Telstar MINI-V/PCR User manual

USER'SMANUAL

VerticalFlowBenches

MINI-V/PCR

™"

?«B UM

MINI-VI rev0507US

Teistar

Industrial,

S.L.

JosepTapiolas,

120

08226TERRASSA(Spain)

Tel.

+349373616

00

Fax:

+34937859342

www.etelstar.com

MINI-V_I_rev0507USPage2

INDEX

1.

DESCRIPTIONOFPRODUCT

2.

GENERALDETAILS

2.1.

2.2.

2.3.

2.4.

2.5.

WorkingPrinciple

Applicationsandworkingdiagram.

Descriptionofcomponents

Certification

TechnicalFeatures

3.TRANSPORT

4.

INSTALLATIONINSTRUCTIONS

4.1.

4.2.

4.3.

4.4.

4.5.

4.6.

4.7.

Placement

Firstconnectionprecautions

Electricsupplyconnection.

Start-up

Switchingoff

Longstop.

U.V.sterilizationstart-up.

5.USER'SINSTRUCTIONS

6.

5.1.

5.2.

5.3.

5.4.

6.1.

6.2.

6.3.

6.4.

6.5.

Generalrecommendations

CONTROLPANELANDALARMS

Standardaccessories

Optionalaccessories

MAINTENANCE

Maintenancetable

Periodiccontrolandcertification

Pre-filter

Absolutefilters.

Spares

7.TROUBLESHOOTING

8.CLEANINGANDDISINFECTION

8.1.

Surfacecleaninganddisinfection

8.2.Maintenancechart

9.GUARANTEECERTIFICATE.

10.

CECERTIFICATION

5

5

6

6

6

6

6

.6

.7

7

8

9

.9

11

11

11

11

.11

12

12

12

12

13

14

15

MIIMI-V_I_revO5O7USPage

3

1.

DESCRIPTION

OF

PRODUCT

InstructionsManual

for

VerticalLaminarFlowCabinetensuringhighsampleprotection.

Model:

MINI-V/PCR

WARNING

It

is

essential

to

read

and

understandthisManualbeforegoingaheadwithVerticalLaminarFlow

Cabinetstart-up.

All

the

instructions

in

thisManualmust

be

obeyed.

Beforecarrying

outany

Maintenancework

onthe

cabinet,switch

itoff

from

the

source

of

supply.

Any

useor

application

notin

keepingwith

the

recommendationsgiven

in

thisManual

may

createrisk

and

meanloss

of

right

to

manufacturer'sguaranteeexempting

the

latterfrom

all

liability.

MANUFACTURER:

TELSTARINDUSTRIAL,

S.L

JosepTapiolas,

120

E-08226

-

TERRASSA

Telf.

+34-93-736-16-00

Fax.+34-93-785-93-42

Web:

www.etelstar.com

E-mail:[email protected]m

2.

GENERAL DETAILS

2.1. WORKING PRINCIPLE

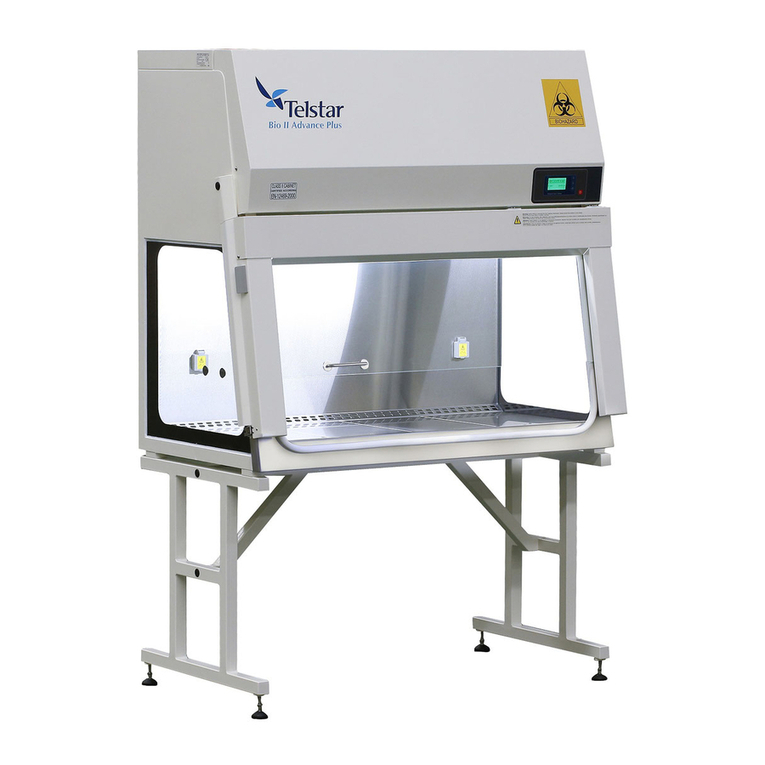

MINI-V/PCRverticallaminarflowcabinets

are

equippedwith

a

highfrequencycentrifugal

fan.

Theoutsidecabinet

is

made

of

stainlesssteelsheet,lacquered

and

ovendried,

of

functional

design

and

optimumdimensions.

Outside

air

taken

in(1)

passesthrough

a

pre-filter

(2),is

sucked

bya fan(3),

impelled

towards

a

plenum,passedthrough

a

HEPAabsolutefilterand,

as

laminarflowenters

the

workarea,reachesClass

100

according

tous

Fed.

Std.209D;

then

itis

forced

outbyit's

highpressure

(7)

Fig.l.

2.2. APPLICATIONS

AND

WORKING DIAGRAM

Thisverticallaminarflowcabinet

is

suitable

for

dealingwithsamples

or

productswhich

involve

the

need

for

sterile

air

conditionsaccording

to

Class

100inthe

workarea,

but

where

neitheroperator

nor

environmentalprotection

is

necessary.

For

principle

see

Diagram

in

Fig.l.

MINI-V_I_rev0507USPage4

WARNING

Under

no

circumstances

canit

work

in

environmentscontainingcorrosive,inflammable

or

explosive

gas.

Under

no

circumstances

can

it

workwithproducts

or

samples,which

are

biologicallypathogenic

orliable

to

affect

the

operator

or

environment

in

anyway

whatsoever.

Under

no

circumstances

can

it

workwithcytostatics(chemotherapy)

or

radiologicsamples.

Fig.

1

Cabinetcomponents.

2.3. DESCRIPTION

OF

COMPONENTS

Fig.

1.

1

Outside

air

inlet.

5

HEPAabsolutefilter.

MINI-V_I_revO5O7USPage

5

2

3

4

Blanketpre-filter.

Centrifugalfan.

Chamberorplenum.

6

7

Workingarea.

Airoutlet.

2.4.

CERTIFICATION

Qualitycontrolandcertificationwithresultsoftestsperformedaccordingtonorms.

Individualcertificateinsideeachcabinet.

2.5. TECHNICAL FEATURES

PREFILTER

FILTER

FAN

LIGHTING

NOISELEVEL

AIRFLOW/SPEED

OUTSIDEDIMENSIONS

(lengthx widthx height)

INSIDEDIMENSIONS

(lengthx widthx height)

POWER/WEIGHT

SUPPLY

G380-85%ASHRAESyntethicfibrefilteringbanket

D.O.P.

>

99,999%EfficiencyHEPAfilters

for

CLASS

100

H-14

Highefficiencycentrifugal

or

doublesuction

fan.

>550

lux

<

56dBa

400

m3/h- 0,40m/s

670

x 520x 1125mm.

630

x 500x 570mm.

0,4

kW- 70Kg

Seethechnicalplate

on

cabinetfront.

3-TRANSPORT

Eachcabinetispackedindividuallyandsuitablyprotectedagainstdamageduringtransport.

ThisManualandindividualcontrolcertificateforeachindividualcabinetissuppliedaspartof

theconsignment.

4.INSTALLATION INSTRUCTIONS

Toensurecorrectverticallaminarflowcabinetstart-up,thefollowinginstructionsshouldbe

followedstepbystep.

4.1.

PLACEMENT

Specialcaremust

be

takenwhenunpacking

the

microprocessorscreen.

Place

inan

areaawayfromdoors,windows

andair

currentsfrom

air

conditioners

and

where

there

is

littlemovementcaused

by

people,

to

avoiddraughts.

Thecabinetmust

be

perfectlysteady

onits

table

or

bench

to

preventvibration.

Topreventoverheating

the

workarea,

itis

advisable

to

keeproomtemperaturewithin

the

limits

of

workcomfort.

feTElSTAR

MINI-V_I_rev0507USPage6

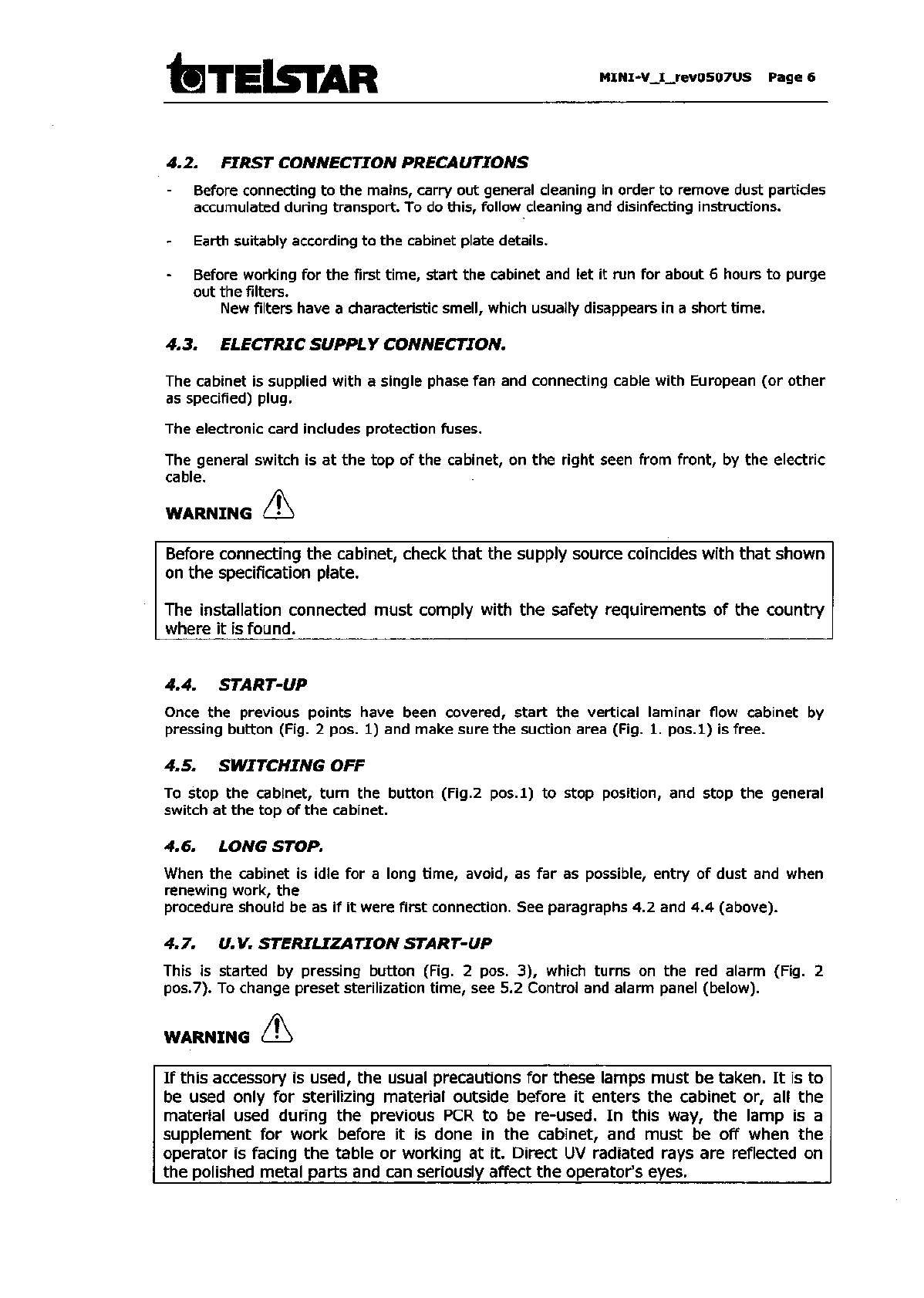

4.2. FIRST CONNECTION PRECAUTIONS

Beforeconnecting

tothe

mains,carry

out

generalcleaning

in

order

to

removedustparticles

accumulatedduringtransport.

Todo

this,followcleaning

and

disinfectinginstructions.

Earthsuitablyaccording

tothe

cabinetplatedetails.

Beforeworking

forthe

firsttime,start

the

cabinet

andletitrunfor

about

6

hours

to

purge

out

the

filters.

Newfiltershave

a

characteristicsmell,whichusuallydisappears

ina

shorttime.

4.3. ELECTRIC SUPPLY CONNECTION.

Thecabinet

is

suppliedwith

a

singlephase

fanand

connectingcablewithEuropean

(or

other

asspecified)

plug.

Theelectroniccardincludesprotectionfuses.

Thegeneralswitch

isatthetopofthe

cabinet,

onthe

rightseenfromfront,

bythe

electric

cable.

WARNING

Beforeconnecting

the

cabinet,checkthat

the

supplysourcecoincideswiththatshown

on

the

specificationplate.

Theinstallationconnectedmustcomplywith

the

safetyrequirements

of

the

country

where

itis

found.

4.4. START-UP

Once

the

previouspointshavebeencovered,start

the

verticallaminarflowcabinet

by

pressingbutton

(Fig.2 pos.1)and

makesure

the

suctionarea

(Fig.1.

pos.l)

is

free.

4.5. SWITCHING

OFF

Tostop

the

cabinet,turn

the

button(Fig.2pos.l)

to

stopposition,

and

stop

the

general

switch

atthetopofthe

cabinet.

4.6. LONG STOP.

When

the

cabinet

is

idle

fora

longtime,avoid,

asfaras

possible,entry

of

dust

and

when

renewingwork,

the

procedureshould

beasifit

werefirstconnection.

See

paragraphs

4.2and4.4

(above).

4.7.

U.V.

STERILIZA TION START-UP

This

is

started

by

pressingbutton

(Fig.2 pos.3),

whichturns

onthered

alarm

(Fig.2

pos.7).

To

changepresetsterilizationtime,

see5.2

Control

and

alarmpanel(below).

WARNING

Ifthisaccessory

is

used,

the

usualprecautions

for

theselampsmust

be

taken.

Itisto

beusedonly

for

sterilizingmaterialoutsidebefore

it

enters

the

cabinet

or,allthe

materialusedduring

the

previous

PCR

tobe

re-used.

In

this

way,

the

lamp

isa

supplement

for

workbefore

itis

done

inthe

cabinet,

and

must

beoff

when

the

operator

is

facing

the

table

or

working

atit.

Direct

UV

radiatedrays

are

reflected

on

thepolishedmetalparts

andcan

seriouslyaffect

the

operator'seyes.

MINI-V_I_rev0507USPage

7

5.USER'SINSTRUCTIONS

5.1. GENERAL RECOMMENDATIONS

Theworkarea

ofthe

cabinetshould

notbe

used

asfor

storinglaboratoryequipment.This

couldproduce

an

accumulation

of

dustwhich

is

bothunnecessary

and

dangerous

for

working

in

sterileconditions.

Even

ifthe

workarea

is

undercleansterilelaminarflow,thatsurrounding

the

cabinet

can

becontaminated.

The

sources

of

contaminationshould

be

known

so

thatthey

canbe

avoidedwheninsertingarms,material

etc.

All

the

materialnecessary

for

workmust

be

free

of

particles

and

cleanedbefore

it

enters.

Materialslike:paper,wood,cardboard,pencils,erasingrubbers,

etc.,

should

notbe

inserted

asthey

all

shedlargeamounts

of

particles.

Bothbefore

and

afterwork,

itis

advisable

to

washarms,hands

and

fingernailswith

germicidesoap.Personnelshouldavoidtouchingtheirmouths

and

eyes.

Longsleevedwhitecoats

are

advisedwithtightcuffs,

and,for

specialwork,protecting

gloves,

(or

alternatively,over-sleeves).Both

the

whitecoats

andthe

over-sleevesmust

be

made

of

materialsleastlikely

to

shedfibre

and

particles.

Thecabinetshould

be

started

10

minutesbeforeworkbegins.Thissweeps

the

workarea

andmaterialinserted

of

particles.

Ifpipettes

are

used,theyshould

be

mechanicsuctiontype;suction

by

mouthmustnever

beused

asitis

easy

to

inhaleaerosols

so

caused.

Whenplatinumhandlesmust

be

used,electricincinerators

or,

better

still,

disposablesingle-

usehandles

are

advised.

If

the

nature

ofthe

work

tobe

doneinvolvesusing

a gas

flamefrom

a

Bunsen

(or

similar)

burner,

the

buttonopeningconstantpressuretype

is

advised.

It

must

be

pointed

out

that

a

constantflameburnercreates

a

considerableamount

of

turbulence.Rememberthat

too

large

a

flame

can

burn

the

absolutefilters.

Shadows

and

turbulenceproduced

by

objects,equipment

and

material

inthe

workarea,

must

be

takenintoaccountbeforeworkbegins

to

assesstheirpossibleeffect.

It

should

be

rememberedthat

air

flowlaminarity

is

onlyrecovered

ata

distance

ofupof2.5

times

the

diameter

ofthe

objectcausing

the

obstruction.

Ifflasks

or

tubes

are

used,theseshould,preferably,

be

screw

cap

ratherthancotton

stopped,

asthe

lattershedslargeamounts

of

particles.

Assoon

asthe

workfinishes,

allthe

disposableproducts,such

as:

handles,Petriplates,

etc.,

as

well

as

means

of

culture,samples,tubes,flasks

andthe

like,

aretobe

taken

outof

thecabinet

and

emptiedintoimpermeablebags,which

canbe

sterilized

if

necessary.

Duringwork

inthe

cabinet

and

cleaning,caremust

be

taken

notto

damage

the

HEPAfilters

byknocking,squirtingliquid

ator

splashing

it.

IDTEISTARMINI-V_I_rev0507USPage8

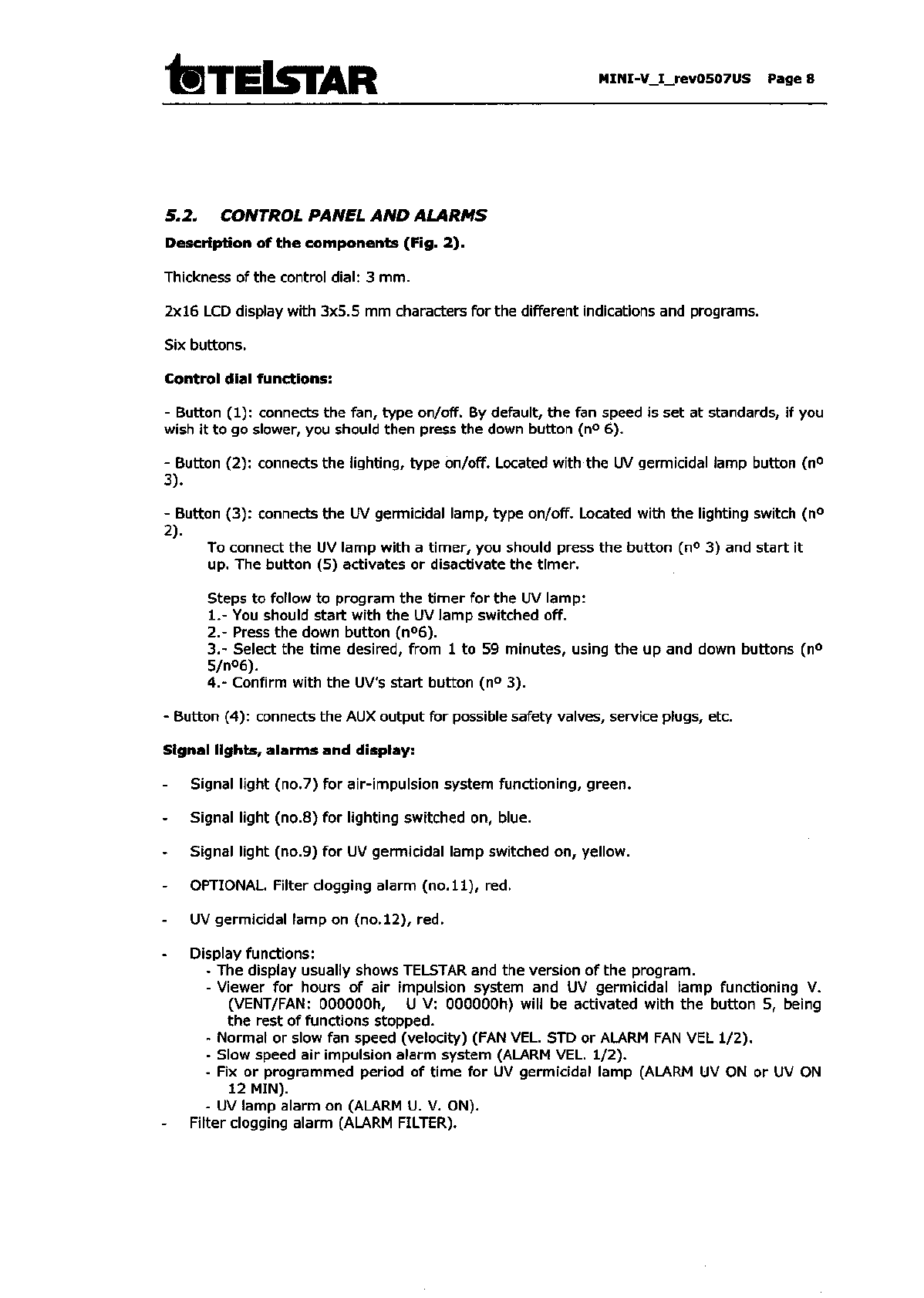

5.2. CONTROL PANEL AND ALARMS

Descriptionofthecomponents(Fig.2).

Thicknessofthecontrol

dial:

3 mm.

2x16LCDdisplaywith3x5.5mmcharactersforthedifferentindicationsandprograms.

Sixbuttons.

Controldialfunctions:

-Button(1):connectsthefan,typeon/off.Bydefault,thefanspeedissetatstandards,ifyou

wishittogoslower,youshouldthenpressthedownbutton(n°6).

-Button(2):connectsthelighting,typeon/off.LocatedwiththeUVgermicidallampbutton(n°

3).

-Button(3):connectstheUVgermicidallamp,typeon/off.Locatedwiththelightingswitch(n°

2).

ToconnecttheUVlampwitha timer,youshouldpressthebutton(n°3)andstartit

up.

Thebutton(5)activatesordisactivatethetimer.

StepstofollowtoprogramthetimerfortheUVlamp:

1.-

YoushouldstartwiththeUVlampswitchedoff.

2.-

Pressthedownbutton(n°6).

3.-Selectthetimedesired,from1 to59minutes,usingtheupanddownbuttons(n°

5/n°6).

4.-

ConfirmwiththeUV'sstartbutton(n°3).

-Button(4):connectstheAUXoutputforpossiblesafetyvalves,serviceplugs,etc.

Signallights,alarmsanddisplay:

Signallight(no.7)forair-impulsionsystemfunctioning,green.

Signallight(no.8)forlightingswitchedon,blue.

Signallight(no.9)forUVgermicidallampswitchedon,yellow.

OPTIONAL.Filtercloggingalarm(no.11),red.

UVgermicidallampon(no.12),red.

Displayfunctions:

-ThedisplayusuallyshowsTELSTARandtheversionoftheprogram.

-ViewerforhoursofairimpulsionsystemandUVgermicidallampfunctioningV.

(VENT/FAN:

OOOOOOh,U V:OOOOOOh)willbeactivatedwiththebutton5,being

therestoffunctionsstopped.

-Normalorslowfanspeed(velocity)(FANVELSTDorALARMFANVEL1/2).

-Slowspeedairimpulsionalarmsystem(ALARMVEL.1/2).

-FixorprogrammedperiodoftimeforUVgermicidallamp(ALARMUVONorUVON

12MIN).

-UVlampalarmon(ALARMU.V.ON).

-Filtercloggingalarm(ALARMFILTER).

MIIMI-V_I_rev0507USPage

9

Fig.

2

5.3.STANDARDACCESSORIES

Thefollowingaccessories

are

installed

in

verticallaminarflowcabinets:

-

3A- 600W.

electricplug.

-

U.V.

germicidelamp

kit.

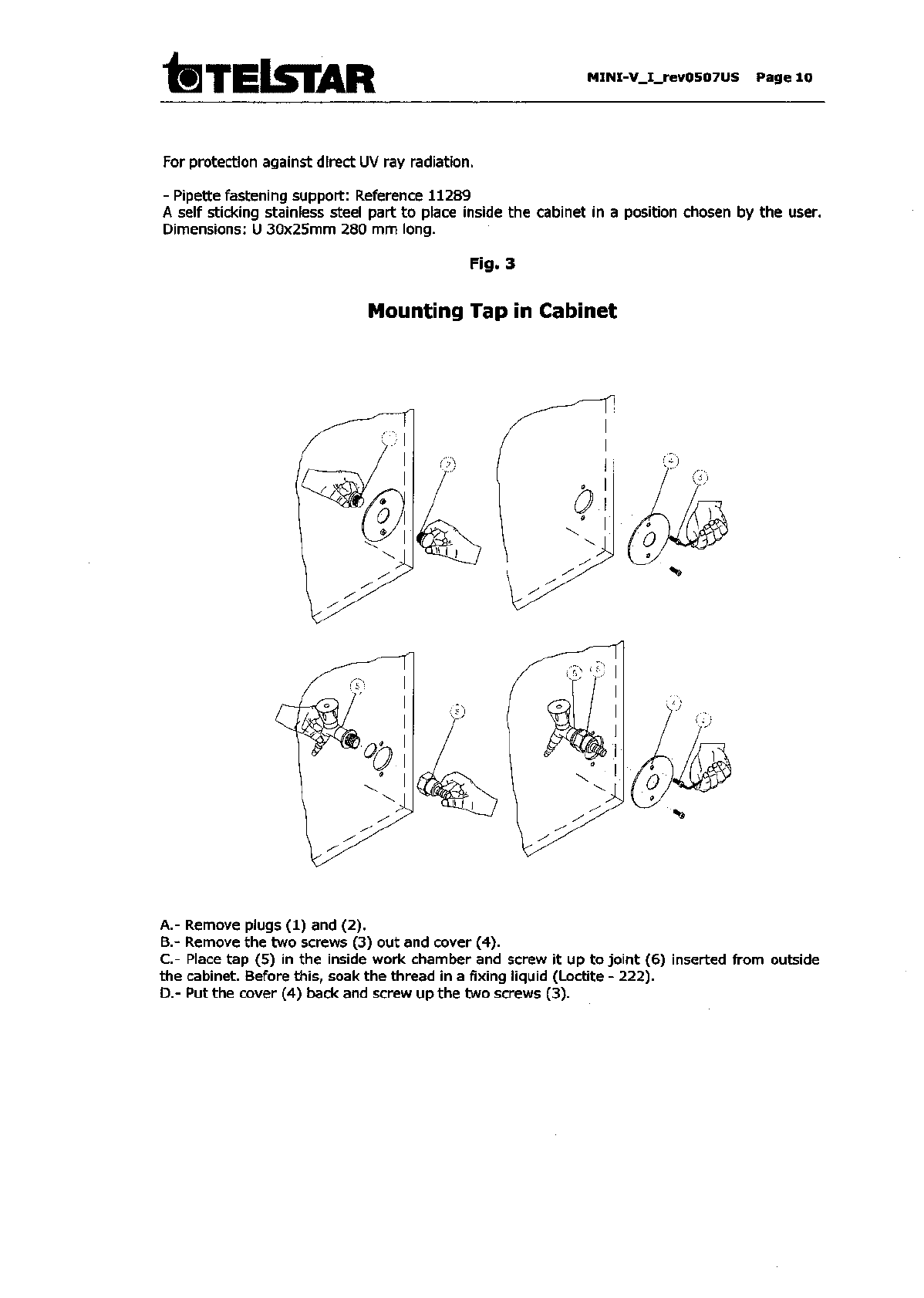

5.4. OPTIONAL ACCESSORIES

-

Gas

cock/tap(Fig.3).Reference:

11253

-Vacuumcock/tap.(Fig.3).Reference:11220

-

Compressed

air

cock/tap(Fig.3).Reference

11254

WARNING

'

Ifcompressed

airor

nitrogen

are

used,careshould

be

taken

to

install

an

absolutefilter

inthe

pipeline

to

preventparticlesgettinginto

the

workarea.

Thecabinet

is

prepared

forthe

user

to

install

a

verysimple

tap(see

instructions

inFig.3).If

morethan

one

sourceconnection

is

needed,

itcanbe

requestedwith

the

order

asitcan

only

be

made

inthe

factory.

-

(U-15)D.O.P.99.999%efficiencyHEPAfilter

for

class

10

installed,withparticlecount

certificate.

-

PolycarbonateDoors.

MINI-V_I_rev0507USPage10

ForprotectionagainstdirectUVrayradiation.

-Pipettefasteningsupport:Reference11289

Aselfstickingstainlesssteelpart

to

placeinside

the

cabinet

ina

positionchosen

bythe

user.

Dimensions:U 30x25mm280mm

long.

Fig.

3

MountingTap

in

Cabinet

A.-Removeplugs

(1)

and

(2).

B.-Removethetwoscrews

(3)

outandcover(4).

C-Placetap

(5)inthe

insideworkchamberandscrew

itupto

joint

(6)

insertedfromoutside

thecabinet.Beforethis,soakthethread

ina

fixingliquid(Loctite

-

222).

D.-Putthecover(4)backandscrewupthetwoscrews(3).

MINI-V_I_rev0507US

Page11

6.

MAINTENANCE

WARNING

Before

embarkingonanymaintenanceorcabinetdismountingwork,switchcabinetofffrom

source.

As

a general

rule,

technicalspecialistsshouldmakeanannualcheckthatallcabinetcomponents

function

correctly.

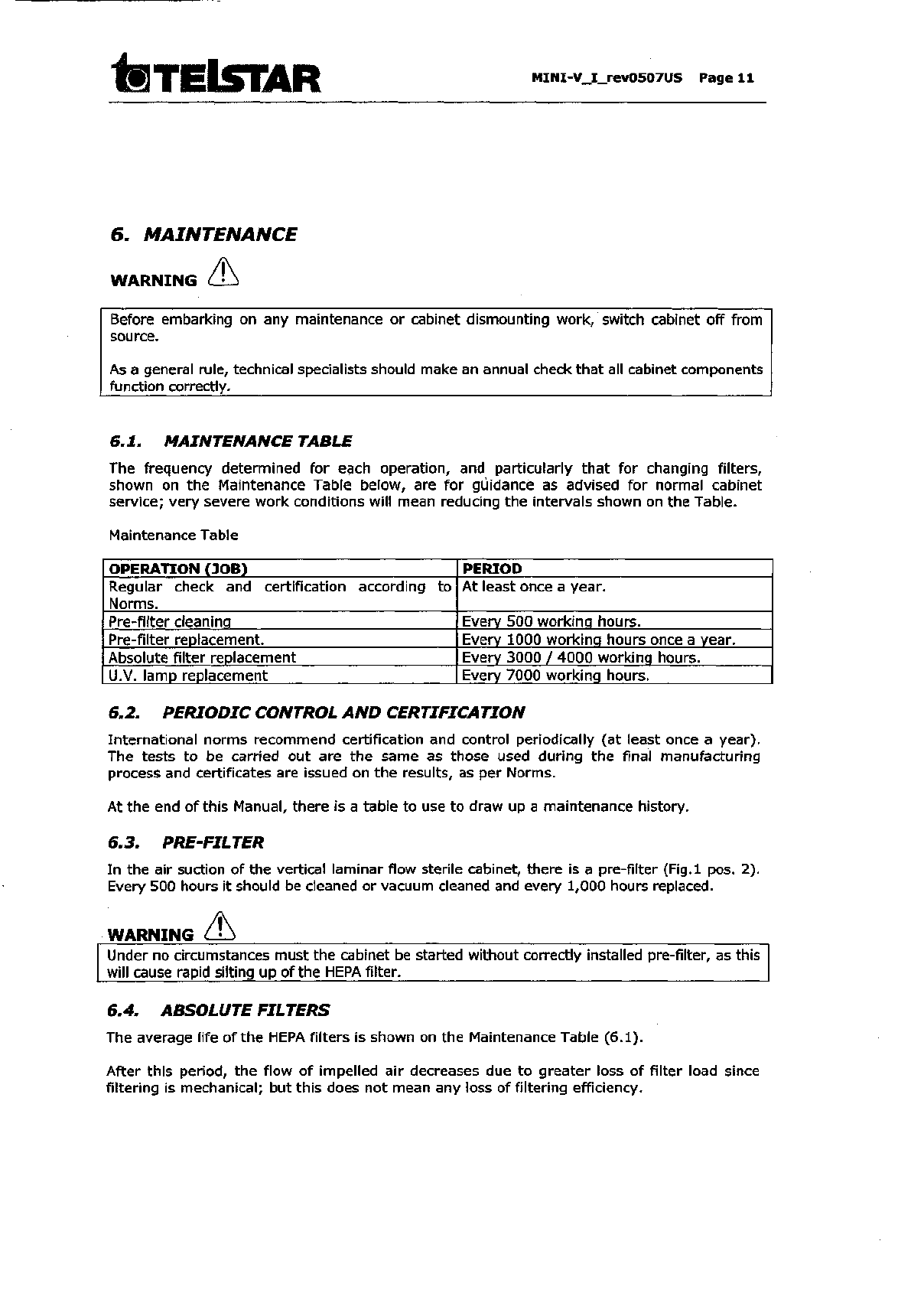

6.1. MAINTENANCETABLE

Thefrequencydeterminedforeachoperation,andparticularlythatforchangingfilters,

shownontheMaintenanceTablebelow,areforguidanceasadvisedfornormalcabinet

service;

verysevereworkconditionswillmeanreducingtheintervalsshownontheTable.

MaintenanceTable

OPERATION(JOB)

Regularcheckandcertificationaccordingto

Norms.

Pre-filtercleaning

Pre-filterreplacement.

Absolutefilterreplacement

U.V.lampreplacement

PERIOD

Atleastoncea year.

Every500workinghours.

Every1000workinghoursoncea year.

Every3000/ 4000workinghours.

Every7000workinghours.

6.2. PERIODIC CONTROL AND CERTIFICATION

Internationalnormsrecommendcertificationandcontrolperiodically(atleastoncea year).

Theteststobecarriedoutarethesameasthoseusedduringthefinalmanufacturing

processandcertificatesareissuedontheresults,asperNorms.

AttheendofthisManual,thereisa tabletousetodrawupa maintenancehistory.

6.3. PRE-FILTER

Intheairsuctionoftheverticallaminarflowsterilecabinet,thereisa pre-filter(Fig.lpos.2).

Every500hoursitshouldbecleanedorvacuumcleanedandevery1,000hoursreplaced.

WARNING

Under

nocircumstancesmustthecabinetbestartedwithoutcorrectlyinstalledpre-filter,asthis

will

causerapidsiltingupoftheHEPAfilter.

6.4. ABSOLUTEFILTERS

The

averagelifeoftheHEPAfiltersisshownontheMaintenanceTable(6.1).

After

this

period,

theflowofimpelledairdecreasesduetogreaterlossoffilterloadsince

filtering

ismechanical;butthisdoesnotmeananylossoffilteringefficiency.

feTElSTAR

MINI-V_I_rev0507USPage12

WARNING

Inorder

to

ensurecorrectfilterinstallation

and

adjustment,

and

alsoabsence

of

leaks,filter

replacementmust

bea

matter

for

specialisttechnicalpersonnelsuppliedwith

the

necessary

controlinstruments:anemometer,leakdetector,aerosolgenerator,particlecounter

etc.

TelstarIndustrial

S.L

representatives

and

distributorshave

a

qualifiedtechnicalteamwith

the

mostup-to-date,healthprotectingcontrolequipment

to

carry

out

periodiccontrolswith

guaranteedsafetyandalsochangefiltersaccording

to

the

Norms.

6.5. SPARES

Ref.

1558

11246

11217

1338

1533

15463

15462

Description

Impelling

fan

and

condenser

HEPA610x457x69mm.

H14

HEPAfilter

ASHRAE

G3

-

80-85%syntheticblanketpre-filter

30Wfluorescentlamp

15Wgermicidelamp

Controlpanel

CPUelectroniccard

7.TROUBLESHOOTING

Problem:

Motorstops.

Possiblecause:Fuseblown.

Solution:

Find

out

cause

of

fusing.Whenthis

has

beensolved,changefuse.

Problem:

Contaminationdetected

in

workarea.

Possiblecause:Absolutefilterperforated;

ithas

comeawayfrom

its

frame;sealingjoint

betweenfilterandcabinetbaseineffective.

Solution:

A

D.O.P.leaktest

is

carried

outbya

specialisttechnician

to

discovercauses

of

contamination

and

absolutefilter

is

replaced

by

him,

if

necessary.

Ifcontaminationcontinuesafter

thenew

absolutefilter

is

installed

and

freshairtightness

(D.O.P)tests

are

carried

out,

the

usershouldstartlookingintocorrectapplication

of

work

procedures,

as

there

maybe

contaminationfrom

an

outsidesource,throughworktools,

hands

or

the

samples.

8.

CLEANING

AND

DISINFECTION

8.1. SURFACE CLEANING AND DISINFECTION

Toclean

the

worktableandsides,sterileclothswill

be

usedwhichshed

no

particles

or

fibres.

Todisinfect,theseclothswill

be

usedslightlydampenedwith

a

disinfectantsolution,whichwill

notaffect

the

paintlacquer

or

thestainlesssteel.

MINI-V_I_rev0507USPage13

Werecommendinsidecleaning

of

the

cabinet

onthe

followingoccasions:

-Beforebeginningwork

in

the

cabinet

-Whenwork

has

finished

-Whenever

a

workprogramme

is

changed

-

If

liquid

has

beenspilt

onthe

worktable

-Beforecarrying

out

a

controltest.

8.2. MAINTENANCE CHART

DATEREMARKS DONE

BY

SIGNATURE

MINI-V_I_rev0507USPage14

9.

GUARANTEE CERTIFICATE

TELSTARINDUSTRIAL,S.L guaranteesthesubstitutionFREEOFCHARGEofallthepieces

sufferingbreakdownintheperiodofONEYEAR,startinginthedateoftheexpeditionofthe

equipment.

Thisequipmenthasundergonesatisfactorilyallthetestsandrevisions.Therefore,any

damagecausedbytransport,wronginstallationorinappropriateuseisexcludedofthis

guarantee.

Thisguaranteedoesnotincludeanyofthefungiblematerialscomprisedintheequipment,

suchasfilters,fluids,filaments,etc.

Theinappropriateuseofthisequipmentprovokestheguaranteetobe

void.

Thisinvolvesthe

exclusionofanyliabilityinconceptofindemnityforeventualdirectorindirectdamagesof

anynature,eithermaterialorpersonal.

Likewise,thisguaranteewillbevoidifpiecesotherthantheonessuppliedbyTELSTAR

INDUSTRIAL,S.L.areusedfortherepairingoftheequipment.

NOTE.

Thisguaranteeisvalidforalltheequipmentunlessotherwise

stated.

Inordertoobtainanyinformationaboutthisguarantee,please

contactwithourQualityAssuranceDepartment.

MINI-V_I_rev0507USPage

15

10.

CE CERTIFICATION

DECLARACION

DE

CONFORMIDAD

DECLARATION

OF

CONFORMITY

Estecertificado

se

emitepara

el

aparatoelectrico/Thiscertificate

is

issued

forthe

electrical

apparatus:

CABINAESTERIL

POR

FLUJOLAMINARVERTICAL

VERTICAL LAMINAR FLOW CLEAN BENCH

MODELO/

MODEL:

MINI-V/PCR

Fabricada

y

sometida

a

Certificacion

por

TELSTARINDUSTRIAL,

S.L./

Manufactured

and

submitted

for

Certification

by

TELSTARINDUSTRIAL,

S. L.

91/368/EEC

y

93/68/EECDirectivasSeguridad

en

Maquinas/Machinery Safety

Directives.

Normativarespecto

a la

cual

se

declaraconformidad/Standard(s)

to

which conformity

is

declared:

EN

292-1,

EN

292-2,

EN294,EN

418,

EN348

73/23/EECDirectivaSeguridadElectrica/Electrical Safety Directive.

Normativarespecto

a la

cual

se

declaraconformidad/Standard(s)

to

which conformity

is

declared:

EN

61010-1(Requisitos

de

seguridad

de

equiposelectricos

de

medida,control

y

uso

en

laboratorio/Safety requirements

for

electrical equipment

for

measurement, control

and laboratory use).

89/336/EECDirectivaCompatibilidadElectromagnetica/Electromagnetic Compatibility

Directive.

Normativarespecto

a la

cual

se

declaraconformidad/Standard(s)

to

which conformity

is

declared:

EN50081, EN 50082-2 (61000-4-2/3/4/5/6/11),EN 55011 ,55022B,EN

61000-3-2/3, 60555

YNormas

de

Construccion/M/idManufacturing Standards:

U.S.Fed.Std.209,

B.S.

5295

El

anode

marcajeCE

fueen

2000/The CEmarking was affixed

in

2000.

Por

la

presente,TELSTARINDUSTRIALdeclara

queel

equipoarribaespecificadocumple

con

las

Directivas

y

Normativasarribamencionadas,siempre

y

cuando

la

instalacion

sea

acorde

a las

especificaciones

del

fabricante.

TELSTAR INDUSTRIAL hereby declares that

the

equipment specified above conforms

to

the above Directives

and

Standards, when installed

in

accordance with

the

manufacturers

specifications.

MerceGuilera

QualityAssurance

Terrassa

May

2007

MINI-V_E_rev0507USPag.2

INDICE

1.DESCRIPCIONDELPRODUCTO

2.

DATOSGENERALES3

2.1.

PrincipioFuncionamiento3

2.2.

Aplicacionesy esquemadefuncionamiento3

2.3.

Descripciondeloscomponentes4

2.4.

Certificacion.5

2.5.Caracterfsticastecnicas5

3.TRANSPORTE5

4.

INSTRUCCIONESDEINSTALACION6

4.1.

Emplazamiento6

4.2.

Precaucionesenlaprimeraconexion6

4.3.

Conexionelectricay deservicios6

4.4.

Puestaenmarcha• 6

4.5.

Desconexion7

4.6.

Paroprolongado7

4.7.

PuestaenmarchaesterilizacionU.V.7

5.INSTRUCCIONESDEUSO7

5.1.

Recomendacionesgenerales7

5.2.Caratulademandos8

5.3.Accesoriosstandard9

5.4.Accesoriosopcionales9

6.MANTENIMIENTO11

6.1.

Tablademantenimiento11

6.2.Controly certificacionperiodicos11

6.3.PrefiItro11

6.4.Filtrosabsolutos12

6.5.Recambios12

7.ANOMALIASDEFUNCIONAMIENTO12

8.LIMPIEZAY DESINFECCION13

8.1.

Limpiezay desinfeccionsuperficial13

9.HISTORICODEMANTENIMIENTO14

10.

CERTIFICADODEGARANTIA15

11.

CERTIFICADOCE16

Table of contents

Languages:

Other Telstar Laboratory Equipment manuals

Popular Laboratory Equipment manuals by other brands

Woson

Woson TANCO Operation manual

Velp Scientifica

Velp Scientifica AREX 5 instruction manual

Forma Scientific

Forma Scientific 1184 manual

Selecta

Selecta PRECISTERM 2L instruction manual

Endress+Hauser

Endress+Hauser Analytik Jena Biometra TSC ThermoShaker manual

Gema

Gema OptiFlow IG07 Operating instructions and spare parts list