T&R TPT9000 Operating instructions

2

GENERAL SAFETY STATEMENT

WARNING

The following safety precautions should be reviewedto avoid injury

to the user and damage to the product (and other products

connected to it). To avoid potential hazards only use this product

as specified.

•Only suitably qualified personnel should use this

equipment. Servicing of this product should only be

carried out by suitably qualified service personnel.

To Avoid Fire Hazards and Personal Injury

•Use the fused leads supplied with the unit.

•Ensure that systems that the unit is to be connected to are

dead.

•Do not connect and disconnect leads whilst outputs are

switched on. Breaking the output circuit with current flowing

may cause arcing.

•Terminal ratings must be observed to prevent fire hazards and

risk of injury to the operator. Consult the product manual for

ratings information before making connections to any terminal.

•It is ESSENTIAL to consult the product manual for rating

information before making any connection to a terminal or

terminal group marked with a warning triangle.

•Only use fuses of a type and rating specified for this product.

•Do not operate the unit out of its case or with any covers or

panels removed.

3

•Do not touch exposed connections and components when

power is present.

•Do not operate the product if any damage is suspected. Refer

the unit to qualified service personnel to be checked.

•Do not operate the unit in wet or damp conditions.

•Do not operate the unit in an explosive atmosphere.

•Warnings from cardiac pacemaker manufacturers state that strong

magnetic fields may affect operation. The TPT9000 may induce

large magnetic fields in transformers and should therefore not be

operated by, or in the vicinity of persons fitted with cardiac

pacemakers or any other electronic or electrical medical implants.

If any further queries occur regarding the usage

and maintenance of the equipment detailed in this

manual, please refer these to the supplier of the

equipment in the first case or to the manufacturer,

T & R Test Equipment Limited.

4

SAFETY TERMS AND SYMBOLS

The following safety symbols appear on the equipment:

WARNING –Refer to manual

Test Button

5

CONTENTS

1. DESCRIPTION OF EQUIPMENT 6

1.1 Connections, controls & display 7

1.1.1 LED messages 10

1.2.1 Environment 12

1.2.2 Supply requirements 12

1.2.3 Connection cable ratings 12

1.2.3 Overload protection 12

2Theory of Operation 13

2.1 Main current output 13

3. APPLICATIONS 15

3.1 Transformer Testing 15

3.1.1 CT Testing 15

3.1.2 Transformer Testing 17

3.1.3 High Primary Impedance Transformer Testing 19

4. MAINTAINANCE 21

4.1 Replacing the Battery 21

5. STANDARD ACCESSORIES 22

5.1 Spares fuses supplied 22

5.2 Standard accessories supplied 22

5.3 Optional accessories/spares 22

6. REVISION 23

6

1. DESCRIPTION OF EQUIPMENT

The TPT9000 is used for determining the correct polarity

of current and voltage transformers. The TPT9000

automatically detects if the transformer has been

connected incorrectly. The setalso includes a proving unit

to check the correct operation of the unit in the field.

The TPT9000 is designed to be used on ‘dead’ systems

(i.e., no externally supplied voltages are present on the

testobject). DonotconnecttheTPT9000to alivesystem.

Always check that the power to the device under test is

off and the circuit is isolated before making any

connections.

7

1.1 Connections, controls & display

Figure 1.1 TPT9000

8

Ref

Item

Function

A

Battery Low LED

Indicates if the internal battery

voltage has dropped below a

useable level

B

Reverse LED

Indicates that the test

transformer has one winding

connected with reversed

polarity to the other

C

Brown terminal

Connect to P1 of the test

transformer

D

Blue terminal

Connect to P2 of the test

transformer

E

Black terminal

Connect to S2 of the test

transformer

F

Red terminal

Connect to S1 of the test

transformer

G

Forward LED

Indicates that both windings of

the test transformer are

connected in the same polarity

H

Error LED

Indicates that the test

transformer has not been

connected properly

I

Test button

Switches the unit on and starts

a test

J

Magnet

For securing the TPT9000 while

testing

K

Battery cover

Remove cover to replace the

battery

9

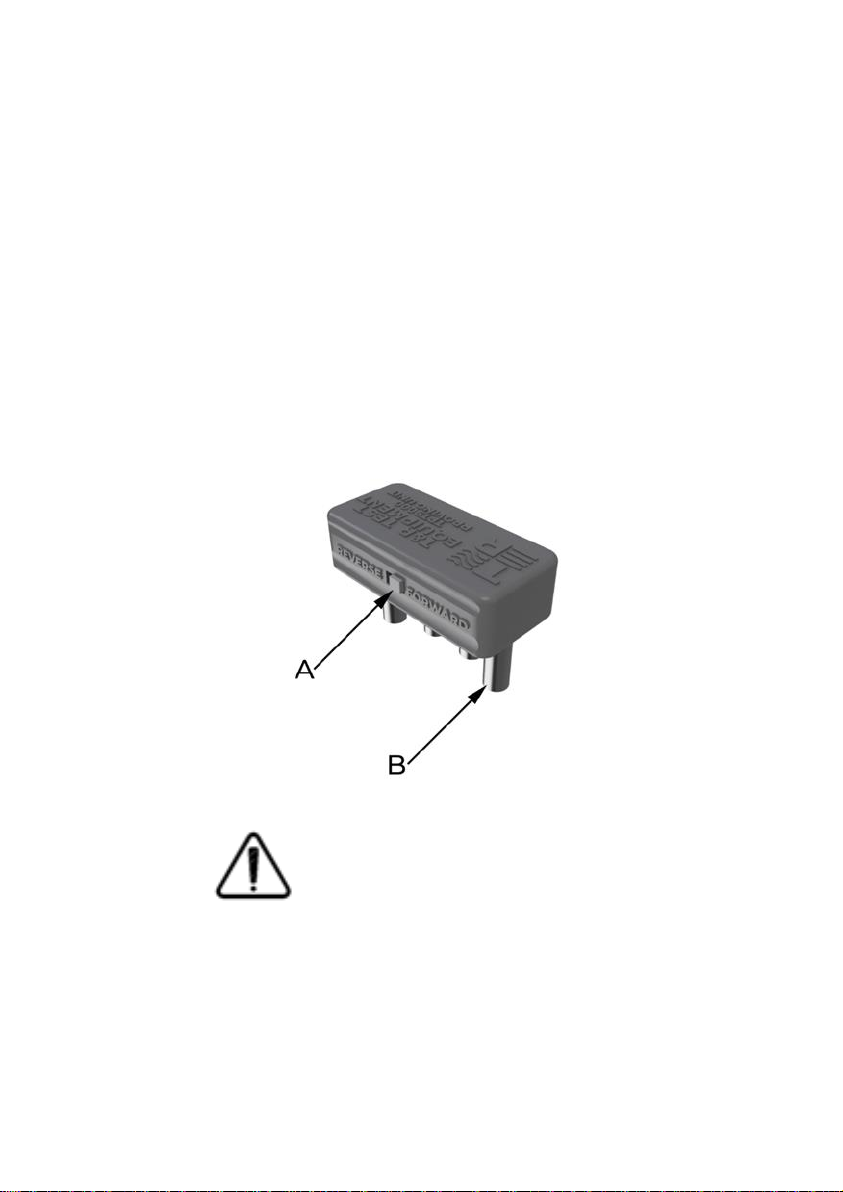

Figure 1.2 Proving Unit

Ref

Item

Function

A

Polarity Switch

Switch test polarity between

Forward and Reverse

B

Connectors

Connectors to fit the proving

unit into the TPT9000

terminals.

10

1.1.1 LED messages

Figure 1.3 Green LED 1 second flash

The Green LED will light for 1 second when the transformer under

test has been connected with both windings in the same polarity.

Figure 1.4 Red LED 1 second flash

The Red LED will light for 1 second when the transformer under

test has been connected with the windings in a different polarity.

Figure 1.5 Amber LED 1 second flash

The Amber LED light for 1 second when the TPT9000 has carried

out a test on the test transformer but no response has been

detected on the return connections. This can be caused by poor

connections to the transformer windings.

11

Figure 1.6 Rapid flashing Amber LED

The Amber LED will rapidly flash for 1 second when the TPT9000

detects that either the transformer under test has a voltage present

or that there is a connection between the Primary and Secondary

windings. Note that the TPT9000 cannot test auto transformers.

Figure 1.7 Amber LED 1 second flash

The Battery Low LED will light up for 1 second when the TPT9000

detects that the internal 9V battery voltage has dropped below a

usable level.

12

1.2 Installation

1.2.1 Environment

The TPT9000 is designed for use in industrial and

electrical substation environments.

Category Rating: CATIII

Maximum altitude: 2000m

Temperature: 0°C to 45°C operating

-20°C to 60°C storage

Relative humidity: 90% non-condensing

Protection rating: IP20 in use

1.2.2 Supply requirements

The TPT9000 requires a single PP39V battery to operate.

The battery level is automatically monitored, the device

will not perform a test if the battery voltage has dropped

below a useable level.

1.2.3 Connection cable ratings

Test Leads 600V CAT IV fused test

leads terminated in shrouded

4mm connectors.

1.2.3 Overload protection

Each of the test leads must be fitted with a F500mA HBC

fuse. This must be replaced with a fuse of the same type.

13

2 Theory of Operation

2.1 Main current output

The TPT9000 first checks that there is no connection

between the Primary and Secondary windings. Note, the

TPT9000 cannot test auto transformers.

If a connection between the windings is detected the test

will be stopped and the Amber ERROR LED will flash

rapidly.

If no connection is detected between the two windings the

TPT9000 will inject a small pulse of current into the

Primary winding.

The unit then waits for a resulting pulse on the Secondary

winding.

If the detected pulse is in the same polarity to the injected

pulse the transformer under test has been connected with

Forward polarity. The Green FORWARD LED will light for

1 second.

If the detected pulse is in the opposite polarity to the

injected pulse the transformer under test has been

connected with Revered polarity. The Red REVERSE

LED will light for 1 second.

If a return pulse is not detected the Amber ERROR LED

will light for 1 second. Check the connections to the test

object.

14

2.2 Proving Unit

The function of the TPT9000 can be checked using the

included proving unit.

Fit the proving unit into the output terminals of the

TPT9000. The switch on the front of the proving unit can

be set so that it appears as either a forward or reverse

connected transformer.

Select forward or reverse and then press the test button.

The corresponding forward, reverse or error LED will light.

Warning:

The TPT9000 is designed to test

transformers that have been disconnected

from all power supplies. Do not apply any

power to the terminals of the unit.

15

3. APPLICATIONS

This chapter describes how to use the TPT9000 to test

different types of transformers.

3.1 Transformer Testing

3.1.1 CT Testing

Figure 2.1 TPT9000 connections to a test CT

▪Check the CT for Primary polarity markings. If the

CT has been marked P1 and P2 or the direction of

the current through the CT is known, this should be

observed when connecting the TPT9000.

▪The Brown output wire from the TPT9000 must be

looped through the central hole of the CT. Pass the

wire in through the P1 side and out of the P2 side.

If the CT does not have its polarity marked but the

direction of current flow is known, pass the brown

wire through positive side of the test transformer.

16

▪Pass the wire out of the P2 side of the CT and back

to the blue terminal of the TPT9000.

▪If the polarity of the primary of the CT is not known,

loop the wire through the central hole in any

direction.

▪Check the secondary side of the CT for polarity

markings.

▪Connect the secondary terminal marked S1 to the

Red input of the TPT9000 and the secondary

terminal marked S2 to the Black input of the

TPT9000.

▪Do not touch the CT or any of the wires during the

test.

▪Press the test button on the TPT9000.

▪The TPT9000 will first test to see if the test

transformer has been connected correctly. If the

Errorled illuminatescheckall theconnectionstothe

test transformer are correct.

▪The TPT9000 will display the polarity of the current

connection to the test CT.

▪If the Forward LED lights, then the unknown side of

the test CT has been connected correctly with

respect to the known side of the test CT.

▪If the Reverse LED lights, then the unknown side of

the test CT has been connected reversed with

respect to the known side of the test CT.

17

3.1.2 Transformer Testing

Figure 2.2 TPT9000 connections to a test transformer

▪Inspect the test transformer for polarity markings.

▪In the case of the Secondary winding connections

being unknown. Connect the Primary in the correct

polarity as shown above. Connect the Brown P1

wire from the TPT9000 to the P1 terminal of the test

transformer. Connect the Blue P2 wire from the

TPT9000 to the P2 terminal of the test transformer.

▪For the unknown secondary connections connect

the Red S1 and the Black S2 wires from the

TPT9000 across the secondary winding.

▪Do not touch the test transformer or any of the wires

during the test.

▪Press the TEST button on the TPT9000.

▪The TPT9000 will display the result of the test.

18

▪A green Forward led shows that the unknown side

has been connected in the same polarity as the

known side.

▪A red Reverse led shows that the unknown side has

been connected in the opposite polarity as the

known side.

▪If the Error led flashes rapidly the TPT9000 has

detected a short circuit between the Primary and

Secondary of the test transformer. Check that the

connections to the test transformer have been

made correctly.

▪If the Error led flashes for 1 second, the TPT9000

has not detected any response from the test

transformer. Check that the connections to the test

transformer have been made correctly. If the

connections are ok but the error persists the

transformer may have a primary winding with a high

impedance. See section 3.1.3.

▪In the case of the Primary winding connections

being unknown. Connect the Secondary in the

correct polarity as shown above. Connect the Red

S1 wire from the TPT9000 to the S1 terminal of the

test transformer. Connect the Black S2 wire from

the TPT9000 to the S2 terminal of the test

transformer.

▪The test and results will be displayed as before.

19

3.1.3 High Primary Impedance Transformer Testing

Figure 2.3 TPT9000 connections to a test transformer with a high

impedance Primary winding

Some transformers have a very high primary

winding impedance. The voltage of the injected

current may be too low to energise the

transformer. Despite the test transformer being

properly connected the Amber ERROR light will

show that no return pulse has been detected. If

the secondary winding has a much lower

impedance, we can still use the TPT9000 to test

the transformer.

▪Connect the P1 high impedance terminal of the test

transformer to the Red S1 terminal of the TPT9000

and the P2 high impedance terminal of the test

transformer to the Black S2 terminal of the

TPT9000.

20

▪Connect the S1 low impedance terminal of the test

transformer to the Brown P1 terminal of the

TPT9000 and the S2 low impedance terminal of the

test transformer to the Blue P2 terminal of the

TPT9000.

▪When you press the TEST button the TPT9000 will

inject the test current into the secondary winding of

the test transformer.

▪Do not touch the test transformer or any of the wires

during the test.

▪The TPT9000 will display the result of the test.

▪The TPT9000 will first test to see if the test

transformer has been connected correctly. If the

Error led illuminates check if the connections to the

test transformer are correct.

▪A green Forward led shows that the unknown side

has been connected in the same polarity as the

known side.

▪A red Reverse led shows that the unknown side has

been connected in the opposite polarity as the

known side.

Table of contents

Other T&R Test Equipment manuals

T&R

T&R 200A-3PH mk2 Operating instructions

T&R

T&R 200A-3PH Operating instructions

T&R

T&R KV30-40 Operating instructions

T&R

T&R PT30-10 mk2 Operating instructions

T&R

T&R PT30-10 Operating instructions

T&R

T&R CU-Ps Operating instructions

T&R

T&R PCU2 mk5 Operating instructions

T&R

T&R PT18-10 mk2 Operating instructions

T&R

T&R KV30-40D mk3 Operating instructions

T&R

T&R KV mk2 Series Operating instructions