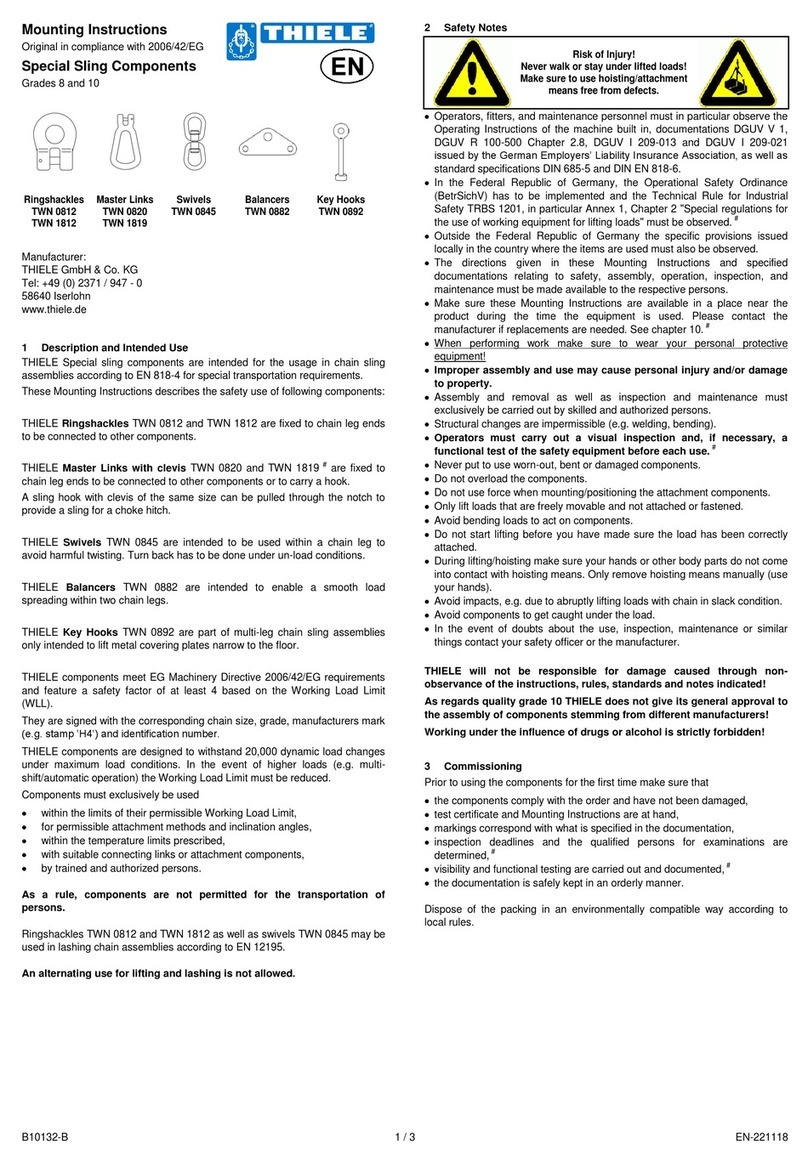

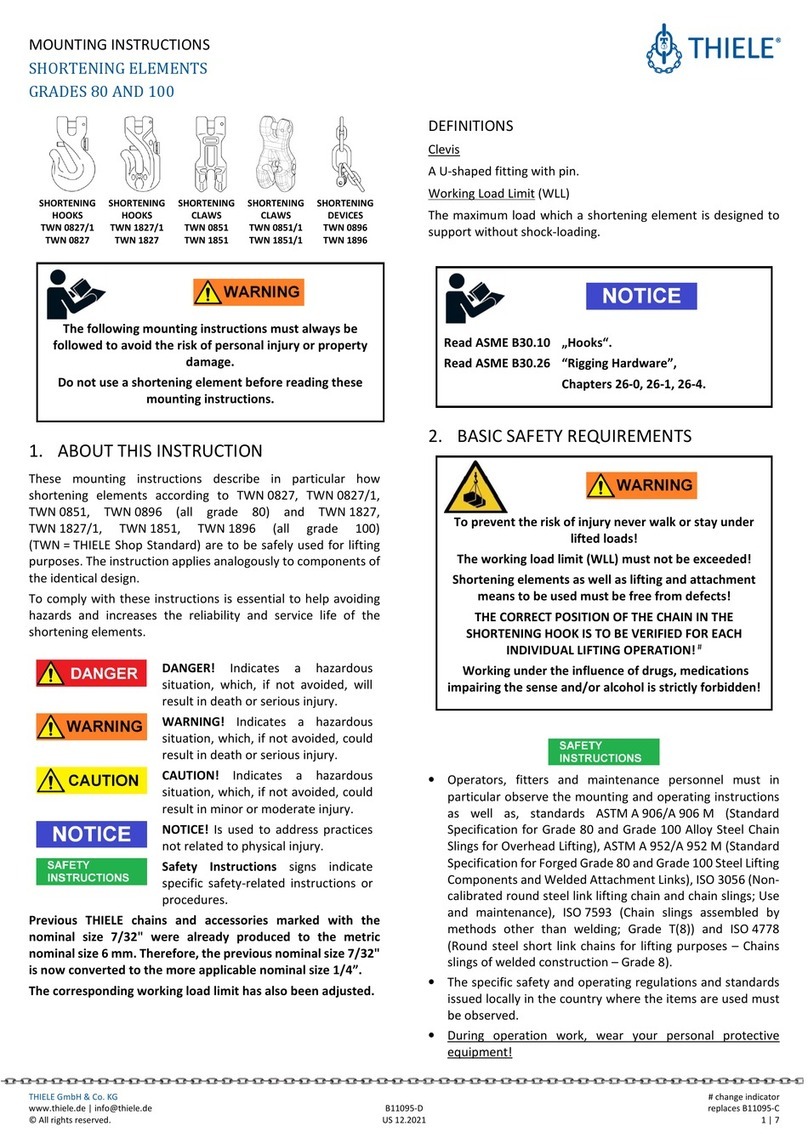

Thiele GRADES 8 User manual

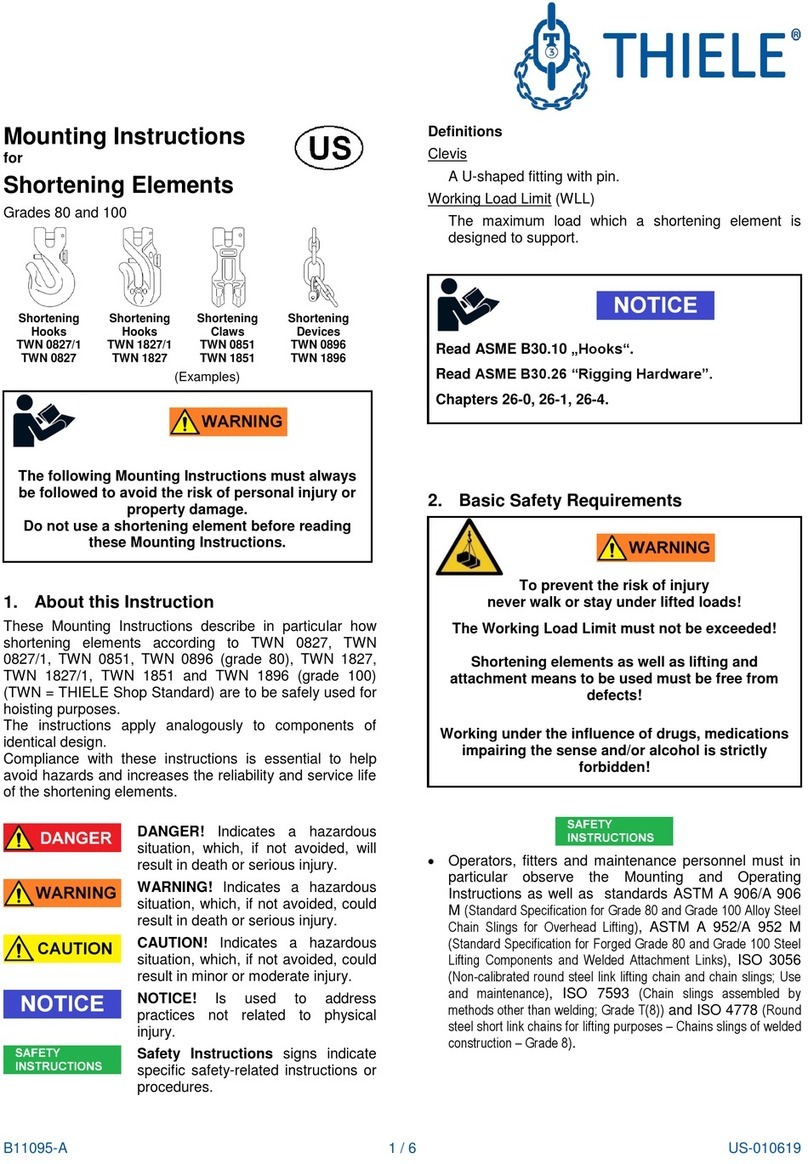

MOUNTING INSTRUCTIONS

SKIP HOOKS

GRADES 8, 10 AND 12

THIELE GmbH & Co. KG # Change indicator

www.thiele.de | info@thiele.de B11 20-A Replacement for -

© All rights reserved. EN 11.2021 1 | 3

Original in compliance with 2006/42/EC

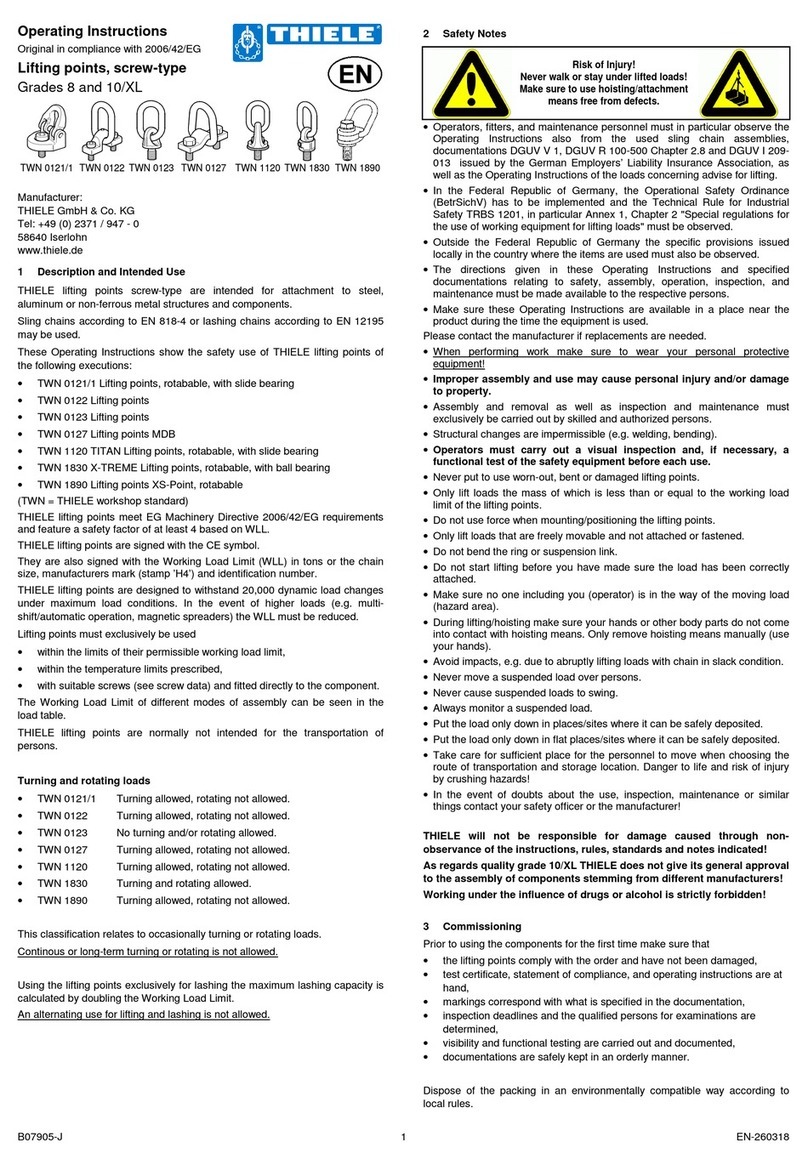

1DESCRIPTION AND INTENDED USE

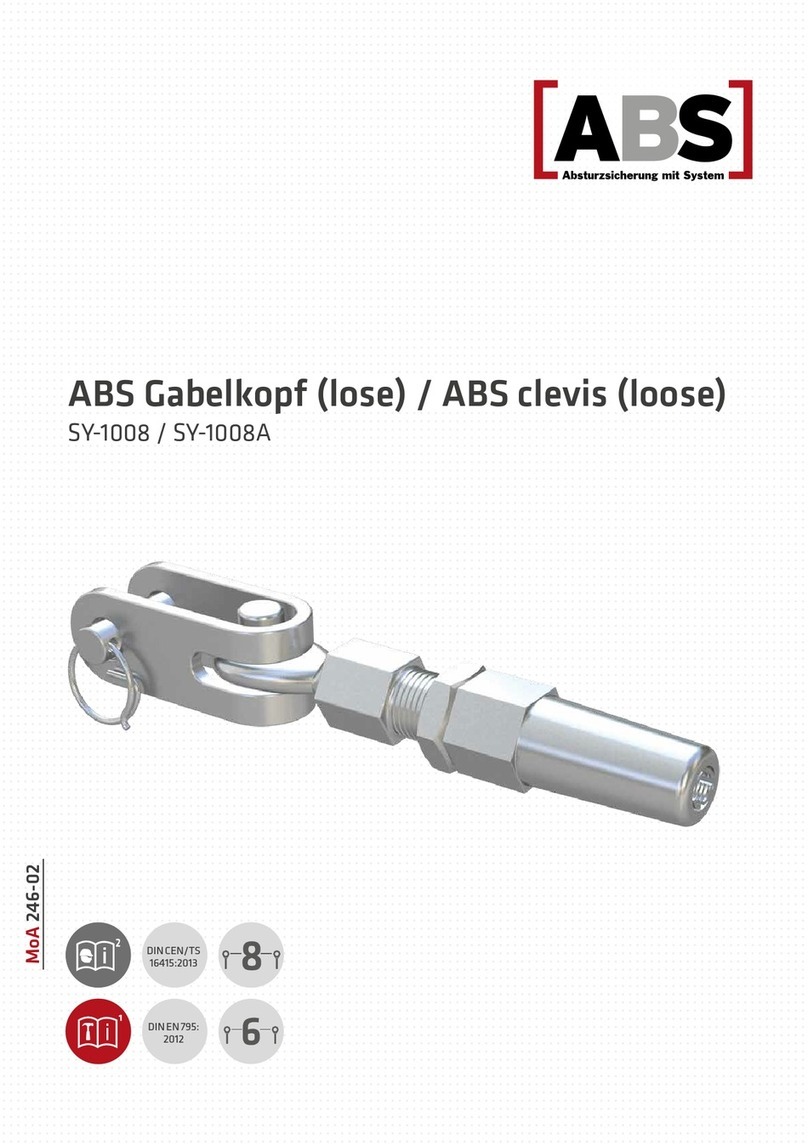

THIELE skip hooks with clevis are exclusively intended as end

fittings of permanently mounted sling chain assemblies on skip

loader vehicles for the attachment of corresponding containers

according to DIN 30720 or similar. In this case, every skip hook

embraces a corresponding container suspension pin.

THIELE skip hooks are designed as self-locking hooks based on

EN 1677-3, which lock automatically when loaded. The hook

opening is smaller than the contour of the securing collar at the

end of the suspension pin. This means that a skip hook cannot

slip off the suspension pin when it is locked.

The integrated clevis is used to attach a chain strand.

The following types are defined by the grade of the associated

chain (TWN = THIELE shop standard):

•Grade 8: TWN 13

•Grade 10: TWN 18

•Grade 12: TWN 24

Skip hooks may only be used:

•within the permissible working load limits,

•within the permissible temperature limits,

•by instructed and authorized persons.

THIELE skip hooks comply with the EC Machinery Directive and have an operating

coefficient of at least 4 in relation to the working load limit.

The skip hooks are marked with the nominal chain size and grade (NG = Nominal size),

manufacturer's mark and traceability code.

THIELE skip hooks are designed to withstand 20 000 dynamic load changes under

maximum load conditions. In the event of higher loads the working load limit must be

reduced.

The skip hooks are powder-coated in colour depending on the grade.

The skip hooks must not be used for transportation of persons or lashing.

2SAFETY NOTES

Risk of Injury!

Never walk or stay under lifted loads!

Make sure to use hoisting/

attachment means free from defects!

•Operators, fitters, and maintenance personnel must in particular observe the

operating instructions of the sling chain assemblies and loads to which the skip hooks

are mounted, documentations DGUV V 1, DGUV R 10 -017, DGUV I 20 -013 and

DGUV I 20 -021 issued by the German Employers’ Liability Insurance Association, as

well as standard specifications EN 818-6.

•In the Federal Republic of Germany, the operational safety ordinance (BetrSichV) has

to be implemented and the technical rule for industrial safety TRBS 1201, in

particular Annex 1, Chapter 2 "Special regulations for the use of working equipment

for lifting loads" must be observed.

•Outside the Federal Republic of Germany, the specific provisions issued locally in the

country where the items are used must also be observed.

•The directions given in these mounting instructions and specified documentations

relating to safety, assembly, operation, inspection, and maintenance must be made

available to the respective persons.

•Make sure these mounting instructions are available in a place near the product

during the time the equipment is used. Please contact the manufacturer if

replacements are needed. See also Chapter 10.

•When performing work make sure to wear your personal protective equipment!

•Improper assembly and use may cause personal injury and/or damage to property.

•Assembly and removal as well as inspection and maintenance must exclusively be

carried out by skilled and authorized persons.

•Structural changes (e.g. welding, bending) are impermissible. Never attempt to make

the opening of the skip hooks smaller by bending or welding in intermediate

elements.

•perators must carry out a visual inspection and, if necessary, a functional test of

the safety equipment before each use.

•Only fit sling chains of the same nominal size (nominal chain diameter - grade).

•Operation without a functioning safety lever is not permitted.

•Never put to use worn-out, bent or damaged skip hooks.

•Do not overload skip hooks or chains. Be sure to observe the working load limit of

the overall vehicle system.

•Do not use force when mounting/positioning the skip hooks.

•Self-locking hooks may only be put under load at the bottom of the hook and not at

the tip of the hook. Clamping of the load at the tip of the hook between the upper

and lower part is not permitted.

•Make sure the load can take the forces to be applied without suffering deformation.

•Lateral loads are not permitted due to the design. Skip hooks must be able to align

themselves in the direction of loading.

•Avoid sharp edges.

•Only lift loads that are freely movable and not attached or fastened.

•Do not start lifting before you have made sure the skip hooks are locked and the load

has been correctly attached.

•Make sure no one including you (operator) is in the way of the moving load (hazard

area).

•During lifting/hoisting make sure your hands or other body parts do not come into

contact with hoisting means. Only remove skip hooks manually (use your hands).

•Make sure that the sling chains are not twisted.

•Avoid impacts, e.g. due to abruptly lifting loads with hoisting means in slack

condition.

•Never move a suspended load over persons.

•Never cause suspended loads to swing.

•Always monitor a suspended load.

•Put the load only down in flat places/sites where it can be safely deposited.

•Take care for sufficient place for the personnel to move when choosing the route of

transportation and storage location. Danger to life and risk of injury by crushing

hazards.

•In the event of doubts about the use, inspection, maintenance or similar things

contact your safety officer or the manufacturer!

THIELE will not be responsible for damage caused through non-observance of the

instructions, rules, standards and notes indicated!

As regards grades 10 and 12 THIELE does not give its general approval to the assembly

of components stemming from different manufacturers!

Working under the influence of drugs, medications impairing the sense and/or

alcohol (including residual alcohol) is strictly forbidden!

3COMMISSIONING

Prior to using the components for the first time make sure that

•the components comply with the order and have not been damaged,

•test certificate and mounting instructions are at hand,

•markings correspond with what is specified in the documentation,

•inspection deadlines and the qualified persons for examinations are determined,

•visibility and functional testing are carried out and documented,

•documentations are safely kept in an orderly manner.

Dispose of the packing in an environmentally compatible way according to local rules.

MOUNTING INSTRUCTIONS

SKIP HOOKS

GRADES 8, 10 AND 12

THIELE GmbH & Co. KG # Change indicator

www.thiele.de | info@thiele.de B11 20-A Replacement for -

© All rights reserved. EN 11.2021 2 | 3

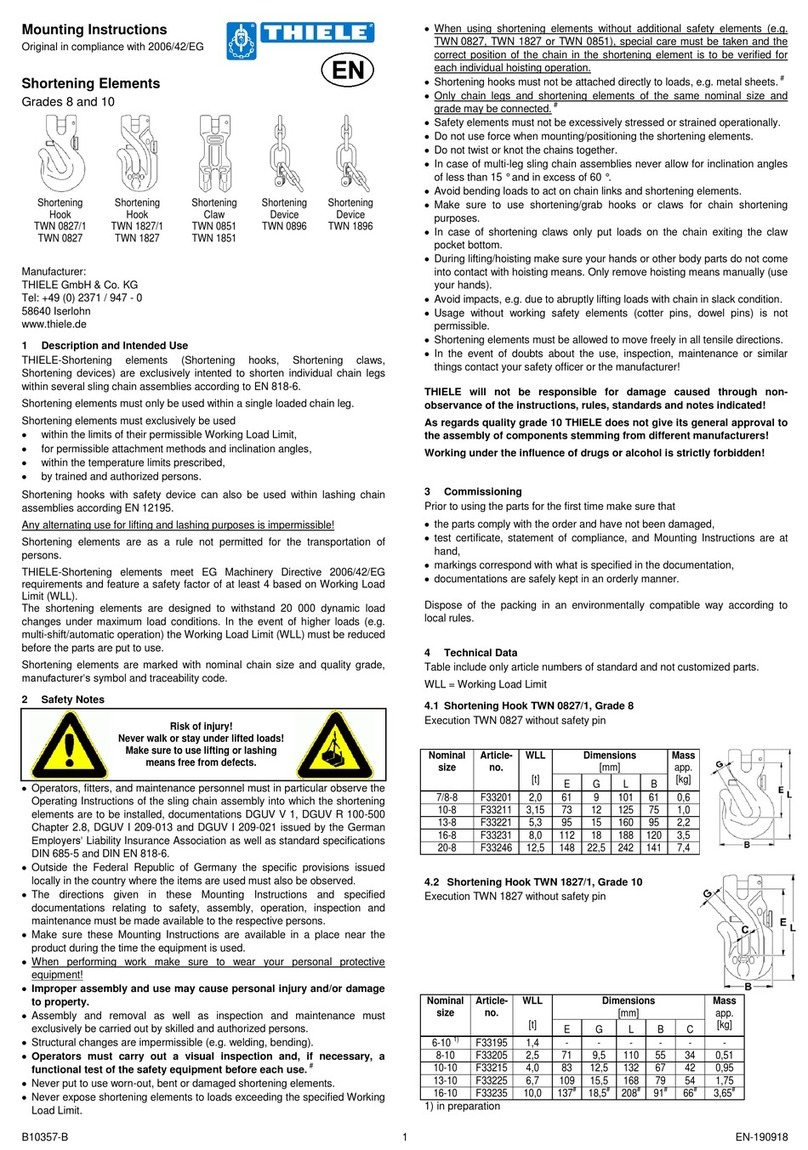

4TECHNICAL DATA

5ASSEMBLY AND REMOVAL

General

Allways assemble/remove skip hooks in load-free condition!

Disassemble the parts in reverse order.

Use a suitable drift punch to drive the dowel pins out.

Suitable drift punches are available by Article No. Z03303.

Dowel pins must only be installed once.

A embly of clevi y tem

1. Remove load bolt and dowel pin.

2. Place end of chain leg between the lateral clevis

elements.

3. Push pin from the side fully into the clevis and

through the last chain link of the leg.

4. Drive dowel pin fully in (must not project) to

secure the pin. The slot must face away from

the pin.

5. Check the chain can move freely.

A embly of afety y tem (only for replacement)

1. Position the safety lever with the leg spring in the closed position of the hook and

insert an auxiliary bolt (Ø < 8 mm, length > 50 mm) laterally into the holes for the

two dowel pins and the safety lever as well as through the spring coils.

2. First drive in the dowel pin 8 x 40 instead of the auxiliary bolt.

3. If the safety lever is then difficult to move, remove the dowel pin and knock it in

again in the reversed position.

4. Then drive the dowel pin 5 x 40 into the already mounted dowel pin, making sure

that the slots of the two dowel pins are opposite each other.

5. Check several times that the safety lever takes its locking position smoothly after

opening and closing the hook and that the hook cannot be opened.

6OPERATION

Normal u e

To place the skip hook on the suspension pin, press the safety lever down by hand

(preferably with the thumb), open the hook and slide the lower hook body over the

suspension pin. If the upper and lower parts of the hook are opened as far as they will

go, this position is held by spring force.

As soon as the lower hook body is correctly positioned, the hook is to be closed by a

turning movement, if necessary against the holding force of the spring of the upper

part.

Check that the skip hook is locked.

Due to the free length of the chain, the unloaded skip hooks rotate around the pins

away from the later loading direction due to their own weight.

When lifting the load, it must therefore be ensured that ALL skip hooks can align

themselves freely in their direction of loading and that the force is applied in the

longitudinal direction. Supporting on other components is not permitted. Make sure

that the possible swivelling movement does not cause the chain to twist in itself

under load.

The skip hooks must always be able to move freely on the suspension pins. Avoid any

bending stress on the skip hooks.

Temperature range

The temperature range of use depends on the grade according to the following table:

Type Grade Temperature range

TWN 13 8 -40 °C ≤ t ≤ 200 °C

TWN 18 10 -30 °C ≤ t ≤ 200 °C

TWN 24 12 -30 °C ≤ t ≤ 200 °C

After the skip hooks have heated up above the max. operating temperature, they may

no longer be put into operation.

Environmental influence

Skip hooks must not be used in environments where acids, aggressive or corrosive

chemicals or their fumes are present.

Hot-dip galvanizing or a galvanic treatment is prohibited as well.

Type

Nominal

size

(NG)

Article

no.

Working

load limit

1)

[t]

Dim.

E

[mm]

Colour Mass

[kg]

TWN 13 13-8 F335000 5,3 167 Rubinrot

3,35

TWN 13 16-8 F335300 8,0 165 Rubinrot

TWN 18 13-10 F335100 6,7 166 Ultramarinblau

TWN 24 13-12 F335200 8,0 165 Nachtblau

1) bserve the working load limit of the overall vehicle system!

1.

2.

3.

MOUNTING INSTRUCTIONS

SKIP HOOKS

GRADES 8, 10 AND 12

THIELE GmbH & Co. KG # Change indicator

www.thiele.de | info@thiele.de B11 20-A Replacement for -

© All rights reserved. EN 11.2021 3 | 3

7SPARE PARTS

Only use original THIELE spare parts.

Before installing spare parts, check that there is no further damage that would justify

taking the unit out of service!

Type

Nominal

size

(NG)

Spare part sets

Spare part set

Pin for clevis +

dowel pin

Safety lever + spring +

dowel pin

TWN 13 13-8 F480131

F48332

TWN 13 16-8 F480161

TWN 18 13-10 F486741

TWN 24 13-12 F3138411

8INSPECTIONS, MAINTENANCE, DISPOSAL

General

Inspections and maintenance must be arranged for by the Owner!

Inspection intervals shall be determined by the Owner!

Inspections must be carried out and documented by competent persons regularly but

at least once a year, or more frequently if the skip hooks are used in heavy-duty service.

After three years at the latest they must additionally be examined for cracks. A load

test shall never be considered a substitute for this examination.

The results of the inspection shall be entered into a register (DGUV I 20 -062 or

DGUV I 20 -063) to be prepared at first use. The register will show characteristic data

as well as identity details.

Immediately stop using skip hooks that show the following defects:

•missing or illegible identification/marking,

•deformation, elongation or fractures,

•cuts, notches, cracks, incipient cracks, pinching,

•damaged parts (spring, pin, dowel pins),

•gap between upper and lower part too large,

•restricted freedom of movement between the upper and lower parts or the safety

lever,

•heating beyond permissible limits,

•severe corrosion,

•strong partial material removal,

•impaired or missing safety latch.

Cleaning (e.g. prior to inspections) must not take place by using flames or methods that

might cause hydrogen embrittlement (e.g. pickling or immersion in acidic solutions).

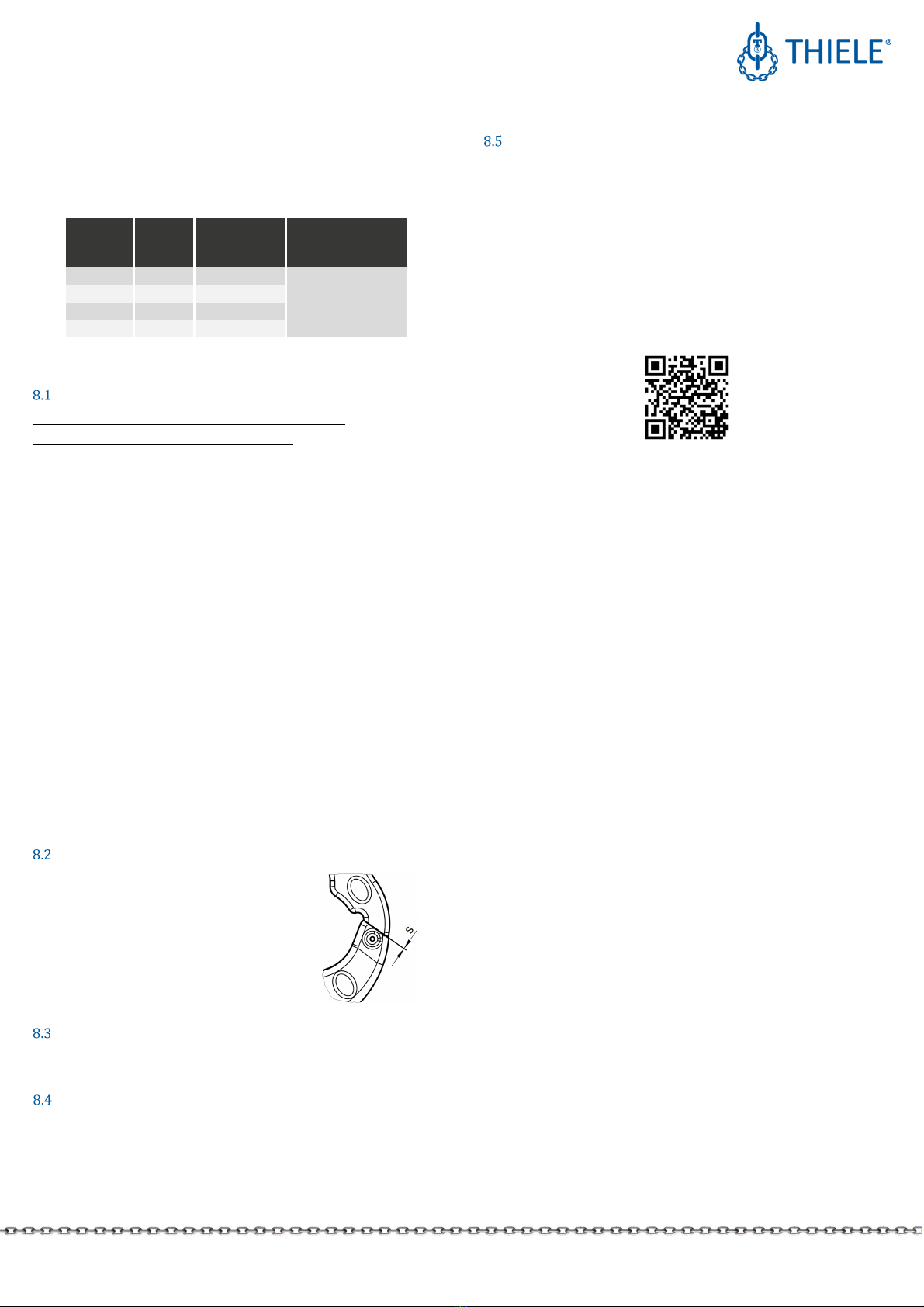

Gap at the hook tip

When locked, the gap between the lower and upper part

of the hook (dimension s) must not exceed 1,5 mm.

A larger gap dimension indicates an overload.

Skip hooks with a too large gap dimension may no longer

be used.

Structural modifications to reduce the gap dimension are

not permitted.

In pection ervice

THIELE offers inspection, maintenance and repair services by trained and competent

personnel.

Maintenace

Maintenance work may only be carried out by qualified persons.

Minor notches and cracks may be eliminated by careful grinding observing the

maximum cross section reduction requirement of 10 % and avoid making more severe

cuts or scores.

All maintenance and repair activities are to be documented.

Di po al

Dispose of worn-out steel components and accessories for scrapping in accordance

with local regulations.

STORAGE

Skip hooks are to be stored in dry locations at temperatures ranging between

0 and +40 °C.

10 THIELE OPERATING AND MOUNTING INSTRUCTIONS

Current operating and mounting instructions are available as a PDF download on the

homepage.

11 IMPRINT

THIELE GmbH & Co. KG

Werkstrasse 3

58640 Iserlohn, Germany

Tel.: +4 (0)2371/ 47-0

This manual suits for next models

2

Other Thiele Safety Equipment manuals

Thiele

Thiele TWN 0868 User manual

Thiele

Thiele TWN 0827/1 User manual

Thiele

Thiele TWN 0798 User manual

Thiele

Thiele TWN 0121/1 User manual

Thiele

Thiele Grade 100 User manual

Thiele

Thiele TWN 0850/2 User manual

Thiele

Thiele Grade 80 User manual

Thiele

Thiele Streamfeeder Pro Series User manual

Thiele

Thiele TWN 0827/1 User manual

Thiele

Thiele TWN 0827/1 User manual