114- 40020

Rev D2of 9

2.4. Specifications

Product Specification 108--40019 covers test and performance requirements.

2.5. Instructional Material

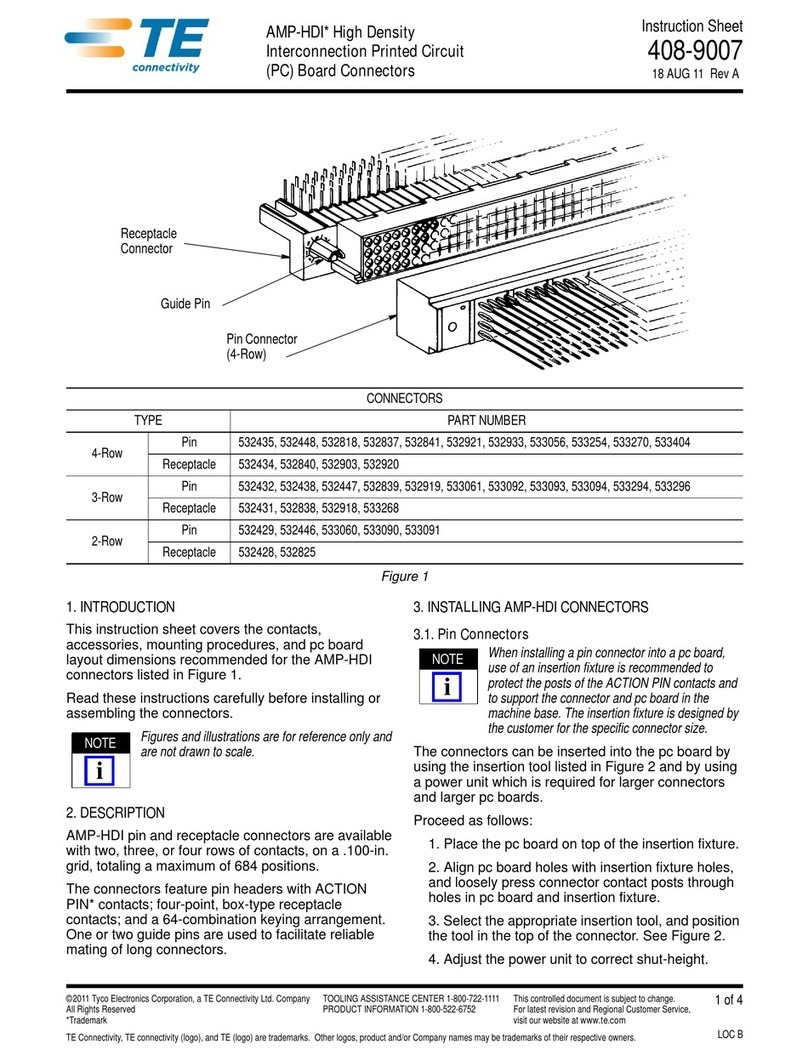

The following list includes available instruction sheets (408--series) that provide assembly procedures for

product, operation, maintenance and repair of tooling; and customer manuals (409--series) that provide setup,

operation, and maintenance of machines.

Document Number Document Title

408--6926 Seating Tools 91268--[ ]

408--6939 Removal Tool 91269--1 for Universal Header Latches

409--5626 SM--3 Machine No. 814700--[ ]

3. REQUIREMENTS

3.1. Storage

A. Ultraviolet Light

Prolonged exposure to ultraviolet light may deteriorate the chemical composition used in the headers.

B. Shelf Life

The headers should remain in the shipping containers until ready for use to prevent damage. The products

should be used on a first in, first out basis to avoid storage contamination that could adversely affect signal

transmissions.

3.2. Material

AMP--LATCH Universal Headers are made from 94V--0 rated black thermoplastic. The ACTION PIN Contacts

are made from phosphor bronze plated with gold on the mating area, and tin/lead or tin on the ACTION PIN

tail, all over nickel underplate.

3.3. Intermateability

The headers are designed to mate with AMP--LATCH Receptacle Connectors such as Novo, AMPMODU*

MTE Connectors, FFC Connectors, and other industry standard receptacles having identical number of contact

positions on 2.54 [.100] centers and compatible polarization. Refer to the instructional material provided with

the mating connectors for termination procedures.

3.4. PC Board

A. Tolerances

Maximum allowable bow of the pc board will be 0.13 mm [.005 in.] over the length of the header.

B. Material and Thickness

The pc board material must be glass epoxy (FR--4 or G--10). The minimum pc board thickness must be

2.03 mm [.080 in.]. Headers are available with post lengths of 4.42 mm [.174 in.] or 15.49 mm [.610 in.].

Contact the Product Information Center at the number listed at the bottom of page 1 for suitability of other pc board

materials and thicknesses.

C. Layout

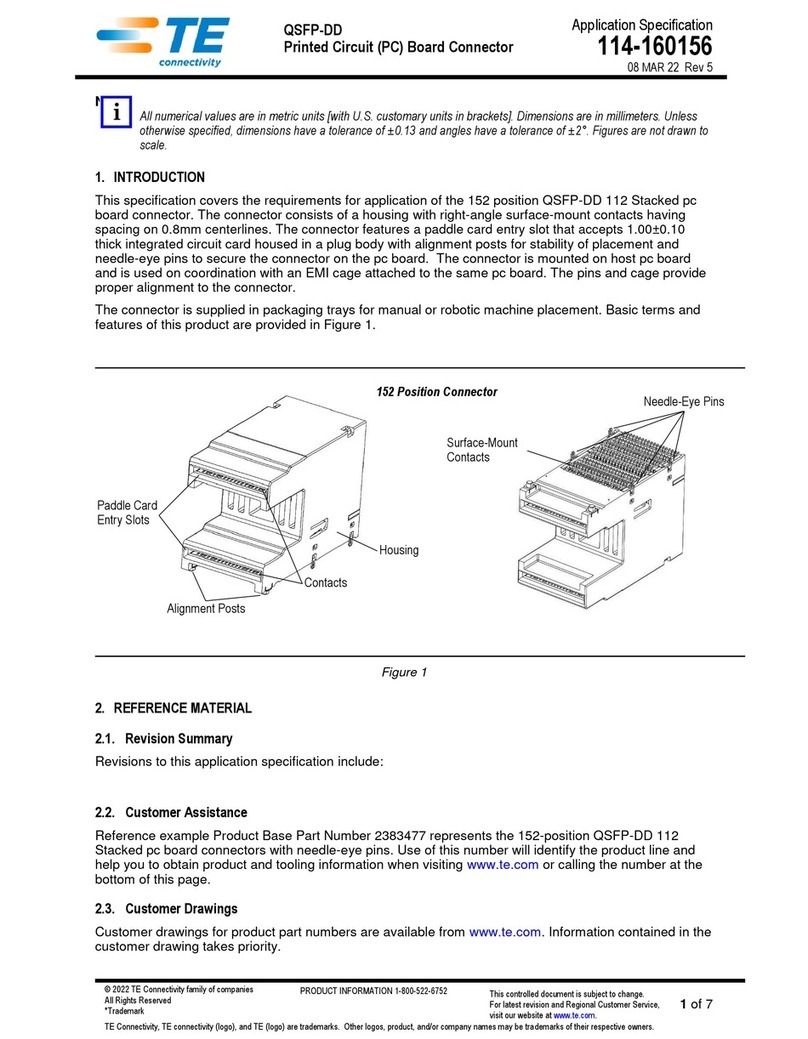

Recommended pc board patterns and dimensions, as well as tolerance, are provided in Figure 2. The

layout shows the top (header) side of the pc board.

Figure 2 represents a typical pc board layout for this product. For dimensions and hole pattern layout for specific

product, obtain the appropriate customer drawing through your TE Representative or refer to the telephone numbers at

the bottom of page 1.

NOTE

i

NOTE

i