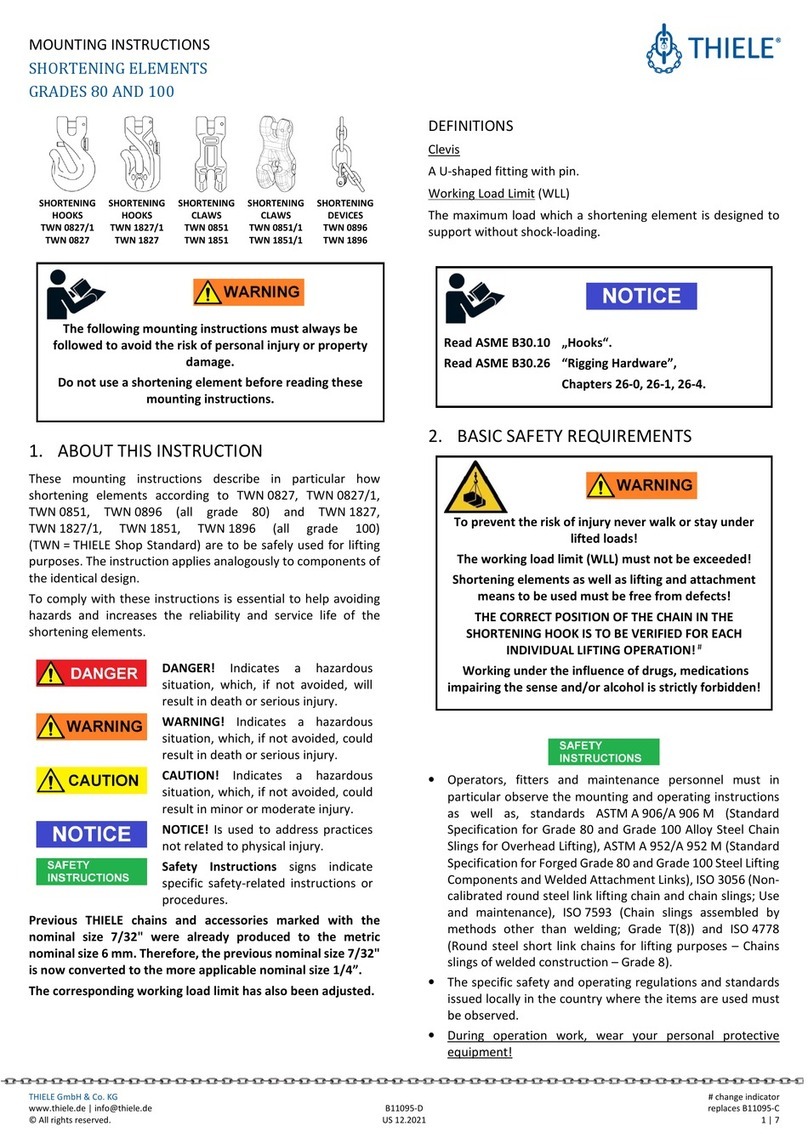

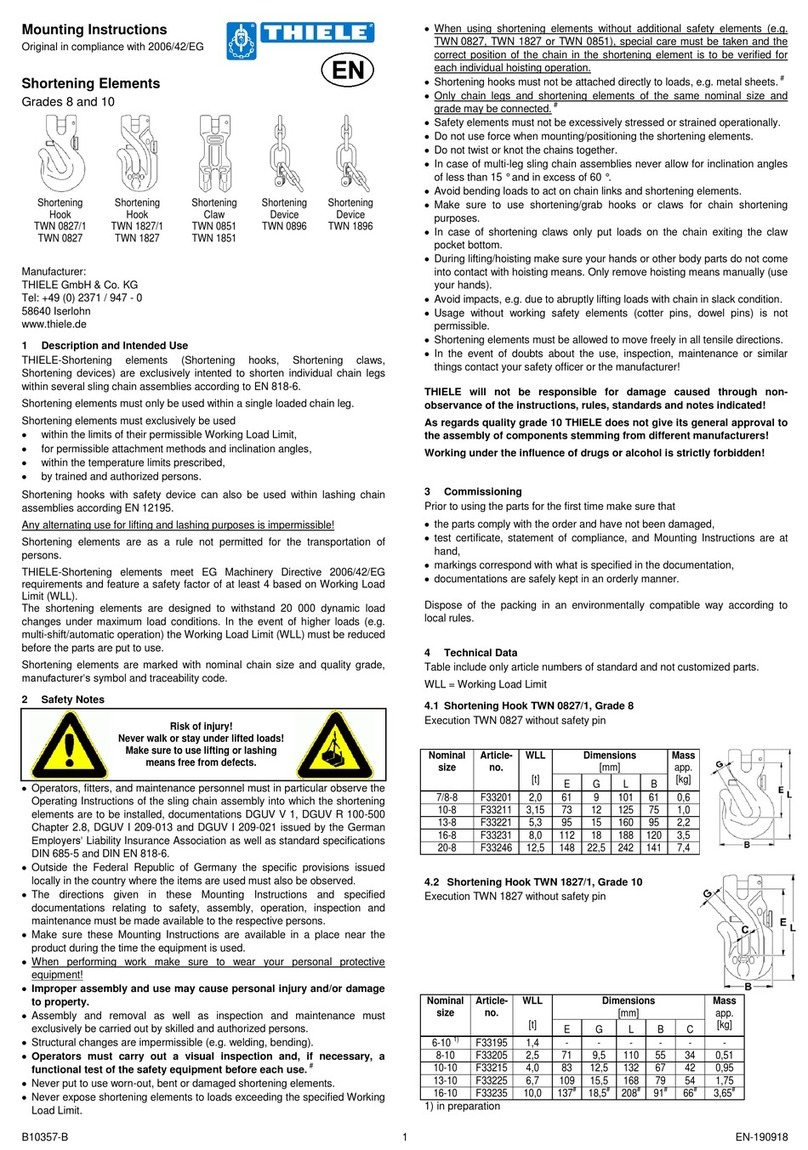

MOUNTING INSTRUCTIONS

SHORTENING ELEMENTS

GRADES 80 AND 100

THIELE GmbH & Co. KG # change indicator

© All rights reserved. US 11.2021 2 | 6

•The directions given in these mounting instructions and

specified documentations relating to safety, assembly,

operation, inspection, and maintenance must be made

available to persons operating and using the shortening

elements.

•These mounting instructions must be available in a place

near the product during the time the equipment is used.

Please contact the manufacturer if replacements are

needed. Also see chapter 11.

•Improper assembly and use may cause personal injury

and/or damage to property.

•Assembly and removal as ell as inspections and

maintenance must exclusively be carried out by skilled,

qualified, trained and authorized persons only.

•Structural changes are impermissible (e.g. elding, bending).

•Operators must carry out a visual inspection and, if

necessary, a functional test of the safety equipment before

each use.

•Never use orn-out, bent or damaged shortening elements.

•Only lift loads that do not exceed the orking load limit of

the corresponding sling chain assembly.

•Never expose shortening elements to loads exceeding the

specified orking load limit.

•When using shortening elements ithout additional safety

elements (e.g. TWN 0827, TWN 1827, TWN 0851 or

TWN 1851), special care must be taken and the correct

position of the chain in the shortening element is to be

verified for each individual lifting operation.

•Shortening hooks must not be attached directly to loads, e.g.

metal sheets.

•Only chain legs and shortening elements of the same

nominal size and grade may be connected.

•No one including you (operator) must be in the ay of the

moving load (hazard area).

•Safety elements must not be excessively stressed or strained

operationally.

•Do not use force hen mounting/positioning the shortening

elements.

•Do not t ist or knot the chains together.

•In case of multi-leg sling chain assemblies never allo for

sling angles of less than 30 ° and in excess of 75 °.

•Avoid bending loads to act on chain links and shortening

elements.

•Make sure to use shortening/grab hooks or cla s for chain

shortening purposes.

•In case of shortening cla s only put loads on the chain

exiting the cla pocket bottom.

•During lifting your hands or other body parts must not come

into contact ith lifting means. Only remove lifting means

manually (use your hands).

•Avoid impacts, e.g. due to abruptly lifting loads ith chain in

slack condition.

•Usage ithout orking safety elements (cotter pins, do el

pins) is not permissible.

•Shortening elements must be allo ed to move freely in all

tensile directions.

•In the event of doubts or concerns about the proper and safe

use, inspection, maintenance or similar things contact your

safety officer or the manufacturer.

THIELE is not responsible for damage caused by

non-observance of the instructions, rules, standards and notes

indicated!

As regard grade 100, THIELE does not give its approval to the

assembly of components sourced from different

manufacturers!

As a rule, shortening elements and chain slings are not

permitted for the transportation of persons.

3. DESCRIPTION AND INTENDED USE

THIELE shortening elements (shortening hooks, shortening

cla s, shortening devices) are exclusively intented to shorten

individual chain legs ithin several sling chain assemblies

according to ASTM A 906/A 906M.

Shortening elements must only be used ithin a single loaded

chain leg.

Shortening elements must exclusively be used

•

ithin the limits of their permissible orking load limit,

•

for permissible attachment methods and sling angles,

•

ithin the temperature limits prescribed,

•

by trained and authorized persons.

THIELE shortening elements meet the

EG Machinery Directive 2006/42/EG requirements and feature

a safety factor of at least 4 based on orking load limit.

The shortening elements are designed to ithstand 20 000

dynamic load changes under maximum load conditions. In the

event of higher loads (e.g. multi-shift/automatic operation), the

orking load limit must be reduced.

Shortening elements are marked ith nominal chain size and

quality grade, manufacturer’s symbol and traceability code.

Shortening hooks ith safety device can also be used ithin

lashing chain assemblies. When used ithin a lashing system,

the maximum lashing capacity (LC) is obtained by doubling the

orking load limit.

Any alternating use for lifting and lashing purposes is

impermissible!