TE Connectivity SolderSleeve CWT Series Reference guide

Other TE Connectivity Cables And Connectors manuals

TE Connectivity

TE Connectivity GS-IPC-500U User manual

TE Connectivity

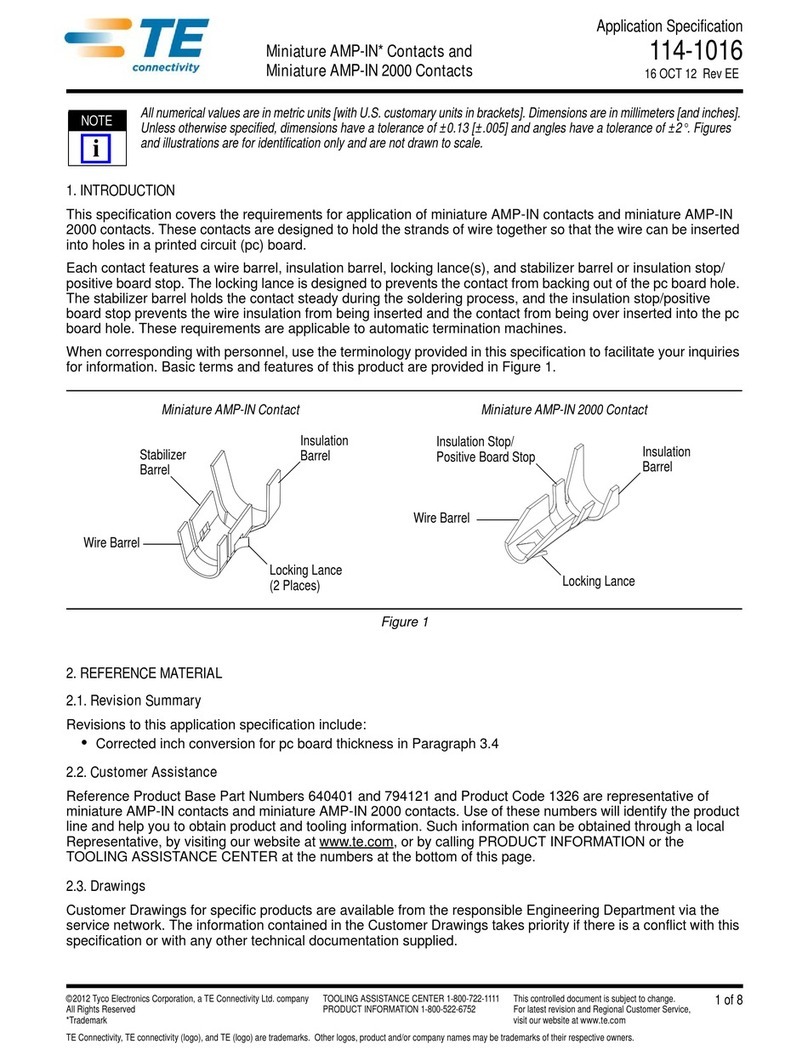

TE Connectivity Miniature AMP-IN User guide

TE Connectivity

TE Connectivity LJSU-4X Series User manual

TE Connectivity

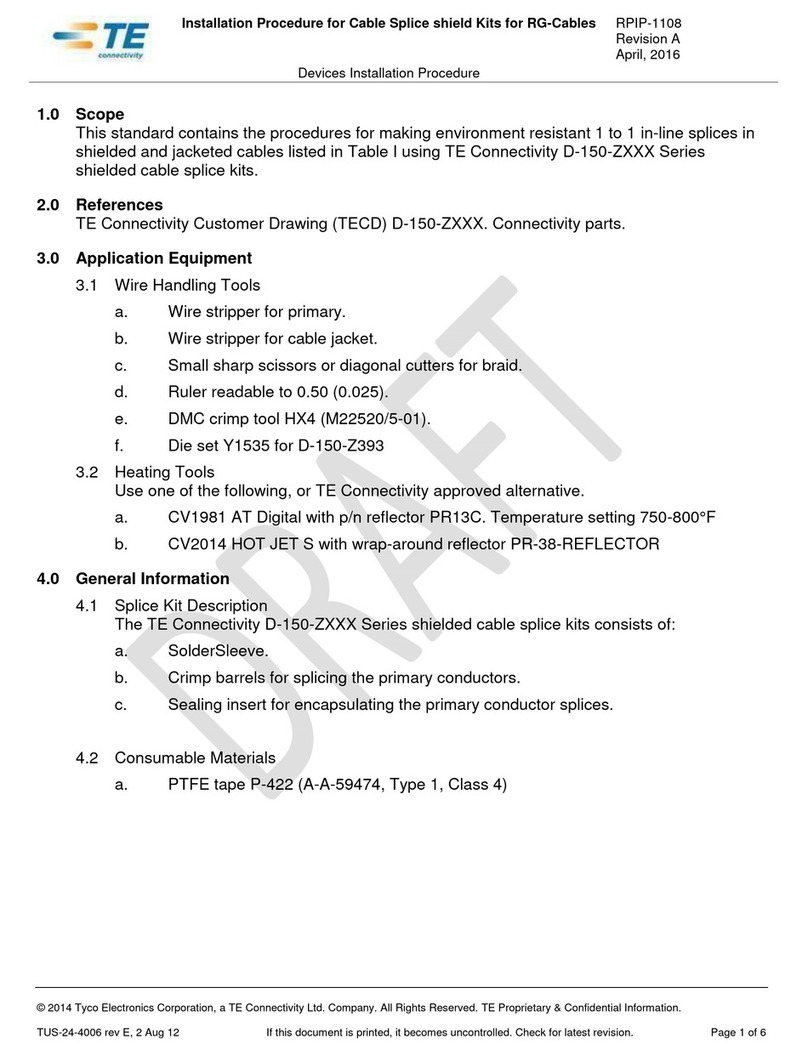

TE Connectivity D-150-Z Series Reference guide

TE Connectivity

TE Connectivity HVA630-5p User manual

TE Connectivity

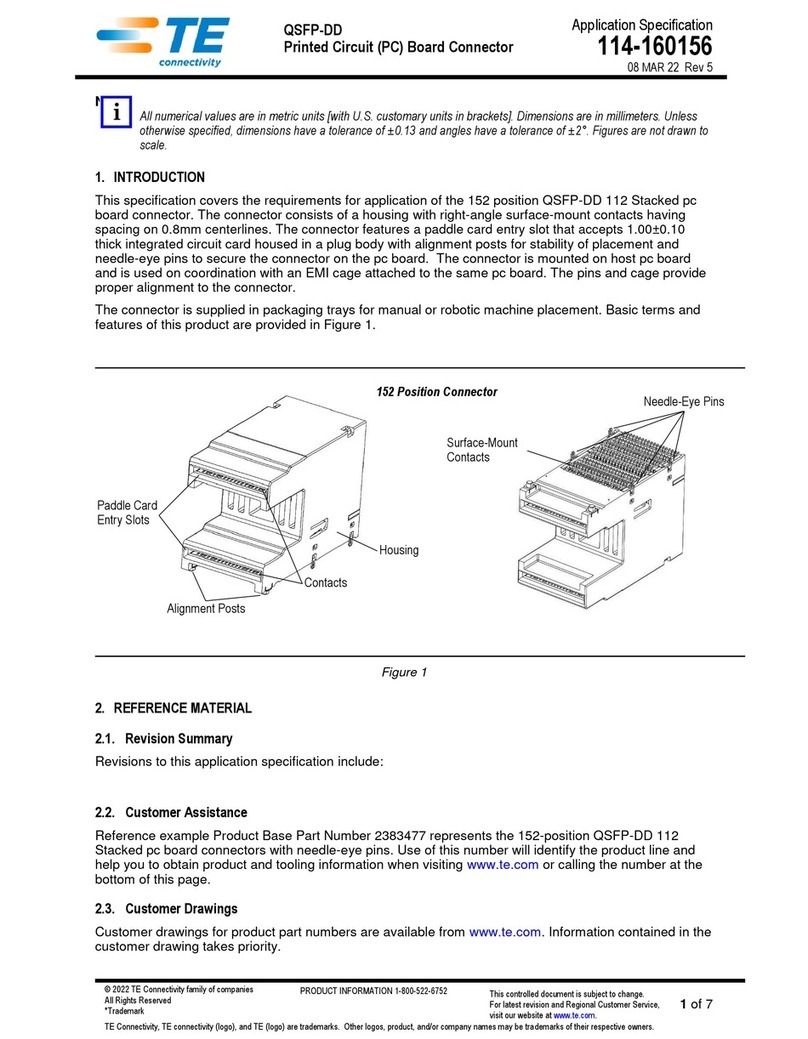

TE Connectivity QSFP-DD User guide

TE Connectivity

TE Connectivity RD-316 User manual

TE Connectivity

TE Connectivity 025/250 User manual

TE Connectivity

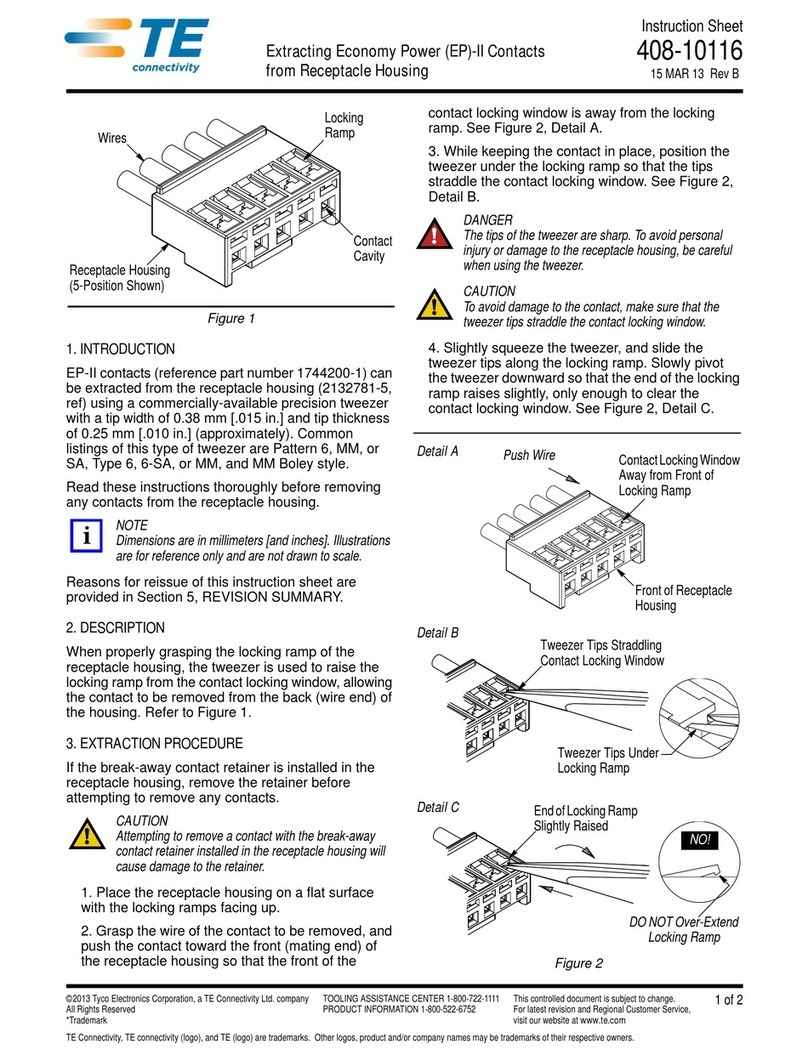

TE Connectivity EP-II User manual

TE Connectivity

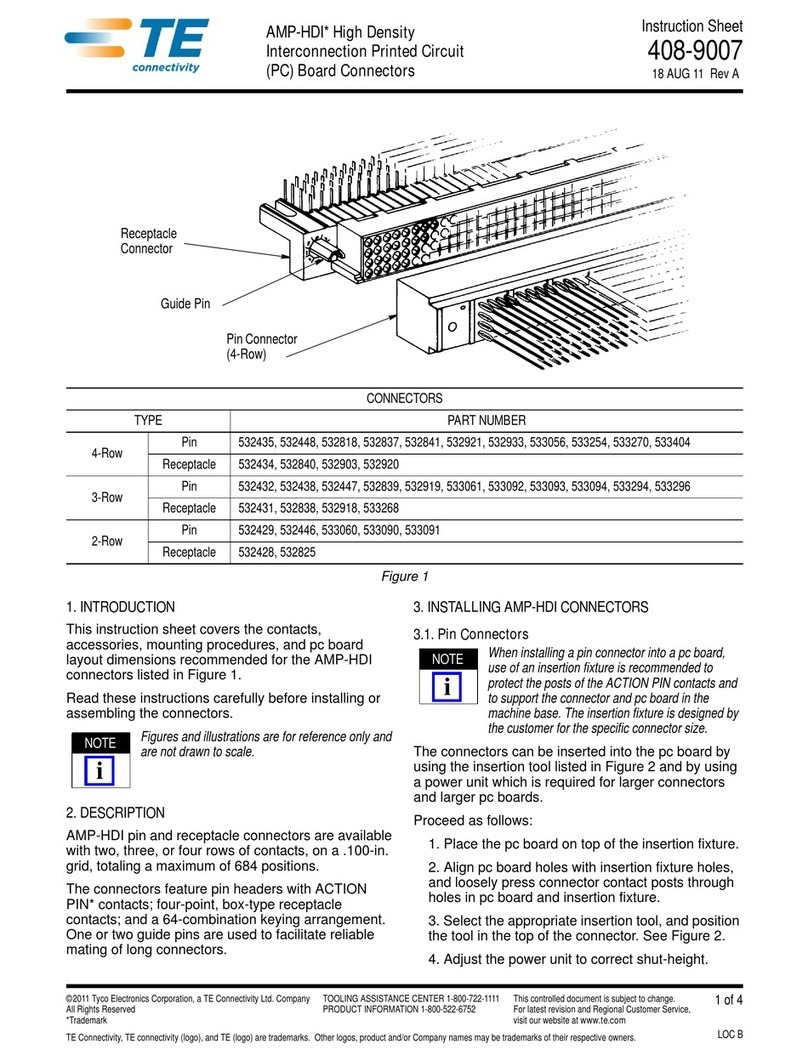

TE Connectivity AMP-HDI User manual

TE Connectivity

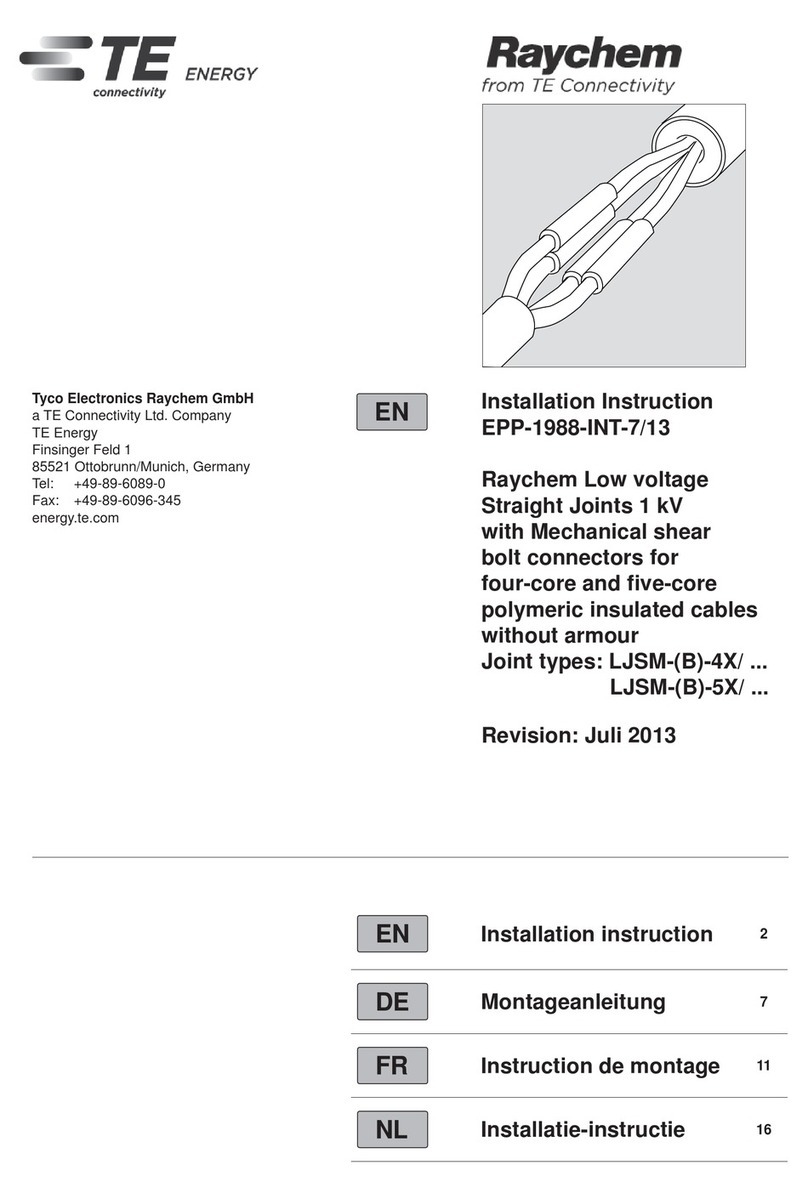

TE Connectivity Raychem LJSM Series User manual

TE Connectivity

TE Connectivity CCS1 User manual

TE Connectivity

TE Connectivity HV-CP User manual

TE Connectivity

TE Connectivity AMPOWER 68361-1 User manual

TE Connectivity

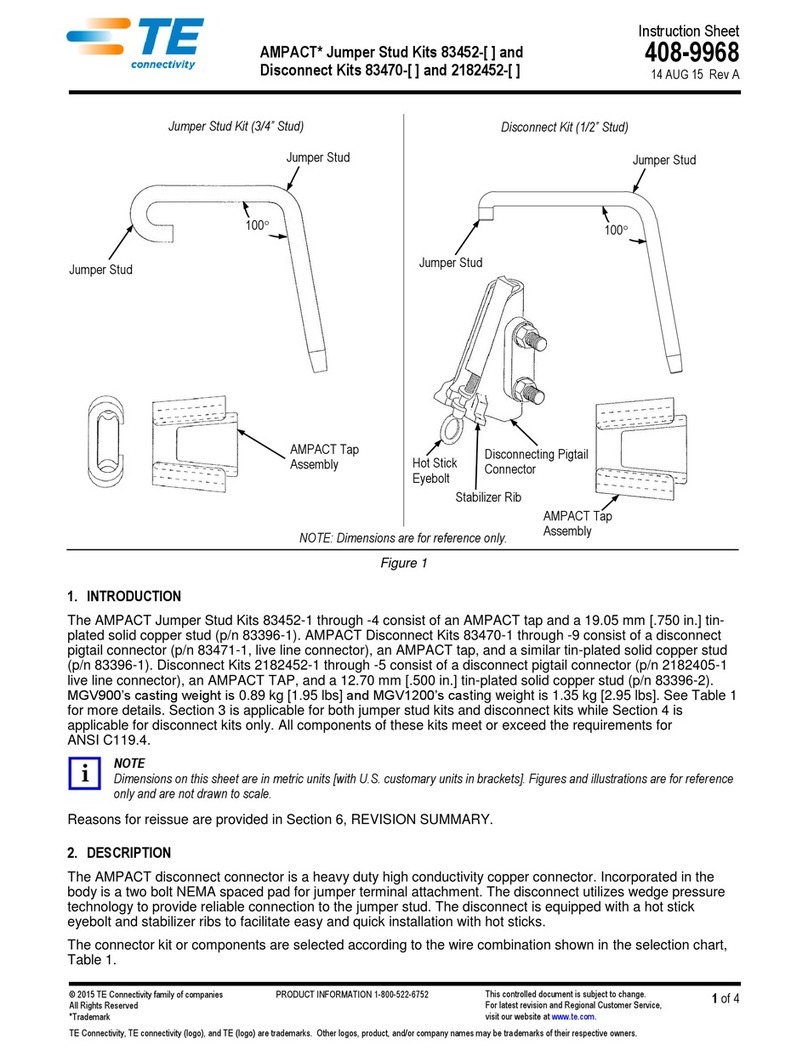

TE Connectivity AMPACT 83452 Series User manual

TE Connectivity

TE Connectivity HVA630-2phm User manual

TE Connectivity

TE Connectivity D5000-S User manual

TE Connectivity

TE Connectivity AMPLIMITE HDP-20 User manual

TE Connectivity

TE Connectivity RAYCHEM D-436 Series Reference guide

TE Connectivity

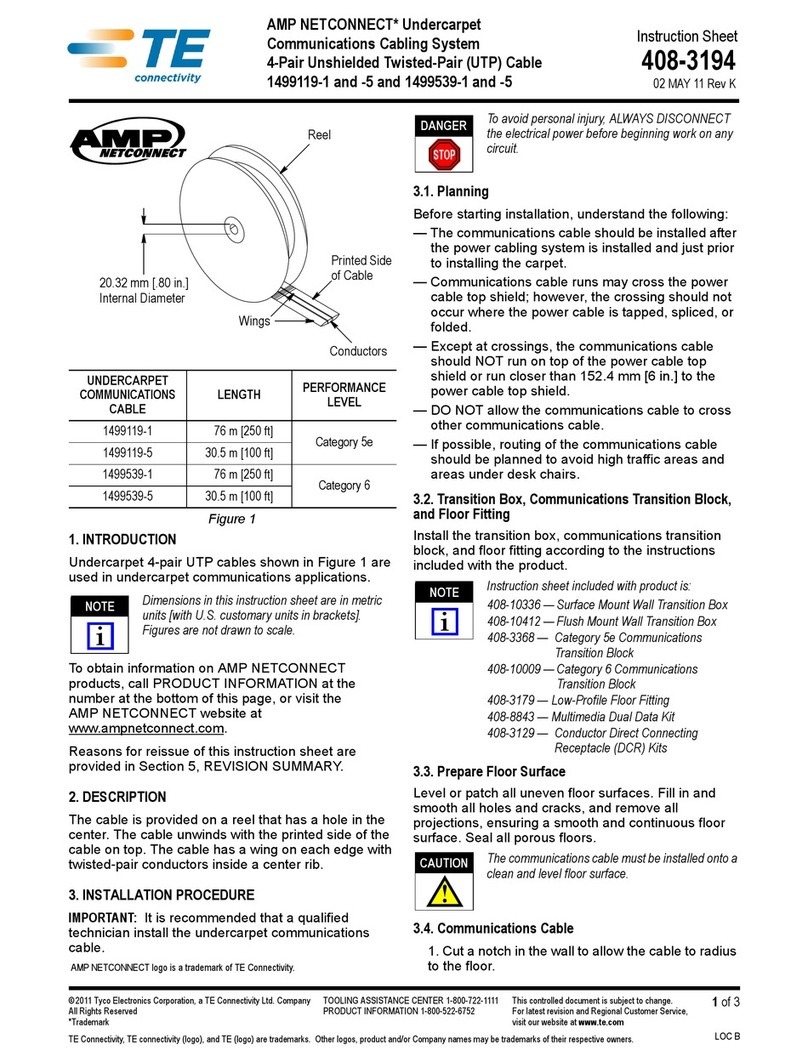

TE Connectivity AMP NETCONNECT 1499119-1 User manual