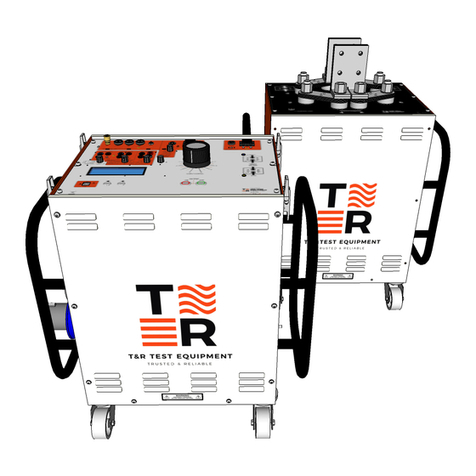

T&R KV30-40D mk3 Operating instructions

1

OPERATING AND MAINTENANCE MANUAL

Product: High Voltage AC Test Set

Type: KV30-40D mk3 or KV15-80D mk3

DESIGNED AND MANUFACTURED BY:

T & R Test Equipment Limited

15-16 Woodbridge Meadows, Guildford, Surrey, GU1 1BJ, United Kingdom

Telephone: 01483 207428 e-mail: sales@trtest.com Web www.trtest.com

2

3

GENERAL SAFETY STATEMENT

WARNING

The following safety precautions should be reviewed to avoid injury to the user and damage to the product

(and other products connected to it). To avoid potential hazards only use this product as specified.

Only suitably qualified personnel should use this equipment. Servicing of this product should

only be carried out by suitably qualified service personnel.

The high voltage generated by this unit is extremely dangerous and may be fatal.

To Avoid Fire Hazards and Personal Injury

Use the correct power supply lead. Only use a suitably rated and approved power supply lead for the

country of use.

Ensure that systems that the unit is to be connected to are dead.

Do not connect and disconnect leads whilst outputs are switched on.

Ensure that the product is grounded. To avoid electric shock, it is essential that the grounding

conductor is connected to the earth ground. Additional earth terminals are provided on the control unit

and high voltage (HV) transformer that must be connected to a local earth. Ensure that the unit is

properly grounded before making any connections to inputs or outputs.

Terminal ratings must be observed to prevent fire hazards and risk of injury to the operator. Consult

the product manual for ratings information before making connections to any terminal.

It is ESSENTIAL to consult the product manual for rating information before making any connection to

a terminal or terminal group marked with a warning triangle.

Only use fuses of a type and rating specified for this product.

Do not operate the unit out of its case or with any covers or panels removed.

Do not touch exposed connections and components when power is present.

Do not operate the product if any damage is suspected. Refer the unit to qualified service personnel

to be checked.

Do not operate the unit in wet or damp conditions

Do not operate the unit in an explosive atmosphere

If any further queries occur regarding the usage and maintenance of the

equipment detailed in this manual, please refer these to the supplier of the

equipment in the first case or to:

T & R Test Equipment Limited

4

HIGH VOLTAGE SAFETY

It is essential to follow safe working procedures when working with high voltage. Information on

accepted codes of practice should be obtained from your local heath and safety regulatory body.

It is essential that the KV30-40D mk3 and KV15-80D mk3 series test sets are only used in a

suitable test environment. EN50191:2010 (Erection and Operation of Electrical Test Equipment)

provides information on the installation and use of test installations and is referenced by health

and safety law in the EU.

IEEE standard 510-1983 (IEEE Recommended Practices for Safety in High-Voltage and High-

Power Testing) also provides a working framework for establishing safe procedures, but must

be read in conjunction with local regulations and accepted codes of practice. Although this

standard has since been withdrawn, it does contain very good practices that are still referenced

today, the following excerpts are taken from IEEE 510:

All ungrounded terminals of the test equipment or apparatus under test should be

considered as energised.

Common ground connections should be solidly connected to both the test set and the test

specimen. As a minimum, the current capacity of the ground leads should exceed that

necessary to carry the maximum possible ground current. The effect of ground potential rise

due to the resistance and reactance of the earth connection should be considered.

Precautions should be taken to prevent accidental contact of live terminals by personnel,

either by shielding the live terminals or by providing barriers around the area.

The circuit should include instrumentation for indicating the test voltages.

Appropriate switching and, where appropriate, an observer should be provided for the

immediate de-energisation of test circuits for safety purposes. In the case of dc tests,

provisions for discharging and grounding charged terminals and supporting insulation

should also be included.

In the use of signal-gathering equipment, each device should be used in such a manner that

it will not present a personnel hazard should it inadvertently become a part of the high-

voltage circuit, or fail to function properly.

High-voltage and high-power tests should be performed and supervised by qualified

personnel.

Consideration should be given to safety regulations which may apply to specific

circumstances; for example, HSE, company, or government regulations.

5

SAFETY TERMS AND SYMBOLS

The following safety symbols appear on the equipment:

CAUTION/WARNING – Refer to manual

DANGER – High voltage

Mains off

Mains on

The following safety symbols appear in this manual:

CAUTION

This action or procedure may be dangerous if not carried out

correctly, and may cause damage to the equipment or

connected equipment.

WARNING

This action or procedure may be cause injury or death to the

operator or other personnel if not carried out correctly using

applicable safety procedures.

7

CONTENTS

1. DESCRIPTION OF EQUIPMENT 9

1.1 Front Panel Overview 10

1.2 Electrical Specification 12

1.2.1 Supply Requirements 12

1.2.2 Output Specifications 12

1.2.3 Zero Voltage Interlock 12

1.2.4 External Interlock 12

1.3 Output Voltage Control 13

1.4 Overload Protection 13

1.4.1 Variable Overload 13

1.5 Metering 14

1.6 Construction 14

2. OPERATION 15

2.1 Safety 15

2.1.1 Installation 15

2.1.2 Operation 15

2.2 Connections (See Figure 2) 18

2.4 Method of Operation 20

3. MAINTENANCE 21

3.1 Removal of Unit from Case 21

4. STANDARD ACCESSORIES 22

5. OVERALL PERFORMANCE SPECIFICATION 23

6. REVISION 25

9

1. DESCRIPTION OF EQUIPMENT

The KV30-40D mk3 is a flexible high voltage AC test system, capable of producing 30kV into a

variety of loads with a maximum of 40mA of current.

The KV15-80D mk3 is a similar high voltage AC test system, capable of producing 15kV into a

variety of loads with a maximum of 80mA of current.

The unit has been designed for general purpose testing insulation systems and measurement

of breakdown voltage on electrical plant, switchgear and components.

Improved digital metering for both accuracy and precision gives the user the ability to read a

digital value and have a visual indication of a ‘needle’.

The equipment has been designed to allow the user/operator to connect the product to an

external test setup with interlocks, and now includes a twist to release emergency stop button.

A timer has been included for timed tests on insulation systems, to meet national and

international testing standards.

10

1.1 Front Panel Overview

Figure 1.1 KV30-40D mk3 front panel

C

B

D

E

F

G

H

J

I

K L M

O

N

P

Q

R

A

11

Ref Item Function

A Earth Terminal Connect the unit to a local ground for safety

B Mains Input Connector Mains supply

C Mains Input Fuse Protection

D Interlock Connector Connect the unit to an external interlock

circuit

E mA Digital Meter Display mA metering

F Mains On/Off Switch Key operated mains switch

G Mains Lamp Mains on indicator

H Timer Range Switch Selects timer setting

I Primary Trip Transformer Primary circuit breaker

J Timer Cancel Button Cancels timer

K Main Output ON Control Switches main output ON

L Main Output OFF Control Switches main output OFF

M Main Output Control Controls the output voltage/current.

N mA Trip Range Switch Selects mA trip current

O mA Trip Reset Switch Resets mA trip

P kV Digital Meter Display kV metering

Q Emergency Stop Switch Emergency Stop

R Main Output Cable High Voltage output cable

12

1.2 Electrical Specification

1.2.1 Supply Requirements

The KV30-40D mk3 and KV15-80D mk3series have a 115/230V auto-selecting mains input.

Supply requirements: 115/230V 10% 1 phase 50/60Hz 1400VA max

1.2.2 Output Specifications

The output voltage, current and duty cycle are as follows:

Unit type Output Voltage

Output current

Continuous 5 min on/15 min off

KV30-40D mk3 30kV 20mA 40mA

KV15-80D mk3 15kV 40mA 80mA

One side of the high voltage transformer output is connected to the earth system of the

equipment.

1.2.3 Zero Voltage Interlock

The equipment is fitted with a zero volt interlock system on the controlling regulator. This

interlock prevents the output being energised unless the controlling regulator is in the minimum

output position.

1.2.4 External Interlock

The KV30-40D mk3 and KV15-80D mk3 is fitted with a 24Vdc external interlock socket. This

interlock prevents the output being energised unless an external circuit is closed. The interlock

circuit may also be used to connect normally closed emergency off switches to the unit wired in

series with any interlock switches.

The interlock circuit uses a 4 pin XLR type latching plug and socket with the circuit wired to pins

1 and 2. Pins 3 and 4 are not connected. The connections below are shown from the rear of

the interlock circuit plug.

Please note that the unit will not operate without either an external interlock circuit connected or

the shorting plug provided with the unit.

13

1.3 Output Voltage Control

The output is controlled from zero by means of a regulating transformer. The transformer is

operated by means of a control knob which is located on the front panel. To increase the output

voltage the knob is turned in a clockwise direction.

1.4 Overload Protection

The equipment is fitted with fixed and variable overload protection circuits as standard.

1.4.1 Variable Overload

The variable overload protection system senses current changes in the high voltage circuit. The

trip level is adjusted by means of a selector switch on the front panel of the unit. The switch

allows the level to be adjusted from 10-110% of normal full load current in eleven steps.

The circuit will activate when the load current exceeds that set by the trip level selector switch.

The circuit will respond more slowly to slowly changing levels of load current.

IMPORTANT NOTE: The variable overload trip circuit does not limit the output

current on short circuit.

14

1.5 Metering

The equipment is fitted with a kV meter that measures the output voltage via a resistive divider

in the HV circuit. It is also fitted with a mA meter that meters the output current in the earthy

end of the HV side of the output transformer.

Unit type

KV meter mA meter

FSD Resolution FSD Resolution

KV30-40D mk3 40kV 0.01kV 50mA 0.01mA

KV15-80D mk3 20kV 0.01kV 90mA 0.01mA

NOTE – Due to the nature of the digital meters, a non-zero reading may be

displayed when the output is off. This should not exceed 0.2 on either meter.

1.6 Construction

The equipment is housed in a robust case with recessed carrying handles. All the controls and

metering are located on the front panel together with all external connections.

15

2. OPERATION

2.1 Safety

The outputs from the KV30-40D mk3 and KV15-80D mk3 are extremely dangerous, and if used

incorrectly could be fatal. The unit must only be installed, operated, and maintained by suitably

qualified and trained (skilled) personnel.

It is essential to follow accepted safety procedures, and local health and safety regulations and

guidelines when installing and operating high voltage equipment. A risk assessment should be

undertaken on both the installation and the working procedures to ensure the safety of test

personnel and all other personnel. EN50191:2010 Defines suitable test installations for this

equipment.

2.1.1 Installation

2.1.1.1 Test Area

The unit must be installed in a suitable high voltage test area completely enclosed by walls or

some type of physical barrier. Appropriate controls and safety measures must be applied to this

area including interlocks connected to the supply or HV unit interlock to ensure that the unit

cannot be switched on unless the area is secure. Refer to EN50191:2010 for further details of

suitable test enclosures. The test area must also be identified with suitable signs.

2.1.1.2 Mains supply

The unit must be connected to a suitable supply via an approved and suitably rated mains

connector with earth connection.

2.1.1.3 Earthing

Particular attention must be made in earthing the equipment, and all earth connections must be

made with substantial conductors with secure joints.

The earth connection on the unit must be connected to a suitable low impedance earth in

addition to the mains earth to the unit.

The earth return from the test object must also be made with a suitable conductor back to the

earth point on the unit.

All earth connections must be able to withstand the largest fault current that may be encountered

in the system.

2.1.2 Operation

It is essential that safe working practices are maintained when conducting high voltage

testing. Safe working procedures must be implemented to accepted standards.

2.1.2.1 Interlocks

The unit is provided with an external interlock circuit that may be used to link to interlock switches

and emergency off switches around a high voltage test area. If no external interlock circuit is

connected, the shorting plug supplied with the unit must be fitted.

16

An interlock should be considered to be a safety back-up feature. An interlock should not be

regarded as a substitute for adequate safety rules and proper operator vigilance.

2.1.2.2 Grounding of the high voltage output

A temporary ground should be applied to the high voltage output when the circuit has been de-

energised using the earth stick provided. When connections are made, or disconnected, the

circuit either side of the connection should be grounded first. Extra earth sticks are available

from T&R Test Equipment as an optional accessory.

If the test circuit includes capacitors, each capacitor should be grounded separately before

connections are made or broken. In the case of capacitors connected in series, the intermediate

terminals should also be grounded.

It is good practice for all capacitive devices to remain short-circuited when not in use.

2.1.2.3 High voltage connection

The HV connection to the test object must be made securely to the test object. Suitable stress

relief components should be used where required to keep electrical stresses within acceptable

limits.

2.1.2.4 High voltage output clearances

The high voltage output from the unit is from a screened cable with an un-screened termination,

and adequate clearances must be maintained between the following parts and any other

conducting object (whether earthed or not):

HV output connection

Non-screened part of output cable (between the bulge in the cable and the output clip)

Non-grounded parts of test object

Any part of the test object not connected to earth should be considered live at the test voltage

potential.

Particular attention should be paid to clearances between any parts of the test object at test

voltage potential and the test enclosure or barriers.

17

EN50191:2010 defines the safety clearance around the high voltage circuit as the prohibition

zone, and stipulates that is must not be possible for personnel or their tools to touch this zone.

The prohibition zone distances for the units are shown below.

Unit Voltage Prohibition zone

KV30-40D mk3 30kV 170mm

KV15-80D mk3 15kV 85mm

EN50191:2010 also details suitable barrier types and heights such that the prohibition zone

cannot be reached by personnel.

2.1.2.5 Emergency Stop

The output can be immediately terminated by pressing the emergency stop. This has a twist to

release mechanism. When activated the unit immediately terminates the High Voltage output.

2.1.2.6 Timer

The timer has two controls: select test time and alarm cancel. When a test time is selected; the

timer starts when the output is switched ON. During the test, the lamp on the CANCEL button

will flash. When the pre-set test time has elapsed the lamp in the CANCEL button will illuminate

and an intermittent audible alarm will sound. To cancel the alarm press the CANCEL

pushbutton.

18

2.2 Connections (See Figure 2)

Before making any connections, please ensure that you are aware of all hazards relating

to the system and environment in which it is operating.

The input lead on the control unit should be connected to a suitable three pin supply connector.

Connect the earth lead from a reliable, efficient earth to the earth terminal on the equipment.

Connect the earth hook lead to the earth terminal on the test set and place the hook on the test

object's high voltage terminal.

IMPORTANT

The output cable is only partially screened. It is therefore essential that the minimum

clearance defined in 2.1.2.4 be maintained around the unscreened portion of the output

cable.

Figure 2 Connection showing earthed test object – before start of test

Note:-The test object is shown earthed via the earth stick as it should be between

tests and before any adjustment to the test object. The earth stick should be removed

from the test object before the test, and replaced after the test is complete.

screened part of HV cable

unscreened part of HV cable

Supply cable

To local earth

screen limit and stress relief

Earth return

Earth stick Test object

20

2.4 Method of Operation

Connect the equipment as described in Section 2.2.

Remove the mains power switch operating key before connecting the equipment to the main

supply. This will ensure the equipment is in the OFF position as the key is only removable in

that position.

Once the equipment is connected to the mains supply the key operated switch can be turned to

the ON position. The following will now occur:

a. Power ON lamp will be lit

b. HV OFF lamp will be lit

c. The Digital Meters will boot up.

d. The variable overload reset lamp will be lit

Press the variable mA Trip reset push-button thus arming the circuit. The indicator lamp in the

reset push-button will go out thus indicating that the circuit is armed.

Check that the primary trip circuit breaker is closed and the external interlock circuit is closed or

the shorting plug is fitted.

Set the desired overload mA trip level.

If required, set a desired test time.

Before commencing a test ensure that the regulator is in the fully anticlockwise position at ‘0’.

Depress the HV ON push-button - this will close the internal circuit breaker. The HV OFF lamp

will extinguish and the HV ON lamp will be lit. The output voltage can now be increased to the

desired level as indicated on the kV meter.

In the event of a test object failure the HV output will be automatically switched off by the

protection system. Depending on the level of the fault, either the electronic trip or the primary

trip circuit breaker will operate.

When the test is completed, turn the regulator control knob fully anti-clockwise and switch off

the HV output and then the main supply.

It is best practice to ‘0’ the regulator control knob after each test.

Before disconnecting the test object ensure the HV connection is grounded using the

earthing stick provided.

This manual suits for next models

2

Table of contents

Other T&R Test Equipment manuals

T&R

T&R PT18-10 mk2 Operating instructions

T&R

T&R Z-OVR Operating instructions

T&R

T&R KV6-80 Operating instructions

T&R

T&R 200A-3PH mk2 Operating instructions

T&R

T&R PT30-10 mk2 Operating instructions

T&R

T&R PT30-10 Operating instructions

T&R

T&R PCU2 mk5 Operating instructions

T&R

T&R PT15-10s Operating instructions

T&R

T&R KV5-100 mk3 Operating instructions

T&R

T&R KV30-40 Operating instructions