TESA-hite 400 / 700

1 MAIN FEATURES

The TESA-Hite 400 / 700 is a mains-independent height gauge, which is suitable for measuring

lengths in the form of external, internal, step, height, depth and distance dimensions. A cast-iron base

with 3 integrated finish-ground supporting lugs ensures the stability of the TESA-Hite 400 700. By

activating the integrated electric pump, an air cushion can be created to facilitate the movement of the

instrument. A rigid column is located under the protective cover, equipped with a guide system that is

absolutely straight and perpendicular to the base. On this slides the measuring head and the

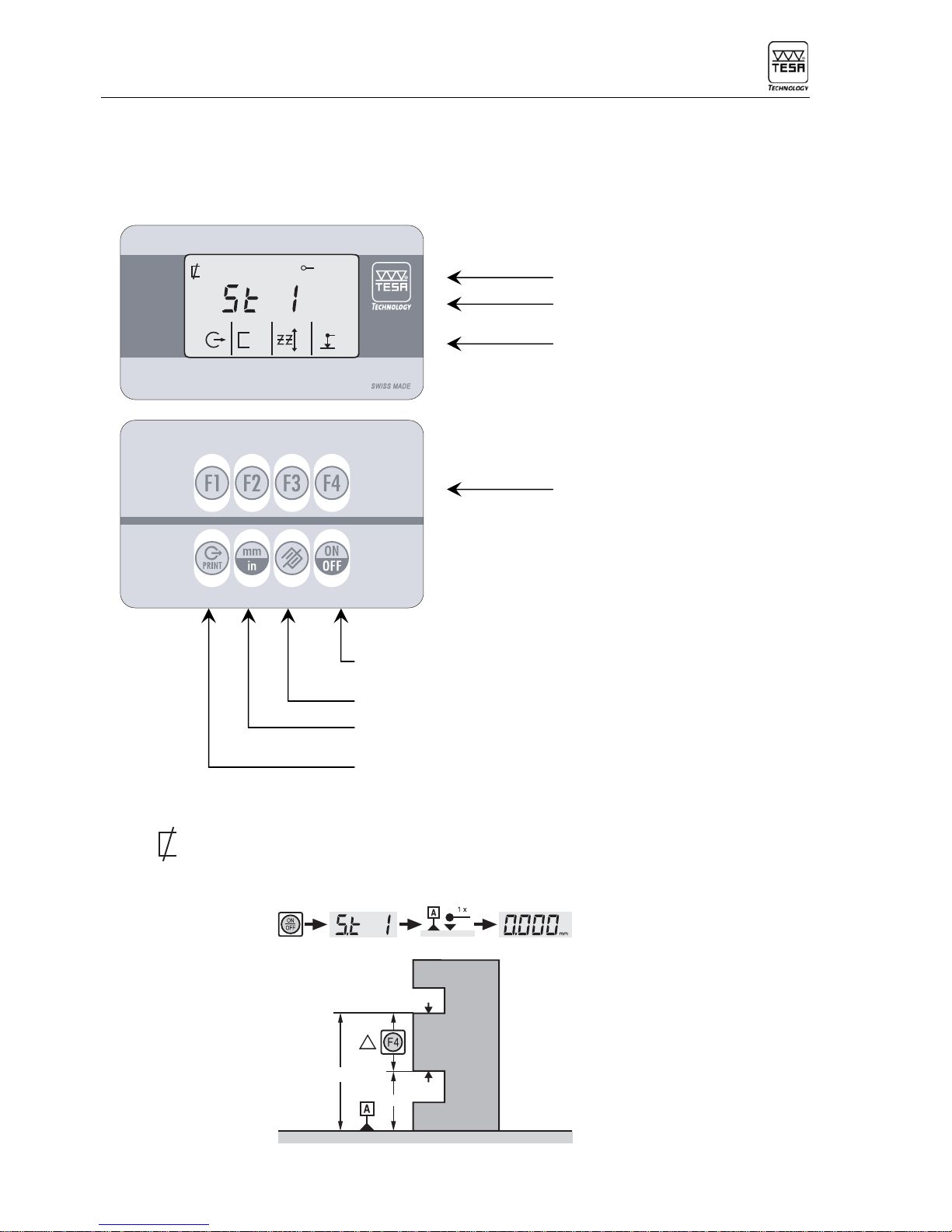

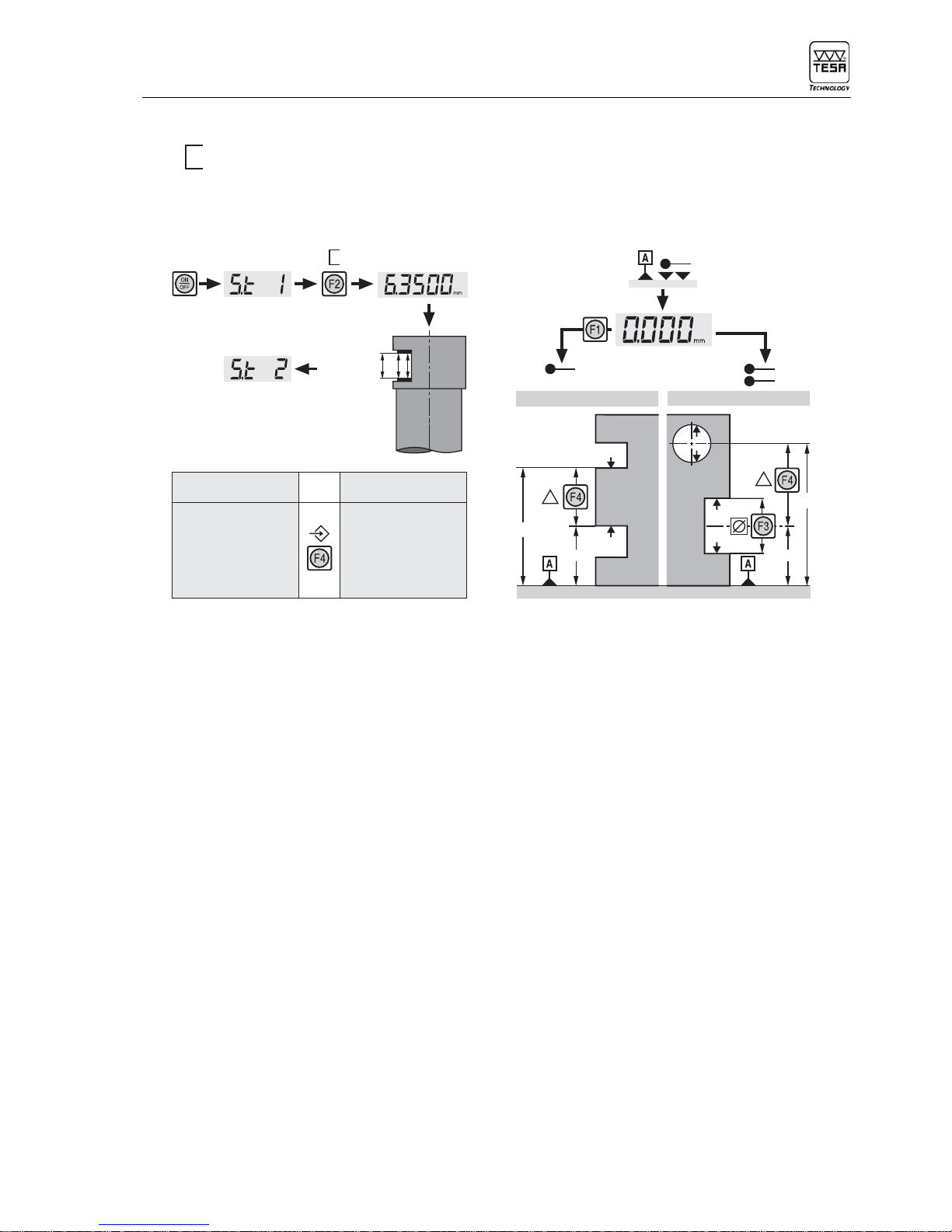

movement of the head is measured by an opto-electronic measuring system (TESA patent). The

measured readings are obtained in a very simple and reliable manner. Firstly the probe is brought into

contact with the point to be measured then immobilised to permit it to stabilise; then, by performing a

further slight rotation of the drive system, the measured reading is automatically recorded by a

dynamic process, with the measuring force at all times remaining constant. An acoustic signal

confirms that the reading has be recorded and it is immediately displayed and, if required, transmitted

via the RS 232 output. Cylindrical surfaces (bores and shafts) can also be measured simply and

reliably by automatically probing to find the culminating point. Although the TESA-Hite 400 / 700 is

manufactured to the highest precision, automatic microprocessor assisted correction makes it even

more accurate: Correction values memorised in the instrument compensate for systematic errors

when measuring lengths.

2 INSTALLATION

2.1 Unpacking and setting up

The TESA-Hite 400/700 is delivered ex factory, packed to protect it from impact and corrosion. Please

use the original packing materials for any subsequent transport.

IMPORTANT:

Your instrument is supplied with a 6V rechargeable battery already inserted. For recharging the

battery, see section 7.2.

Before fitting the standard accessories, release the measuring carriage by unscrewing the light grey

knurled screw (10) Fig. 1 on the hand wheel.

Securely fit the probe 5 to the probe-fixing arm 4 itself fitted to the mounting pin 3. Ensure that the

two knurled screws on the probe-fixing arm are well tightened.

After, unlock the measuring head by moving the slide downward until the insert touché the granite

plate; exert a force on the handwheel, like if you would do a probing down; this will unlock the

transport carriage from the measuring carriage.

However, we recommend you firstly read this instruction manual.

5