T&R Z-OVR Operating instructions

1

OPERATING AND MAINTENANCE MANUAL

Product: Cable Impedance Test System

Type: Z-OVR

Software version 1.04

DESIGNED AND MANUFACTURED BY:

T & R Test Equipment Limited

15-16 Woodbridge Meadows, Guildford, Surrey, GU1 1BJ, United Kingdom

Web: www.trtest.com

2

GENERAL SAFETY STATEMENT

CAUTION

The following safety precautions should be reviewed to avoid injury to the user and damage to the product

(and other products connected to it). To avoid potential hazards only use this product as specified.

Only suitably qualified personnel should use this equipment. Servicing of this product should

only be carried out by suitably qualified service personnel.

To Avoid Fire Hazards and Personal Injury

Use the correct power supply lead. Only use a suitably rated and approved power supply lead for

the country of use.

Ensure that systems that the unit is to be connected to are isolated from the supply and earthed.

Do not connect and disconnect leads whilst outputs are switched on. Breaking the output circuit with

current flowing may cause potentially fatal arcing.

Ensure that the product is grounded. To avoid electric shock, it is essential that the grounding

conductor is connected to the earth ground. An additional earth terminal is provided on the unit that

should be connected to a local earth. Ensure that the unit is properly grounded before making any

connections to inputs or outputs.

Terminal ratings must be observed to prevent fire hazards and risk of injury to the operator. Consult

the product manual for ratings information before making connections to any terminal.

It is ESSENTIAL to consult the product manual for rating information before making any connection

to a terminal or terminal group marked with a warning triangle.

Only use fuses of a type and rating specified for this product.

Do not operate the unit out of its case or with any covers or panels removed.

Do not touch exposed connections and components when power is present.

Do not operate the product if any damage is suspected. Refer the unit to qualified service personnel

to be checked.

Do not operate the unit in wet or damp conditions.

Do not operate the unit in an explosive atmosphere.

Do not operate the unit if there is the possibility of lightning strikes on the line under test or connected

lines.

If any further queries occur regarding the usage and maintenance of the equipment detailed

in this manual, please refer these to the supplier of the equipment in the first case or to the

manufacturer, T & R Test Equipment Limited.

3

SAFETY TERMS AND SYMBOLS

The following safety symbols appear on the equipment:

CAUTION/WARNING – Refer to manual

Mains off

Mains on

The following safety symbols appear in this manual:

CAUTION

This action or procedure may be dangerous if not carried out

correctly and may cause damage to the equipment or

connected equipment.

WARNING

This action or procedure may cause injury or death to the

operator or other personnel if not carried out correctly using

applicable safety procedures.

! Note This is useful information that may make testing easier, help

in interpretation of results or prevent confusion.

5

CONTENTS

1. DESCRIPTION OF EQUIPMENT 7

1.1 Panel layout and functions 8

1.1.1 Control unit 8

1.1.2 Output unit 10

1.1.3 Display 12

1.1.4 Warning messages 12

1.2 Installation 13

1.2.1 Environment 13

1.2.2 Supply requirements 13

1.2.3 Cables 14

1.2.4 System connections 17

1.2.5 Overload protection 18

1.3 Functions 18

1.3.1 Output 18

1.3.2 Metering 19

1.3.5 Result storage 23

2. THEORY OF OPERATION 26

2.1 Kelvin connection 26

2.2 Impedance testing 27

2.3 Phase reversal to avoid interference 28

3. OPERATION 29

3.1 Setting up 29

3.1.1 System connections 30

3.1.2 Line connections 30

3.2 Testing 33

3.3 After Testing 34

4. MAINTENANCE 35

6

4.1 Output Control Brushes 35

4.2 Removal of the Z-OVR from Case 35

5. STANDARD ACCESSORIES 37

5.1 Spare Fuses Supplied: 37

5.2 Standard Accessories Supplied: 37

6. OVERALL PERFORMANCE SPECIFICATION 39

6.1. Insulation Resistance at 1000V DC 39

6.2. Applied Voltage Test 39

6.3. Accuracy of Instruments 39

6.3.1 Current metering 39

6.3.2 Voltage metering 39

6.3.3 Phase metering 39

7. REVISION 41

7

1. DESCRIPTION OF EQUIPMENT

The Z-OVR is a line/cable impedance measurement system for high voltage ac systems. The

impedance of the line is measured by injecting a current and measuring the magnitude and

phase angle of the voltage developed across the line. The resistance and reactance of the line

are calculated from these results and displayed. The system uses a 4-wire measurement with a

Kelvin connection to the line under test to eliminate measurement errors due to voltage drops

in the leads.

The unit has the facility to store test results to a USB memory key.

The system consists of a separate control unit containing all metering and control functions and

an output unit that provides the high current output and isolation of measured voltages. All

connections to the line are made via the output unit.

The system is supplied with three overhead line Kelvin clamps, one earth Kelvin clamp, one

earth lead and all interconnecting and supply leads.

Three outputs are provided on the output unit (75V 80A, 150V 40A and 300V 20A) to allow a

wide range of lines to be tested.

.

WARNING

The Z-OVR system must only be used on ‘dead’ systems (i.e. no externally

supplied voltages are present on the test object) with safety earths applied.

Extreme caution must be applied due to the possibility of induced voltages from

other energised circuits. Under no circumstances connect a PCU1 to a live system

or lines without earths applied.

WARNING

Under no circumstances use any of the leads supplied with the unit as earthing

equipment for high voltage lines or cables. Approved earthing equipment must be

used in accordance with accepted working practices before connections can be

made between the line and Z-OVR.

8

B C D E

S

T

F

G

H

I

J

K

L

M

N

O

P

Q

R

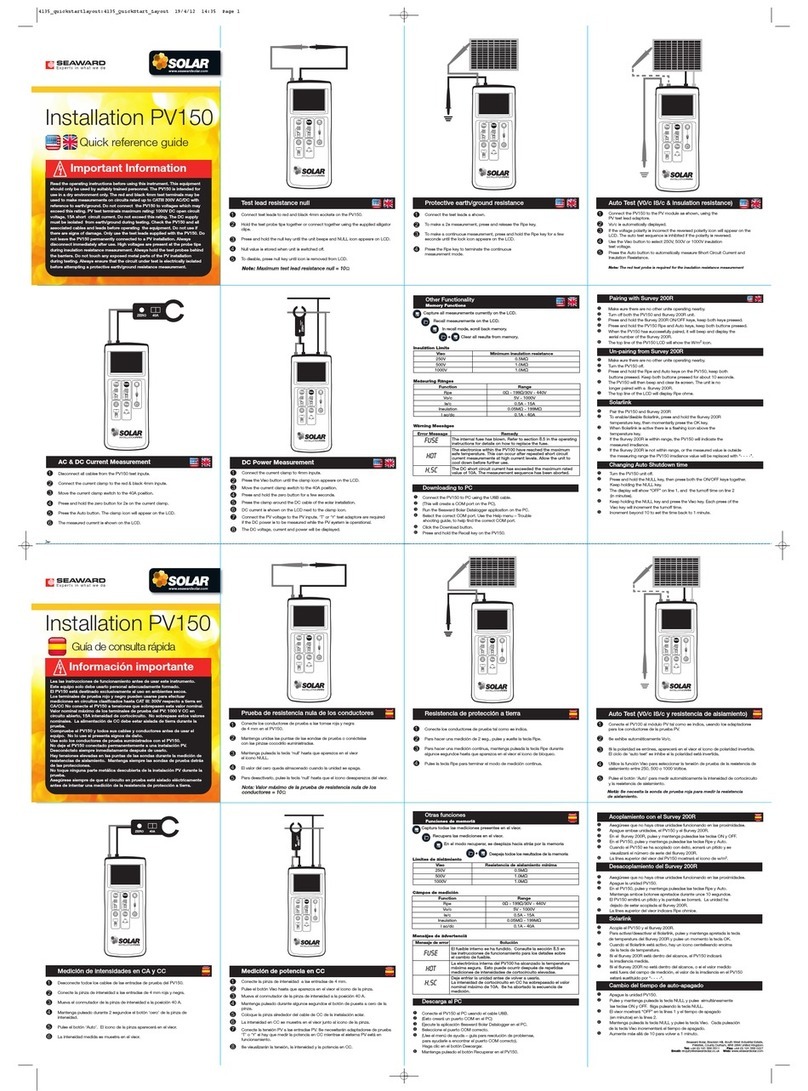

1.1 Panel layout and functions

1.1.1 Control unit

Figure 1.1 Z-OVR front panel

A

9

ITEM FUNCTION

A Output unit metering connection Metering/control connection to output unit

B Output circuit breaker Protection for control unit output

C Output unit power connector Power supply to output unit

D Mains input switch/circuit breaker Supply isolation switch and protection

E Mains inlet connector Mains supply connection

F Earth Terminal Terminal for optional connection to local

earth for enhanced safety

G Fuse Fuse for metering and control circuits

H Power indicator Supply on indicator

I RS232 connector Serial connection for PC/printer connection

J Main output control Sets output current

K Output off button Switches output off. Illuminates green to

show that output is off.

L Output on pushbutton Switches output on. Illuminates red to show

that output is on.

M Adj. digital pot Control to select values for result storage

N Impedance measurement select Selects calculated value to display-

impedance, frequency or harmonics

O Store pushbuttons Pushbutton switches for store result and

selection

P Liquid crystal display Shows current, voltage and calculated values

Q Voltmeter range select Selects voltage measurement range

R Store result select Controls result storage functions

S Ammeter range select Selects ammeter range

T USB sockets USB sockets for keyboard and memory key

10

A B

C

D

E

F

G

H I

J

1.1.2 Output unit

Figure 1.2 Output unit front panel

11

ITEM FUNCTION

A Output commoning block Allows three phase cables to be connected

together for parallel measurement. All four

terminals are connected together.

Note: push connector to release before

pulling to remove plug from socket.

B Voltage input sockets Voltage measurement input

C Voltage input fuses Fuses to protect voltage input

D 300V 20A output socket Highest voltage, lowest current output.

Note: push connector to release before

pulling to remove plug from socket.

E 150V 40A output socket Mid range current output.

Note: push connector to release before

pulling to remove plug from socket.

F 75V 80A output socket Lowest voltage, highest current output.

Note: push connector to release before

pulling to remove plug from socket.

G Z-OVR metering connection Metering/control connection to control unit

H Power connector Power supply from control unit

I Protective earth terminal Connect to low impedance local earth

J Common output socket Common connector for output current

12

1.1.3 Display

The Z-OVR display simultaneously shows the injected test current, measured voltage and one

of a number of other parameters depending on the position of the IMPEDANCE switch. For full

details see section 1.3.4.

Output current Phase angle Voltage input

Impedance Reactance

Output current Phase angle Voltage input

Frequency of measured voltage

Output current Phase angle Voltage input

Harmonic value 1 Harmonic value 2

Output current Phase angle Voltage input

Harmonic value 1 Harmonic value 2

Figure 1.3 Z-OVR metering values

1.1.4 Warning messages

Figure 1.4 Over-current trip warning message

When an over current or duty cycle trip occurs, the green OFF pushbutton must be pressed to

clear the trip condition.

Figure 1.5 Duty cycle trip warning message

I ¢ V

10.00A

90.0°

1.00V

IMPEDANCE

Z=100.0m©

X=100.0m©

I ¢ V

10.00A

90.0°

1.00V

FREQUENCY

50.00Hz

I ¢ V

10.00A

90.0°

1.00V

Voltage Harmonics

1: 200.0V

2: 0.0%

I ¢ V

10.00A

90.0°

1.00V

Current Harmonics

1: 50.0A 2: 0.0%

Output tripped

Press Green to Reset

Duty Cycle Trip

Press Green to Reset

Impedance

Frequency

Harmonic V

Harmonic I

13

Caution

Allow the unit to cool for the rated off time for the main output after a duty cycle trip

Figure 1.6 Unit over temperature warning message

Caution

After an over temperature trip, the unit will automatically reset when the temperature

falls to an acceptable level. If the unit is over temperature, switching the unit off and

back on will not clear the message – the unit must be allowed to cool.

1.2 Installation

Caution

The Z-OVR

control units and output unit are heavy. Avoid lifting where possible.

Ensure that two people are used to lift the units and that appropriate manual

handling techniques are used.

1.2.1 Environment

Z-OVR is designed for use in indoor industrial and electrical substation environments.

Maximum altitude: 2000m

Temperature: 0°C to 45°C operating

-20°C to 60°C storage

Relative humidity: 90% non-condensing

Protection rating: IP20

1.2.2 Supply requirements

230V±10% 50/60Hz 1 phase 6.5kVA.

The unit is supplied fitted with a 32A CEE plug. If it is necessary to fit a different plug, the supply

cable has the following core colours:

Earth Green/yellow

Live Brown

Neutral Blue

The equipment must be earthed through the mains supply. In addition, the output unit must be

earthed using the supplied earth lead to a suitable low impedance local earth (such as the base

of a transmission tower).

The earth terminal on the control unit should be connected to a low impedance local earth if the

supply earth is suspect.

Caution

Ensure that the unit is connected to an appropriate supply by a suitably rated

connector and that the system is adequately earthed.

Over Temperature

Press Green to Reset

14

1.2.3 Cables

The following cables are supplied with the Z-OVR system.

Supply/interconnection cables Length Purpose

Mains supply cable 5m Supply to control unit

Power interconnection cable 5m Connects output unit to control unit

Metering interconnection cable 5m Connects output unit to control unit

Earth cable 10m Connects output unit to safety earth

15

Output cables Length Purpose Rating

Output cable phase A

(red)

12mm² current injection

terminated in 6mm

connector

6mm² voltage sense

terminated in 4mm

shrouded plug

10m Duplex lead fitted with Kelvin

clamp for overhead line

connection.

Max conductor size 80mm

diameter.

80A

CAT I

300V*

Warning

Output cable phase B

(yellow)

12mm² current injection

terminated in 6mm

connector

6mm² voltage sense

terminated in 4mm

shrouded plug

10m Duplex lead fitted with Kelvin

clamp for overhead line

connection.

Max conductor size 80mm

diameter.

80A

CAT I

300V*

Warning

Output cable phase C

(blue)

12mm² current injection

terminated in 6mm

connector

6mm² voltage sense

terminated in 4mm

shrouded plug

10m Duplex lead fitted with Kelvin

clamp for overhead line

connection.

Max conductor size 80mm

diameter.

80A

CAT I

300V*

Warning

Output cable ground

(green)

12mm² current injection

terminated in 6mm

connector

6mm² voltage sense

terminated in 4mm

shrouded plug

10m Duplex lead fitted with Kelvin

clip.

Max jaw opening 27mm.

80A

CAT I

300V*

Warning

*voltage

ratings

Warning

The voltage ratings shown relate to the cable and 4mm/6mm connectors to

connect to the output unit. The cables are terminated in un-insulated clamps for

connection to lines that must NOT be handled whilst the output is on.

Make all connections to the test object with the supply off (supply switch in the

off position) and the cables unplugged from the output unit.

16

The phase clamp connections supplied with the unit are designed for connection to cylindrical

conductors on overhead lines. An optional alternative set of phase leads is available for

connection to other types of conductors and terminals using Kelvin clips as on the earth lead.

Phase A Kelvin clip lead part number:

AX136-0007

Phase B Kelvin clip lead part number:

AX136-0008

Phase C Kelvin clip lead part number:

AX136-0009

17

1.2.4 System connections

Figure 1.7 System connections

18

1.2.5 Overload protection

Location Protection

Mains supply Hydraulic-magnetic circuit breaker

Control unit output Hydraulic-magnetic circuit breaker

Control unit control/metering T4A HRC 32mm fuse

Voltage input 2xT250mA HRC 32mm fuses

1.3 Functions

1.3.1 Output

The output has three ranges. The highest currents are available on the lowest voltage outputs.

When testing, start with the lowest output voltage output. If the required test current cannot be

achieved (because the impedance of the line is high) use a higher voltage output.

Output unit Open Circuit

Voltage

Continuous

current

Intermittent current

5 min on/

15 min off

Maximum

current

NLU75/80

75V 40A 80A 100A*

150V 20A 40A 40A

300V 10A 20A 20A

*100A available for short periods

Each output is rated for a continuous current and for higher intermittent currents. The maximum

ON time for intermittent currents is enforced by the unit, and the output will be switched off if the

rating is exceeded. The display will then show the following message until the green OFF button

is pressed to clear the trip condition:

Figure 1.8 Output tripped

!

NOTE

If the metering cable is not connected between the control unit and the external

output unit, the ammeter will not function, and the output will not switch on when the

output ON push-button is pressed. The metering cable between the control and

external output unit acts as an interlock circuit.

Output tripped

Press Green to Reset

19

1.3.2 Metering

The Z-OVR is fitted with a true rms ammeter and voltmeter with hold facility.

1.3.2.1 Ammeter ranges

Figure 1.9 Ammeter

Four true rms current metering ranges are provided. The range is selected using the AMMETER

switch on the control unit. A current trip is set at 105% of the full scale of the range.

Ammeter range

Metering full

scale Resolution Accuracy Trip current

2A 2.000A 0.001A ±1%rdg+5d 2.1A

10A 10.00A 0.01A ±1%rdg+5d 10.5A

20A 20.00A 0.01A ±1%rdg+5d 21A

100A 100.0A 0.1A ±1%rdg+5d 105A

1.3.2.2 Voltmeter ranges

Figure 1.10 Voltmeter

Three true rms voltage metering ranges are provided. The range is set using the VOLTMETER

switch on the control unit. The voltage measuring input is isolated by a switched range VT. The

VT provides safety isolation from the line under test, but has a relatively low input impedance

on the 10V and 30V ranges. Do not use the 10V or 30V range with test currents of less than 5A

to maintain accuracy.

Caution

Ensure that the maximum voltage applied to the voltage input does not exceed the

range selected. Fuses are provided on the input to protect the VT. If the voltage

for the range selected is too high the fuses on the VT input will blow.

I ¢ V

10.00A

90.0°

1.00V

IMPEDANCE

Z=100.0m©

X=100.0m©

I ¢ V

10.00A

90.0°

1.00V

IMPEDANCE

Z=100.0m©

X=100.0m©

20

Voltmeter range Resolution Accuracy Input impedance

10.00V 0.01V ±1%rdg±5d ~1k

30.00V 0.01V ±1%rdg±5d ~1k

300.0V 0.1V ±1%rdg±5d ~50k

Accuracy

note

Always Use the 300V metering range if the test current is less than 5A.

1.3.2.4 Phase angle measurement

Figure 1.11 Phase angle

The phase angle between the voltage and current is calculated by taking an FFT (Fast Fourier

Transform) of both the current and voltage and calculating the phase difference between the

fundamental components.

The phase angle of the current is measured relative to the voltage. A phase angle of -90° would

signify that the current is lagging the voltage by 90° (an inductive load). A phase angle of +90°

would signify that the voltage is leading the current by 90° (a capacitive load).

Range Resolution Accuracy

-179.9º - 180.0º 0.1º ±1º

I ¢ V

10.00A

90.0°

1.00V

IMPEDANCE

Z=100.0m©

X=100.0m©

Table of contents

Other T&R Test Equipment manuals

T&R

T&R CU-Ps Operating instructions

T&R

T&R KV30-40 Operating instructions

T&R

T&R 200A-3PH mk2 Operating instructions

T&R

T&R PCU2 mk5 Operating instructions

T&R

T&R KV mk2 Series Operating instructions

T&R

T&R PT18-10 mk2 Operating instructions

T&R

T&R KV5-100 mk3 Operating instructions

T&R

T&R 200A-3PH Operating instructions

T&R

T&R PT30-10 mk2 Operating instructions

T&R

T&R PT30-10 Operating instructions