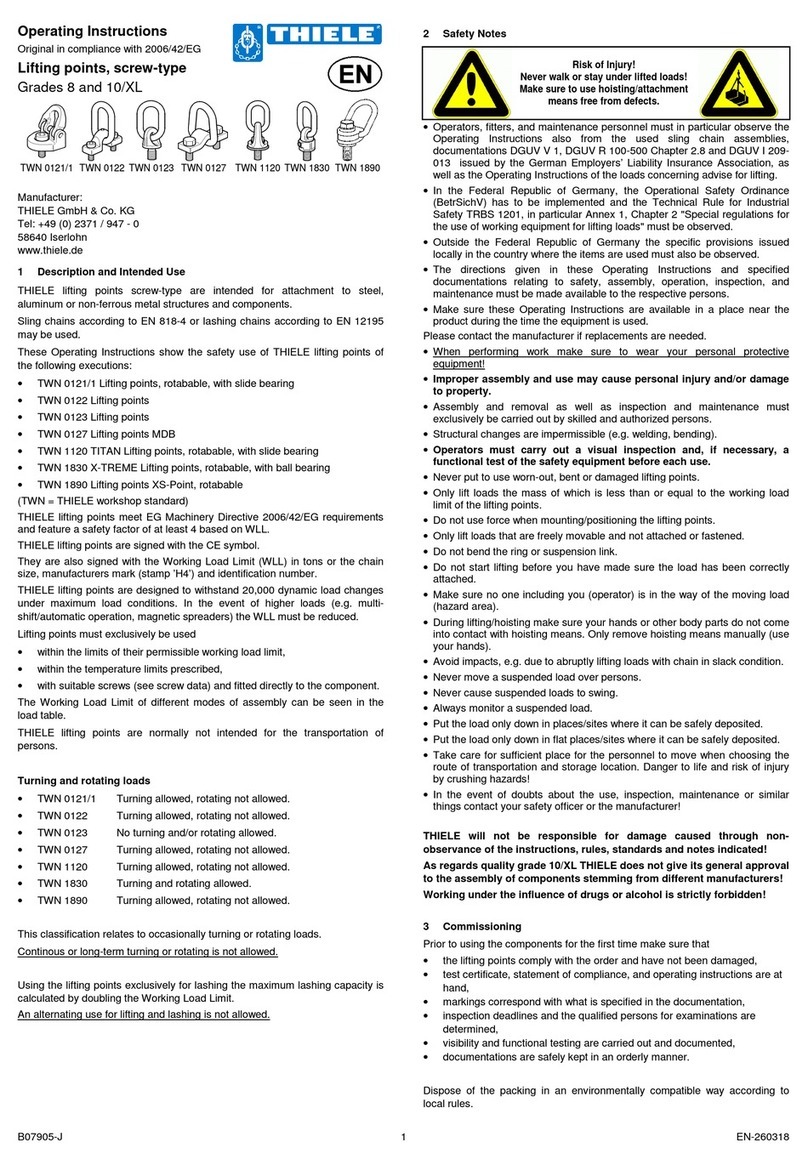

OPERATING INSTRUCTIONS

RAPID SHORTENING CLAWS

GRADE 100

THIELE GmbH & Co. KG # change indicator

www.thiele.de | info@thiele.de 11086- replaces 11086-A

© All rights reserved US 03.2022 2 | 5

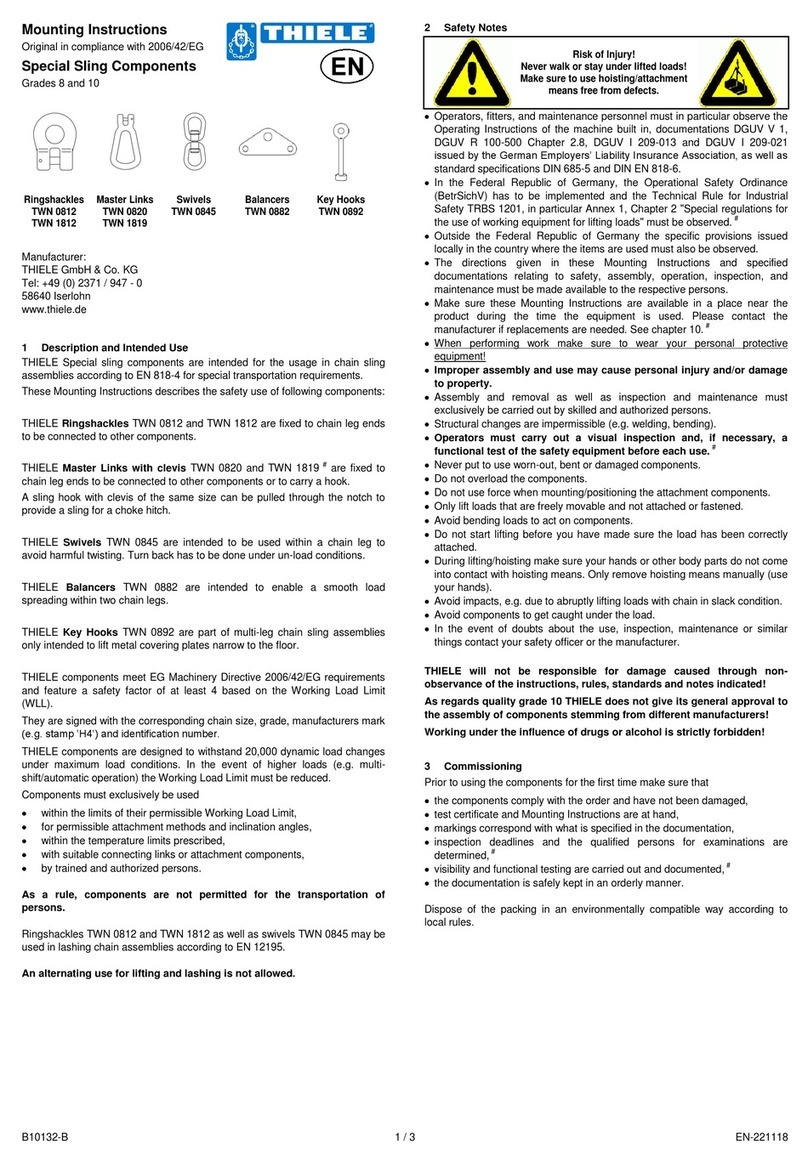

•These operating instructions must be available in a place

near the product during the time the equipment is used.

Please contact the manufacturer if replacements are

needed. Also see chapter 11.

•During operation work, wear your personal protective

equipment!

•Improper assembly and use may cause personal in ury

and/or damage to property.

•Assembly and removal as well as inspections and

maintenance must exclusively be carried out by skilled,

qualified, trained and authorized persons only.

•Structural changes are impermissible (e.g. welding,

bending).

•Operators must carry out a visual inspection and, if

necessary, a functional test of the safety equipment

before each use.

•Never use worn-out, bent or damaged shortening claws.

•Only lift loads that do not exceed the working load limit of

the sling chain assembly.

•Never expose chains and claws to loads exceeding the

specified working load limits.

•Do not use force when mounting/positioning the

attachment components.

•Do not twist or knot the chains together.

•Never guide shortening claws over edges or load them

sideways.

•Avoid sharp edges. Use edge protectors or reduce the

working load limit by 20 %.

•In case of multi-leg sling chain assemblies never allow for

sling angles of less than 30 ° and in excess of 75 °.

•Avoid bending loads to act on shortening claws.

•Do not start lifting before you have made sure the load has

been correctly attached.

•Make sure no one including you (operator) is in the way of

the moving load (hazard area).

•During lifting make sure your hands or other body parts do

not come into contact with lifting means. Only remove

lifting means manually (use your hands).

•Avoid impacts, e.g. due to abruptly lifting loads with chain

in slack condition.

•Never move a suspended load over persons.

•Never cause suspended loads to swing.

•Always monitor a suspended load.

•Put the load only down in flat places/sites where it can be

safely deposited.

•Avoid parts of the sling chain assembly to get caught under

the load.

•Operation without functioning safety devices (dowel pins,

springs, safety latches) is not permitted.

•The shortened part of the chain legs must not be loaded

and not used as an endless chain.

•Shortening claws must be able to align themselves freely in

the loading direction.

•Take care for sufficient place for the personnel to move

when choosing the route of transportation and storage

location. Danger to life and risk of injury by crushing

hazards!

•In the event of doubts or concerns about the proper and

safe use, inspection, maintenance or similar things contact

your safety officer or the manufacturer.

THIELE is not responsible for damage caused by non-

observance of the instructions, rules, standards and notes

indicated!

As regard grade 100, THIELE does not give its approval to the

assembly of components sourced from different

manufacturers!

As a rule, RAPID shortening claws are not permitted for the

transportation of persons.

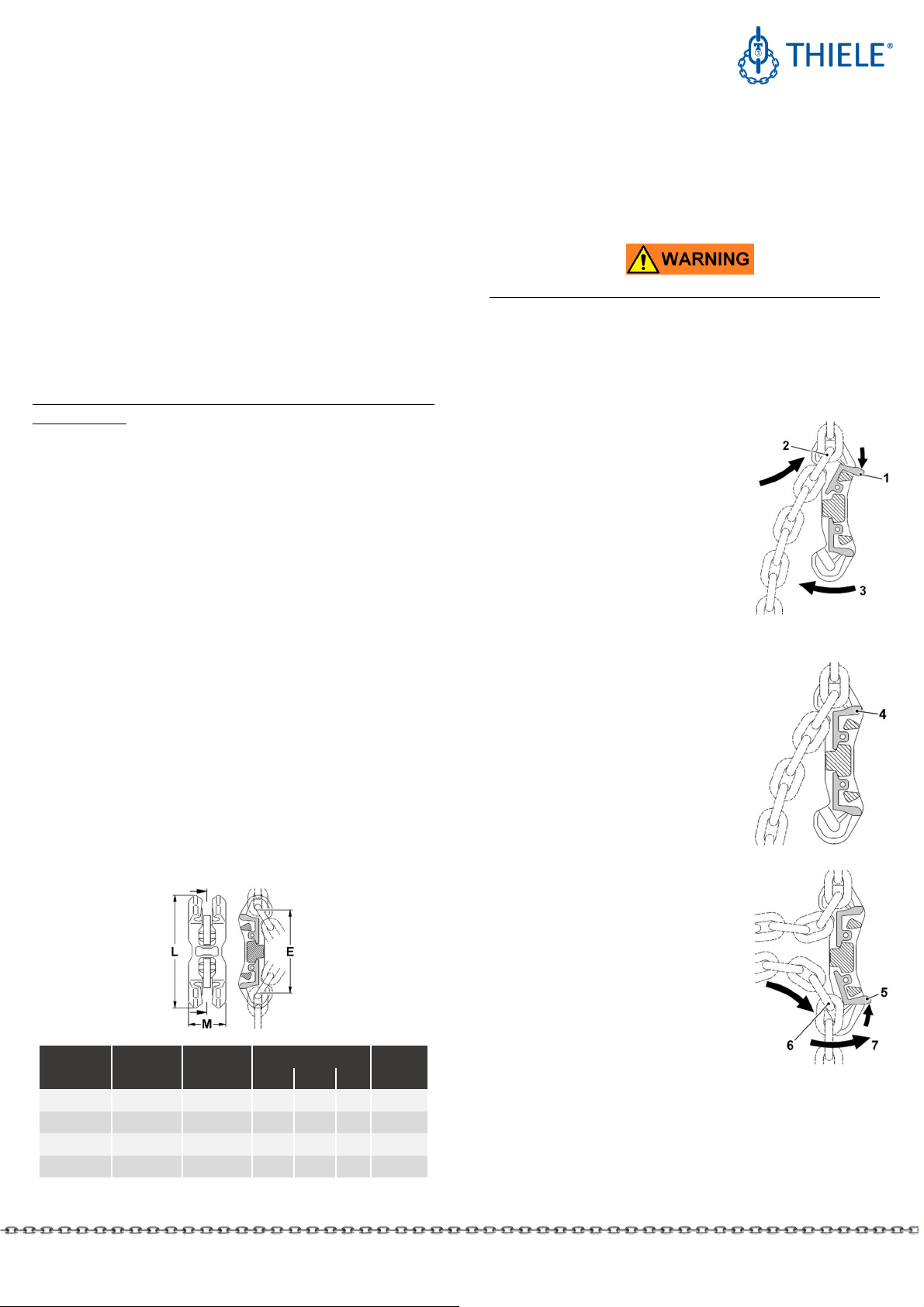

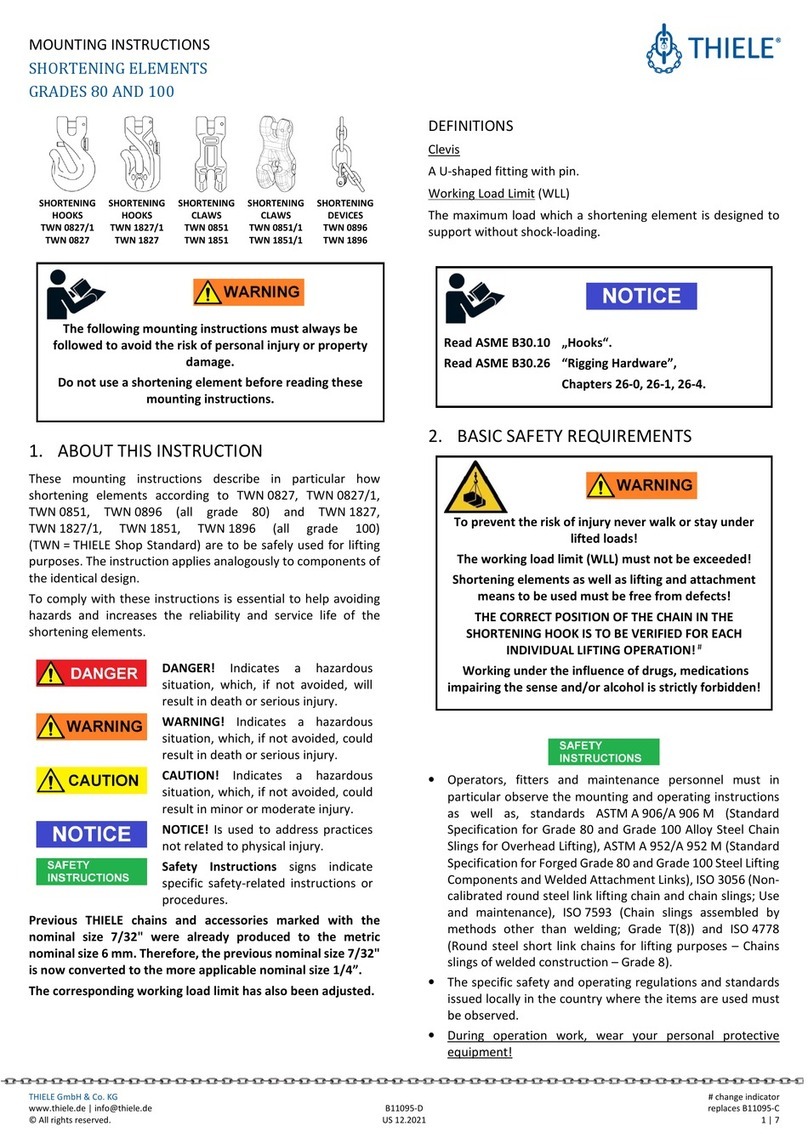

3. DESCRIPTION AND INTENDED USE

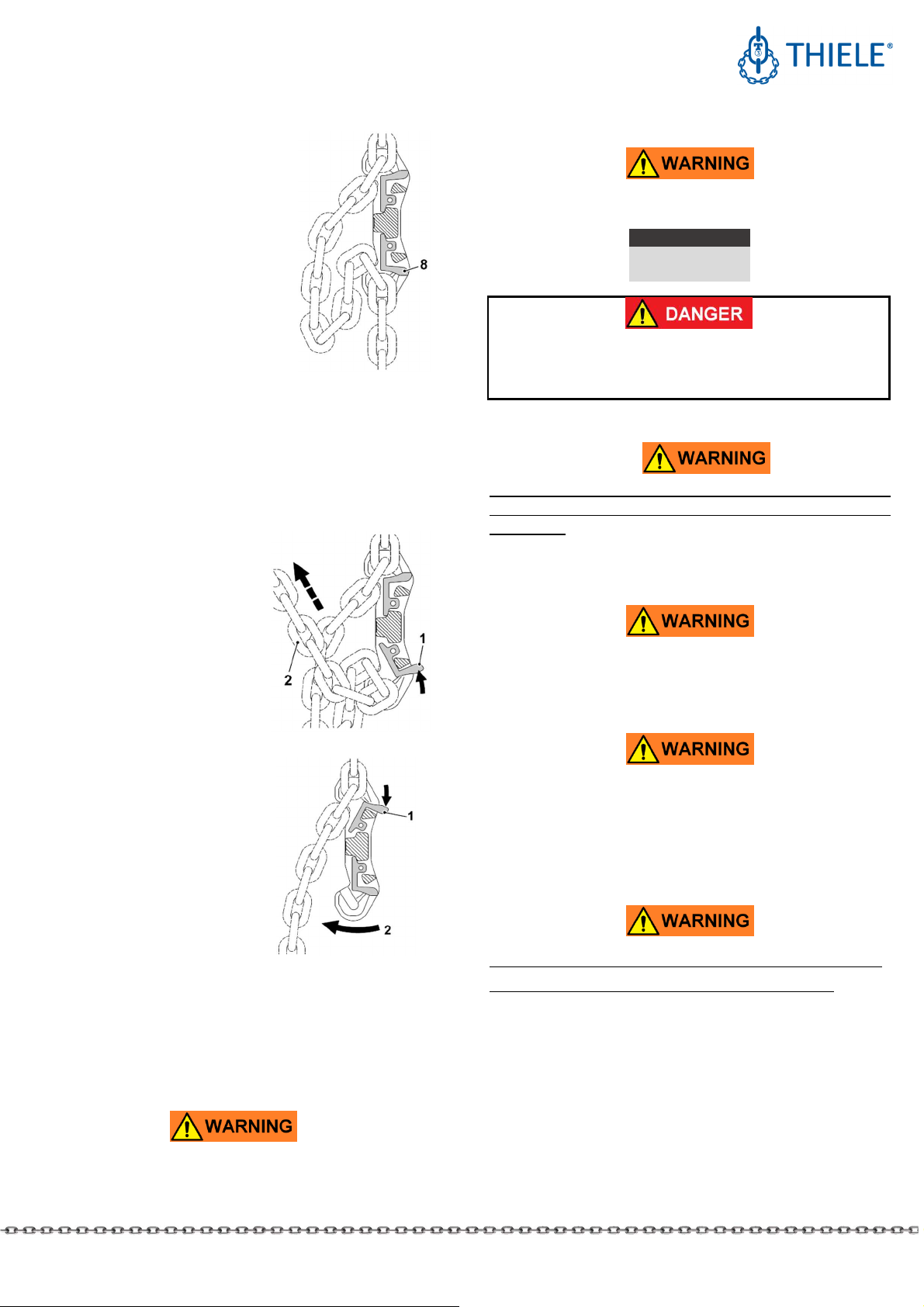

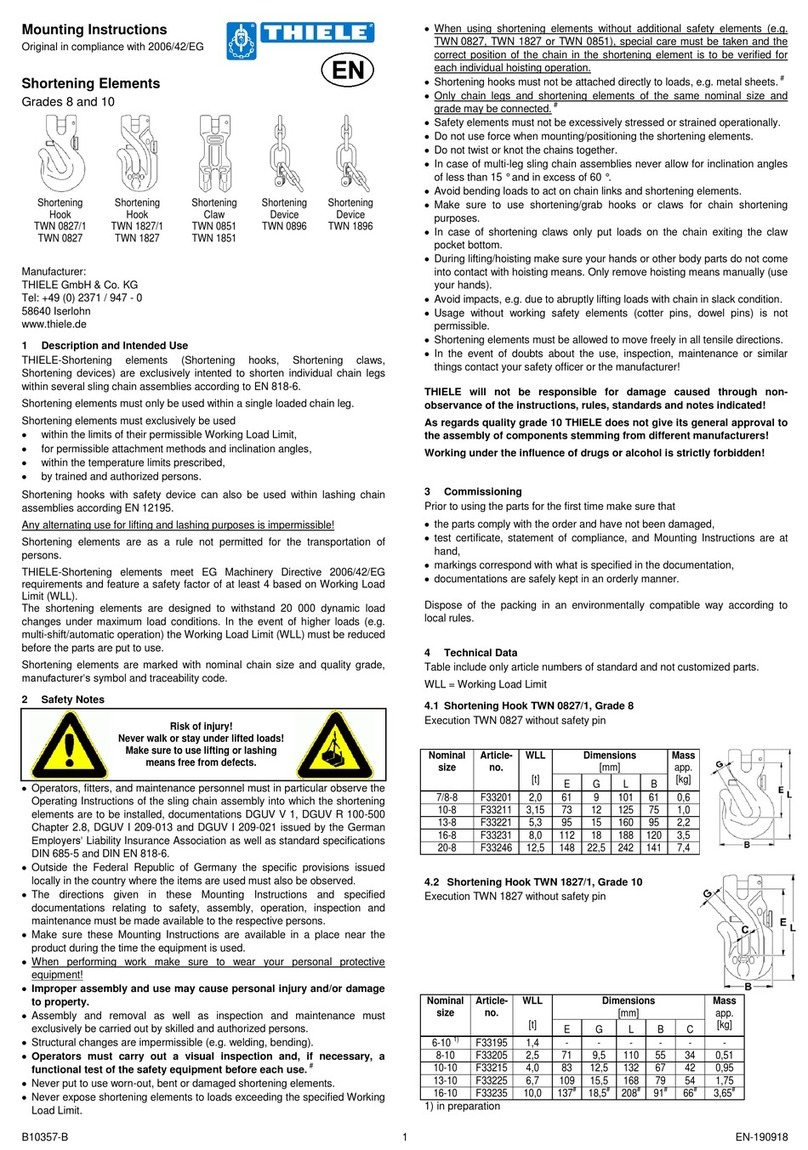

RAPID shortening claws according to TWN 1852 are exclusively

intended for shortening individual chain legs of sling chain

assemblies of grade 100 according to ASTM A 906/A 906M.

They can be used anywhere in the chain leg as a permanent or

non-permanent connection.

They are constructed symmetrically in terms of safe handling

and have safety latches against unintentional release of the

chain.

RAPID shortening claws should only be used within one loaded

chain leg and only together with chains according to the

marked nominal size and grade 100.

They are not intended for connecting different chain legs.

RAPID shortening claws must exclusively be used:

•

within the limits of their permissible working load limit,

•

for permissible attachment methods and sling angles,

•

within the temperature limits prescribed,

•

by trained and authorized persons.

Failure to do so may cause serious injury or property damage.

When using RAPID shortening claws within sling chain

assemblies observe their operating instructions. In particular,

the working load limits as a function of the number of chain

legs and angle of inclination are documented here.