IM-LYOQUEST-EN-2101 3 / 58

TABLE OF CONTENTS

1. SYMBOLS, ABBREVIATIONS AND STICKERS .................................................... 5

2. GENERAL DATA ................................................................................................

2.1. Aim of this manual ........................................................................................ 6

2.2. Application ................................................................................................... 6

3. DESCRIPTION OF THE FREEZE DRYER .............................................................. 7

3.1. Technical features ......................................................................................... 7

4. INSTALLATION INSTRUCTIONS ....................................................................... 8

4.1. Transport and unpacking................................................................................ 8

4.2. Placing on site .............................................................................................. 8

4.3. Electrical connection ...................................................................................... 9

5. BEFORE START-UP ......................................................................................... 10

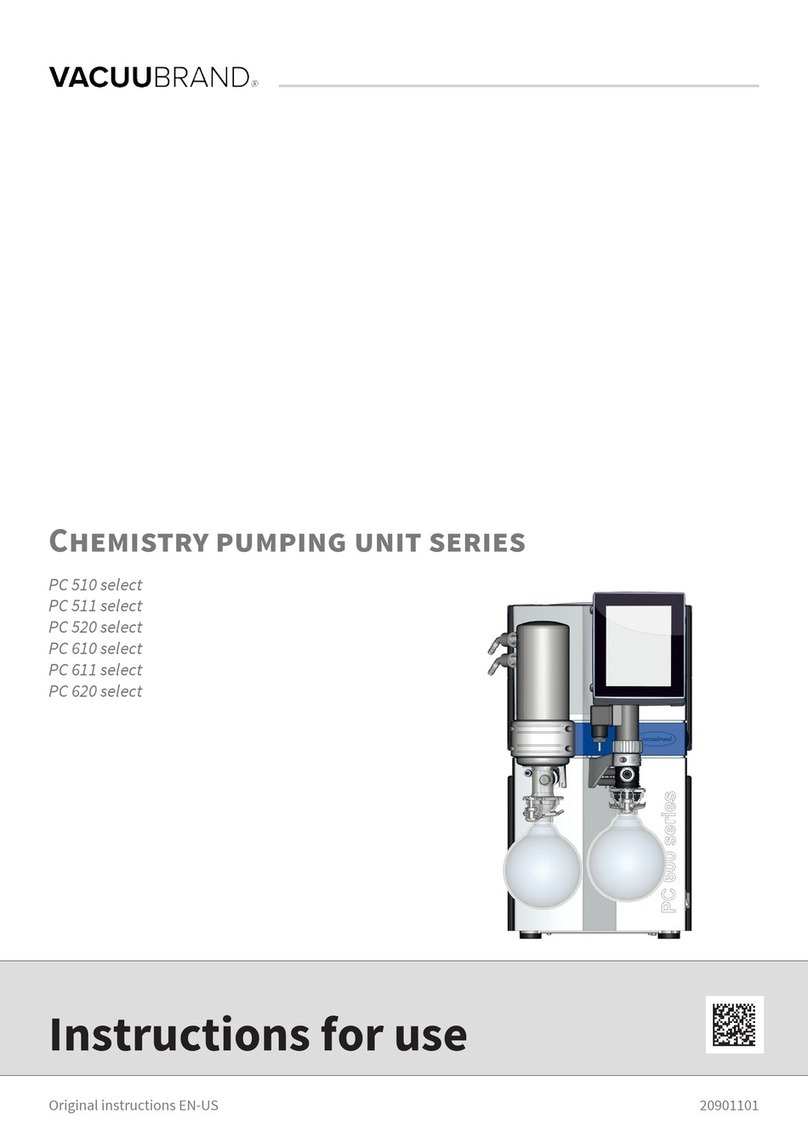

5.1. Vacuum pump ............................................................................................ 10

5.2. efrigerating unit ........................................................................................ 11

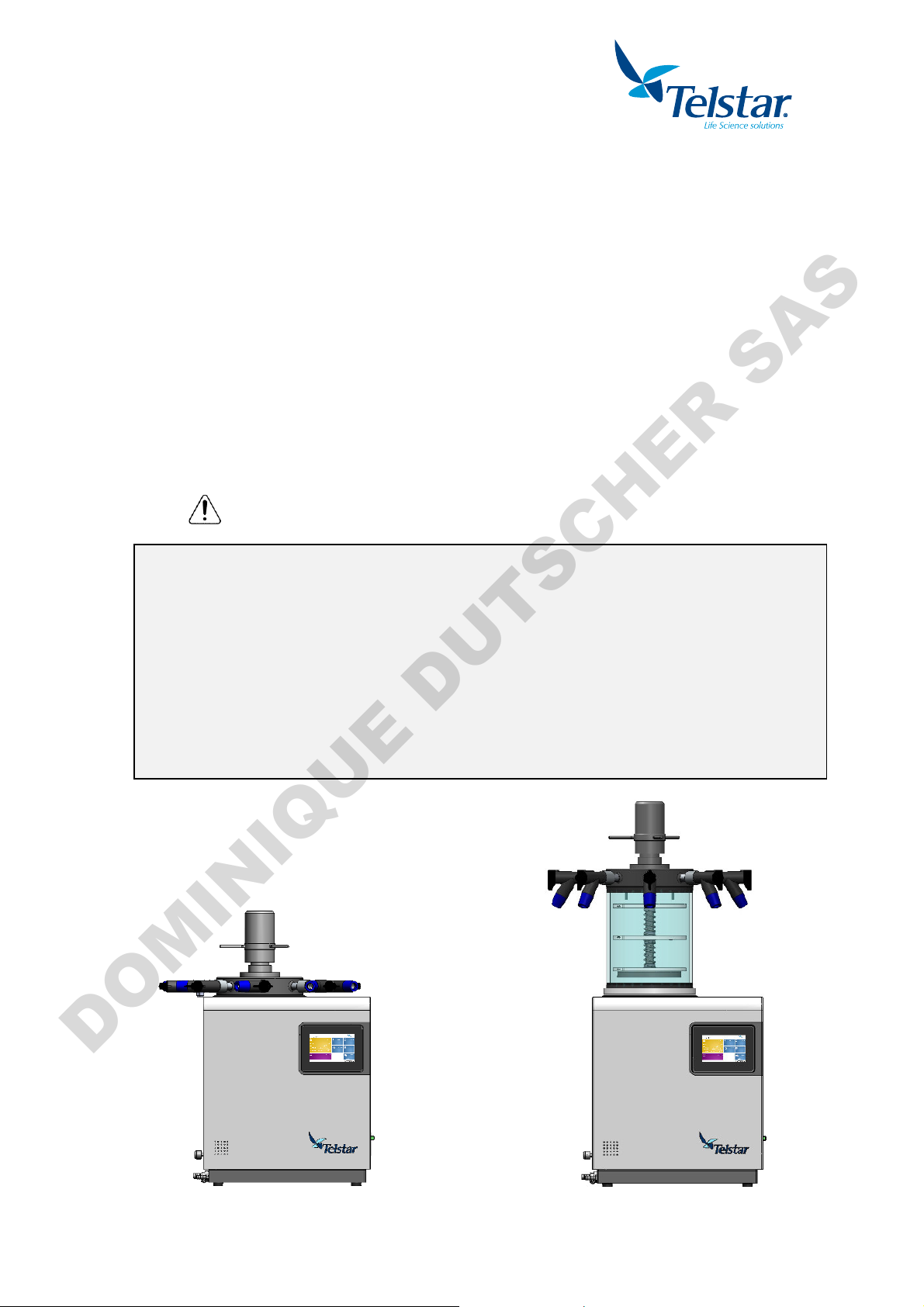

. DETAILS OF THE FREEZE-DRYER .................................................................... 11

6.1. Description ................................................................................................. 11

7. RECOMMENDATIONS ..................................................................................... 12

7.1. Ice condenser ............................................................................................. 12

7.2. Greasing .................................................................................................... 12

7.3. Long storage .............................................................................................. 12

8. WORKING PRINCIPLE .................................................................................... 13

8.1. Freeze ....................................................................................................... 13

8.2. Lyophilization ............................................................................................. 13

8.2.1. In manifold ........................................................................................... 13

8.2.2. In chamber ........................................................................................... 14

8.2.3. End of the process ................................................................................. 15

8.3. Lyophilization modes ................................................................................... 15

8.4. Selectable processes ................................................................................... 15

9. OPTIONAL ACCESSORIES ............................................................................... 1

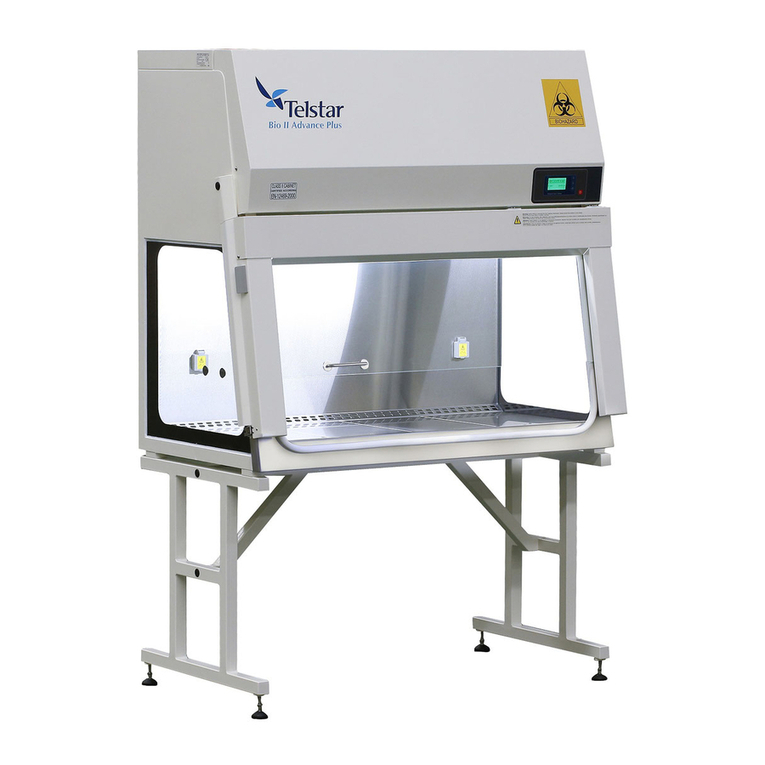

9.1. Chambers .................................................................................................. 16

9.2. Manifolds ................................................................................................... 18

9.3. Flasks condensations collector (Drip tray) ...................................................... 18

9.4. Lyologger software ...................................................................................... 19

10. OPERATION AND CONTROL INSTRUCTIONS ................................................ 20

10.1. Start up ..................................................................................................... 20

10.1.1. Main indo ......................................................................................... 20

10.2. Freeze-drying ............................................................................................. 22

10.2.1. Probes ................................................................................................. 23

10.2.2. Recipe .................................................................................................. 23

10.2.3. Semiautomatic cycle .............................................................................. 25

10.3. Auxiliary cycles ........................................................................................... 26

10.3.1. Defrosting ............................................................................................ 26

10.3.2. Alarms ................................................................................................. 27

10.3.3. Alarms list ............................................................................................ 28

10.4. Synoptic .................................................................................................... 29

10.5. Settings ..................................................................................................... 31

10.5.1. Language ............................................................................................. 32

10.5.2. Date/hour ............................................................................................. 32

10.5.3. IP Settings ............................................................................................ 33

10.5.4. Technical Service ................................................................................... 33

10.6. ecipe edition ............................................................................................. 34

10.6.1. Load recipe ........................................................................................... 35

10.7. Users ......................................................................................................... 36

10.7.1. User’s levels ......................................................................................... 36

10.7.2. User login ............................................................................................. 36

10.7.3. Pass ord change ................................................................................... 37

10.7.4. Users management ................................................................................ 38

10.7.5. User’s log out ........................................................................................ 40