This manual is intended for studying principles of operation,

correct use, operating conditions and maintenance of the Wire-

less Surface Acoustic Glass Break Detector Astra-Z-6145

(hereinafter “detector”) (Fig. 1).

The manufacturer reserves the right to make alteration regard-

ing refinement of the product without prior notification. All

changes will be imported into new edition of the operation

manual.

List of Abbreviations

Astra-Zitadel System –the on-site Wireless Intrusion / Fire

Detection and Alarming System Astra-Zitadel;

Astra-Zitadel System Control Panel –Astra-Z-812M, Astra-Z-

8945 ver.A, Astra-8945 Pro or Astra-812 Pro Control Panel (with

connected Astra-Z Wireless Extender);

MSS Astra-Z –Astra-Z Monitoring Software Suite;

MSS Astra Pro: Astra Pro Monitoring Software Suite;

LT –Laser Tester Astra-942;

Battery –power supply battery.

1 Function

1.1 The detector detects the breaking of

glass in closed glassed rooms, generates the

alarm notification and sends the notification to

the Control Panel of the Astra-Zitadel System

via radio channel.

Types of glass:

- conventional and protected with a polymer

film, thickness from 2,5 mm to 8 mm;

- armored glass, thickness from 5,5 mm and

6 mm;

- figure glass, thickness from 4 mm to 7 mm;

- laminated construction glass, thickness from 6 mm to 8 mm;

- tempered glass, thickness from 4 mm to 6 mm space is at

least 0,1 m2(length of one of the sides is at least 0,3 m).

1.2 The detector supports connection of external hard-wired

detectors with NO/NC outputs of «dry contact»-type.

Note: Zone-GND Input does not have current control.

1.3 The detector is powered by lithium-thionyl- chloride bat-

tery of AA size with voltage of 3.6 V (included in the delivery

set).

2 Operating Principle

2.1 The principle of operating is based on the registration of

breaking glass by means of analysis of an acoustic signal in

the sound frequency range. The microphone is a sensor. An

electric signal proceeds from the microphone comes to micro-

controller, which forms an alarm notification in accordance with

specified operation algorithm.

2.2 Schematics of the detection zone are shown in Fig. 2.

Fig. 2

3 Specifications

Technical Parameters of Acoustic Channel

Two operating frequency bands:

- first (high), kHz ............................................................. 4 to 6

- second (low), Hz....................................................100 to 200

Detector coverage range, m, min...............................................6

Detection area angle, degrees, min....................................120

Technical Parameters of Radio Channel

Operating frequency range, MHz......................2400 to 2483.5

Number of active channels with 5 MHz increment................16

Channel width, MHz................................................................2

Wireless coverage range, line-of-sight, m, min...................300

General Technical Parameters

Detector current consumption, mA, max:

- radio module OFF............................................................0.13

- radio module ON ..............................................................105

Battery replacement indication threshold, V ....................2.7-0.2

Power supply voltage lower threshold (deactivating

threshold retaining battery discharge indication), V.............2.1

Overall dimensions, mm, max .............................101.56332

Weight (without battery), kg, max ......................................0.07

Average battery service life, years, min.....................................2

Operating Conditions

Temperature range, °С................................from -20 up to +50

Relative air humidity, %..............................up to 95 at + 35 °С

no moisture condensation

4 Delivery Set

Wireless Surface Acoustic

Glass Break Detector Astra-Z-6145...................................1 pcs.

Battery ER14505 ...............................................................1 pcs.

Screw 2.9×25.....................................................................4 pcs.

Dowel 5х25........................................................................4 pcs.

Operating Manual............................................................1 copy.

5 Structure

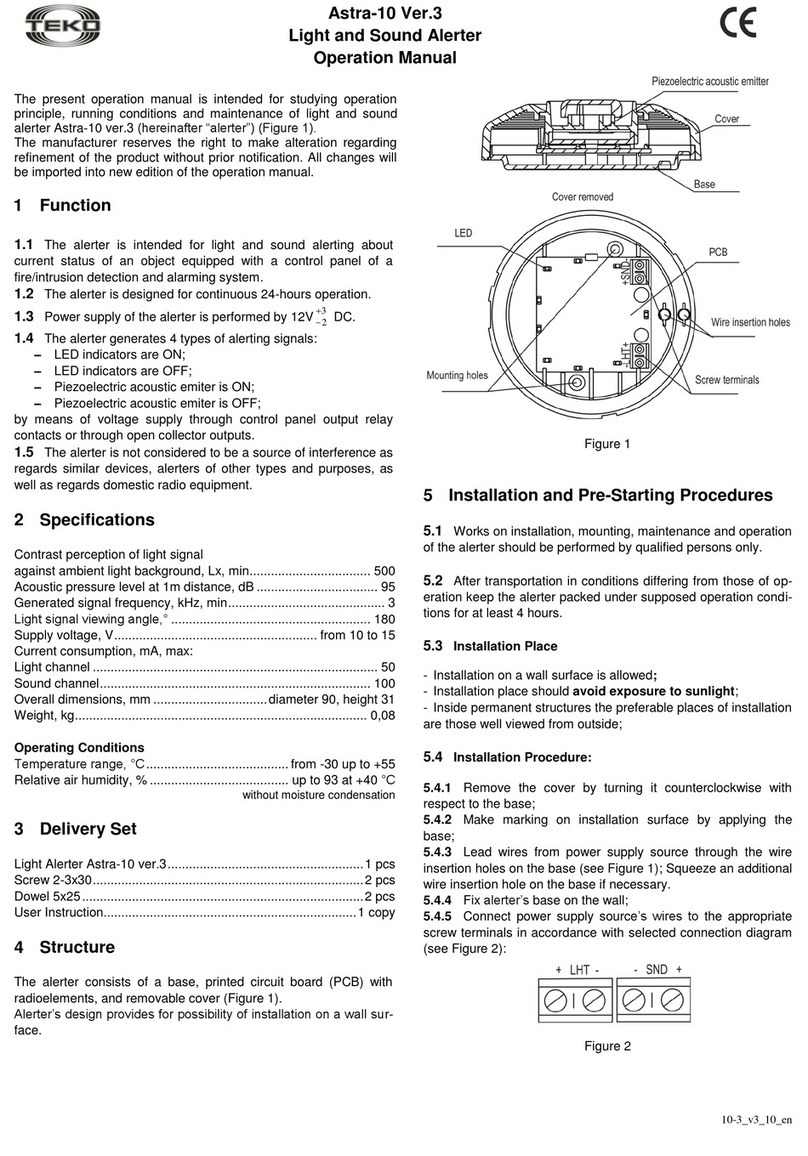

Fig. 3

5.1 Structurally, the detector is designed as a unit consisting of a

base and a removable cover. The unit houses a printed circuit

board with radio elements (Fig. 3).

5.2 Mounted on PCB is a Zone-GND terminal block for con-

necting external emergency detectors (gas leak, water leak,

etc.). Wire length is 3 m max.

5.3 Mounted on PCB is a Tamper Switch (S1button), which

results in the «Tampering»notification when the cover is re-

moved.

5.4 Mounted on PCB are LEDs: red (for monitoring the detec-

tor’s operability) and white (for wireless network status supervi-

sion).