4

OPERATION

Stand alone operation

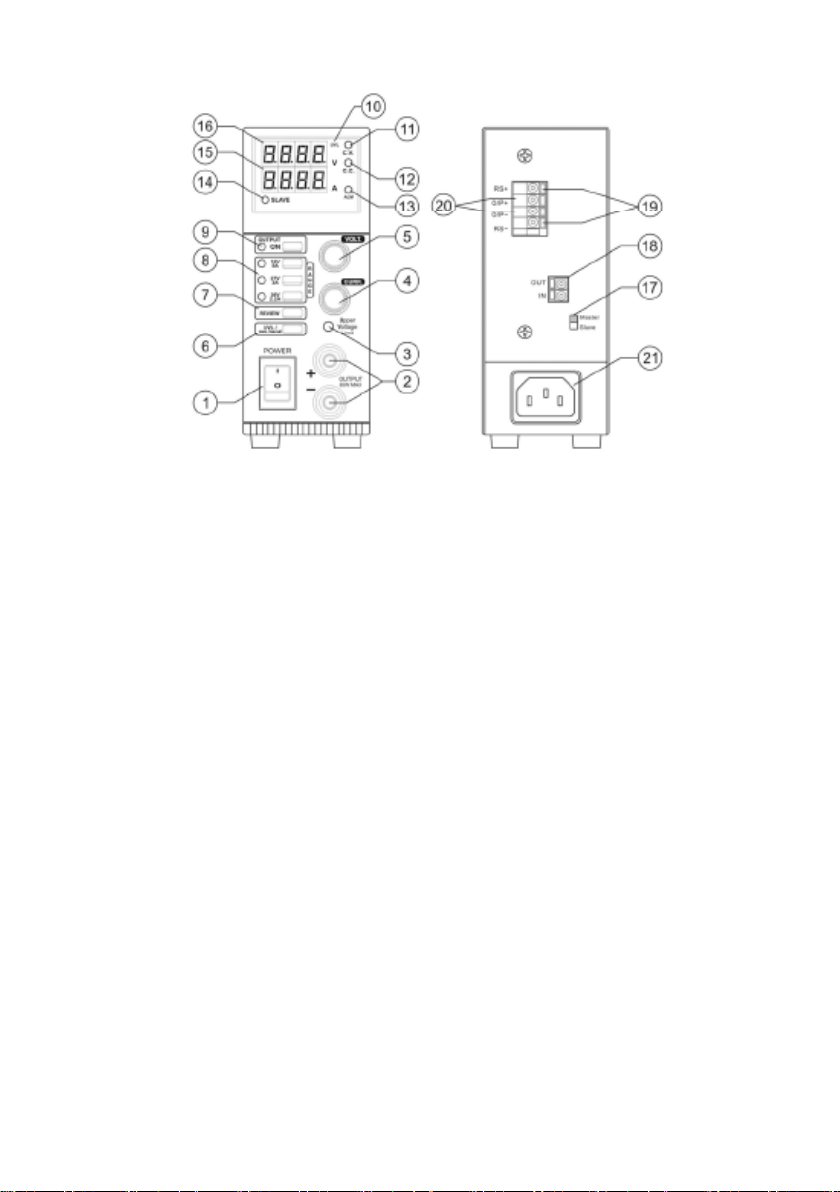

• Make certain that the power supply is set for MASTER operation. To do this, maker

sure the MASTER/SLAVE selector on the rear panel (17) set to MASTER position.

All controls will function as with any a normal power supply.

• With no load connected to the power supply, turn the power supply ON via the

POWER switch on the front panel (1).

• The LED display should light up, however there will not be any reading on the

voltmeter or ammeter.

• Press the OUTPUT ON button (9), its green LED will light up and the voltmeter will

display the set output voltage.

• Take note of the preset RANGE (8) by which LED is illuminated. Adjust the VOLT

control (5) and note the effect on displayed voltage on the LED display.

Selection of Voltage and Current Range

• The three buttons in the RANGE panel (8) will determine the voltage and current

range available from the supply. Depress the corresponding button to place the

power supply in the desired range.

• The appropriate LED will illuminate to show which range the supply is in.

Note: To protect the connected load, the OUTPUT (9) will return to OFF status any time

the output RANGE (8) is changed. The Volt and Amp display will return to zero.

Viewing Settings

• The REVIEW button (7) allows you to check voltage and current limiting settings of

the power supply while the OUTPUT (9) is turned off, or when no load is connected.

This is especially helpful since conventional power supplies require the connection

of some type of load to view the current limit setting.

• To operate, press and hold the REVIEW button (7) to display voltage and current

limiting values.

Note: This is a momentary push button and will only display the settings while held

depressed.

Setting the Current Limiting Value

• Press and hold the PREVIEW button (7).

• Turn the current adjustment (5) to your desired current limit value.

Viewing the Upper Voltage Limit (UVL)

Press UVL/VOLTAGE button (6) to display the default value of Upper Voltage Limit.

The UVL LED (10) will light up during this operation.

Setting the Upper Voltage Limit (UVL) value

• This limited access setting utilizes a recessed screwdriver adjustment on the

front panel (3). Note this is a delicate control and care should be exercised when

adjustment is made.

• While pressing the UVL button (6), insert the small screw driver into (3), slowly turn

clockwise to increase and counter–clockwise to decrease the UVL value.

Note: that only one UVL value can be set for all three ranges. When the output voltage

exceeds the set UVL, the output terminal will automatically turn off and the ALM LED

(13) will illuminate.