TELETRAC NAVMAN TM470 Series Installation guide

TM470 Installation overview

6.2.2016

www.TeletracNavman.com

1

Recommended Installation Practices

Review this installation manual to become familiar with all installation procedures and electrical wiring

requirements prior to starting the installation. This installation guide has been prepared to provide you with

details necessary to complete the TM470 installation.

Use of proper tools and testing equipment is required. Never use a grounding style test light. Use only a

Digital Multi Meter (DMM) to test wires in the vehicle. It is strongly recommended that one of the battery post

cables is disconnected or battery disconnect switch is engaged prior to making electrical connections.

The recommended method of electrical connections for the TM470 is “Poke and Wrap”. “Poke and Wrap”

is described in detail later in this guide. It is critical to ensure that all electrical connections are properly

insulated with quality electrical tape. Do not use butt connectors, crimp connectors or any other means to

connect wires. Failing to ensure proper connections may result in warranty being voided and damage to the

TM470 and/or the vehicle.

Ensure that all wiring is protected from heat sources and sharp metal edges and is routed in such

manner that it will not get damaged or pinched when vehicle components and trim are reinstalled. Run new

wiring along factory harnesses and secure with quality cable zip-ties. Be sure to leave a “service loop” near the

TM470, enough slack in the wiring to allow working room and strain relief.

The TM470 is NOT waterproof, never mount the TM470 in the engine compartment. When mounting the

TM470, determine best possible location under the dash and make sure that the TM470 will be securely attached

using self-tapping screws or cable zip-ties. Do not force or jam the TM470 into tight places instead of mounting

it. When mounting the TM470, do not obstruct any serviceable areas such as fuseboxes, etc. The TM470 and its

wiring must be mounted away from any moving parts such as brake, gas, and clutch pedals and linkages.

Follow all safety guidelines outlined in this guide, the applicable TM470 Installation Manual as well as

those set forth by industry and government.

3

Recommended Tools and Supplies

4

Mobile electronics installation requires a variety of different tools. The following list

provides a good example of therange of tools that will be required for installation.

Tool List (recommendations):

•Panel Popper (Snap On, Mac, Craftsman, Klein)

•Wire stripper-multi gauge (Snap On, Mac, Craftsman, Klein) Crimp Tool (Snap On, Mac, Craftsman, Klein)

•Wire cutters

•Cordless drill- variable speed reversible

•Assorted screw driver bits set for cordless drill

•Magnetic nut-drivers

•Skew-driver (right-angle screw driver adaptor) (Mac, Milwaukee Tool, Skew)

Basic Supplies:

•Ring Terminals

•Zip-ties

•Electrical Tape

•Spare fuses (Various sizes and values)

•Self-tapping screws

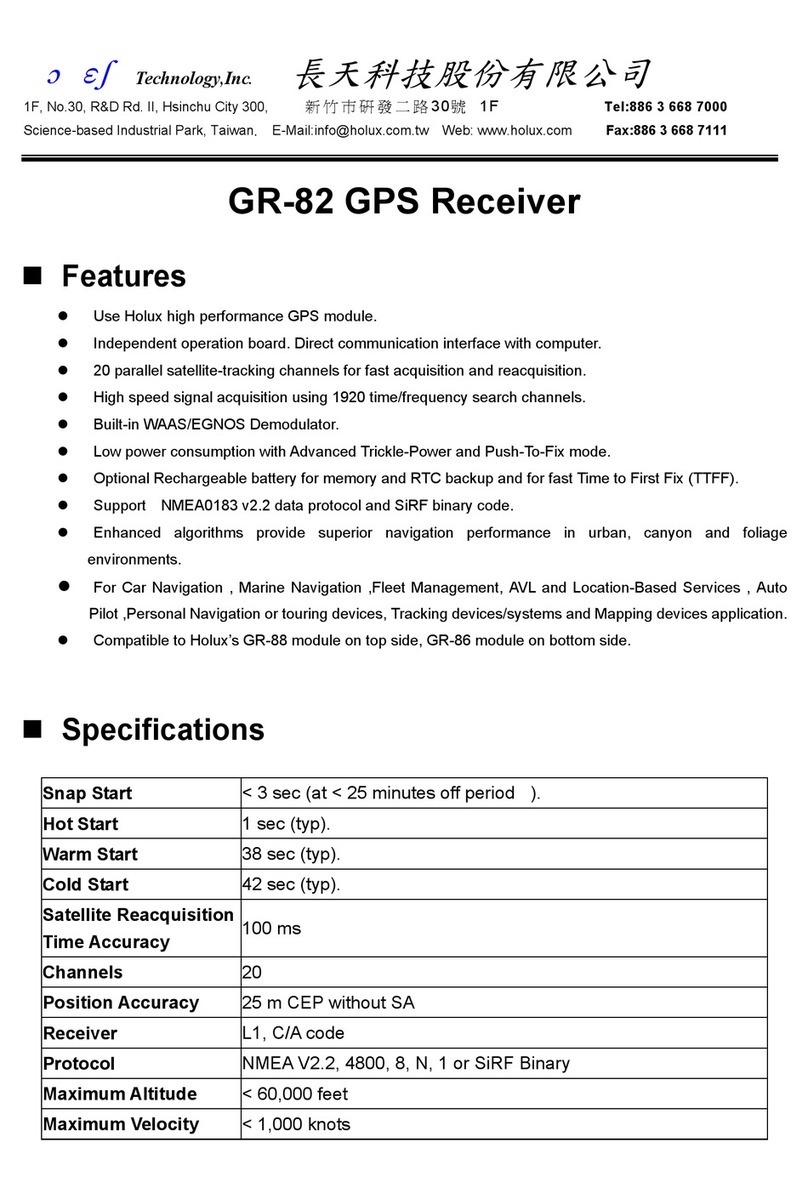

TM470 Platform Overview

5

Overview

The purpose of this document is to provide the installer with instructions on how to install the TM470 platform in its various configurations. The

installation of the system into the vehicle correctly is important for the continued reliability of the system as well as the customers satisfaction.

Correctly following the installation guidelines provided and proper testing of the system and all its features are imperative.

TM470 configurations

TM470V6

Designed for installation in any on-road vehicle.

Provides configurable inputs/outputs i.e. PTO capture, starter kill.

TM470V8

Identical to V6 but adds vehicle diagnostics capability.

Will have different configuration of external components for VD capture depending on platform being installed.

6-Pin heavy duty truck

9-pin heavy duty truck

2013+ Mack

2013+ Volvo

OBDII

TM470V8 HOS

This configuration adds Hours of Service components required for DOT compliance.

FIL Light

Driver interface screen (Garmin, CTO)

TM470V6

6

TM470V6 Installation Overview

7

Overview

This will provide the installer with instructions on how to install the TM470V6. The install of the TM470V6 is a basic 3 wire configuration with

connections for ignition, power and ground.

TM470V6 Kit Components

•TM470

•Combination wedge antenna

•Hardware installation kit

•Fuses

•Fuse holders

•Zip-ties

•Butt connectors

•Ground ring terminal and required screw

•Power harness cable

•Harness is specific to the TM470V6

•Provides power connections as well as inputs and outputs as required for customer installation

Pre-Installation Vehicle Inspection

8

A complete inspection of the vehicle and its major components that could be effected by the installation on the GPS system should be

inspected and documented. This should be done for the benefit of the customer as well as the installer. Failure to complete and document a

vehicle inspection opens the installer up to damage claims that may not be related to the installation they have performed.

Recommended inspection points should include but are not limited to –

•Headlamps

•Turn signals

•Radio

•Dome light

•HVAC system

•Windshield wipers

•Dash warning lights (ABS, Check engine, Tire monitor, etc.)

•Vehicle interior (Headliner, seats, dash, etc.)

•Vehicle exterior (Obvious dents, scratches, and other damage)

•Start the vehicle

•The ability for the vehicle to be safely started and run is a requirement to

complete the installation of the GPS system. If the vehicle cannot be safely started

and run it is recommended the vehicle be rescheduled for installation so customer

can get the current issue preventing it from starting corrected.

If you find any issues with the vehicle during this inspection it is recommended that the installer stop the

installation and contact the designated POC. It is recommended that they agree there is an existing issue with

the vehicle and acknowledge this be signing installers installation paperwork.

TM470V6 component Overview

9

•GPS/GPRS combo antenna

•Installation hardware kit

•TM470 VLU

•V6 Power harness

TM470V6 VLU placement

•All equipment and wiring must be installed in a manner that will conceal its location.

•Installation must be in a dry location with minimal exposure to dust ,moisture ,heat and unnecessary vibration.

•It is always best to mount the unit to a flat surface; it should not be mounted on curves, dips or humps since this can degrade the security of the

unit.

•Mount the unit to the chassis of the vehicle utilizing the mounting tabs. Always secure the unit with screws or zip-ties.

•Always check behind the place where any screws will penetrate to make sure you are not going to drill into a fuel or brake line, wiring harness,

etc.

•Be careful when mounting touching an existing factory harness because vibration may cause an electrical short. Great care must be taken to

prevent chaffing.

•Mount the unit so it will not cause any physical interference with the normal operation of movable equipment in the vehicle such as seats,

pedals, hinges, air conditioning vents, etc.

•Never mount any component to vehicle air lines. Damage to the air lines will cause a catastrophic failure disabling the use of the vehicle.

10

TM470V6 VLU Placement Unapproved Locations

Unapproved mounting locations:

•In a Truck bed

•In the Engine Compartment

•Exterior of the vehicle

•Any place with extreme heat such as exhaust systems or heater cores

•Away from any sources of RFI such as the vehicle computer and alarm

•Near the AM/FM radio or its antenna path

•Near a CB radio or its antenna path

11

Power Connections

12

Identifying correct wires

•Remove any interior trim as necessary to gain access to the vehicles wiring as well as any areas where interconnecting wire harnesses

may be located.

•Attach fuse holders to the Constant and Ignition wires of the TM470 power harness.

•It is always recommended the installer locate the constant and ignition wires at the ignition switch. (This is not a given acceptable

location for connection. There may be extreme difficulties accessing the ignition switch wires, the wires may be low amperage control

wires not acceptable to power the TM470. In these cases the installers experience and knowledge will allow connections in other

appropriate locations.)

•Always use a multimeter in identifying the appropriate wires following the guidelines on the next page.

•All connections must be either soldered (preferred) or poke and wrapped. Scotch-Loc, or T-Tap connections may not be used, if they are

discovered during a QC inspection they will be corrected and installer will be billed for repairs.

•Use of supplied provided fuse holders is mandatory, their placement should be as close to the connection point in the vehicle as possible. These

fuses are provided to protect the vehicle not the TM470.

Power Connections continued

Constant power connection

•The correct wire will have power regardless of key position. This connection should have power even if the key is removed from the ignition.

The red wire from the TM470 will be connected here.

Ignition power connection

•The correct wire will have power when the key is in the on/run position and also while the engine is cranking. It will not have power with the

key off or removed. The pink wire from the TM470 will be connected here.

Caution must be taken if the vehicle has a main battery disconnect switch, if equipped the constant (red wire) connection should be made on the

battery side (hot at all times) unless the customer has advised they don’t want this.

13

Poke & Wrap power connection method

The recommended method of connecting the wires is by

soldering. As an alternative the connection can be made using

the Poke & Wrap method. This is only appropriate when the

connection is made inside the cab or an area that is completely

weatherproof.

Strip –Using wire strippers remove approximately ¾” of

insulation from the source wire. Also strip approximately 1”of

insulation from the fused TM470 wire.

Divide –Using a tool with a point divide the source wires down

the middle.

Poke –Insert the fused wires stripped portion through the

middle.

Twist –Twist the fused wire around the source wire, 4-6 times

is recommended.

Lock –Now bend the fused wire back onto the wrapped

section. This helps ton act as a lock for this connection.

Secure –Apply high quality electrical tape to isolate your

connection. You should also add a zip-tie over the connection

to act as a tamper seal and makes sure the connection stays

for the life of the installation.

14

Strip

Divide

Poke

Twist

Lock

Secure

Ground Connection

Locate a strong spot in the metal near the transceiver to connect the ground lead. A good mechanical connection of the ground lead is vital,

since a bad connection may cause the transceiver to locate poorly and behave erratically. Scrape away any paint or coating on the metal

where the ground will be attached, and then use a star washer between the metal and the ground terminal.

Vehicles with aluminium and fibreglass bodies require special handling. Oxidation and electrolysis create problems with aluminium bodies,

and fibreglass does not conduct current. In these cases, run the lead to the battery and connect it to the negative side.

We recommend not using the existing factory wires attached to ground; this could cause interference or noise. It is noted that the TM470

performance will be seriously degraded.

15

Antenna Mounting

•Antenna should be placed as high as possible in the dash with a clear view out the windshield with no metallic obstructions.

•Antenna must be secured in place to assure it does not move and degrade signal.

•Test the antenna prior to putting everything back together because some dashboards are made with carbon composites that will deteriorate

the signal strength.

16

The TM470 antenna is a dual antenna. The GPS antenna module and the GPRS Quad Band antenna are fitted inside the single wedge type

enclosure.

Antenna can be mounted either covertly or exposed. While the covert installation is recommended always verify with the POC this is what the

want.

Input/output Connections

Wire Color

Function

Description

Orange

Input

Positive

Positive input connection. Used for PTO, Seat belt, etc..

Grey

Input Negative

Negative input connection. Used for PTO, Seat belt, etc..

Blue

Output 1

Output driver for relay. Use would be starter kill.

Yellow

Output

2

Output driver for relay.

PRESENTATION NOTE, IF NECESSARY17

The TM470V6 has 2 inputs and 2 outputs for connection to the vehicle. Connections are only made if required in your work order. Installer

should make connection using the input wire best associated with the function they are adding.

If you are making a positive PTO connection the Orange wire would be utilized, a negative would use the Grey wire.

The Blue output is designed as a negative input to drive an external relay. This wire should never be connected directly to anything other then a

relay.

TM470V8

18

TM470V8 installation Overview

19

Overview

This will provide the installer with instructions on how to install the TM470V8. The install of the TM470V8 is a basic 3 wire configuration with

connections for ignition, power and ground. This unit also adds Vehicle diagnostics capture.

TM470V8 Kit Components

•TM470

•Combination wedge antenna

•Hardware installation kit

•Fuses

•Fuse holders

•Zip-ties

•Butt connectors

•Ground ring terminal and required screw

•Power harness cable

•Harness is specific to the vehicle type being installed.

•A JBus harness captures constant power and ground through the 6 or 9 pin harness.

•OBDII will utilize a 3-pin harness that allows the installer to get constant and ground connections separate from the OBDII

connector. *It is important to note the TM470 can get constant power and ground through the connector similar to the

JBus harness but this should never be used.

•Provides power connections as well as inputs and outputs as required for customer installation

•Vehicle diagnostic components (Only one of the available options)

•JBus 6 or 9 pin harness

•OBDII Kit (OBDII box, OBDII Y-cable & OBDII extension Cable)

•2013+ Volvo 1939 interface harness

•2013+ Mack interface harness

Pre-Installation Vehicle Inspection

20

A complete inspection of the vehicle and its major components that could be effected by the installation on the GPS system should be

inspected and documented. This should be done for the benefit of the customer as well as the installer. Failure to complete and document a

vehicle inspection opens the installer up to damage claims that may not be related to the installation they have performed.

Recommended inspection points should include but are not limited to –

•Headlamps

•Turn signals

•Radio

•Dome light

•HVAC system

•Windshield wipers

•Dash warning lights (ABS, Check engine, Tire monitor, etc.)

•Vehicle interior (Headliner, seats, dash, etc.)

•Vehicle exterior (Obvious dents, scratches, and other damage)

•Start the vehicle

•The ability for the vehicle to be safely started and run is a requirement to

complete the installation of the GPS system. If the vehicle cannot be safely started

and run it is recommended the vehicle be rescheduled for installation so customer

can get the current issue preventing it from starting corrected.

If you find any issues with the vehicle during this inspection it is recommended that the installer stop the

installation and contact the designated POC. It is recommended that they agree there is an existing issue with

the vehicle and acknowledge this be signing installers installation paperwork.

This manual suits for next models

3

Table of contents

Other TELETRAC NAVMAN GPS manuals

TELETRAC NAVMAN

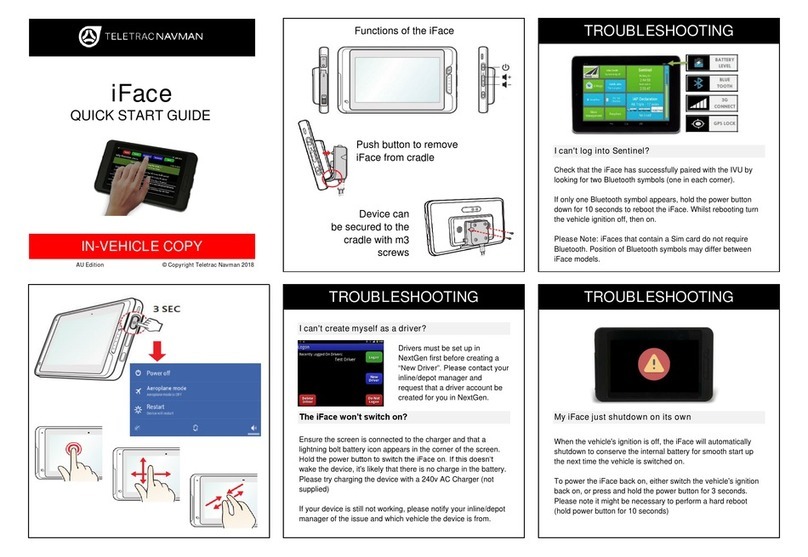

TELETRAC NAVMAN iFace User manual

TELETRAC NAVMAN

TELETRAC NAVMAN Qtanium 400 User manual

TELETRAC NAVMAN

TELETRAC NAVMAN Qube300 Installation guide

TELETRAC NAVMAN

TELETRAC NAVMAN Qtanium200 User manual

TELETRAC NAVMAN

TELETRAC NAVMAN Qtanium 100 User manual

TELETRAC NAVMAN

TELETRAC NAVMAN iFace User manual

TELETRAC NAVMAN

TELETRAC NAVMAN Qtanium 100 User manual