Application Specification

©2012 Tyco Electronics Corporation, a TE Connectivity Ltd. company

All Rights Reserved

*Trademark

TE Connectivity, TE connectivity (logo), and TE (logo) are trademarks. Other logos, product and/or company names may be trademarks of their respective owners.

1of 8

TOOLING ASSISTANCE CENTER

1-800-722-1111

PRODUCT INFORMATION

1-800-522-6752

This controlled document is subject to change.

For latest revision and Regional Customer Service,

visit our website at www.te.com

114-1016

Miniature AMP-IN* Contacts and

Miniature AMP-IN 2000 Contacts 16 OCT 12 Rev EE

Allnumerical valuesare inmetric units[withU.S.customary unitsinbrackets]. Dimensionsare inmillimeters [andinches].

Unless otherwise specified, dimensions have a tolerance of ±0.13 [±.005] and angles have a tolerance of ±2°. Figures

and illustrations are for identification only and are not drawn to scale.

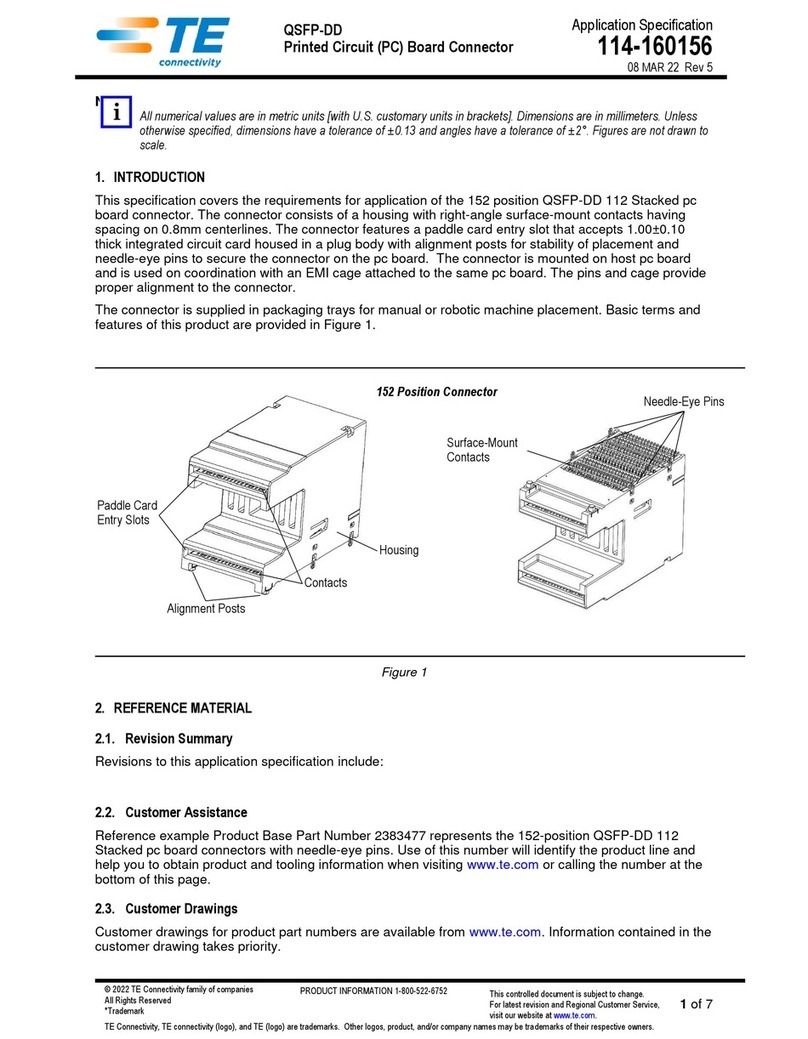

1. INTRODUCTION

This specification covers the requirements for application of miniature AMP-IN contacts and miniature AMP-IN

2000 contacts. These contacts are designed to hold the strands of wire together so that the wire can be inserted

into holes in a printed circuit (pc) board.

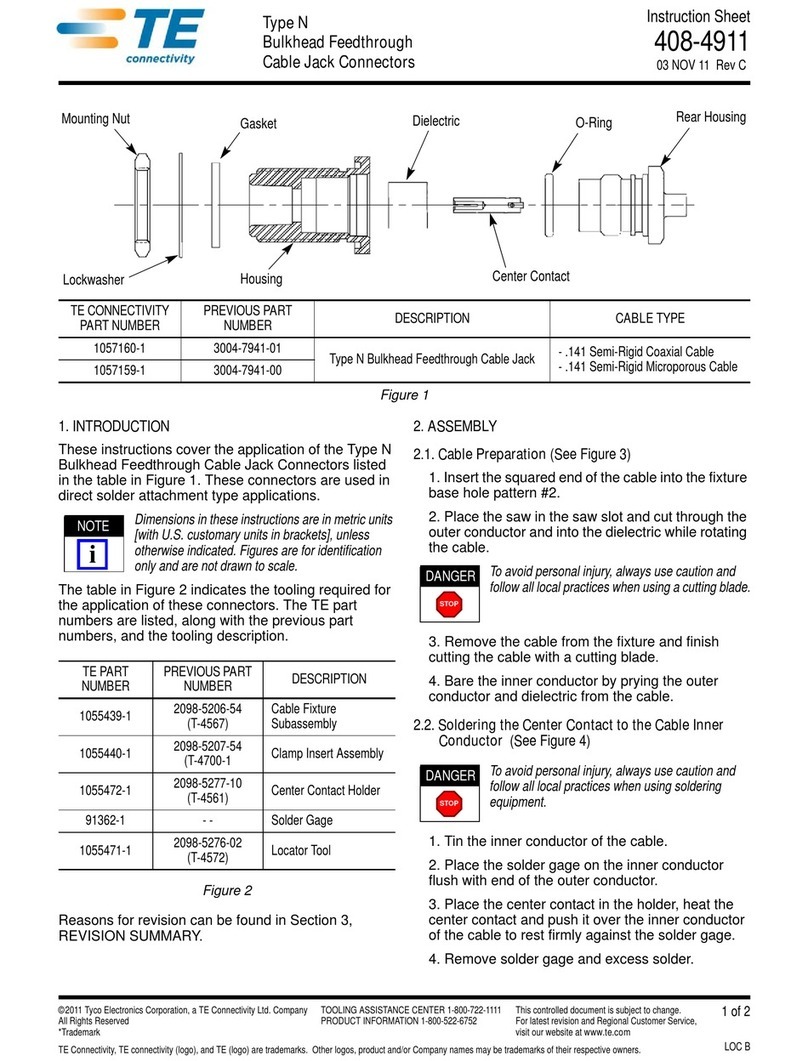

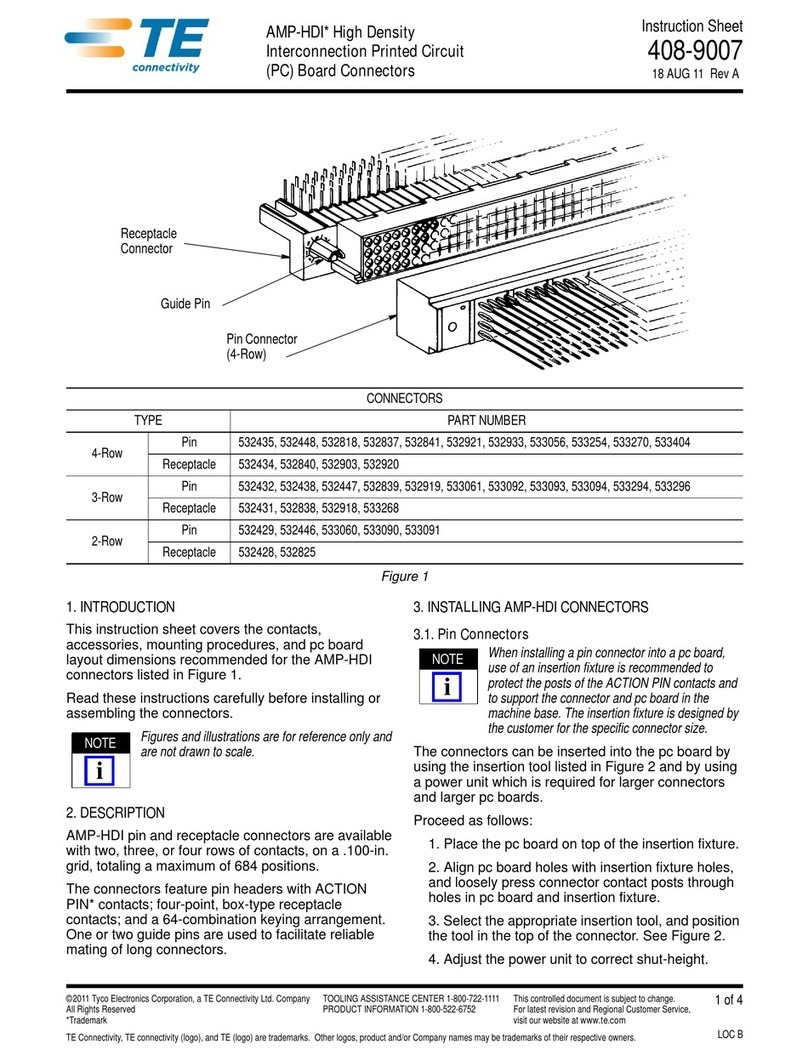

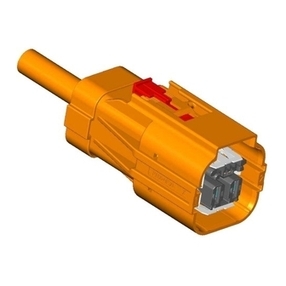

Each contact features a wire barrel, insulation barrel, locking lance(s), and stabilizer barrel or insulation stop/

positive board stop. The locking lance is designed to prevents the contact from backing out of the pc board hole.

The stabilizer barrel holds the contact steady during the soldering process, and the insulation stop/positive

board stop prevents the wire insulation from being inserted and the contact from being over inserted into the pc

board hole. These requirements are applicable to automatic termination machines.

When corresponding with personnel, use the terminology provided in this specification to facilitate your inquiries

for information. Basic terms and features of this product are provided in Figure 1.

Miniature AMP-IN Contact Miniature AMP-IN 2000 Contact

Insulation Stop/

Positive Board Stop

Locking Lance

Wire Barrel

Insulation

Barrel

Wire Barrel

Insulation

Barrel

Stabilizer

Barrel

Locking Lance

(2 Places)

Figure 1

2. REFERENCE MATERIAL

2.1. Revision Summary

Revisions to this application specification include:

•Corrected inch conversion for pc board thickness in Paragraph 3.4

2.2. Customer Assistance

Reference Product Base Part Numbers 640401 and 794121 and Product Code 1326 are representative of

miniature AMP-IN contacts and miniature AMP-IN 2000 contacts. Use of these numbers will identify the product

line and help you to obtain product and tooling information. Such information can be obtained through a local

Representative, by visiting our website at www.te.com, or by calling PRODUCT INFORMATION or the

TOOLING ASSISTANCE CENTER at the numbers at the bottom of this page.

2.3. Drawings

Customer Drawings for specific products are available from the responsible Engineering Department via the

service network. The information contained in the Customer Drawings takes priority if there is a conflict with this

specification or with any other technical documentation supplied.