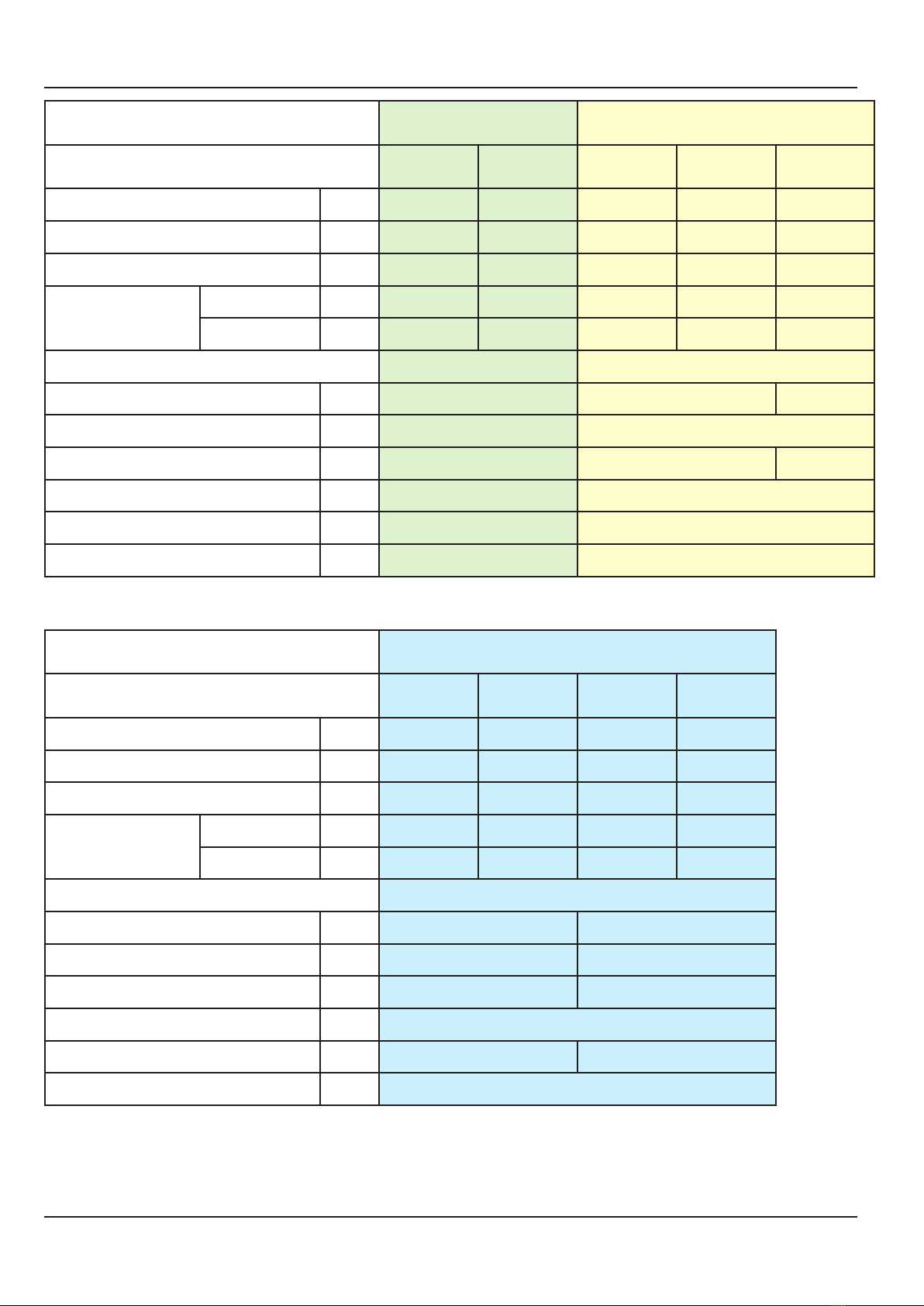

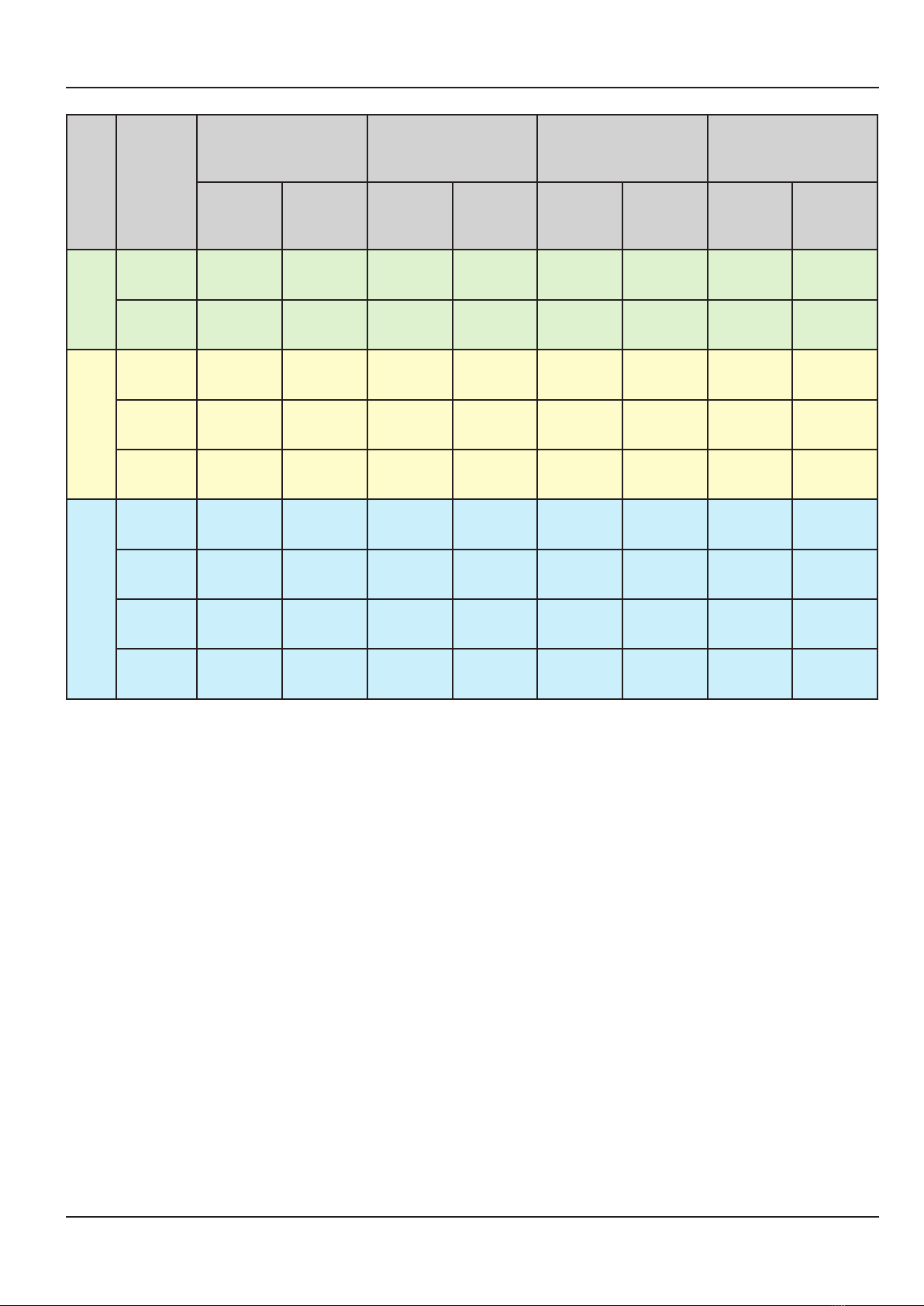

3.2 TECHNICAL FEATURES OF THE COMBUSTION UNIT . . . . . . . . . . . . . . . . . . . . . .7

3.2.1 Code table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

3.2.3 Features of the generator components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

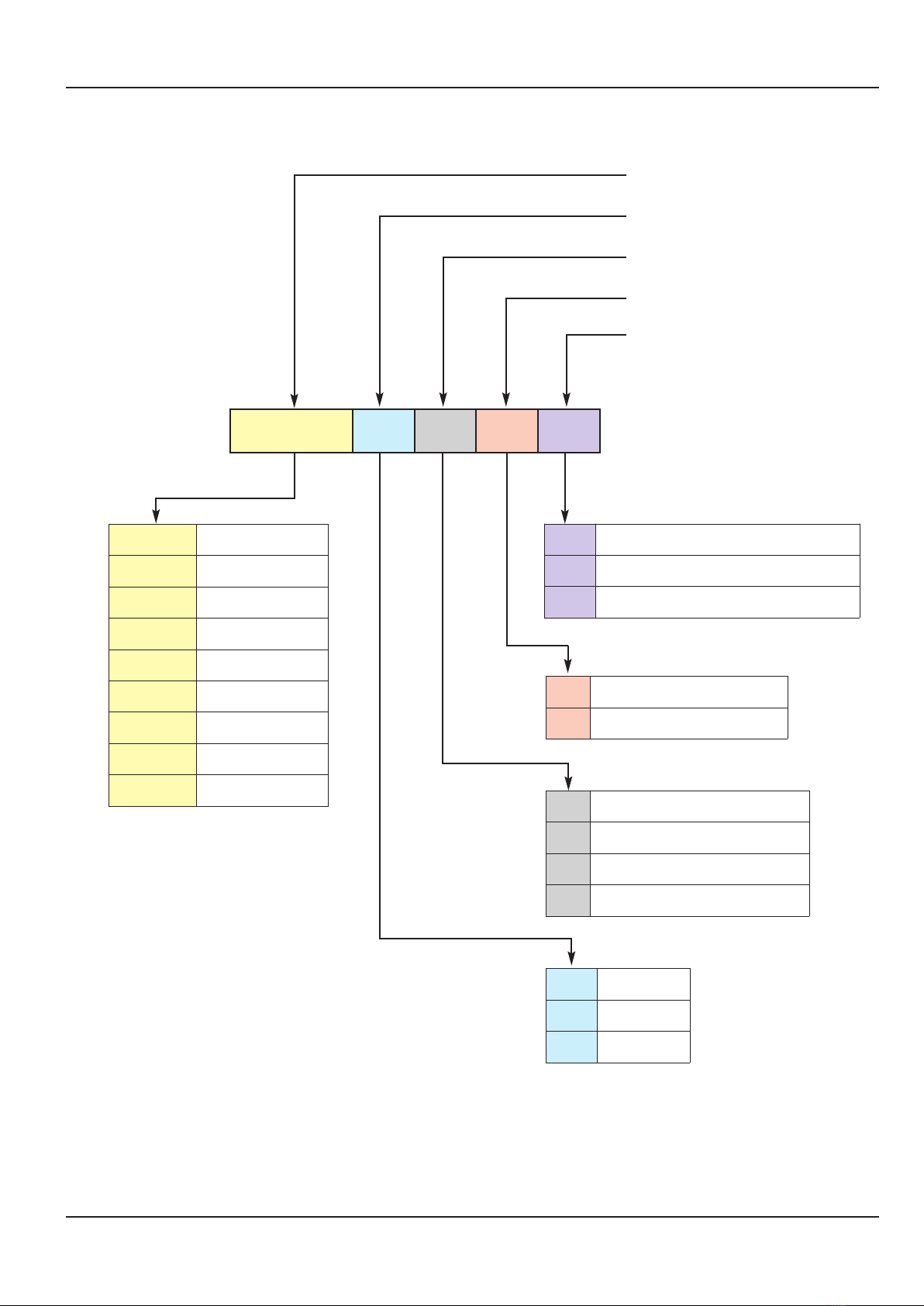

3.2.2 Main components in the generator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

3.3 EXPLOSION OF THE THERMAL UNIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

3.4 DIMENSIONS OF THE GENERATOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

3.5 DIMENSIONS OF THE RADIANT BAND . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

3.6 OHA 100, OHA 200, OHA 400 COMBUSTION HEAD . . . . . . . . . . . . . . . . . . . . . . .16

3.6.1 Diaphragm and electrode positions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

4 INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

4.1 INSTALLATION AREA AND SAFETY DISTANCE . . . . . . . . . . . . . . . . . . . . . . . . . .20

4.2 MINIMUM DISTANCE BETWEEN THE OHA RADIANT BAND AND INFLAMMABLE

MATERIALS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

4.3 ASSEMBLY SEQUENCE FOR THE BAND . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

4.4 MODULAR PLATFORM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

4.4.1 Platform composition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

4.4.2 Assembling the standard platform (without glass fixing bracket kit and panel support kit

REI120) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

4.4.3 Hole for platform with glass holder kit and REI120 panel support kit . . . . . . . . . . . . . . . . . .29

4.5 ASSEMBLING THE HEATING UNIT ON THE PLATFORM . . . . . . . . . . . . . . . . . . .29

4.6 TILTED BRACKET FOR ROOF UNIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

4.7 CONNECTING THE COMBUSTION CHAMBER EXTENSION . . . . . . . . . . . . . . . .31

4.8 CONNECTING THE COMBUSTION UNIT TO THE BAND . . . . . . . . . . . . . . . . . . .32

4.9 ASSEMBLING THE BANDS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

4.9.1 Side connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

4.9.2 Connections between pipes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

4.9.3 Mounting the curves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

4.9.4 Mounting the expansion joins . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

4.9.5 90° Side connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .44

4.9.6 Assembling the end closed cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

4.9.7 Asembling the “T” branch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46

4.9.8 Assembling the top insulation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47

4.9.9 Vertical connections for the radiant band positioned on two different levels . . . . . . . . . . . . .50

4.9.10 Assembling the bottom grid (optional) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .51

4.9.11 Assembling the top shell (optional) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .52

4.9.12 Assembling the reflecting sides (optional) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .53