T&R PCU2 mk5 Operating instructions

1

OPERATING AND MAINTENANCE MANUAL

Product:

Primary Current Injection System

Type:

PCU2 mk5

LU5000, LU6000, LU8000

DESIGNED AND MANUFACTURED BY:

T & R Test Equipment Limited

15-16 Woodbridge Meadows, Guildford, Surrey, GU1 1BJ, United Kingdom

Fax.: 01483 511229 Web: www.trtest.com

3

GENERAL SAFETY STATEMENT

WARNING

The following safety precautions should be reviewed to avoid injury to the user and damage to the

product (and other products connected to it). To avoid potential hazards only use this product as

specified.

Only suitably qualified personnel should use this equipment. Servicing of this product

should only be carried out by suitably qualified service personnel.

To Avoid Fire Hazards and Personal Injury

Use the correct power supply lead. Only use a suitably rated and approved power supply lead for

the country of use.

Ensure that systems that the unit is to be connected to are dead.

Do not connect and disconnect leads whilst outputs are switched on. Breaking the output circuit

with current flowing may cause potentially fatal arcing.

Ensure that the product is grounded. To avoid electric shock it is essential that the grounding

conductor is connected to the earth ground. An additional earth terminal is provided on the unit that

should be connected to a local earth. Ensure that the unit is properly grounded before making any

connections to inputs or outputs.

Terminal ratings must be observed to prevent fire hazards and risk of injury to the operator. Consult

the product manual for ratings information before making connections to any terminal.

It is ESSENTIAL to consult the product manual for rating information before making any connection

to a terminal or terminal group marked with a warning triangle.

Only use fuses of a type and rating specified for this product.

Do not operate the unit out of its case or with any covers or panels removed.

Do not touch exposed connections and components when power is present.

Do not operate the product if any damage is suspected. Refer the unit to qualified service

personnel to be checked.

Do not operate the unit in wet or damp conditions.

Do not operate the unit in an explosive atmosphere.

Do not leave the unit unattended during operation.

The PCU2 system has a very high output current (up to 6000A), and therefore generates large

magnetic fields around the output leads. Care must be taken in siting the unit next to items sensitive

to magnetic fields (such as computer monitors and other sensitive equipment).

Warnings from cardiac pacemaker manufacturers state that strong magnetic fields may affect

operation. Any high current unit such as the PCU2 should therefore not be operated by, or in the

vicinity of persons fitted with cardiac pacemakers or any other electronic or electrical medical

implants.

If any further queries occur regarding the usage and maintenance of the equipment detailed in this

manual, please refer these to the supplier of the equipment in the first case or to the manufacturer,

T & R Test Equipment Limited.

4

SAFETY TERMS AND SYMBOLS

The following safety symbols may appear on the equipment:

CAUTION/WARNING –Refer to manual

CAUTION –Hot. Parts may become hot during use –ensure parts are

cool before touching.

Mains off

Mains on

The following safety symbols may appear in this manual:

CAUTION

This action or procedure may be dangerous if not carried

out correctly, and may cause damage to the equipment or

connected equipment.

WARNING

This action or procedure may be cause injury or death to

the operator or other personnel if not carried out correctly

using applicable safety procedures.

CAUTION –

HOT

Parts of the equipment may become hot during use, and

must be allowed to cool before touching.

5

CONTENTS

1DESCRIPTION OF EQUIPMENT 7

1.1 Front Panel Layout 8

1.1.1 Loading unit 9

1.1.2 Control unit 9

1.2 Electrical Specification 10

1.2.1 Supply Specifications 10

1.2.2 Output Specifications 10

1.2.3 Output Lead Set Ratings 11

1.2.4 Metering 11

1.2.5 Overload trip 12

1.2.6 Loading unit over temperature trip 13

1.2.7 Timing System 13

1.3 Construction 13

1.4 Installation 13

2OPERATION 15

2.1 Loading Unit Configuration 15

2.2 Main Output 16

2.3 Connections 17

2.3.1 Earthing 17

2.4 Timing System 18

2.4.1 Timer Modes 18

2.4.2 General Procedure for Timing Tests 19

3APPLICATION NOTES –TESTING SPECIFIC DEVICES 21

3.1 Over-current Devices with Auxiliary Contacts 21

3.1.1 Timer Mode 21

3.1.2 Connections 21

3.1.3 Test Procedure 21

3.2 Timing of auto-reset/reclosing devices 22

6

3.2.1 Timer Mode 22

3.2.2 Connections 22

3.2.3 Test Procedure 22

3.3 Timing Devices with NO Auxiliary Contacts 23

3.3.1 Timer Mode 23

3.3.2 Connections 23

3.3.3 Test Procedure 23

4MAINTENANCE 24

5ACCESSORIES 25

5.1 Standard Accessories 25

5.2 Optional Accessories 25

6OVERALL PERFORMANCE SPECIFICATION 27

7REVISION 29

7

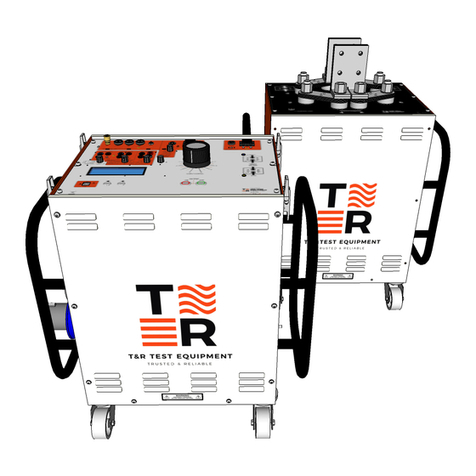

1 DESCRIPTION OF EQUIPMENT

The PCU2 is a primary current injection system designed to be used in conjunction with a T&R

Test Equipment loading transformer. Depending on the loading unit used, currents up to

6000A are available for 5 minutes and 12kA for 1 second.

Accurate true rms metering facilities and a flexible timing system are provided.

WARNING

The PCU2 and associated loading units are designed to be used on ‘dead’ systems (i.e.

no externally supplied voltages are present on the test object). Under no

circumstances connect the PCU2 or loading unit to a live system. Always check that

the power to the device under test is off and the circuit is isolated and grounded before

making any connections.

WARNING

The PCU2 and associated loading units are not designed for unattended operation.

8

1.1 Front Panel Layout

Figure 1.1 PCU2 and loading unit front panels

9

1.1.1 Loading unit

ITEM

FUNCTION

A

Output terminals

High current output to object under test

Caution –the output terminals and test

leads may become hot during use.

B

Power input

Power input from control unit

C

Metering output

Metering output to control unit

1.1.2 Control unit

ITEM

FUNCTION

D

Timer

Displays trip time of device under test

E

Contact inputs

Sense contact state of device under test

F

Timer mode switch

Select timer mode

G

Metering input

Metering input from loading unit

H

Ammeter

Displays load current

I

Ammeter range switch

Selects ammeter low/high range

J

Ammeter series/parallel switch

Selects Series/parallel connection for

metering

K

Loading unit output

Power output to loading unit

L

Pulse mode selector

Selects 0.5s pulse mode on output

M

Output on/off pushbuttons

Switches output on and off

N

Output control

Sets output current

P

Output circuit breaker

Protects output

Q

Mains on/off switch/circuit breaker

Isolates unit from mains supply

R

Auxiliary fuse

Metering and timing fuse

S

Power indicator

Power supply on indicator

T

Mains input

Mains supply inlet

V

Earth stud

Connect to local earth

10

1.2 Electrical Specification

1.2.1 Supply Specifications

Supply voltage: 230V 10%

Single phase, 50/60Hz

Maximum power requirement 23kVA 5 min on/15 min off

44kVA overload 1 second

1.2.2 Output Specifications

Loading

Unit

Output

arrangem

ent

Voltage

Current

Current

Continuous

5 min on/

15 min off

5 sec on/

1 min off

1 sec on/

1 min off

LU5000

Series

8V

1250A

2500A

4000A

5000A

Parallel

4V

2500A

5000A

8000A

10000A

LU6000

Series

6.6V

1375A

3000A

4800A

6000A

Parallel

3.3V

2750A

6000A

9600A

12000A

LU8000

Series

8V

1250A

2500A

4000A

5000A

Parallel

4V

2500A

5000A

8000A

10000A

The maximum output current in the series or parallel arrangement is available with a duty

cycle of 5 minutes on followed by 15 minutes off.

Details of configuring the output to series or parallel mode may be found in section 2.

11

1.2.3 Output Lead Set Ratings

The optional 3000AL, 4000AL, 5000AL, 6000AL lead sets supplied for use with the PCU2 are

made up from a number of 70mm2cores and have different continuous and intermittent

ratings. The rating is also affected by the arrangement of the individual 70mm2cables making

up the high current cable. The leads are supplied with the cables strapped together, but to

achieve their maximum rating the straps must be cut and the cores laid out side by side whilst

testing.

Lead set type

Continuous rating

5 minute on/ 15

minute off rating

1 sec on/ 1

minute off

rating

Cores strapped

together

Cores laid out

flat

Cores strapped

together

Cores strapped

together

3000AL

1200A

3000A

1500A

6000A

4000AL

1400A

4000A

2000A

8000A

5000AL

1600A

5000A

2500A

10000A

6000AL

1800A

6000A

3000A

12000A

8000AL

1800A

6000A

3000A

12000A

CAUTION

The cables and terminals will become hot in use. Ensure adequate cooling time is allowed

before touching cables or connectors after tests.

Note: The output leads should not be rested against any sharp edges whilst testing. The insulation

on the cables softens as it heats up, and it is possible for sharp edges to damage the

insulation on the cable under these circumstances. Eddy current heating may occur in ferrous

metals that the pair of cable rests against, and this could heat the cable insulation further.

1.2.4 Metering

The output current is metered by a digital memory ammeter with an LED display. The current

reading is continuously updated when the output is energised, and the value held when the

output is de-energised.

In timing modes where the contact inputs are used to signify the end of a test, the last valid

current measurement before the contacts changed state is held. This also occurs when using

the current operated timer mode.

The ammeter’s minimum response time is 200ms to capture a reading. If the duration of the

current is less than 200ms the ammeter’s display will display “Err”.

12

The full scale range of the ammeter is dependant on the loading unit. A switch is provided on

the PCU2 to switch the meter between the series and parallel range.

Loading Unit

Output

arrangement

Ammeter

range

Meter full

scale

Resolution

Accuracy

LU5000

LU8000

Series

Low

2500A

1A

0.6% 6d

High

5.00kA

10A

0.6% 6d

Parallel

Low

5000A

1A

0.6% 6d

High

10.00kA

10A

0.6% 6d

LU6000

Series

Low

3000A

1A

0.6% 6d

High

6.00kA

10A

0.6% 6d

Parallel

Low

6000A

1A

0.6% 6d

High

12.00kA

10A

0.6% 6d

If the metering cable is not connected between the PCU2 MK5 control unit and the external

loading unit, the ammeter will not function and the output will not switch on.

1.2.5 Overload trip

The output of the unit is protected by an overload trip that operates at approximately 115% of

full load current.

Loading Unit

Output

arrangement

Metering range

Overload trip

current

LU5000

LU8000

Series

Low

2875A

High

5750A

Parallel

Low

5750A

High

11500A

LU6000

Series

Low

3450A

High

6900A

Parallel

Low

6900A

High

13800A

The unit is also protected by a circuit breaker on the control unit output. This will trip before the

electronic trip on high range (at approximately 10000A for an LU5000/8000 or 12000A for an

LU6000).

13

1.2.6 Loading unit over temperature trip

An over-temperature trip is fitted on the transformer in the loading unit. If an over-temperature

condition occurs, the control unit output will be switched off and the output will be disabled

until the unit has cooled. While the output is disabled, both the red ON pushbutton and the

green OFF pushbutton will be extinguished. When the unit has cooled sufficiently to continue,

the green OFF pushbutton will light.

1.2.7 Timing System

Contact open circuit voltage 24Vdc

Contact short circuit current 100mA

The PCU2 is fitted with an integrated timing system which is linked to the main output and two

sets of contact inputs. The system is highly flexible, and allows for the timing of all common

protection devices and trips. The timer may also be used to time external events not linked to

the output of the set.

Full details of operating the timer are given in section 2.

Timer mode

Range

Resolution

Accuracy

Internal start

0-999.999s

1ms

0.01% rdg 2d

Single contact

0-999.999s

1ms

0.01% rdg 2d

Dual contact

0-999.999s

1ms

0.01% rdg 2d

Current operated

0-999.999s

1ms

0.01% rdg 3d

NOTE: In current operated mode timing results obtained with test currents below 20% of the selected

ammeter range, and on measured times of 19ms and below, are of doubtful accuracy.

The PCU2 has two contact inputs which are used to start and stop the timer depending on the

mode selected. Contact set 1 has a connection for volt-free contacts and for triggering by a

DC voltage, and contact set 2 has a connection for volt-free inputs. In each case, the input

auto-selects for normally open or normally closed contacts. The contact state is shown by an

LED that is off when the contact is closed and on when the contact is open.

The maximum open circuit voltage across the contact input is 24V, and the short circuit current

through the contacts is limited to 100mA.

1.3 Construction

The PCU2 MK5 control unit is housed in a robust steel case with castors for mobility. The

front panel is protected by a steel cover which is fixed to the main case with catches. The unit

is also fitted with steel handles at each end of the main chassis.

The external loading unit is housed in a steel case which is similar in construction to the PCU2

control unit. The loading unit is not fitted with a protective cover.

1.4 Installation

The PCU2 and associated loading units are designed for use in an indoor environment.

14

Before installation, a suitable mains connector must be connected to the 3-core mains input

cable provided. The connector and supply must be rated for 100A. It is also important to

ensure that the unit is adequately earthed. It is suggested that the earth stud on the side of the

unit is connected to a low impedance local earth. This is essential if the unit is used in a sub-

station environment.

15

2 OPERATION

This chapter describes how to use the PCU2 and loading unit in a variety of applications.

Specific examples are given in the applications section. The interconnections between the

control unit and loading unit are shown in figure 2.2.

2.1 Loading Unit Configuration

The loading units have two output windings which may either be connected in parallel or

series, allowing the output to be configured for a higher current with a lower voltage or a lower

current with a higher voltage.

The links on the control unit must be connected to select series or parallel operation:

Configuration

Link

terminals

Series

2-3

6-7

Parallel

1-3

2-4

5-7

6-8

Figure 2.1 Loading unit series/parallel selection

To change the links, first remove all eight retaining nuts, and then remove the output terminal

plates. Re—configure the links as required, and then replace the output terminal plates and

nuts. Ensure that all of the nuts are tightened.

The switch on the control unit must also be set to “series” or “parallel” to set the ammeter to

the correct range.

16

The current and voltage available from each loading unit in series or parallel mode is shown

below.

Loading

Unit

Output

arrangement

Voltage

Current

Current

Continuous

5 min on/

15 min off

5 sec on/

1 min off

1 sec on/

1 min off

LU5000

Series

8V

1250A

2500A

4000A

5000A

Parallel

4V

2500A

5000A

8000A

10000A

LU6000

Series

6.6V

1375A

3000A

4800A

6000A

Parallel

3.3V

2750A

6000A

9600A

12000A

LU8000

Series

8V

1250A

2500A

4000A

5000A

Parallel

4V

2500A

5000A

8000A

10000A

2.2 Main Output

The main output from the PCU2 control unit is a 0-230V supply rated at 100A for 5 minutes

on/15 minutes off. This output is NOT isolated from the mains, and is not designed to be used

without an isolating loading unit. The units are designed to drive the T&R LU5000-LU8000

loading units, which provide an isolated low voltage high current output.

The main output is switched on and off using the on and off pushbuttons. The current level is

controlled by the main output control and protected by the output circuit breaker.

The main output may be switched to continuous mode or pulse mode. In pulse mode the

output switches on for 0.5s when the output on button is pressed. This is particularly useful for

setting up the current into thermal devices to reduce heating in the load.

17

2.3 Connections

The connections between the PCU2 and loading unit are shown in figure 2.2.

6

7

LOADING UNIT

CONTROL UNIT

MAINS

SUPPLY

LOADING UNIT POWER CONNECTION

METERING CONNECTION

OUTPUT

3

2

15

OUTPUT TERMINAL

48

OUTPUT TERMINAL

LU5000

CONTROL UNIT

3

26

7

3

26

7

Figure 2.2 PCU2 and loading unit connections

WARNING

It is vital to ensure that secure, low impedance connections are made between the output of

the loading unit and the object under test. Ensure that the output cables are suitable rated for

the test current to avoid danger of fire. If the connection to the load is broken whilst current is

flowing, arcing may occur.

CAUTION

The output terminals and test leads may become hot during use. Allow adequate time to

cool after the test before touching.

2.3.1 Earthing

If the supply earth to the PCU2 is of doubtful integrity the earth terminal on the PCU2 should

be connected to a solid local earth.

18

2.4 Timing System

The PCU2 timing system is very flexible, and is closely integrated with the main output. A

summary of the start and stop events for the timer is shown in the table below.

Timer Mode

Timer Start Condition

Timer Stop Condition

Off

-

-

Internal Start

Main output on

Contact set 1 change

Single Contact

Contact set 1 change

Contact set 1 change

Dual Contact

Contact set 1 change

Contact set 2 change

Current Operated

Current >20% of range

Current <20% of range

The timer is reset by pressing the small pushbutton on the front of the timer display. In each

mode that the timer is active, the output of the unit must be switched on to arm the timer.

Contact set 1 has a contact input for volt-free contacts and a Vdc input for dc voltages. The

Vdc input may be used to trigger the timer from a dc voltage, and will trigger from either the

voltage switching from zero to 24-240Vdc or 24-240Vdc to zero. The voltage must be

connected with positive to the red “Vdc” terminal and negative to the blue “com” terminal.

Contact set 2 has a volt-free contact input.

2.4.1 Timer Modes

2.4.1.1 Timer Mode: Off

In the ‘off’ mode, the timer has no effect on the operation of the set, and the timer does not

run. This mode is used to set the required current through the test object before a timing test.

2.4.1.2 Timer Mode: Internal Start

The internal start mode starts the timer when the main output is switched on, and stops the

timer on the first change of contact set 1. When the timer is stopped, the output of the unit is

automatically switched off.

2.4.1.3 Timer Mode: Single Contact

In single contact mode, the timer starts on the first change of state of contact set 1 after the

output is switched on, and stops on the second change on contact set 1. The output is

automatically switched off when the timer is started. The timer is reset when the output is

switched on. This timer mode is ideally suited to timing auto-reclose devices.

2.4.1.4 Timer Mode: Dual Contact

Dual contact mode uses both contact set 1 and contact set 2. The timer starts on the first

change of contact set 1 after the output is switched on, and stops on the first change of

contact set 2. The output of the unit is automatically switched off when the timer starts.

19

2.4.1.5 Timer Mode: Current Operated

Current operated mode is used to time devices that have contacts in series with the current

sense element. This includes many types of circuit breakers and trips.

The timer is started when the output current exceeds 20% of full scale of the selected

metering range, and stops when the current falls below this threshold.

2.4.2 General Procedure for Timing Tests

2.4.2.1 Connections

Ensure that the unit is switched off and the test object is isolated and grounded before making

any connections.

Connect the loading unit to the control unit as shown in figure 2.2.

Select the desired series/parallel output arrangement on the loading unit, and connect the

output cables to the test object. Select the appropriate loading unit series/parallel position on

the PCU2 loading unit connection switch.

Connect the supply lead to the mains and move the supply switch to the on position. The

supply on lamp should now be illuminated.

2.4.2.2 Testing

It is advisable to make a preliminary test on the test object, starting at zero voltage, in order to

test the load impedance, before performing the test with regulator set at higher values.

Therefore, ensure the regulator knob is fully anti-clockwise before switching on.

Ensure the timer mode switch is in the off position, and depress the on push-button. Increase

the current by rotating the output control knob in a clockwise direction until the desired current

is indicated on the ammeter. Press the output off push-button.

Connect the test object contacts to the contact terminals on the test set, select the internal

start timer mode, and reset the timer if necessary. If the test object has no auxiliary contacts

(e.g. thermal breakers), it will be necessary to use the current operated timer mode.

When the output on pushbutton is pressed, the following will occur:

a. The timer will start and current will flow through the test object.

b. When the test object's contacts change state the timer will stop and the test current

will be automatically switched off.

c. 2 seconds must now elapse before the timer function is active and ready for a repeat

test.

It is usual to repeat a test several times, checking that the times are consistent. However, it is

advisable to allow the device under test to cool between tests particularly if the test is being

carried out at large over-current factors.

2.4.2.3 After Testing

On completion of the test, return the regulator to zero and switch off the supply. Before

disconnecting the test object ensure the mains supply switch is in the OFF position.

This manual suits for next models

3

Table of contents

Other T&R Test Equipment manuals

T&R

T&R 200A-3PH Operating instructions

T&R

T&R KV5-100 mk3 Operating instructions

T&R

T&R CU-Ps Operating instructions

T&R

T&R KV6-80 Operating instructions

T&R

T&R PT30-10 mk2 Operating instructions

T&R

T&R KV30-40D mk3 Operating instructions

T&R

T&R PT30-10 Operating instructions

T&R

T&R Z-OVR Operating instructions

T&R

T&R PT18-10 mk2 Operating instructions

T&R

T&R PT15-10s Operating instructions