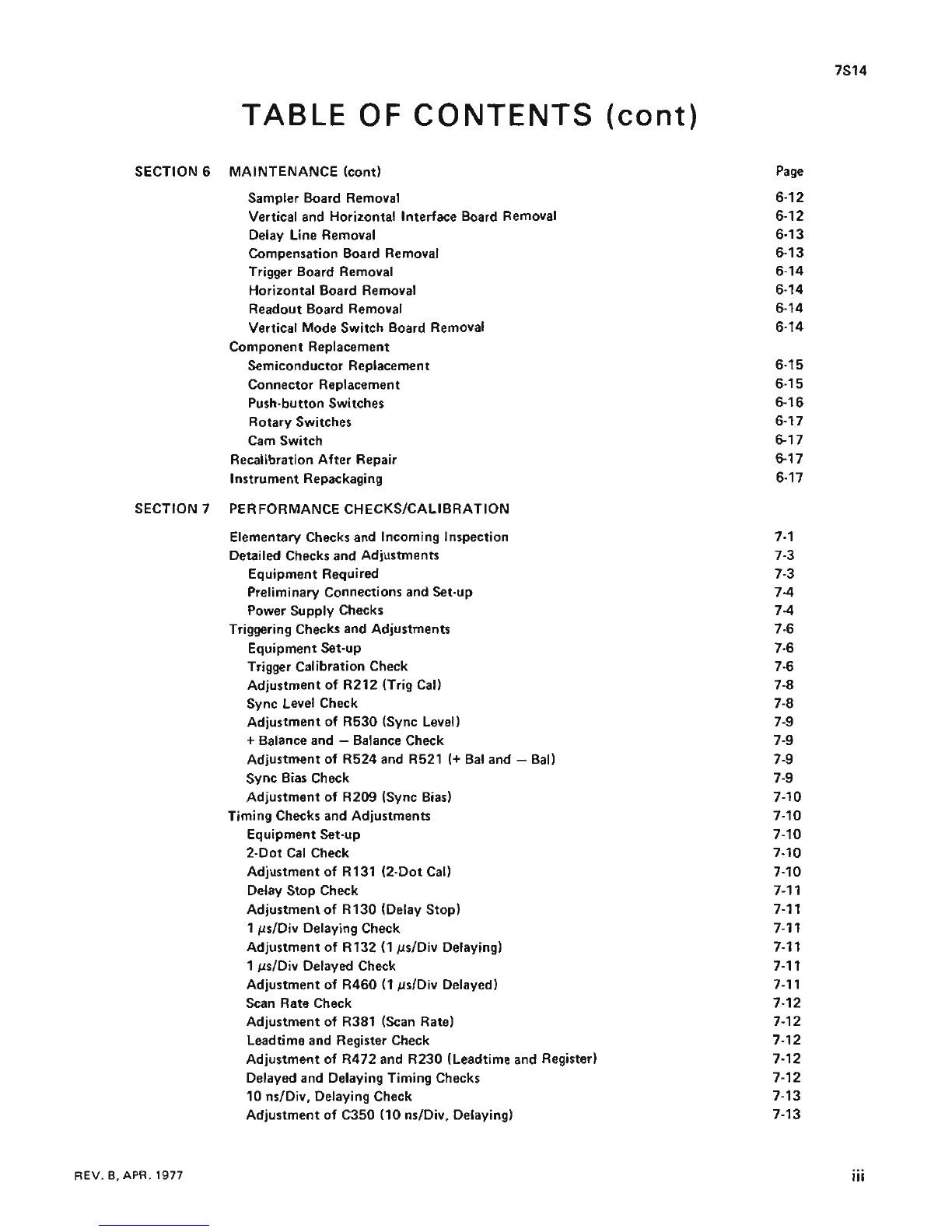

Genaral

Information

Section

1-7S14

CHARACTERISTICS

The

Tektmnlx7S14 Dual

Trace

May&

Sweep

Sampler

is

a

general

purpuse

samplingunit with

a

DE-1

000

MHz

bandwidth.

It will

operate

In

any

Tektrmlx

7000

Senes

mainframe.

Tha

front paneltem~nologyis similar to

that

of

convent~nalmc~llosoopes.

The

7514 has

two time

bases

to

provide "delaying" and

"delaved

sweep"

'ation.

The

ddaved

sweep

starts after

mints

is

the

productof the reading

on

the

Delay

Kme

Mult

dial

times

the

DelayingSweep

WDiv

ming.

Delay

lines inthe inputsignel channels permitdisplay

of

the leading

edge

of

the trigering waveform.

The

Auto

Level meprovides

a

bright baseline

in

the

absence

of

a

triggering signal. Other featurer indude 2mVldiv

sensitiviw, low tangential noise, versatiletr~ggetingmpabil-

itiss,

a

broad

range

of

sweep

rate, and

crt

readout

of

both

the

attenuation

and

timing values.

the

sttlected

delay lyntenral, givingthe effect

of

a

wide-range

sweep

operation.

The

delayed sweep

starts

after the The characterirtics

given

in

the

followingTableapplwover

selected delw interval, giving the

etfecf

of

a

wide-range an ambient temperature

range

from

O'C

to

+W*C

after

€he

sweep magn~fier.

The

calibrated

delay

replam the "time imtrurnem

has

been

=librated

at

+25'~

t5'~.

Under

these

pos~tion"

control

fountl

on

most

sampling time-baseunits. conditions, the

7S14

will

pwform

to

therequirementsgiven

in

the Performance

Check

section

of

this

manual.

The

JS14

has

a

two

dot

time-interval mmsuremem

method

that

prowdep

a means

of

measuring

the

time The Supplemental

information

column

of

the

Table

been

two

mints

on

the

"normal" (delaying)d~splav.

A

provides additional information

about

the operation

of

the

brightened

dot

on

the trace

can

be

m~t~onedto the

start

7514.

Characteristiu given in the Supplemental Infor-

of

the event to

be

measured.

A second brlghtend

dot

an

mation column

are

not

requirementsinzhernselves

and

are

be

pdsit~oned

to

the

end

of

the

event

bv

using the Delay not necessarily

checked

rn

the Performance Check

Time

Mult control.

The

time interval between the

two

~rocedure.

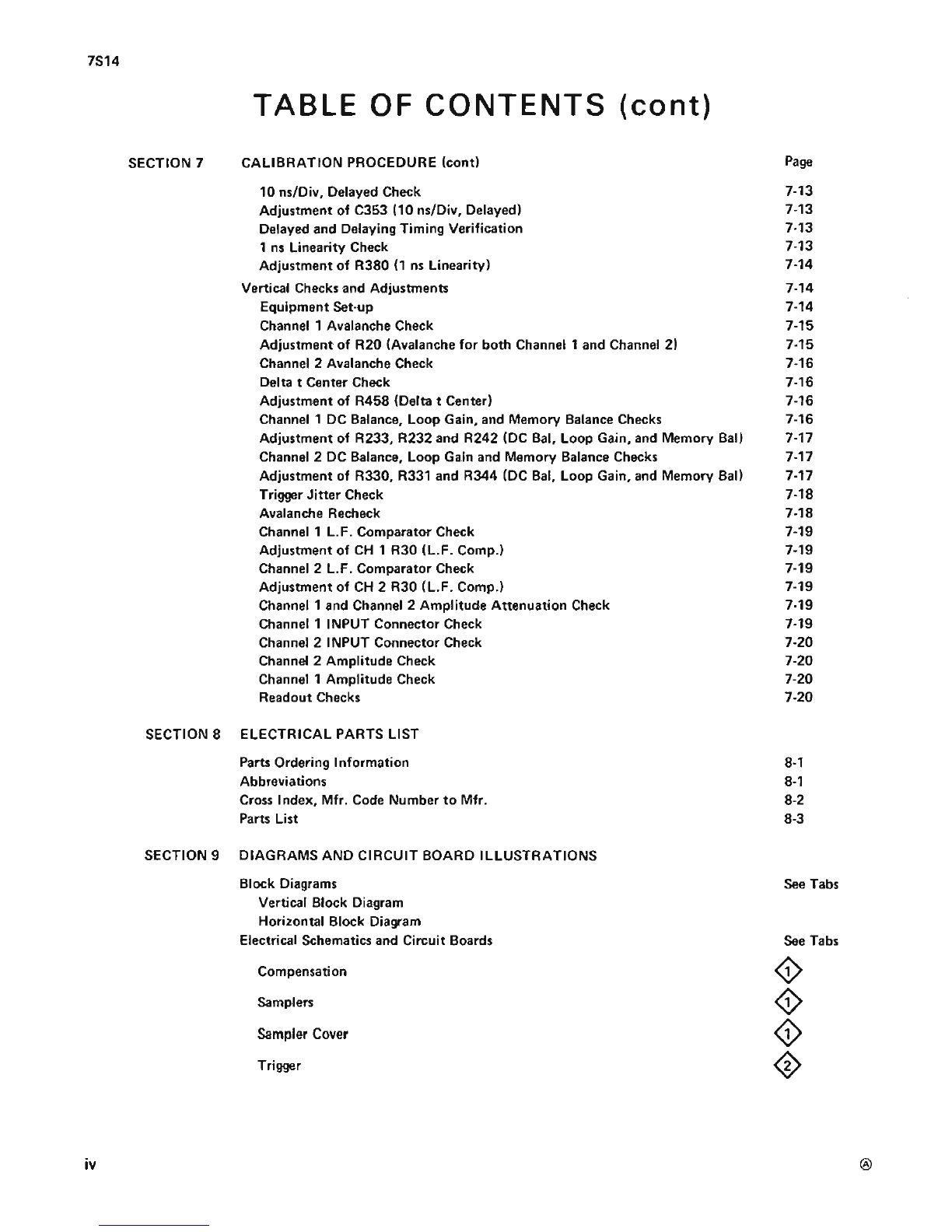

ELECTRICAL

CHARACTERI!XICS

VERTICAL

SYSTEM

I

I

350

ps

or Iesa,

10%

to

90%

of step pulse

]

I1

Step Aberrations

+2%,

-3%.

total

of

5%

or

Teps

P-P

within made with Tektronix

284

Pulse

first

5

m

after

step transition;+l%.

-3%.

includes aberntiom from the

totat of

2%

or

less

P-P

thereafrer.

Bandwidth

(-3

dB)

I

DC

to

1

GHr

or

more.

(

Calculmedfrom risetime.

Accuracy

I

Within

23%

(with

VARIABLE

at

CAP].

I

Input

Reistance

DeflectionFactor

50

within

2%.

I

2

mVlDiv to

0.5

VIDiv.

8

stew,

4-2-5

sequence.

MaximumOperation

2

V

P-P

(DC

+Peak

AC]

within a

+2

V

to

-2

V

window

at

any

sensitivity.

Variable

Input

Signal

Range

At least 251. Extends

urnlibrated

deflection

factor

to

I

approximately

800

pV/Div.

Maximum

Overload

*5

V.