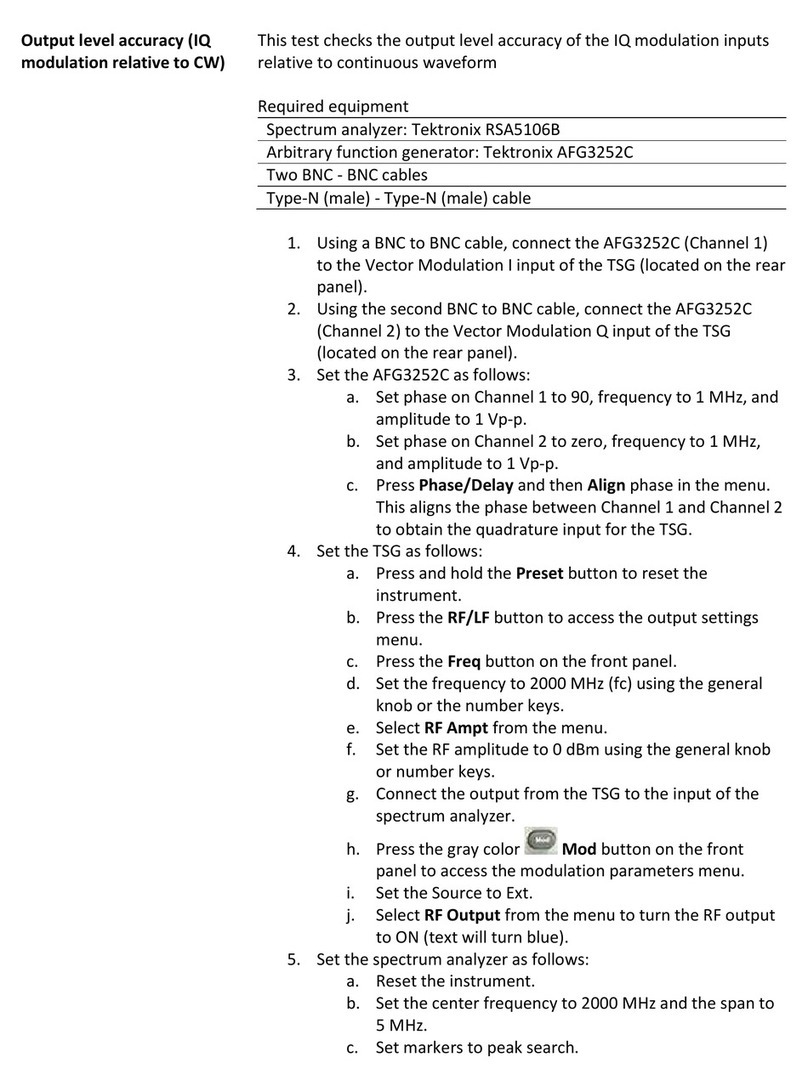

Operating

In

struct

io

n

s-7

8

52

To install the

7852

into a plug-in compartment, push it

in

until it fits firmly i

nto

the compartment.

To

remove, pull

the release latch (see Fig. 2·2) to disengage

the

unit from

the indicator oscilloscope and pull it

out

of the plug-in

compartment. Even though the horizontal gain

of

the

inc:li-

cator

oscilloscope

is

standardized to minimize adjustment

when inserting plug·ins. the sweep calibration

of

the

7852

should be checked. The procedure for checki

ng

the unit

is

given under Sweep Calibration Check

in

the First-Time

Operating Instructions

of

this section.

REl.EASE

l.ATCH

.,"

TWIll.

,.-

~~

DUAL TIME BASE

Fig.

2·2.

L

oe.

t

io

n of

re

le

s$fI

l

atc

h.

FRONT·

PANEl

C

ONTROLS

and CONNECTORS

General

All

controls required for the operation of

the

7652

are

located on the front panel

of

the unit (see Fig. 2·3) with

the

exception of the internal DELAYED TRIGGER

SOURCE and

MA

IN

-FRAME

DE

L

AY

I

NG

MODE

sw

itches.

To make full use

of

the capabilities

of

this instrument, the

operator should be familiar with the function and use

of

each

of

these controls. A detailed description

of

the front·

panel controls and connectors

is

given here.

Main Triggering Controls

LEVEL/SLOPE

2·2

The LEVEL/SLOPE control deter-

mines whether the trigger

ci

rcuit

responds on the positive-going

or

negative-going portion

of

the trigger

signal. When the indicator line on

the

outer

ring of the

lEVEL!

SLOPE control

is

to the left

of

center, the display starts on the

positive-going portion

of

the wave-

form (notice positiveijoing wave-

form symbol to l

eft

of

control). To

the right

of

center, the display

starts on the negativeijoing portion

TRIG'D

LAMP

of

the waveform (notice negative·

going

waveform symbol). When

several cycles

of

a signal appear

in

the display. the

se

lection of the

trigger slope

is

often unimportant.

However.

if

only a certain portion

of

a cycle

is

to be displayed, correct

setti

ng

of the LEVEL/SLOPE con·

trol

is

important to provide a dis·

play which starts on the desired

slope

of

the input signal.

The lEVELISLOPE control

deter

·

mines the voltage level on the trig.

ger signal

at

which the display

is

triggered,

as

well

as

selecting the

tr

igger

slope. The center knob

of

the LEVEL/SLOPE control pro·

vides about a 3:1 reduction

in

rela·

tion to the

outer

indicator ring, to

allow precise

level

selection. This

control can also be turned through-

out

the complete 3600 rotation to

allow continuous triggering over the

selected slope. When the

lEVEL!

SL

OPE

control

is

set to the line on

either the positive-going

or

nega-

t ive-going waveform symbol the

sweep

is

triggered near

the

zero-volt

Ievei of the trigger signal lAC

coupled only). As the LEVEL!

SLOPE control

is

rotated

;may

from the zero line, the displayed

waveform starts

at

a

point

carre·

sponding to the position

of

the

ind icator tine on the associated

slope

waveform

symbol.

For

example,

if

the LEVEL/SLOPE

control

is

turned clockwise from

the zero line

on

the positiveijoing

slope symbol. the displaved wave·

form starts

at

a more positive level.

Before

setting the triggering

level,

select the TRIGGERiNG

MODE, COUP

LI

NG

and SOURCE.

Then

adj

ust the lEVEL/SLOPE

control

SO

the displayed waveform

starts

at

the

desired point. The trig-

gering slope can be changed

at

any

time

by

rotating the LEVEL!

SLOPE

control

to the corre-

sponding point on the

other

sl

ope

waveform symbol.

The TRIG'D lamp provides a con-

venient indication of the condition

of

the trigger circuits.

If

the

MAIN

®