Second Edition • First Printing Operator's Manual

Introduction

Part No. 1314196GT Genie Superlift Contractor®1

Introducti on

About this manual

Genie appreciates your choice of our machine for

your application. Our number one priority is user

safety, which is best achieved by our joint efforts.

This book is an operation and daily maintenance

manual for the user or operator of a Genie

machine.

This manual should be considered a permanent

part of your machine and should remain with the

machine at all times. If you have any questions,

contact Genie.

Product Identification

The machine serial number is located on the serial

label.

Serial label Serial number stamped on

chassis

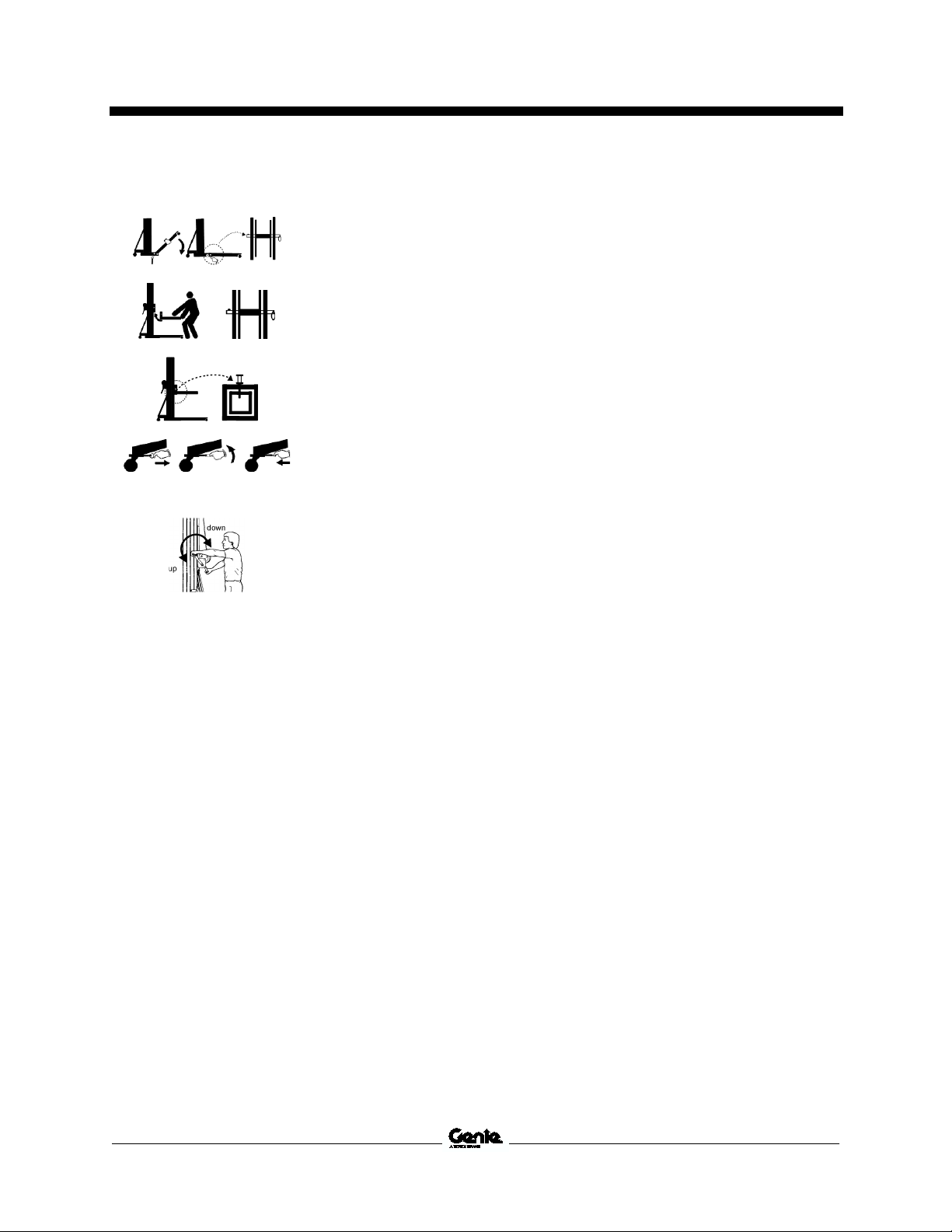

Intended Use and Familiarization

Guide

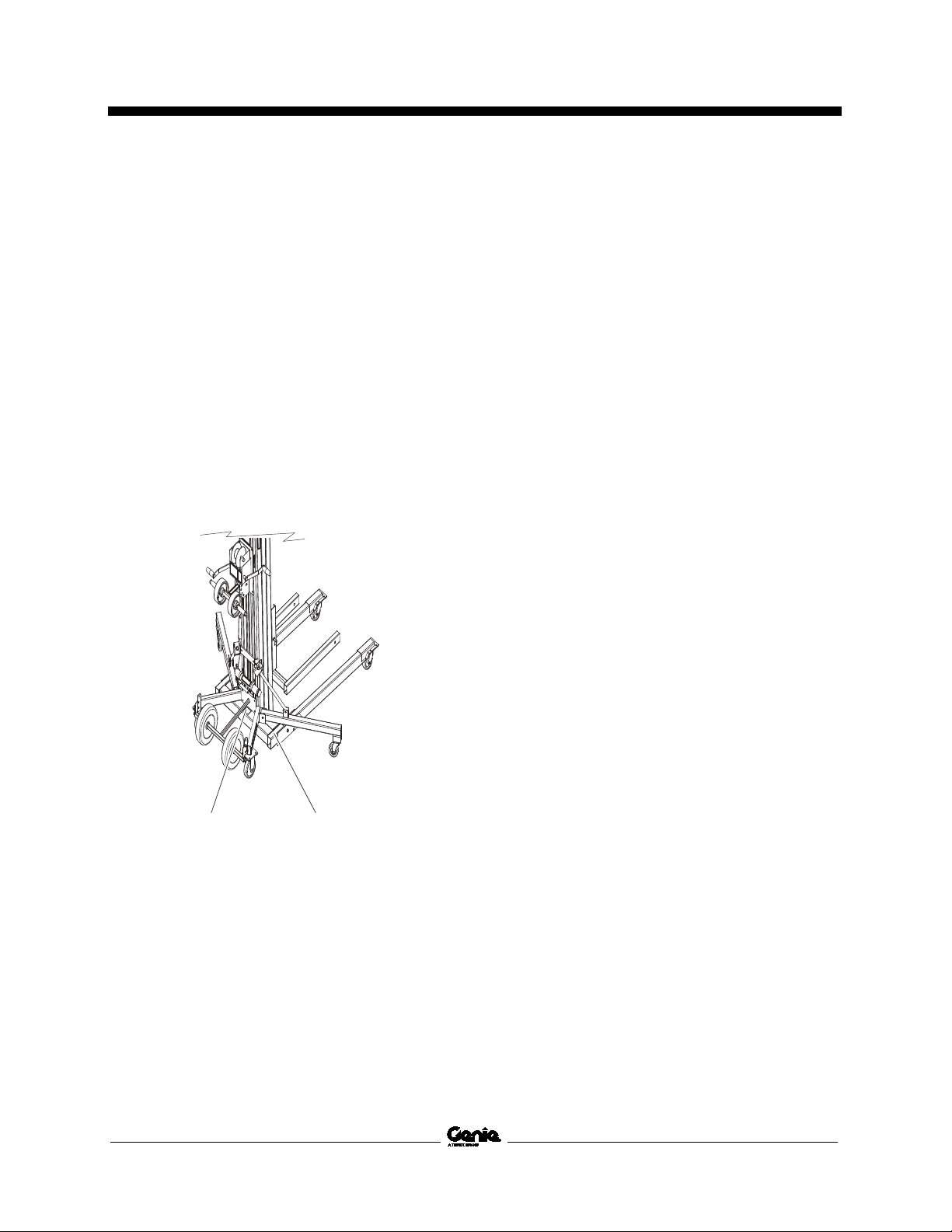

The intended use of this machine is to lift material.

Before operating the machine, it’s the operator’s

responsibility to read and understand this

familiarization guide.

Each person must be trained to operate a

material lift.

Familiarization with the material lift must be

given to each person who is authorized,

competent and trained.

Only trained and authorized personnel should

be permitted to operate the machine.

The operator is responsible to read,

understand, and obey the manufacturer’s

instructions and safety rules provided in the

Operator’s Manual.

The Operator’s Manual is located in the

manual storage container, on the machine.

For specific product applications, see

Contacting The Manufacturer.