The Handy THPLS7TP Installation and maintenance instructions

Page 1

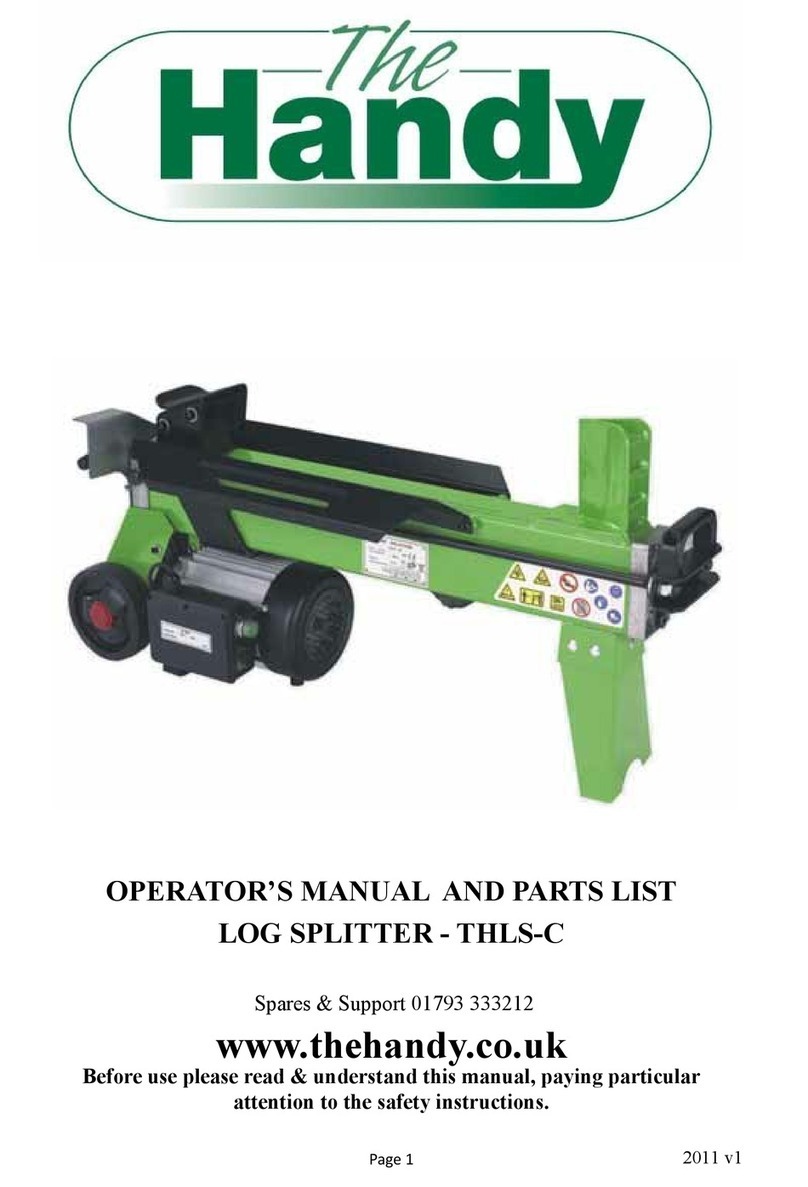

OPERATOR’S MANUAL AND PARTS LIST

PETROL LOG SPLITTER - THPLS7TP

Sales & Helpline 01793 333220

www.thehandy.co.uk

Before use please read & understand this manual, paying particular

attention to the safety instructions.

2010 v1

Page 2

CONTENTS

SAFETY INSTRUCTIONS 3

MAJOR PARTS 4

FUEL 5

SPECIFICATIONS 5

ASSEMBLY 6-7

OPERATION 8-9

PARTS DIAGRAM AND LIST 10-11

EC DECLARATION OF CONFORMITY 12

Page 3

SAFETY INSTRUCTIONS

Read and understand the owner’s manual and labels afxed

to the logsplitter. Learn its application and limitations as well

as the specic potential hazards. Retain these instructions for

reference.

• Use sturdy footwear and a helmet with eye and ear protection.

Protect exposed parts of your body. Wear heavy duty gloves,

preferably made of leather.

• Do not wear loose clothing or jewellery. Keep hair, clothing and

gloves away from moving parts.

• Do not operate the logsplitter if you are tired, ill or under the

inuence of alcohol or drugs.

• Do not smoke when using the logsplitter and ensure caution when

handling fuel. We recommend you fuel the machine at least 3m

away from where you wish to work in case any spilt fuel ignites

when starting the engine.

• Ensure that bystanders, children and pets keep well away when

starting or trimming - at least 15m.

• Do not operate the machine on a steep slope.

• Inspectthemachineandallattachmentsbeforeuseforanywornor

damaged parts. Do not use until the parts are repaired or replaced.

• Before starting the engine make sure you have a clear work area

and secure footing.

• The logsplitter should not be exposed to direct sunlight, high

temperatures or damp and wet conditions. In addition, do not use

in a conned space but in a well ventilated, outdoor area.

• Ensure that the engine is turned off before transporting or carrying

out any maintenance. Allow to cool down to avoid accidentally

touching the hot exhaust.

• Clean the logsplitter after each use and, if storing for a prolonged

period, drain down the fuel in the tank. Remove the spark plug

and put a few drops of oil into the cylinder before pulling the

starter a couple of times to distribute the oil evenly. Replace the

spark plug.

Page 4

MAJOR PARTS

1 Transport Handle 2 Ram Travel Adjusting Rod

3 Split Wedge 4 Ram

5 Control Levers Connection Bracket 6 Top Motor Shield

7Fuel Tank 8 Wheels

9 Base 10 Oil Tank Cover / Air Bleeder

11 Table Lock Down Hook 12 Support Table

13 Side Bracket, Support Table 14 Front Bracket, Support Table

15 Control Lever 16 Control Lever Guard

17 Adjustable Log Holder 18 Log Holder Adjusting Knob

Page 5

FUEL

SPECIFICATION

Model No THPLS7TP

Engine Briggs & Stratton I/C 65

Log Size Capacity Diameter = 12-32cm

Length = 104/78/52cm

Maximum Force 7 ton

Hydraulic Pressure 17.8 Mpa

Hydraulic Oil Capacity 6 litres

Ram Travel 475mm

Forward Speed 4.9cm/sec

Retract Speed 22.3cm/sec

Noise Pressure Level 88.1 dB(A) under no load

93.0 dB(A) under full load

Overall Sizes Length = 107cm

Width = 46cm

Height = 147cm

Weight 125kg

Fuel is highly ammable and its vapours can explode if ignited. Take precautions

when using to reduce the risk of injury or accident.

• When lling or draining the fuel tank, do so in a clean well-ventilated area.

• Do not smoke or allow sparks or ames to come anywhere near the log splitter.

• Keep tools away from live electrical parts and connections to avoid sparking or ignition.

• Always allow the engine to cool down before re-fuelling. Do not remove the fuel cap or

add fuel when the engine is hot.

• Fill the fuel tank with fresh unleaded petrol to no more than ½” below the bottom of the

ller neck to allow room for expansion.

• Wipe up any spilt fuel and ensure that fuel cap is tightened securely.

• Drain down any fuel in the tank if you are not going to use the log splitter for at least 6

weeks.

• Dispose of any unwanted fuel or oil in a responsible way - take to your local recycling

centre.

Page 6

ASSEMBLY

At least two people are required to unpack the log splitter package because of its weight.

Following the diagrams above, carefully unpack the log splitter, using B and C to support

package A.

You should have the following contents:

Log Splitter Frame; Control Lever and Guard Assembly; Removable Support Table; Owner’s

Manual.

Page 7

ASSEMBLY. cont’d

• Pull Spring Pin (A) to remove Lock Pin (B).

• Apply a thin coat of grease to both surfaces of the Control

Lever Guard as shown.

• Insert Control Lever and Guard Assembly and ensure that

the Control Lever End xes into the slot of the Connection

Bracket (C)

• Lock the Control Lever and Guard Assembly down with the

Lock Pin (B) and Spring Pin (A).

• Repeat on the other side.

• Three positions are available for the Support Table for

different splitting lengths.

• At every postion Lock Down Hooks (D) are tted to the

frame.

• Insert the Support Table in the required brackets (E).

• Turn the Lock Down Hooks (D) by 90 degrees to secure

the table.

Before starting the log splitter for the rst time you will need to

bleed the air out of the hydraulic system

The cover of the oil tank should be loosened until air can go in

and out of the oil tank freely. Airow through the oil tank ller

should be detectable during operation.

Failure to do this will keep the sealed air compressed in

the hydraulic system and continuous air compression

and decompression will blow the seals of the hydraulic

system and cause permanent damage.

Before moving the log splitter, make sure the oil tank cap is

tightened to avoid any leakage. There are two wheels to

facilitate moving. If using a crane to move the machine, lay

hoist around the housing, never the handle.

Page 8

Work safely and save effort by planning your work beforehand.

Position your logs so that they can be easily lifted onto the log

splitter and, either stack close by or load onto a truck/trolley as

soon as they are split.

Inspect your logs and do not attempt to split logs containing

nails, wire or debris which could damage the log splitter.

The splitter can accomodate logs up to 104cm in length.

When cutting up limbs or large sections do not cut longer than

100cm. Place the support table into the position nearest to the

log length - 52cm, 78cm or 104cm, and secure.

Before operation, apply a thin coat of grease to the surfaces

of the ram.

• Loosen the oil tank cover a few turns to allow air to move

freely as described above. Re-tighten when you have

nished splitting.

• Fill engine with SAE30 oil to the ‘full’ mark on the dipstick.

Check the level of the oil.

• Fill fuel tank with unleaded petrol.

• Start the engine - the wedge ram should rise to the highest

position automatically.

• If operating in low temperatures, allow the engine to run for

15mins to preheat the oil.

• Check the operation of both control levers by lowering so

that the splitting ram lowers to approx 5cm above the

highest table position. Release either lever and the splitting

wedge will stay in the same postion. Release both levers at

the same time and the splitting wedge will return to the

highest position.

To set the wedge ram stroke:

• Move splitting wedge to desired position. The upper position

of the ram wedge travel should be about 3-5cm over the

logs to be split.

• Turn off the engine.

• Release the Setscrew (A) with L key.Raise Adjusting Rod

(B) until resistance is felt by the spring inside. Tighten the

Setscrew.

• Release both control levers and start engine.

• Check the upper position of the splitting wedge.

Page 9

OPERATION, cont’d

To operate:

• Place log on support table vertically and sitting at. Do

not attempt to split a log at an angle and do not place the

log across the splitter - always split in the direction of the

grain.

• Adjust the Log Holders (A) to suit the diameter of the log.

• Hold the log with the clamping brackets closely in the

control lever guards.

• Lower levers to start splitting.

• Releasing either of the levers stops the motion. Releasing

both levers returns the splitting wedge to the upper

position.

Hints and Tips:

• Never attempt to load the log splitter whilst the ram is in

motion.

• Never try to split two logs at once.

• Keep your hands away from the splits and cracks which

appear whilst the log is being split.

• Do not remove jammed logs with your hands - stop the

engine and loosen the log by a downward stroke on the log

with a hammer.

• Do not force the tool and do not make alterations to the

log splitter as this could be dangerous and invalidate your

warranty.

• Do not try to split logs larger than recommended in the

specications table.

• After long periods of operation the splitting wedge may

need sharpening. Use a ne toothed le to remove burrs,

or at spots on the edge.

• Check the level of the hydraulic oil regularly using the

dipstick. In addition the oil should be changed once a

year.

Recommended oils are:

SHELL Tellus 22

MOBIL DTE 11

ARAL Vitam GF22

BP Energol HLP-HM 22

Page 10

PARTS DIAGRAM

WIRING DIAGRAM

Page 11

PARTS LIST

No Part No Description Qty No Part No Description Qty

1 TH107-1 Upright Tube Weld B&S 1 41 TH107-41 CCQ Cylinder 1

2 TH107-2 Pump Guard 1 42 TH107-42 Hex Bolt 2

3 TH107-3 Spring Washer 6 1 43 TH107-43 Lever Handle 2

4 TH107-4 Screw M6x12 1 44 TH107-44 Locknut M8 2

5 TH107-5 O Ring 23.6x3.55G 1 45 TH107-45 Pin D 1

6 TH107-6 Cap 1 46 TH107-46 Operating Handle 2

7 TH107-7 Washer 10 26 47 TH107-47 Thin Nut 6

8 TH107-8 Lockout Lever 6 48 TH107-48 Washer 8 14

9 TH107-9 Bolt M10x35 8 49 TH107-49 Control Link Plate 1

10 TH107-10 Clamping Fork (Right) 1 50 TH107-50 Nut 1

11 TH107-11 Right Guard Assy 1 51 TH107-51 Draw Rod Lock Cover 1

12 TH107-42 Knob M8x20 2 52 TH107-52 Supporting Ring 1

13 TH107-13 Fork 2 53 TH107-53 Draw Rod 1

14 TH107-14 Control Lever Shaft 2 54 TH107-54 Draw Sleeve Nut 1

15 TH107-15 Work Table 2 1 55 TH107-55 Thin Nut M16 1

16 TH107-16 Plastic Insert 4 1 56 TH107-56 Draw Sleeve 1

17 TH107-17 Plastic Insert 2 1 57 TH107-57 Hose Clamp 22-28 4

18 TH107-18 Plastic Insert 1 1 58 TH107-58 Bolt M6x30 1

19 TH107-19 Plastic Insert 3 1 59 TH107-59 CA Valve 1

20 TH107-20 Clamping Fork 1 (Left) 1 60 TH107-60 Wedge Bracket Weld B 1

21 TH107-21 Left Guard Assy 1 61 TH107-61 T Connector, Tape 1

22 TH107-22 Screw M6x10 6 62 TH107-62 Washer Groupware 20 12

23 TH107-23 Washer 6 6 63 TH107-63 Valve Tube Nozzle 1

24 TH107-24 Locknut M10 6 64 TH107-64 High Pressure Oil Hose 24 1

25 TH107-25 Wheel A 2 65 TH107-65 Valve Injection Nozzle 1

26 TH107-26 Circlip 16 2 66 TH107-66 Oil Return Pipe 1

27 TH107-27 Bolt M16x15 1 67 TH107-67 High Pressure Oil Hose 1

28 TH107-28 Washer Groupware 16 1 68 TH107-68 Nozzle 9/16-18-UNF-

2BXM20x1.5 1

29 TH107-29 Sliding Plate 4 69 TH107-69 Gear Pump 1

30 TH107-30 Knob 1 70 TH107-70 Orientation Ring 1

31 TH107-31 Wedge Bracket Round

Cover 2 71 TH107-71 Joining 1

32 TH107-32 Round Cover 1 72 TH107-72 Engine (B&S) 1

33 TH107-33 Square Cover 1 73 TH107-73 Bolt M8x35 4

34 TH107-34 Nut M20 3 74 TH107-74 Rubber Washer (UR) 1

35 TH107-35 High Pressure Oil Hose 24 1 75 TH107-75 Bolt M8x30 4

36 TH107-36 Spring Washer 8 6 76 TH107-76 Same Rev Joint CL090

12.7-20 1

37 TH107-37 Locknut M6 1 77 TH107-77 Orientation Screw 2

38 TH107-38 Bolt M8x25 2 78 TH107-78 Intake House 1

39 TH107-39 Circlip 22 4 79 TH107-79 Tie-in 20 1

40 TH107-40 Lock Shaft 1 80 TH107-80 Nozzle 3/4-16-UNF-

2BXM20x1.5 1

Page 12

EC DECLARATION OF CONFORMITY

Declaration of Conformity

Pursuant to the regulations of the following EC Directives:

- Machinery Directive 98/37/EC

Handy Distribution Ltd hereby declares that the product:

Machine Type: Log Splitter

Machine Model: THPLS7TP

Conforms to the main safety requirements of the EC Directives listed above.

This conformity is based on the following standards and normative documents:

- 98/37/EC - ANNEX I

- EN609-1:1999+A1

The responsible person, based within the EC, is identied below

Name: Mr Simon Belcher

Title: Managing Director

Company: Handy Distribution Ltd

Address: Hobley Drive, Stratton St Margaret, SWINDON, SN3 4NS

Signature: Date: 15th Nov 2008

Page 13

To order spare parts and see the complete range of garden

machinery and garden equipment from Handy, visit:

www.thehandy.co.uk

Other manuals for THPLS7TP

1

Table of contents

Other The Handy Log Splitter manuals

The Handy

The Handy THLS-4 Installation and maintenance instructions

The Handy

The Handy THLS-6G User manual

The Handy

The Handy THLS-6-PLUS User manual

The Handy

The Handy THPLS7TP User manual

The Handy

The Handy THLSS-B Installation and maintenance instructions

The Handy

The Handy THLSV7 User manual

The Handy

The Handy THLS-TABLE User manual

The Handy

The Handy THFLS User manual

The Handy

The Handy THLSV6 User manual

The Handy

The Handy THLS-C Installation and maintenance instructions