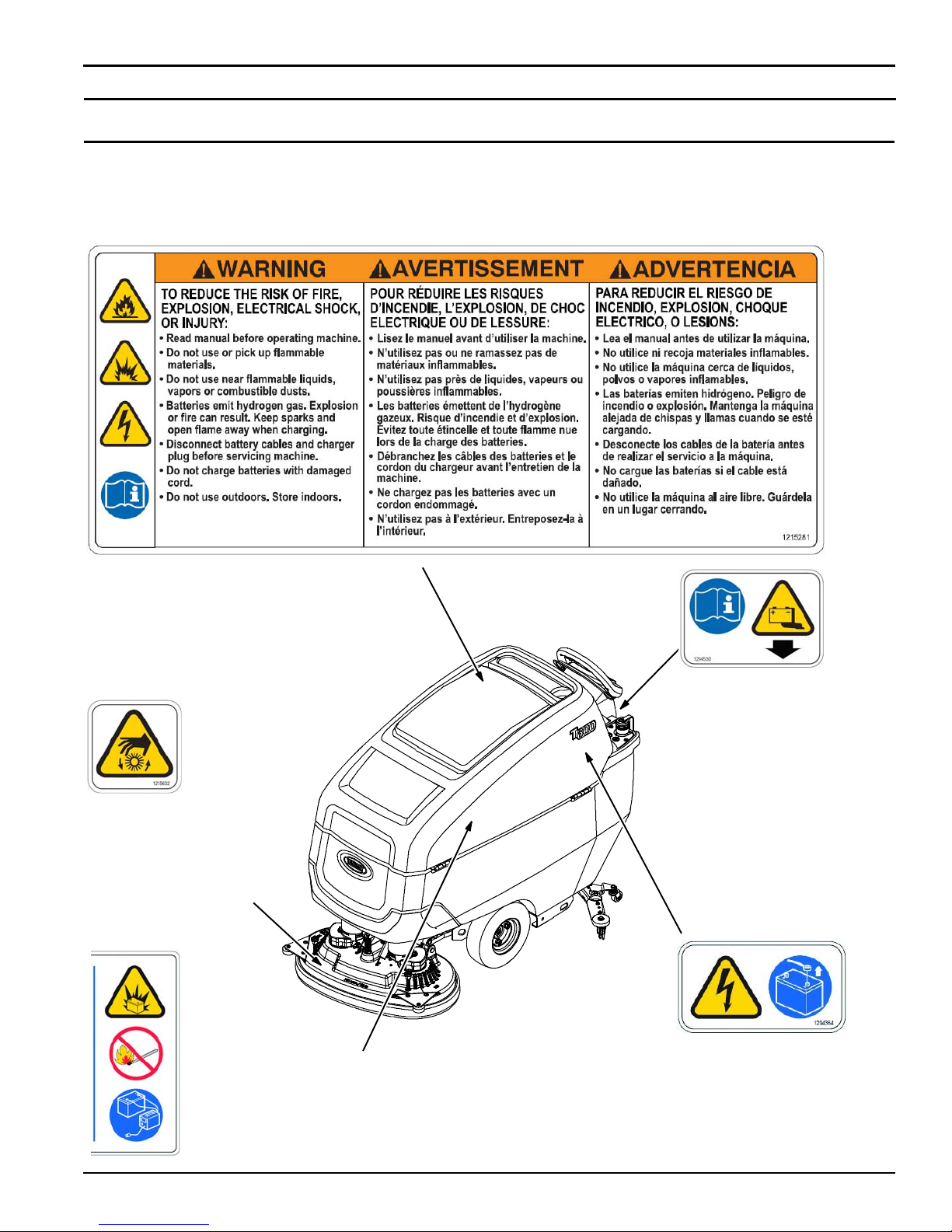

SAFETY

Tennant T600 EE (04-2018) 5

IMPORTANT SAFETY INSTRUCTIONS - SAVE THESE INSTRUCTIONS

The following warning precautions are used throughout

this manual as indicated in their description:

WARNING: To warn of hazards or unsafe

practices which could result in severe personal

injury or death.

FOR SAFETY: To identify actions which must be

followed for safe operation of equipment.

The following information signals potentially

dangerous conditions to the operator. Know when

these conditions can exist. Locate all safety devices on

the machine. Report machine damage or faulty

operation immediately.

WARNING: To Reduce the Risk of Fire,

Explosion, Electric Shock or Injury:

- Read manual before operating machine.

- Do not use or pick up flammable materials or

reactive metals.

- Do not use near flammable liquids, vapors or

combustible dusts.

This machine is not equipped with an

explosion proof motor. The electric motor will

spark upon start up and during operation

which could cause a flash fire or explosion if

machine is used in an area where flammable

vapors/liquids or combustible dusts are

present.

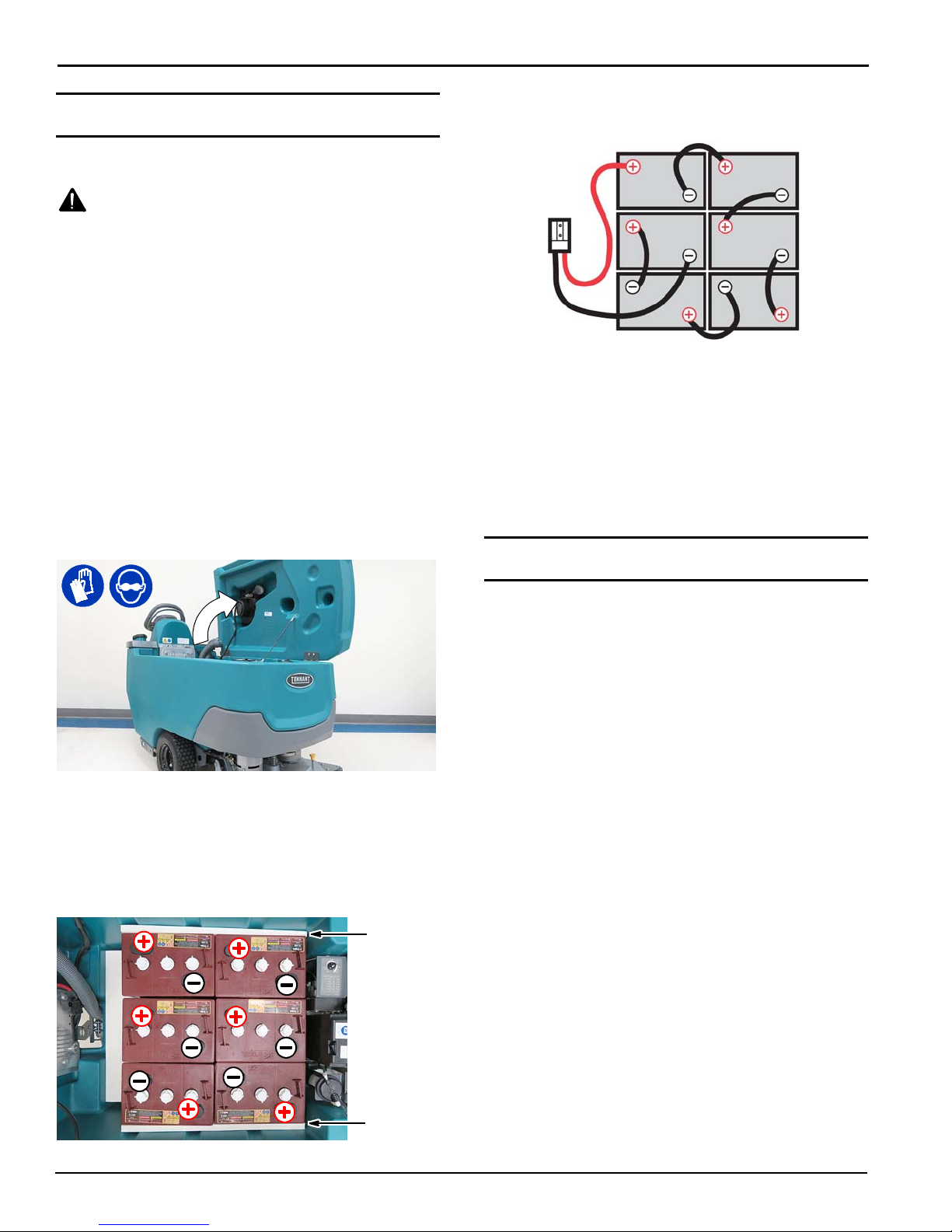

- Batteries emit hydrogen gas. Explosion or fire

can result. Keep sparks and open flame away

when charging.

- Disconnect battery cables and charger cord

before cleaning and servicing machine.

- Do not charge batteries with damaged cord. Do

not modify plug.

If the charger supply cord is damaged or

broken, it must be replaced by the

manufacturer or its service agent or a similarly

qualified person in order to avoid a hazard.

- Do not use outdoors. Store indoors.

- Spinning pad/brush, keep hands away.

WARNING: This machine contains chemicals

known to the state of California to cause cancer,

birth defects, or other reproductive harm.

FOR SAFETY:

1. Do not operate machine:

- Unless trained and authorized.

- Unless operator manual is read and

understood.

- Unless mentally and physically capable of

following machine instructions.

- Under the influence of alcohol or drugs.

- While using a cell phone or other types of

electronic devices.

- If not in proper operating condition.

- In outdoor areas. This machine is for

indoor use only.

- In areas where flammable vapors/liquids or

combustible dusts are present.

- With pads or accessories not supplied or

approved by Tennant. The use of other

pads may impair safety.

- In areas with possible falling objects.

- In areas that are too dark to safely see the

controls or operate machine.

2. Before operating machine:

- Check machine for fluid leaks.

- Make sure all safety devices are in place

and operate properly.

- Set the directional lever before pulling start

bail.

3. When operating machine:

- Use only as described in this manual.

- Report machine damage or faulty operation

immediately.

- Wear closed-toe, non-slip work shoes.

- Reduce speed when turning.

- Go slowly on inclines and slippery

surfaces.

- Always be aware of surroundings while

operating machine.

- Drive slowly through doorways and narrow

openings.

- Be cautious of the squeegee near

bystanders and obstacles.

- Do not scrub or transport on inclines that

exceed 2% grade.

- Follow site safety guidelines concerning

wet floors.

- Follow mixing, handling and disposal

instructions on chemical containers.

- Do not carry passengers on machine.

- Use care when reversing machine.

- Keep children and unauthorized persons

away from machine.

- Do not allow machine to be used as a toy.

- Do not leave machine unattended when

filling solution tank with auto-fill feature.

- Park machine on level surface when filling

solution tank with auto-fill feature.