•Assembly and removal as well as inspections and

maintenance must exclusively be carried out by skilled,

qualified, trained and authorized persons only.

•Structuralchanges are impermissible (e.g. welding,bending).

•Operators must carry out a visual inspection and, if

necessary,a functional test ofthe safetyequipment before

each use.

•Never use worn-out,bentor damaged liftingpoints.

•Only lift loads that do not exceed the Working Load Limit of

the lifting points screwtype.

•In case of using a 3-or 4-leg chain slingassembly never allow

for inclination angles of less than 30°and in excess of 75°.

•Do notuse force when mounting/positioning the attachment

components.

•The load must resist and tolerate the forces to be applied

withoutsuffering deformation.

•Only lift loads that are freely movable and not attached or

fastened.

•Do not bend the ring.

•Never install more than one connecting componentto a ring.

•Do not start lifting before you have made sure the load has

been correctly attached and balanced.

•No one including you (operator) must be in the way of the

moving load (hazard area).

•During liftingyour hands or other bodyparts mustnotcome

into contact with lifting means. Only remove lifting means

manually (use your hands).

•Avoid impacts,e.g.due to abruptlylifting loads with chain in

slack condition.

•Never move a suspendedload overpersons.

•Never causesuspendedloads to swing.

•Always monitor a suspendedload.

•Put the load only down in flat places/sites where it can be

safely deposited.

•Assume for sufficient place for the personnel to move when

choosing the route of transportation and storage location.

Danger to life and risk of injury by crushinghazards!

•In the eventof doubts or concerns about the properand safe

use, inspection, maintenance or similar things contact your

safety officer orthe manufacturer.

THIELEis not responsible fordamage caused bynon-observance

of the instructions,rules,standards and notes indicated!

Asa rule, liftingpointsare not permittedfor thetransportation

of persons.

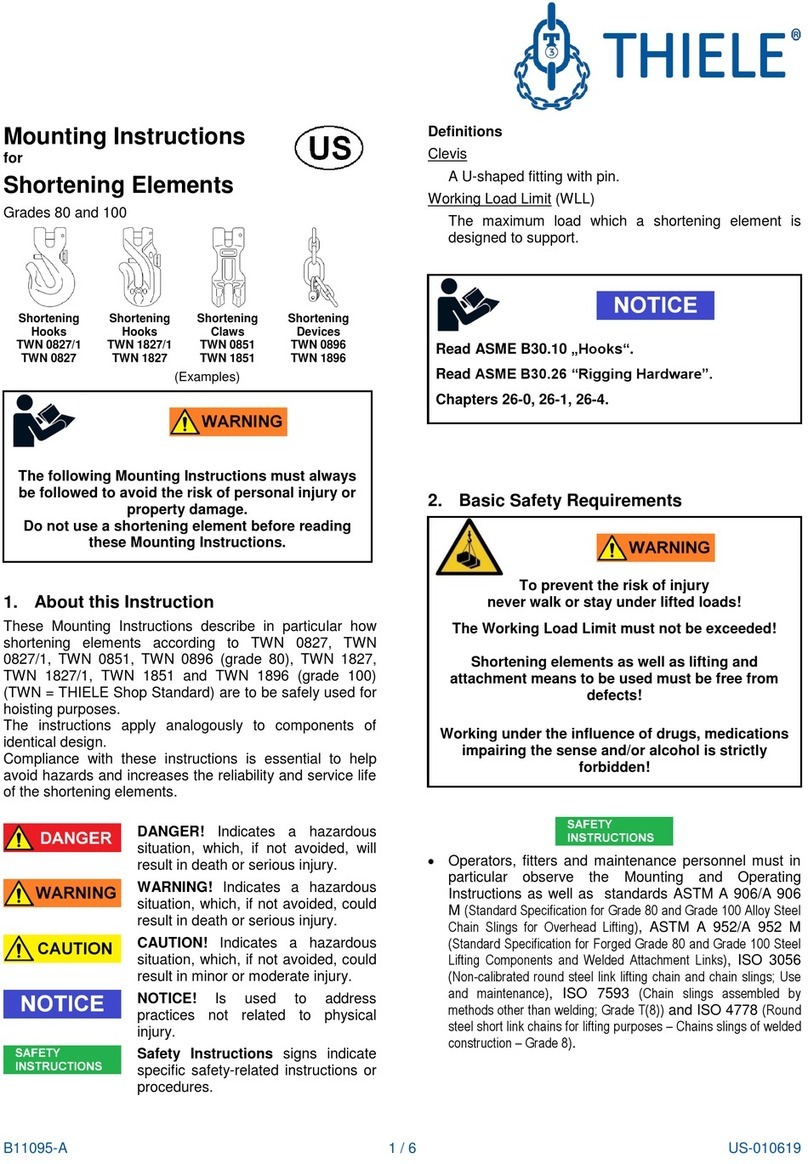

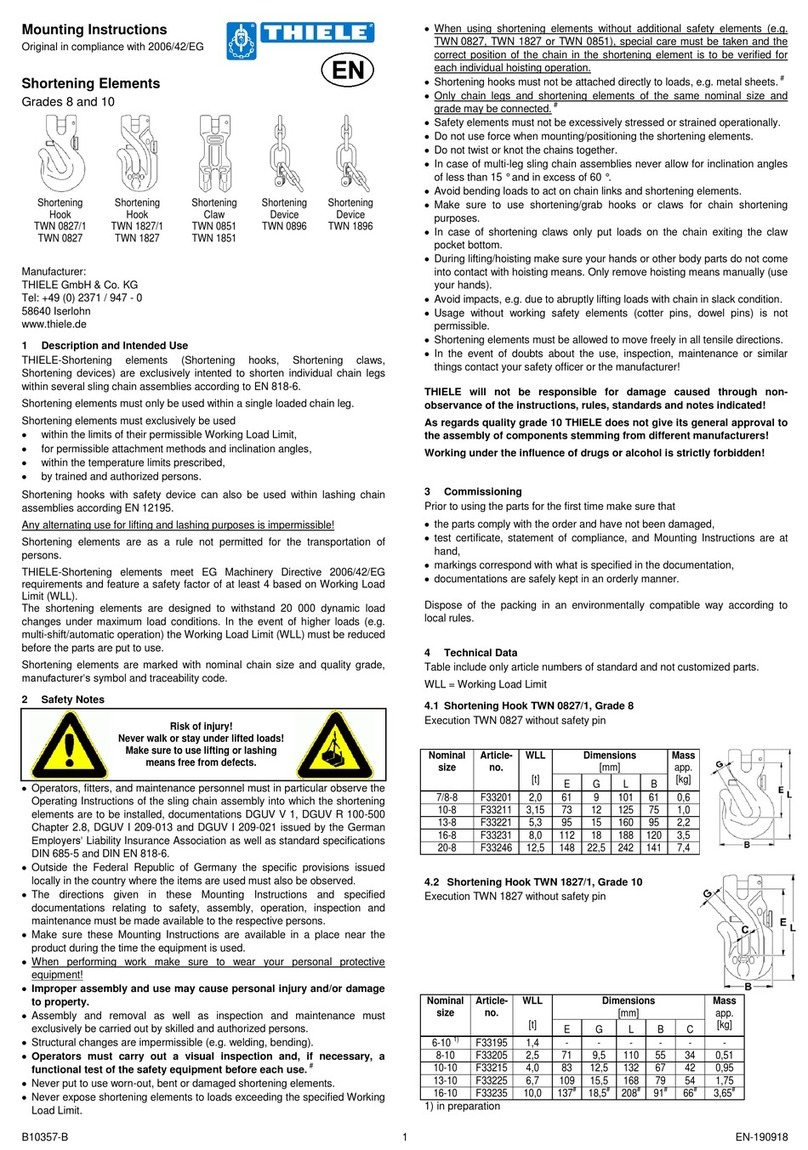

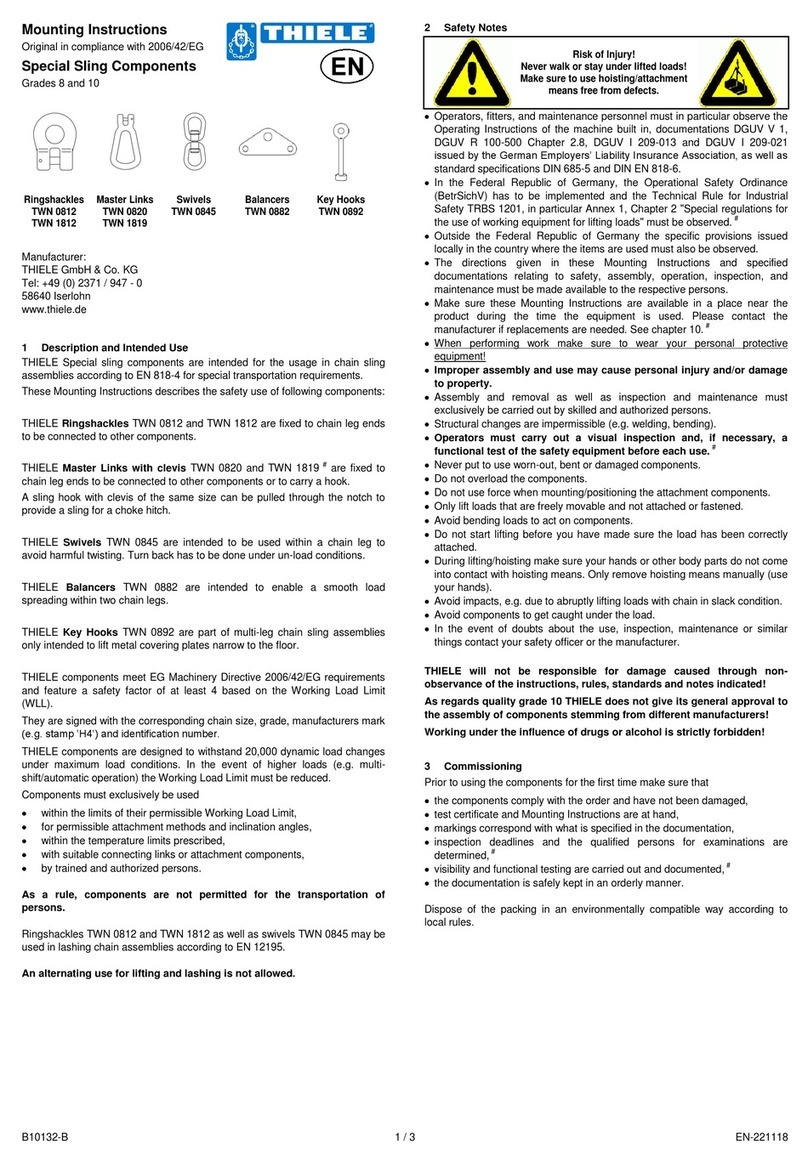

3. DESCRIPTIONAND INTENDED USE

THIELE lifting points screw-type are exclusively intended for

attachment to steel, aluminum or non-ferrous metal structures

and components.

Sling chains according to ASTM A 906/A906M may be used.

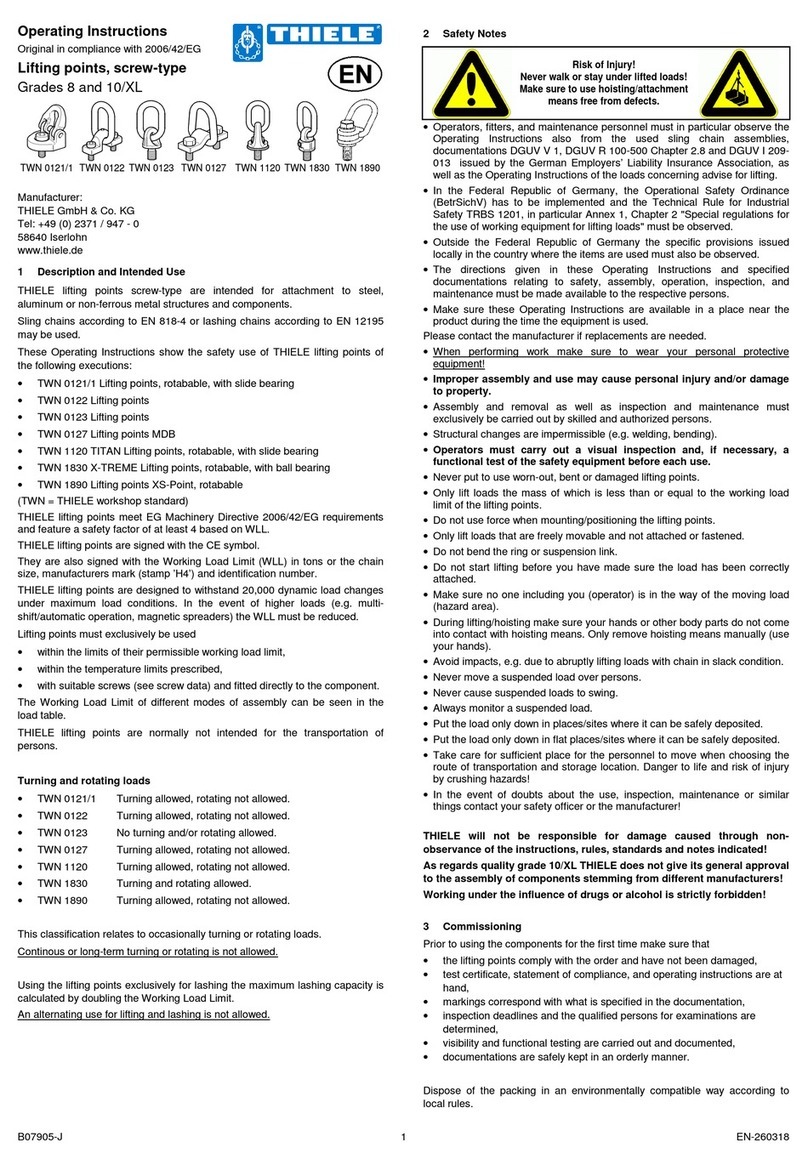

These Operating Instructions showthe safety use of THIELE lifting

points of the following executions:

•TWN0121/1 Liftingpoints,rotatable,with slide bearing

•TWN0122 Liftingpoints

•TWN0123 Liftingpoints

•TWN 0127 Lifting points MDB

•TWN1120 TITANLifting points,rotatable, with slidebearing

•TWN1830 X-TREME Lifting points, rotatable,with ball bearing

•TWN1884 KE-Eyebolt,with ball bearing

•TWN 1890 Lifting points XS-Point, rotatable

THIELE lifting points meet EG Machinery Directive 2006/42/EG

requirements and feature a safety factor of at least 4 based on

Working LoadLimit.

They are signed with the Working Load Limit in tons or the

nominal chain size, manufacturer’s mark and traceability code.

TWN 1830 are additionally marked on the bottom part with the

date of manufacture in the form "mm.yy" (mm = month, yy =

year).Example:"1220" = production in December 2020 #

THIELE lifting points are designed to withstand 20,000 dynamic

load changes under maximum load conditions. In the event of

higher loads (e.g. multi-shift/automatic operation) the Working

Load Limitmustbe reduced.

Lifting points must exclusively beused

•within the limits of their permissible WorkingLoad Limit,

•within the temperature limits prescribed,

•with suitable screwsand fitted directlyto the component,

•by trained and authorizedpersons.

Using the lifting points exclusively for lashing the lashing

capacity iscalculated by doublingthe Working LoadLimit.

An alternatinguse forlifting and lashingis not allowed.