MNR 9021550 / 2011-11-08www.phoenixcontact.com

DEUTSCHENGLISHFRANÇAISESPAÑOL

Einbauanweisung für den Elektroinstallateur

Installation notes for electrical personnel

Instructions d'installation pour l'électricien

Instrucciones de montaje para el instalador eléctrico

Istruzioni di installazione per l'elettricista

Instruções de instalação para o eletricista

Elektrik tesisatçısıiçin montaj talimatı

Инструкция по монтажу для электромонтажника

组装说明 (供电力安装技师使用)

DE

EN

FR

ES

IT

PT

TR

RU

ZH

PHOENIX CONTACT GmbH & Co. KG

Flachsmarktstraße 8, 32825 Blomberg, Germany

Fax +49-(0)5235-341200, Phone +49-(0)5235-300

Dok.-Nr.: 83050386 - 01© PHOENIX CONTACT 2011 10278801

D-SUB-Stecker für CAN

1. Kurzbeschreibung

D-SUB-Stecker mit axialer Kabelzuführung, mit

Schraubklemmenanschluss für CAN-Bussysteme

bis 1 MBit/s.

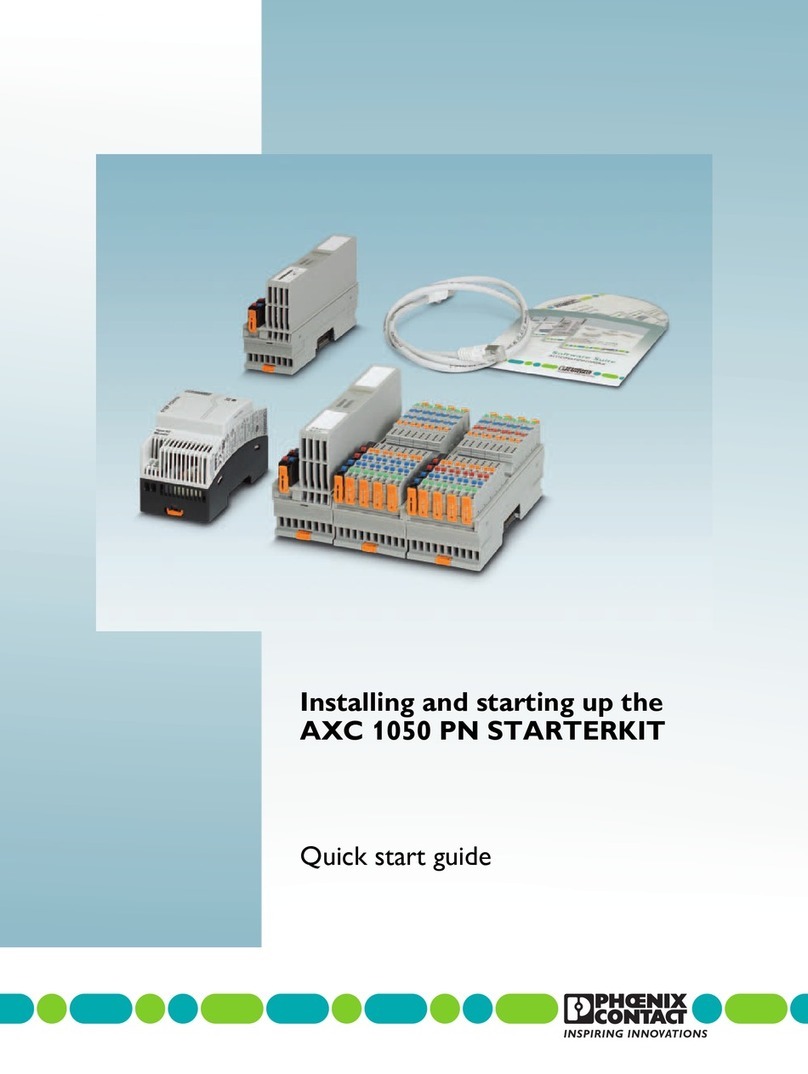

Der Abschlusswiderstand (3, Abb. 1) ist zuschalt-

bar integriert und schaltet beim Aktivieren gleich-

zeitig die weiterführende Busleitung ab (Abb. 2).

Dieses erlaubt die einfache und segmentweise In-

betriebnahme des Bussystems.

Die Zugentlastung (6, Abb. 1) ist in die Gehäuse-

halbschalen integriert.

2. Anschlusshinweise

Der Stecker darf nur mit einem CAN-

Buskabel (CiA Draft Recommendation

303-1) mit einem Durchmesser von

8 mm verwendet werden!

• Isolieren Sie das Kabel mit den angegebenen

Abisolierlängen ab (Abb. 3).

• Verschrauben Sie die abisolierten Leiter in den

entsprechenden Kontakten des Anschlussblocks

(2, Abb.1).

• Schließen Sie die ankommende Busleitung

BUS IN immer an die Klemmenanschlüsse

GND/1C-/1C+ an (auch am Anfang des Bussys-

tems!).

• Schließen Sie die weiterführende Busleitung

BUS OUT immer an die Klemmenanschlüsse

GND/2C-/2C+ an (Abb. 2). Beachten Sie dabei

die farbige Bedruckung der Anschlussklemmen.

• Schließen und verschrauben Sie abschließend

die Gehäusehalbschalen (1/5). Hierdurch wird

die Schirmanbindung und Zugentlastung (6) für

die Busleitung aufgebaut.

3. Busabschlusswiderstand

• Aktivieren Sie die Abschlusswiderstände am An-

fang und Ende des Bussystemes mit dem Schie-

beschalter (3, Abb. 1). Dadurch werden die

Anschlussklemmen (2C-/2C+) für die

weiterführende Busleitung abgeschaltet.

An allen anderen Knotenpunkten des Bus-

systems muss der Abschlusswiderstand de-

aktiviert sein!

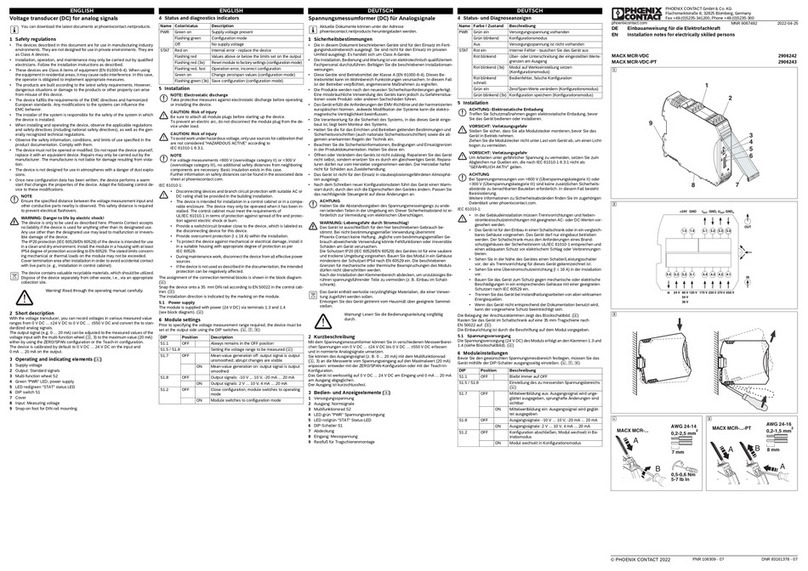

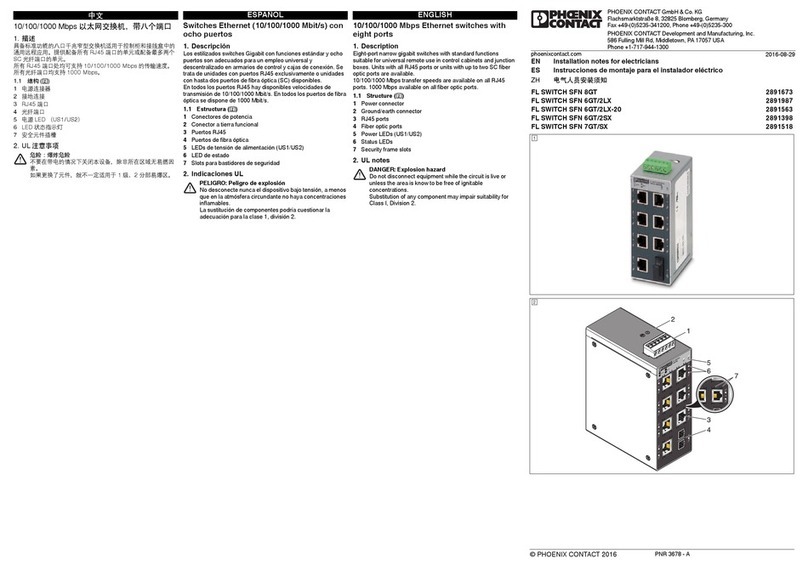

1Gehäuseoberschale

2Anschlussblock

3Schiebeschalter

4Befestigungsschrau-

be UNC

5Gehäuseunterschale

6Zugentlastung

7Gehäuseschraube

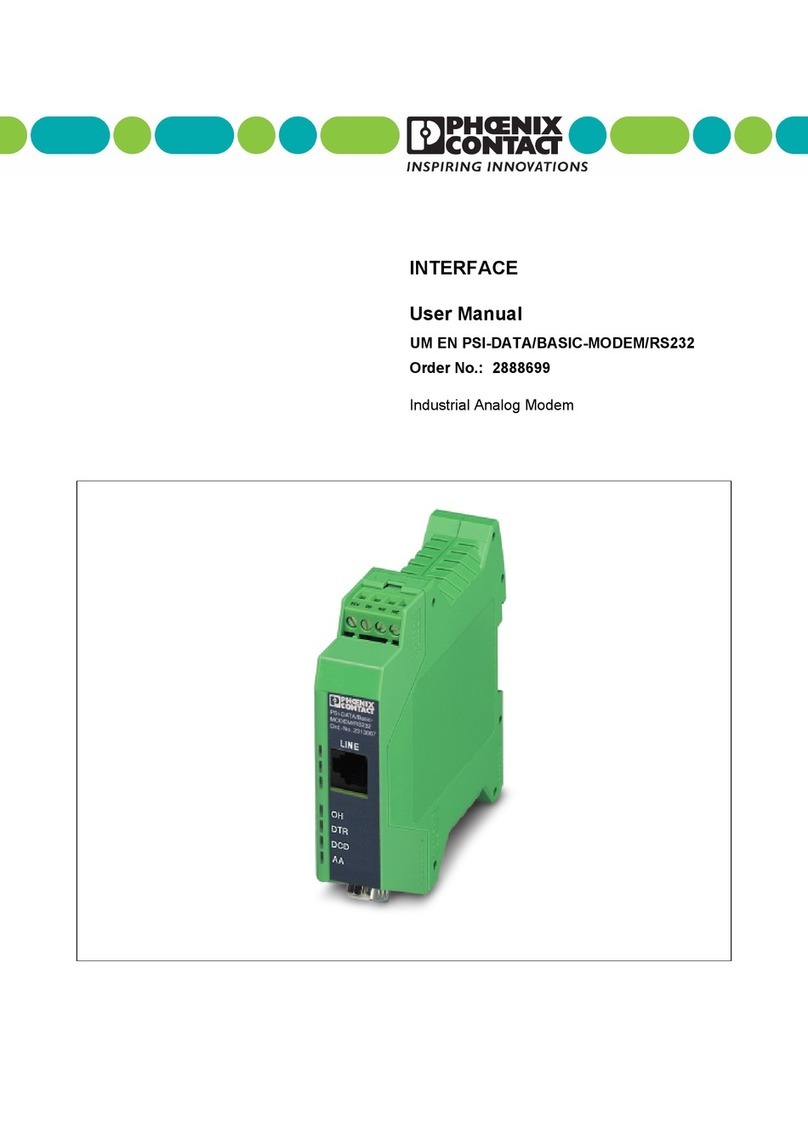

D-SUB connector for CAN

1. Short description

D-SUB connector for axial cable entry, with screw

connection for CAN bus systems up to 1 Mbit/s.

The integrated termination resistor (3, fig. 1) is

switchable; when it is activated, it simultaneously

switches off the outgoing bus line (fig. 2).

This makes easy, segment-by-segment startup of

the bus system possible.

The strain relief (6, fig. 1) is integrated into the two

half-shells of the housing.

2. Connection notes

The connector may only be used

with a CAN bus cable

(CiA Draft Recommendation 303-1)

with a diameter of 8 mm!

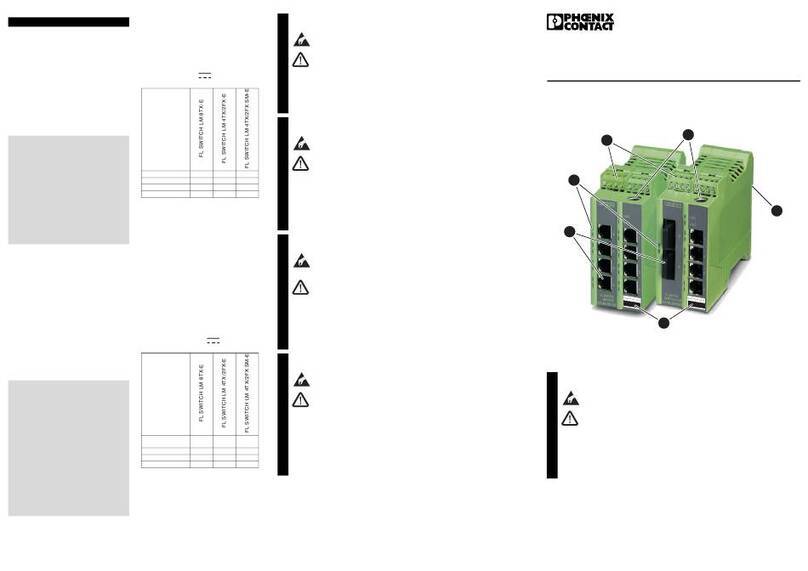

• Strip the cable as per the specified stripping

lengths (fig. 3).

• Push the stripped conductor into the correspon-

ding contacts of the terminal block (2, Fig.1).

• Always connect the incoming bus line BUS IN at

terminal connections GND/1C-/1C+ (also at the

starting point of the bus system!).

• Always connect the outgoing bus line BUS OUT

at terminal connections GND/2C-/2C+ (fig. 2).

The color of the connecting terminal blocks label-

ing must then be observed.

• Subsequently close and screw tight the two

housing shells (1/5). This establishes the shield

connection and the strain relief (6) for the bus

line.

3. Bus termination resistor

• Use the slide switch to activate the termination re-

sistors at the start and end points of the bus sys-

tem (3, fig. 1). This deactivates the connection

terminal blocks (2C-/2C+) for the outgoing bus

line.

The termination resistor has to be deactiva-

ted at all other nodes of the bus system!

1Upper shell of the

housing

2Terminal block

3Slide switch

4Mounting screw UNC

5Lower shell of the

housing

6Strain relief

7Housing screw

Connecteur SUB-D pour CAN

1. Description succincte

Connecteur SUB-D pour introduction axiale du

câble, avec blocs de jonction à vis pour systèmes

de bus CAN jusqu’à 1 Mbits/s.

La résistance de terminaison (3, Fig. 1) est intégrée,

activable et désactive automatiquement le câble de

bus sortant (Fig. 2). Ceci permet la mise en service

simple et par segment du système de bus.

La décharge de traction (6, Fig. 1) est intégrée

dans les deux moitiés du boîtier.

2. Consignes de raccordement

Le connecteur ne doit être utilisé

qu'avec un câble bus CAN

(CiA Draft Recommendation 303-1)

à un diamétre de 8 mm !

• Dénuder le câble de la longueur prescrite

(Fig. 3).

• Vissez les conducteurs dénudés dans les contacts

correspondants du bloc de connexion (2,Fig.1).

• Toujours raccorder le câble de bus entrant

BUS IN aux connexions GND/1C-/1C+

(ceci concerne également le début du système

de bus).

• Toujours raccorder le câble de bus sortant

BUS OUT aux connexions GND/2C-/2C+

(Fig. 2). Respecter les repérages de couleur des

bornes de raccordement.

• Pour finir, monter et visser les moitiés du boîtier

(1/5). Ceci établit automatiquement le raccorde-

ment de blindage et la décharge de traction (6)

du câble de bus.

3. Résistance de terminaison du bus

• Activer les résistances de terminaison situées au

début et en fin du système de bus à l'aide du

commutateur coulissant (3, Fig. 1). Les bornes

de raccordement (2C-/2C+) du câble de bus sor-

tant sont ainsi désactivées.

La résistance de terminaison de tous les au-

tres nœuds du système de bus doit être

désactivée !

1Partie supérieure du

boîtier

3Bloc de connexion

2Interrupteur coulissant

4Vis de fixation UNC

5Partie inférieure du

boîtier

6Dispositif antitraction

7Vis du boîtier

SUBCON-PLUS-CAN/AX

Conector D-SUB para CAN

1. Breve descripción

Conector D-SUB para introducción axial de cable,

con conexión por tornillo para sistemas de bus

CAN hasta 1 Mbits/s.

La resistencia de cierre (3, Fig. 1) integrada es

conectable y, al activarse, desconecta simultánea-

mente la línea de bus de salida (Fig. 2).

Esto posibilita la puesta en servicio fácil y por seg-

mentos del sistema de bus.

La compensación de tracción (6, Fig. 1) está incor-

porada en las mitades de carcasa.

2. Indicaciones sobre la conexión

¡El conector sólo debe emplearse con

un cable de bus CAN (CiA Draft

Recommendation 303-1) con un

diámetro de 8 mm!

• Pele el cable a las longitudes especificadas (Fig. 3).

• Enrosque los conductores desaislados en los

contactos correspondientes del bloque de

conexión (2, Fig.1).

• Conecte siempre el cable bus de entrada BUS IN

en las conexiones de bornes GND/1C-/1C+

(¡también al comienzo del sistema de bus!).

• El cable de bus de salida BUS OUT se conecta

siempre en las conexiones de bornes GND/2C-/

2C+ (Fig. 2). Tenga en cuenta la rotulación a co-

lor de los bornes de conexión.

• Cierre y atornille a continuación las mitades de

carcasa (1/5). Quedan así montadas la conexión

de pantalla y la compensación de tracción (6)

para el cable de bus.

3. Resistencia de cierre de bus

• Active la resistencia de cierre al comienzo y el final

del sistema de bus con el conmutador deslizante

(3, Fig. 1). Se desconectan así los bornes de co-

nexión (2C-/2C+) para el cable de bus de salida.

¡La resistencia de cierre tiene que estar

desactivada en todos los demás nodos del

sistema de bus!

1Parte superior de caja

2Bloque de conexión

3Conmutador

deslizante

4Tornillo de fijación UNC

5Parte inferior de caja

6Compensador de

tracción

7Tornillo de caja

1

2

3

7

6

5

4

Abb./Fig./Şekil/Pис./ 图1 Abb./Fig./Şekil/Pис./ 图2

102705A011

BUS

IN

BUS

OUT

120 Ω

1

5

6

9

GND 1C- 1C+ GND 2C- 2C+

D-SUB-9 female 1

6GND

(as option)

2C-

7C+

3GND

8

4

9V+

5CAN Shld

17

20

31,5

58,2

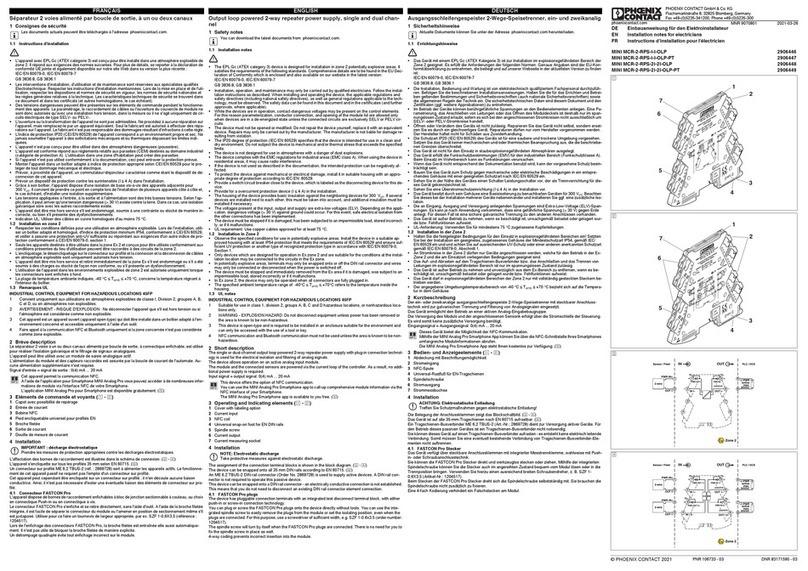

Abb./Fig./Şekil/Pис./ 图4

[mm]

[inch]

0.787"

2.290"

0.669"

1.240"

Abb./Fig./Şekil/Pис./ 图3

[mm]

[inch]

BUS IN + BUS OUT

65

13

24

0.512"

0.945"

0.197"

0.236"

Datos técnicos Caractéristiques techniques Technical Data Technische Daten

SUBCON-PLUS-CAN/AX SUBCON-PLUS-CAN/AX SUBCON-PLUS-CAN/AX SUBCON-PLUS-CAN/AX 2306566

Tensión máxima Tension max. Max. voltage Max. Spannung 50 V

Capacidad de corriente Capacité de charge Current carrying capacity Strombelastbarkeit 100 mA

Ciclos de enchufe Cycles d'enfichage Insertion/withdrawal cycles Steckzyklen > 200

Protección Degrée de protection Degree of protection Schutzart IP40

Diámetro de cable máx./mín. Diamètre du câble max./min. Cable cross section max./min. Kabeldurchmesser max./min. 8,4 mm / 7,6 mm

Temperatura ambiente servicio Température ambiante fonctionnement Ambient temperature Operation Umgebungstemperatur Betrieb -20 °C… +75 °C

almacenamiento stockage Storage Lagerung -20 °C… +80 °C

Fijación SUBCON (Fig. 1, 4) Fixation SUBCONNEC (Fig. 1, 4)SUBCONfixing (fig.1,4) SUBCON-Befestigung (Abb. 1, 4) 4-40 UNC / 0,4 Nm

Conexión a rosca Raccordement vissé Screw connection Schraubanschluss

Sección de conexión rígido / AWG

flexible / AWG

Section raccordable rigide / AWG

souple / AWG

Connection cross section solid / AWG

stranded / AWG

Anschlussquerschnitt starr / AWG

flexibel / AWG

0,14-1,5 mm2 / 26-16

0,14-1,0 mm2 / 26-18