Dual/single outputs booster charger

2

2. Introduction

2.1 General introduction

TBB’s DM series charger is an in-vehicle charging solution which specified designed for on-board

application such as RV, Marine, Utility Vehicle, Truck etc.

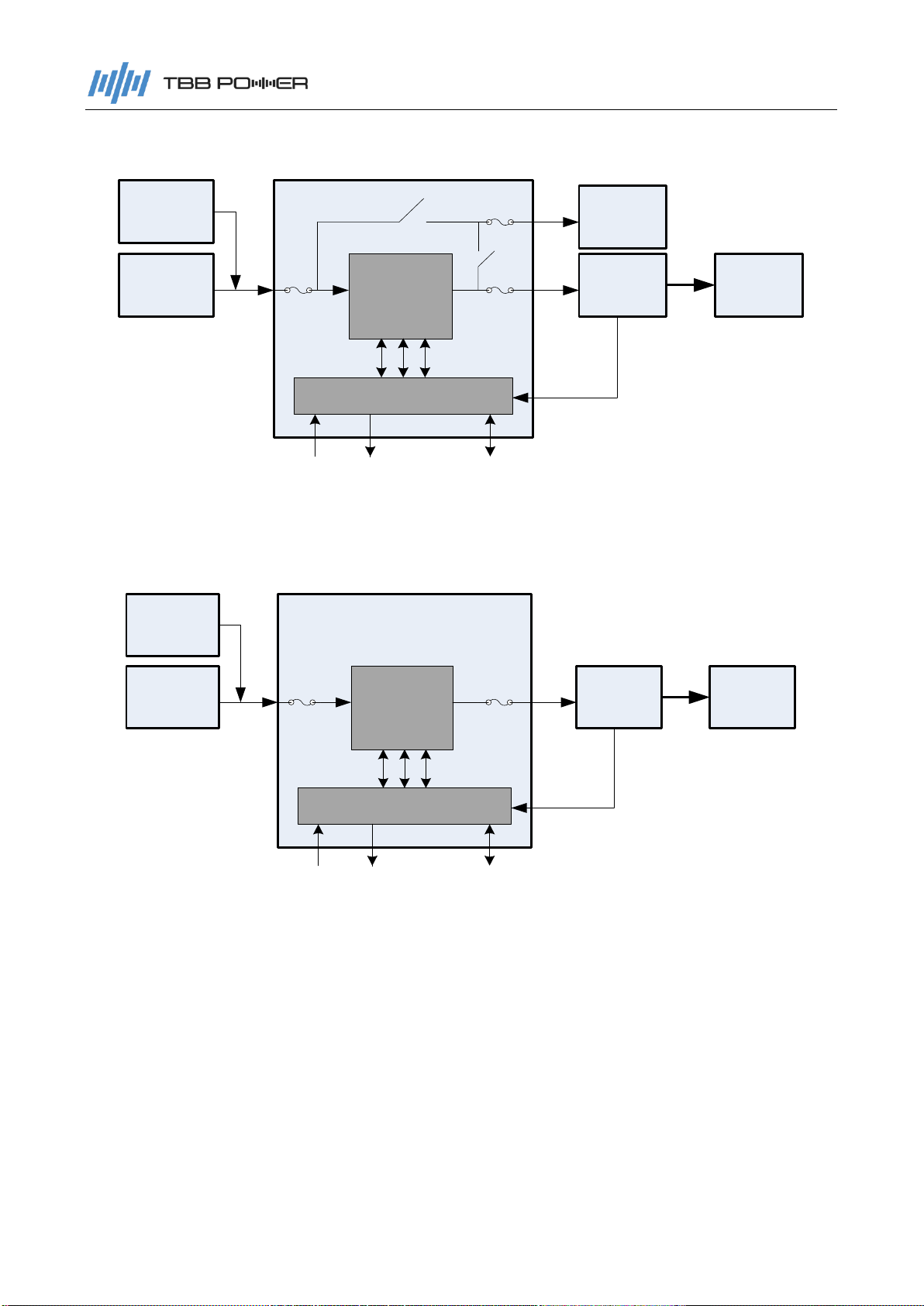

Dual outputs DMT1250 comes with a brilliant feature of dual outputs: one is for auxiliary battery

charging with charge current up to 30A, and the other one is dedicated to power a DC load

(Typically a DC fridge) with current up to 20A. When vehicle engine is running, DMT1250 will draw

power from engine to charge battery as well as to power DC load; when vehicle engine is turned off,

DMT1250 will draw power from auxiliary battery to power DC load. So that connected DC load could

be powered always either by engine or auxiliary battery.

Single output DM1230 and DM1245 are the booster charger only with charge current up to 30A or

45A respectively for 12V system.

Single output DM2430 is a booster charger only with charge current up to 30Afor 24V system.

All DM and DMT chargers are Euro-6 engine compatible, which is able to charge auxiliary battery

properly and fully with much wider variable voltage output from engine.

Features

Dual outputs, separate circuits for charging battery and powering DC load (DMT1250);

Non-isolation design with max efficiency 96%;

Euro-6 engine (Smart alternator) compatible;

TBB Premium II multiple stages charging algorithm;

Multiple battery chemical for optional including lithium battery;

Built-in automatic temperature compensated charging;

Plug and Play for easy installation;

Natural cooling without fan;

Supports RS485 communication;

Protection against input/output over voltage, output over current, output short circuit, internal

over temperature, battery over temperature, battery low temperature protect for LFP etc.

Back-charging function.