Telstar Clean Air EuroFlow Series User manual

EF

EF/B

User manual

English Version 10.0

(valid for software V4.9 and higher)

Series EuroFlow,

Type EF

Biological Safety Cabinet Class II

&

Type EF/B

Biological Safety Cabinet Class II

Types:

EF 4

EF 5

EF 6

EF/B 4

EF/B 6

Offers protection for personnel,

environment and product.

Before using the safety cabinet, please read

this manual carefully. The required

instructions have to be carried out first.

Clean Air Techniek B.V.

Kuipersweg 37

3449 JA Woerden

Nederland

t: +31 (0) 348 41 11 14

f: +31 (0) 348 42 26 84

e: info@cleanair.eu

i: www.cleanair.eu

EuroFlow EF and EF/B Biological Safety Cabinet

UM-EFAB-EN10.doc

2

Preface

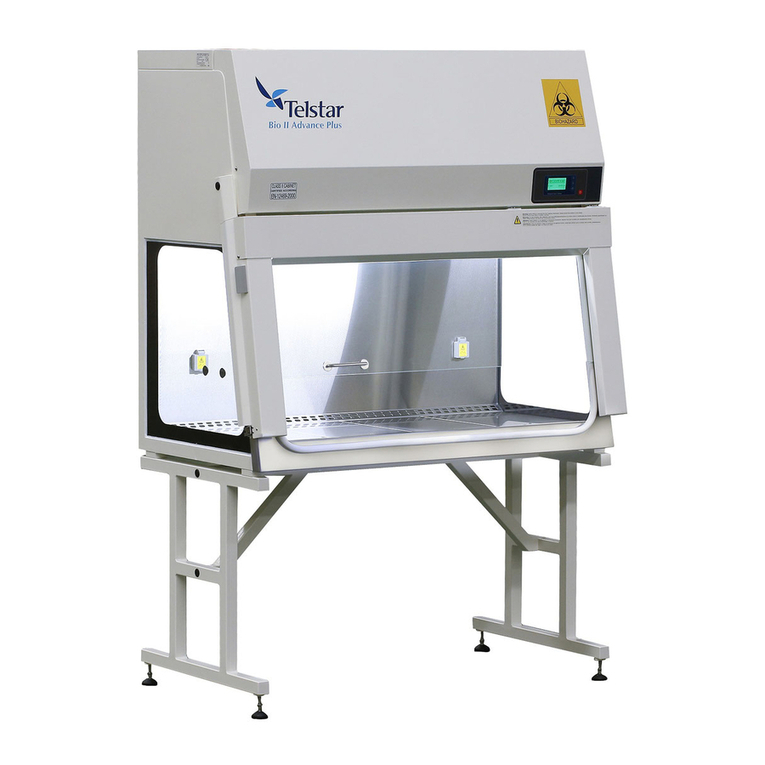

Congratulations with your new biological safety cabinet Class II, Series EuroFlow, type EF and/or

type EF/B. This Dutch quality product is designed, produced and tested by Clean Air Techniek B.V.,

in our production facility in Woerden, The Netherlands.

The primary function of the safety cabinet is safety for operator, product and environment. Basic

principle of the design are the latest standards regarding biological safety. Type EF meets all the

latest requirements, including the European standard EN 12469:2000 for Microbiological Safety

Cabinets. Type EF/B meets all the latest requirements, including the European standard EN

12469:2000 for Microbiological Safety Cabinets and DIN 12980:2005-06 for Safety Cabinets for

cytotoxics.

The standards EN 12469:2000 and DIN 12980:2005-06 describe only the minimum requirements.

They serve as the base for the high demands Clean Air Techniek B.V. pursuits for its products.

Type EF and type EF/B are high quality products, constructed with high grade components and

materials.

Besides providing biological safety, the wishes and demands of the operators have been important

basic principles for the design. Examples are ergonomics, design and usability.

The above-mentioned motivations have resulted in the most progressive safety cabinets currently

available, known for their superior quality, reliable performance, solid construction and many

available options, accessories, related products and the possibility to incorporate weighing

systems, microscopes etc or even build completely custom made cabinets. Furthermore, type EF

and EF/B are service friendly installations.

The safety cabinet is equipped with new techniques, such as:

•Microprocessor control with a LCD display for the interface with the operator

•Automatic up speeding fan; when the filter resistance increases, the necessary airspeeds

are maintained

•Window construction with a user-friendly hinge mechanism

We thank you for buying this cabinet and wish you good times working with the biological safety

cabinet class II type EF and/or type EF/B. For questions, advice, training, validation, service and

product adjustments please contact us.

Clean Air Techniek B.V.

Version table

Ver. 10.0 02-08-10 MPE Logo updated, preface revised

Version: Date: From serial

number:

By: Check: Change:

©Copyright 2010

All rights reserved. Nothing from this edition may be copied, or used in an automated database, or made public, either electronic,

mechanical, by photocopies, recordings, or in any manner, without preceding written permission of Clean Air Techniek B.V. This also

counts for the accompanying figures and/or plans.

Clean Air Techniek B.V. is entitled to change parts on each desired moment, without preceding or direct notification of the customer.

The content of this user manual can be changed without preceding warning as well. For information concerning maintenance activities

or repairs which are not mentioned in the user manual, please contact the service organization.

This user manual has been put together with all possible care, but Clean Air Techniek B.V. cannot take the responsibility for possible

mistakes in this user manual or for the consequences of it.

EuroFlow EF and EF/B Biological Safety Cabinet

UM-EFAB-EN10.doc

3

TOC

1Introduction_______________________________________________ 6

1.1 EF___________________________________________________________________6

1.2 EF/B _________________________________________________________________7

2Safety____________________________________________________ 8

2.1 Use in conformity with regulations _________________________________________8

2.2 Modifications and changes to the installation _________________________________8

2.3 Authorized persons _____________________________________________________8

2.4 General safety aspects __________________________________________________9

2.5 Cytotoxic danger (EF/B only) ____________________________________________10

2.6 Explanation user safety symbols __________________________________________10

3Installation ______________________________________________ 11

3.1 Assembly-instruction ___________________________________________________11

3.2 Transport instructions __________________________________________________12

3.3 Dismantling & Disposal _________________________________________________12

4Product description ________________________________________ 13

4.1 Type plate ___________________________________________________________14

4.2 Short user manual (sticker)______________________________________________14

4.3 Body of the cabinet ____________________________________________________14

4.4 Hinge-slide window ____________________________________________________15

4.5 Top hood ____________________________________________________________15

4.6 Worktop _____________________________________________________________15

4.7 Aerofoil______________________________________________________________15

4.8 Plenum-construction ___________________________________________________15

4.9 Drip tray/pre-filter (only EF/B and as an option for the EF)_____________________16

4.10 Downflow HEPA filter___________________________________________________16

4.11 Downflow protection ___________________________________________________16

4.12 Exhaust HEPA filter ____________________________________________________16

4.13 Support frame (optional)________________________________________________16

4.14 Feet support (assembled on 4.13) ________________________________________16

4.15 Front panel __________________________________________________________16

4.16 Back panel ___________________________________________________________17

4.17 Main power connection _________________________________________________17

4.18 Electronics ___________________________________________________________17

4.19 Operating panel _______________________________________________________18

4.20 FL-lighting ___________________________________________________________18

4.21 Fan_________________________________________________________________18

4.22 Optional Fittings ______________________________________________________18

4.23 Sockets______________________________________________________________21

4.24 Housing of the first HEPA filter (EF/B only) _________________________________21

4.25 First HEPA filters (EF/B only)_____________________________________________21

EuroFlow EF and EF/B Biological Safety Cabinet

UM-EFAB-EN10.doc

4

5Control__________________________________________________ 22

5.1 Using the cabinet______________________________________________________22

5.2 Top hood/sliding window _______________________________________________22

5.3 Display interface ______________________________________________________25

5.4 Starting up the cabinet _________________________________________________26

5.5 Locking functions cabinet _______________________________________________27

5.6 Power save mode _____________________________________________________28

5.7 Turn off _____________________________________________________________28

5.8 Control UV (optional)___________________________________________________29

5.9 Control gas supply (optional) ____________________________________________30

5.10 Control sockets _______________________________________________________31

5.11 Menu functions _______________________________________________________31

5.12 General Information ___________________________________________________32

5.13 Information status cabinet ______________________________________________40

5.14 Settings _____________________________________________________________42

6Alarms __________________________________________________ 47

6.1 Most frequent window alarms ____________________________________________47

6.2 Flow alarms __________________________________________________________48

6.3 Other alarms _________________________________________________________49

7Cleaning_________________________________________________ 51

7.1 Cleaning the installation ________________________________________________51

7.2 Cleaning the UV-light (optional) __________________________________________53

7.3 Guideline for cleaning of cytotoxic contaminated surfaces (EF/B only) ____________54

8Small maintenance and testing _______________________________ 56

8.1 Periodic maintenance __________________________________________________56

8.2 Replacement of the pre-filter ____________________________________________56

8.3 Replacing the Fluorescent-light (FL light) ___________________________________59

8.4 Service contact _______________________________________________________59

8.5 Service Contract_______________________________________________________60

8.6 Testing ______________________________________________________________60

9Technical specifications _____________________________________ 61

9.1 Physical surrounding ___________________________________________________61

9.2 General specifications __________________________________________________61

10 Trouble shooting __________________________________________ 65

Appendix I: Support frames EF & EF/B _____________________________ 66

Appendix II: Disinfection________________________________________ 67

Appendix III: Replacement of the HEPA filters _______________________ 68

1. When does a HEPA filter need to be replaced? ______________________________68

2. Replacement of HEPA filters _____________________________________________69

Appendix IV: Efficiency test of the HEPA filters_______________________ 74

EuroFlow EF and EF/B Biological Safety Cabinet

UM-EFAB-EN10.doc

5

Requirements ______________________________________________________________74

Appendix V: Measuring method air velocities ________________________ 76

Air velocities downflow_______________________________________________________76

Air velocities inflow*1________________________________________________________76

Appendix VI: Lay-out boards_____________________________________ 78

Appendix VII: Alarm-test procedure _______________________________ 79

Appendix VIII: Stickers _________________________________________ 81

Appendix IX: Information installed options__________________________ 84

Exhaust hood ______________________________________________________________84

Installed options microprocessor _______________________________________________84

Appendix X: User code__________________________________________ 87

Activating the user code _____________________________________________________87

Changing the user code ______________________________________________________88

Appendix XI: Required specifications ______________________________ 89

Overview of the required specifications according to EN 12469:2000 __________________89

Overview of the required specifications according to DIN 12980:2005 _________________90

Appendix XII: Part list critical components __________________________ 91

Appendix XIII: Short user manuals ________________________________ 93

Appendix XIV: TUV Low Pressure Mercury Lamps _____________________ 94

Appendix XV: Statement of the agreement for machines _______________ 95

Appendix XVI: Memo___________________________________________ 96

Index_______________________________________________________ 97

EuroFlow EF and EF/B Biological Safety Cabinet

UM-EFAB-EN10.doc

6

1Introduction

1.1

EF

The EF is a class II Biological Safety Cabinet. It gives the user the possibility to work safely and

sterile with bioagentia without complete physical barrier between person and experiment (through

work opening (C)).

•Working surface (A) is kept clear of particles by

means of a clean downflow of air.

•Because of the downflow air passed through a

HEPA filter (High Efficiency Particulate Air), the

working area of the cabinet is free of particles.

•This airflow is laminar, the airflow has got no

turbulence and has got a constant air speed.

•Through the work opening (C) air is drawn into

the workspace (inflow), towards the front slots of

the worktop. This protects the personnel against

pathogenic aerosols that might be released.

•The downflow and inflow air is then drawn

through a pre-filter (B) by a fan (E). This fan

blows the air in the correct proportion to the

downflow HEPA filter (D) and the exhaust HEPA

filter (F).

•The extracted air of the cabinet can recirculate

into the laboratory or can be blown into an

exhaust channel.

Figure 1 Sectional view EF

EuroFlow EF and EF/B Biological Safety Cabinet

UM-EFAB-EN10.doc

7

1.2

EF/B

The EF/B is a class II Biological Safety Cabinet. It gives the user the possibility to work safely and

sterile with bioagentia without complete physical barrier between person and experiment (through

work opening (C)).

•Working surface (A) is kept clear of particles by

means of a clean downflow of air.

•Because of the downflow air passed through a

HEPA filter (High Efficiency Particulate Air), the

working area of the cabinet is free of particles.

•This airflow is laminar, the airflow has got no

turbulence and has got a constant air speed.

•Through the work opening (C) air is drawn into

the workspace (inflow), towards the front slots of

the worktop. This protects the personnel against

pathogenic aerosols that might be released.

•The downflow and inflow air is then drawn

through a pre-filter (B) and a V-shaped HEPA filter

(G) by a fan (E), mounted on a plenum

construction. This fan blows the air in the correct

proportion to the downflow HEPA filter (D) and the

exhaust HEPA filter (F).

•The extracted air of the cabinet can recirculate

into the laboratory or can be blown into an

exhaust channel.

•In case the cabinet is used for cytostatics

production, the cabinet has to be connected to an

external exhaust channel.

Figure 2 Sectional view EF/B

EuroFlow EF and EF/B Biological Safety Cabinet

UM-EFAB-EN10.doc

8

2Safety

2.1

Use in conformity with regulations

Personnel that is not properly informed about the safety regulation and/or does not meet the

requirements mentioned in

§2.3 Authorized persons

, is not allowed to use the cabinet.

Improper use of the cabinet is not allowed.

2.2

Modifications and changes to the installation

In order to operate the installation safely changes and/or alterations shall only be made by Clean

Air Techniek B.V., or shall be made after consultation with and permission in writing from Clean Air

Techniek. If modifications and changes are made on own initiative, without permission from Clean

Air Techniek B.V., the parts of the installation concerned are no longer covered by the warranty.

Clean Air Techniek B.V. cannot be held liable for the consequences of the modifications and the

dangers, which might possibly occur as a result. The modifications mentioned here include the

connection of the installation to an exhaust system.

2.3

Authorized persons

Operating the installation

The cabinet shall only be used by personnel which:

•is familiar with the content, regulations and warnings which are mentioned in this operating

manual;

•is familiar with how to operate the cabinet;

•is familiar with the start up procedure, the stop procedure and Knows how to react in case of

emergency;

•is familiar with the regulations to keep the safety in all circumstances;

•is capable to end a disturbance.

Maintenance and repair general

Maintenance shall only be performed by professional service engineers, who are sufficiently trained

by Clean Air Techniek B.V. to:

•Estimate and avoid the dangers of the installation;

•Estimate the consequences of their actions.

•Before starting maintenance to the installation (mechanical and/or electric) disconnect the

power supply. Pay attention to rotating parts, after switching off the installation the fans will

still rotate for a while.

Maintenance and repair of the electrical installation

Maintenance shall only be performed by professional electro-technical service engineers, who are

sufficiently trained by Clean Air Techniek B.V. when:

•They can estimate and avoid the dangers of the installation;

•They can estimate the consequences of their actions;

EuroFlow EF and EF/B Biological Safety Cabinet

UM-EFAB-EN10.doc

9

•They are sufficiently informed about the operation of the installation and the operation of the

sub-systems.

2.4

General safety aspects

1. The installation shall never be used for any (micro-) biological or any other potentially dangerous work,

unless the fan is switched into working mode, the sliding window is in working position and there is no

alarm.

2. It is strongly advised not to slide the window out of the working position, during working with the

installation. When it is necessary to increase the work opening, this interruption needs to be as short as

possible.

3. When the installation is not used, the window shall always be closed, with the fan off, or switched onto

power-save mode, to prevent that dust particles etc. from the room can get into the installation (or worse:

material from the installation can get into the room).

4. Always try to limit the amount of equipment in the workspace. Each object in the workspace will disturb

the pattern of the airflow and a large number of equipment may lead to serious disruptions.

5. Materials such as Petri dishes or tissues should, during activities, never cover the slots of the worktop,

since no protection of the personnel can be guaranteed.

6. Do not use a centrifuge in the workspace. Even a small centrifuge is large in comparison with the work

surface and its presence may seriously disrupt the airflow. In addition, all centrifuges themselves create an

airflow, which may fling particles out of the casing.

7. When homogenizers are used in the installation, all reservoirs have to be secured by screw connections,

so that a sudden emission of fluids or aerosols will be avoided. To protect the personnel, glass reservoirs are

suitable for protection. High-speed homogenizers may cause air turbulence, as do centrifuges.

8. Even with the best technology, there may still be a risk that the hands and arms of the personnel get

contaminated during the work. Movements shall be kept to a minimum. Protective clothing shall have tightly

fitting cuffs. The use of hand gloves and over sleeves is recommended.

9. Always use a chair with the correct height. This enables the personnel to have a good view through the

sliding window. User should sit in such a position, that looking under the edge of the sliding window during

the work is not possible.

10. It is important to keep the biological safety cabinet clean. Minor contaminations are not always

immediately visible and could easily be forgotten. This increases the possibility that potentially infective

material is left behind and may cause serious contamination of the interior of the installation or worse.

Regularly clean the worktop, the bottom side, as well as the space under the worktop, in particular. In case

of doubt consider disinfection or contact Clean Air Techniek B.V. about the possibilities.

11. Transport and installation of the cabinet is only allowed for authorized staff. Please contact the

manufacturer or the seller of the products.

EuroFlow EF and EF/B Biological Safety Cabinet

UM-EFAB-EN10.doc

10

2.5

Cytotoxic danger (EF/B only)

Before starting work in cytotoxics production the hazard risks of cytotoxics handling need to be

evaluated and documented (industrial safety act, hazardous substances regulations). Based on

these findings the employees must be instructed.

2.6

Explanation user safety symbols

GENERAL DANGER

You can harm yourself and others seriously if you

do not follow the procedures carefully.

DANGER FOR ELECTROCUTION

BIOLOGICAL DANGER

DANGER OF EXPLOSION

DANGER BY INDUSTRIAL VEHICLE

CYTOTOXIC DANGER

EuroFlow EF and EF/B Biological Safety Cabinet

UM-EFAB-EN10.doc

11

3Installation

GENERAL DANGER

Be careful: high centre of gravity, crossover point.

Never hinge the window, as long as the cabinet is

not placed on the support frame

The cabinet must be installed in a safe way. Clean Air Techniek B.V. supplies an optional support

frame, which is designed for this purpose.

When the cabinet is purchased without a support frame, it is advised to discuss the installation

with the supplier.

3.1

Assembly-instruction

The cabinet has to be placed on the support frame recommended by the supplier. The assembly

needs to be done as specified in instruction underneath.

Assembly support frame

Build the support frame (see

Appendix I: Support frames EF & EF/B on page 66

for an explaining

drawing):

•Mount the support yoke (Pos. 1) to the reinforcement plate (Pos. 3);

•Mount (optional) feet support (Pos. 2).

•Item no. 6 is used to position the cabinet to the support frame (see

§3.1 Placing the cabinet on

page 11

).

Placing the cabinet

•Place the cabinet right on the forks of a forklift truck or lifting platform;

DANGER BY INDUSTRIAL VEHICLE

Be careful: Make sure the cabinet cannot slide from

the forks.

•Move the cabinet to the correct height and position, perform this action as precise as possible

above the support frame;

•The weight must be equally divided between the both forks and the cabinet must be horizontal

levelled;

•The cabinet should be aligned with the covers of the support frame.

The two cones on top of the yokes will help aligning;

•Mount the cabinet to the support frame by means of the four inner hexagonal cylinder screws

M8x12 (Pos. 6). See

Appendix I: Support frames EF & EF/B on page 66

;

•Connect the wire to a grounded socket that is easy accessible.

EuroFlow EF and EF/B Biological Safety Cabinet

UM-EFAB-EN10.doc

12

In case of maintenance the cabinet must be completely free of voltage. This means that the

connector in the socket must be easy to reach, otherwise a main-switch must be mounted

between the cabinet and the power supply so that the cabinet can be cut off of the power-circuit.

3.2

Transport instructions

Before moving the cabinet make sure the power cable is disconnected of the power supply

The cabinet must be transported on a strong solid pallet.

After every transport the cabinet must be tested and calibrated.

GENERAL DANGER

Be careful: High center of gravity, crossover point.

3.3

Dismantling & Disposal

For dismantling and disposal follow the next instructions:

•See

§7.1 Cleaning the installation on page 51;

•See

§8.2 Replacement of the pre-filter on page 56

;

•See

Appendix II: Disinfection on page 67;

•See

Appendix III: Replacement of the HEPA filters on page 68;

•Break the unit down into its component parts. You can re-cycle these components parts,

dispose them in accordance with local requirements.

For advice or information about dismantling or disposal please contact Clean Air Techniek B.V.

EuroFlow EF and EF/B Biological Safety Cabinet

UM-EFAB-EN10.doc

13

4Product description

Figure 3 Sectional view EF

Figure 4 3D view EF

Figure 5 Sectional view EF/B Figure 6 3D view EF/B

EuroFlow EF and EF/B Biological Safety Cabinet

UM-EFAB-EN10.doc

14

Part list EF and EF/B

1 Type plate

2 Short user manual

3 Body of the cabinet

4 Hinge/slide window

5 Top hood

6Worktop

7Aerofoil

8Plenum-construction

9Drip tray/pre-filter

10 Downflow filter

11 Downflow protection (build in)

12 Exhaust filter

13 Support frame (optional)

14 Feet support

15 Front panel

16 Back panel

17 Mains connection

18 Electronics

19 Operating panel

20 Lightning

21 Fan

22 Optional fittings

23 Sockets

EF/B only:

24 Housing of first HEPA filter

25 First HEPA filter

4.1

Type plate

The type plate (

Figure 3, Figure 4, Figure 5

and

Figure 6,

Pos. 1) mentions instructions that are

important for the connection of the biological safety cabinet. See

Appendix VIII: Stickers on page

81

.

4.2

Short user manual (sticker)

The short user manual (

Figure 3, Figure 4, Figure 5

and

Figure 6,

Pos. 2) gives a brief overview of

the primary functions, and is included with the cabinet. See also

Appendix XIII: Short user manual

on page 93

.

4.3

Body of the cabinet

The body of the installation (

Figure 3, Figure 4, Figure 5

and

Figure 6,

Pos. 3) is made of epoxy-

coated steel. The interior of the body is made of stainless steel (304). The body is leak tight as per

LI-C (table 1 and 4 of the EN 12469:2000-standard). The body has been tested according to the

method described in annex 2 of the EN 12469:2000.

EuroFlow EF and EF/B Biological Safety Cabinet

UM-EFAB-EN10.doc

15

4.4

Hinge-slide window

The hinge-slide window (

Figure 3, Figure 4, Figure 5

and

Figure 6,

Pos. 4) is a tightly closing,

manually operated glass window. It can be slid up or down, and opened and closed by means of

handgrips. The window construction contains two guiding profiles with a compression spring. The

spring will push a ball into a hole in the guiding shaft when the window enters the working

position (this working position is also indicated by means of two blue indication stickers).

The window can be hinged, but only in the hinge position, the top hood has to be opened first.

See

§5.2 Top hood/sliding window on page 23

. The hinge option offers the advantage that even

larger objects can be placed inside the working space. It also makes cleaning the working space as

well as the inside of the window easier(see

7.1 Cleaning the installation

on page 51

).

4.5

Top hood

In and behind the top hood (

Figure 3, Figure 4, Figure 5

and

Figure 6,

Pos. 5) a number of

electrical components are assembled.

•FL lighting

•Operating panel / operating board

•Interface board, including engine control

•Additional option print.

If you wish to check one of these components, you need to hinge the top hood.

To check the interface board, the safety-cover has to be taken away (authorized service personnel

only). Caution! Some of the components are live and therefore carry a risk of electrical shock as

long as the mains plug is connected.

4.6

Worktop

The workroom contains a stainless steel (type 304) worktop (

Figure 3, Figure 4, Figure 5

and

Figure 6,

Pos. 6) with a deepened work surface. This deepened work surface is called the safe

working area (for information about the dimensions see

§9.2 General specifications on page 61)

.

At the front and the back there are air slits, which are essential to the functioning of the

installation. At the two sides two panels have been placed (See detail Pos. 6)

4.7

Aerofoil

The aerofoil (

Figure 3, Figure 4, Figure 5

and

Figure 6,

Pos. 7) is used for a better air conduction

and to support the elbow. During work with the cabinet the aerofoil needs to be installed. The

aerofoil is made of coated aluminium for better ergonomics. (less weight and less heat

transportation)

4.8

Plenum-construction

The plenum-construction (

Figure 3, Figure 4, Figure 5

and

Figure 6,

Pos. 8) divides the air, which

is let in by the fan, between the downflow HEPA filter and the exhaust HEPA filter.

EuroFlow EF and EF/B Biological Safety Cabinet

UM-EFAB-EN10.doc

16

4.9

Drip tray/pre-filter (only EF/B and as an option for the EF)

The pre-filter with drip tray (EF:

Figure 3

and

EF/B:

Figure 5,

Pos. 9) is assembled under the

worktop. The installation is equipped with this to protect the interior of the installation against

pollution by coarse materials and to collect spilled fluids. Furthermore the pre-filter will enhance

the life span of the HEPA filter significantly.

4.10

Downflow HEPA filter

The downflow HEPA filter (

Figure 3, Figure 4, Figure 5

and

Figure 6,

Pos. 10) has a very high

efficiency: Class H14 in accordance with EN1822. After assembling, each filter will be tested

separately according to EN12469:2000, Annex D. Through the service panel the downflow filter

can be reached (Pos. 15).

4.11

Downflow protection

The downflow filter has a build-in protection grid (

Figure 3, Figure 4, Figure 5

and

Figure 6,

Pos.

11).

4.12

Exhaust HEPA filter

The exhaust HEPA filter (

Figure 3, Figure 4, Figure 5

and

Figure 6,

Pos. 12) has a very high

efficiency: Class H14 in accordance with EN1822. After assembling, each filter will be tested

separately according to EN 12469:2000, Annex D. Through the topside of the cabinet the exhaust

filter can be reached.

4.13

Support frame (optional)

For a stable positioning of the cabinet, we strongly recommend the use of the especially designed

support frame from the supplier (

Figure 3, Figure 4, Figure 5

and

Figure 6,

Pos. 13).

This support frame includes an in steps adjustable feet support for a good ergonomic work

position (

Figure

3

, Figure 4, Figure 5

and

Figure 6,

Pos. 14). As well, the feet support will increase

the stability of the cabinet. In addition, it is recommended to use an in height adjustable, well

disinfectable chair to optimize the work position.

4.14

Feet support (assembled on 4.13)

The support frame includes an in steps adjustable feet support for a good ergonomic work position

(

Figure 3, Figure 4, Figure 5

and

Figure 6,

Pos. 14). As well, the feet support will increase the

stability of the cabinet. In addition, it is recommended to use an in height adjustable, well

disinfectable chair to optimize the work position.

4.15

Front panel

The service panel (

Figure 3, Figure 4, Figure 5

and

Figure 6,

Pos. 15) can be dismantled to get

access to:

•the downflow filter;

EuroFlow EF and EF/B Biological Safety Cabinet

UM-EFAB-EN10.doc

17

•the fan.

GENERAL DANGER / BIOLOGICAL DANGER

Cabinet must be disinfected before removing the

front panel

4.16

Back panel

The back panel (

Figure 3, Figure 4, Figure 5

and

Figure 6,

Pos. 16) can be dismantled to get

access to:

•optional fittings;

•sockets.

GENERAL DANGER / BIOLOGICAL DANGER

Cabinet must be disinfected before removing the

back panel

4.17

Main power connection

The main power connection (Figure 3, Figure 4, Figure 5

and

Figure 6,

Pos. 17) is positioned on

the top of the cabinet. The cord length is maximum 3 meters and should always be accessible. See

§9.2 General specifications on page 61

for details

.

4.18

Electronics

The electronics (

Figure 3, Figure 4, Figure 5

and

Figure 6,

Pos. 18) consist of:

•Operational print; positioned in the top hood behind the operating panel;

•Control print, positioned under the top hood, behind the safety-cover, including:

oFuse holders (see

§9.2 General specifications on page 61

for fuse-numbers).

oFan control. The control is free adjustable in the range between 0% and 100%

oAn Air velocity compensating microprocessor regulates the fan speed to compensate

for main power fluctuations and filter pollution.

oIndependent potential free output contact (interface board connector J6).

See

Interface board on page 78.

oMain filter

oLight ballast + starter for UV (Option)

oLight ballast for FL-light

oOption board (see

Appendix

VI: Lay-out boards

on page 78

)

EuroFlow EF and EF/B Biological Safety Cabinet

UM-EFAB-EN10.doc

18

4.19

Operating panel

Figure 7 Operating panel

The operating panel (

Figure 3, Figure 4, Figure 5

and

Figure 6,

Pos. 19 and

Figure 7

) consists of:

1. Display;

2. Function keys (4x);

3. Fixed keys (4x);

4. Signals.

4.20

FL-lighting

The Fluorescent-lighting (

Figure 3, Figure 4, Figure 5

and

Figure 6,

Pos. 20) is assembled behind

the top hood.

4.21

Fan

The fans with the motor (

Figure 3, Figure 4, Figure 5

and

Figure 6,

Pos. 21) are maintenance-free,

double suction fans. The “Air Velocity Compensating Microprocessor” controls the fan power for

any disrupting factors such as voltage drops or filter pollution. With an installation with a double

exhaust HEPA filter, an additional fan is built in. The fan regulations are mounted behind the light

hood.

4.22

Optional Fittings

(

Figure 3, Figure 4, Figure 5

and

Figure 6,

Pos. 22)

Gas connection

This connection is assembled together with a gas valve. Normally, both the inlet and outlet gas

connections are hose connections, suitable for hoses with an inner diameter of 10 mm. All

connections on the gas supply have to be done with a certified gas hose.

After the connection on the gas supply, the gas connections have to be tested on leakage by a

certified installer.

An electrical gas valve has to be assembled on the gas connection (see Annex A.9 of the EN

12469:2000 standard) as an extra safety precaution. A coupling via the electrical system of the

EuroFlow EF and EF/B Biological Safety Cabinet

UM-EFAB-EN10.doc

19

installation makes sure that the valve can only be operated in work mode and will be switched off

automatically by leaving this mode.

The gas valve switch-function is only visible when the fan in work mode is and there are no

air speeds alarms.

Positions of the supply connection EF

•The connection, that is located inside the installation, is standard assembled on the back part

inside the work space of the biological safety cabinet.

•The connection, that is located outside the installation, is standard assembled in the bottom of

the installation.

•The connection, that is located outside the installation, can be assembled by customer request

in left or right side panel or top of the installation.

Positions of the supply connection EF/B

•The connection, that is located inside the installation, is standard assembled on the back part

inside the work space of the biological safety cabinet.

•The connection, that is located outside the installation, is standard assembled in the left or

right side panel of the installation.

•The connection, that is located outside the installation, can be assembled by customer request

in top of the installation. For EF/B-series assembly of this connection on the bottom is not

possible.

Bunsen burner lead-through set

The Bunsen burner can be plugged into the outlet with a short cable inside the work space. The

plug of the foot pedal can be inserted into an outlet. The Bunsen burner can only operate when

the cabinet is in safe work mode and button (Gas) is activated. Recommended to apply is

the Fuego Bunsen burner, available at Clean Air Techniek B.V.

Positions of the supply connection EF

•The connection, that is located inside the installation, is standard assembled in the back panel

of the workspace.

•The connection, that is located outside the installation, is standard assembled in the bottom of

the installation.

•The connection, that is located outside the installation, can be assembled by customer request

in left or right side panel or top of the installation.

Positions of the supply connection EF/B

•The connection, that is located inside the installation, is standard assembled in the back panel

of the workspace.

•The connection, that is located outside the installation, is standard assembled in the left or

right side panel of the installation.

•The connection, that is located outside the installation, can be assembled by customer request

in top of the installation. For EF/B-series assembly of this connection on the bottom is not

possible.

Vacuum connection

This connection is always assembled in combination with a vacuum tap.

Positions of the supply connection EF

•The connection, that is located inside the installation, is standard assembled in combination

with a vacuum tap in the back panel of the workspace.

EuroFlow EF and EF/B Biological Safety Cabinet

UM-EFAB-EN10.doc

20

•The connection, that is located outside the installation, is standard assembled in the bottom of

the installation.

•The connection, that is located outside the installation, can be assembled by customer request

in left or right side panel or top of the installation.

Positions of the supply connection EF/B

•The connection, that is located inside the installation, is standard assembled in combination

with a vacuum tap in the back panel of the workspace.

•The connection, that is located outside the installation, is standard assembled in the left or

right side panel of the installation.

•The connection, that is located outside the installation, can be assembled by customer request

in top of the installation. For EF/B-series assembly of this connection on the bottom is not

possible.

UV light

The UV light is meant for disinfection of the working surface of the safety cabinet.

When the UV light switches on, the FL lighting switches off. The UV light can only be switched on

when the window is closed (window on aerofoil) or when the cabinet is in disinfection mode

(aerofoil lifted up and window at its lowest point), this makes sure the user will not get in contact

with UV-C radiation.

The UV switch-function is only visible when the window is closed.

DANGER FOR BURNING

Avoid direct contact with UV-C radiation. This causes

burns to the skin and eyes.

The UV light can be switched on and off on the display (see

§5.8 Control UV (optional) on page

29

). It is also possible to adjust the UV disinfection, for each day a certain disinfection period can

be defined (see

§5.11 Set up 7 days clock UV on page 31)

.

Watch Out!

Do not touch the UV-lamp with the hand and keep the

lamp fat free; otherwise the lifetime will decrease. The

UV-light must be cleaned with alcohol (70%) regularly

(switch off the installation). See

§7.2 Cleaning the UV-

light (optional) on page 53.

This manual suits for next models

5

Table of contents

Other Telstar Laboratory Equipment manuals

Popular Laboratory Equipment manuals by other brands

Hermle

Hermle Z 130 M operating manual

Cole Parmer

Cole Parmer HO-200 Series user manual

Marshall Amplification

Marshall Amplification Gemini EM user guide

Intervet

Intervet Spraycox II Operation

S.C.A.T. Europe

S.C.A.T. Europe SymLine asecos Assembling and installation manual

Selecta

Selecta PRO-NITRO S manual