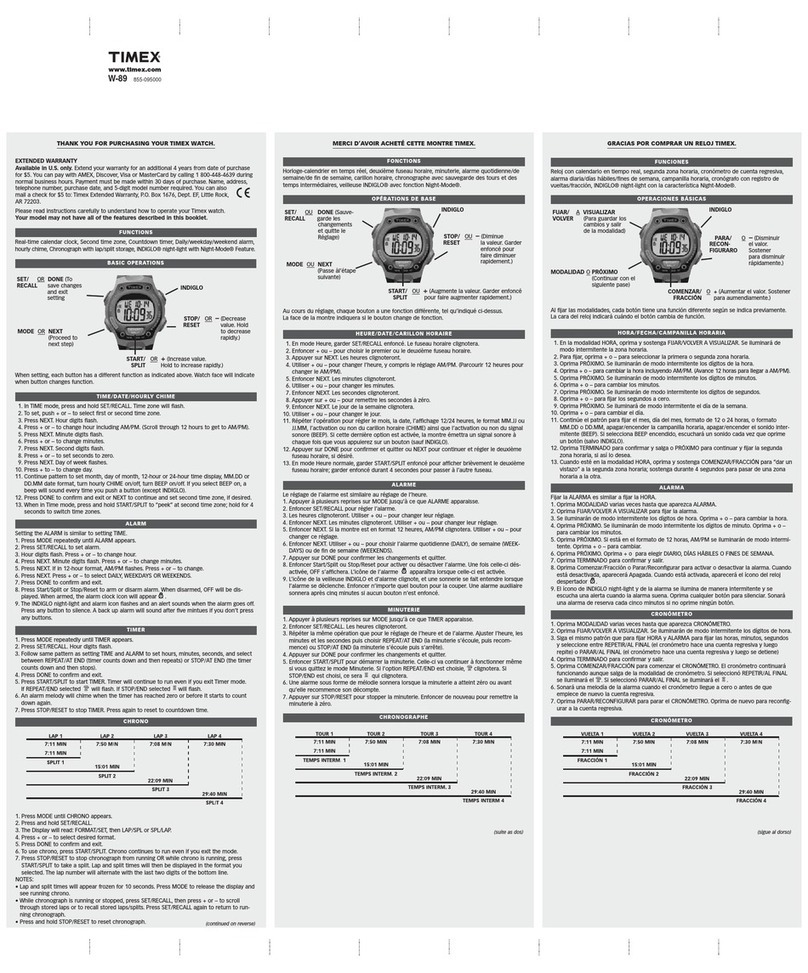

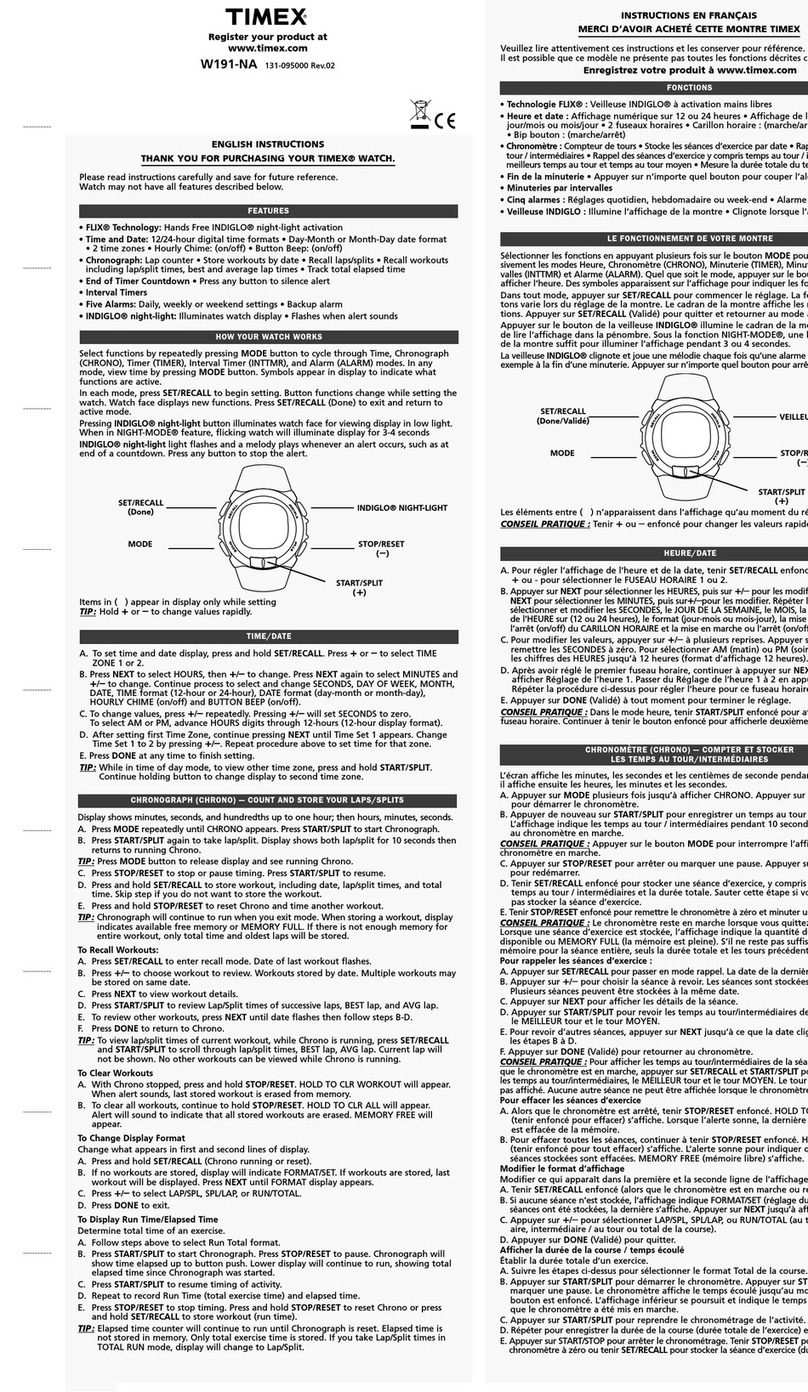

Timex 22 User manual

Other Timex Watch manuals

Timex

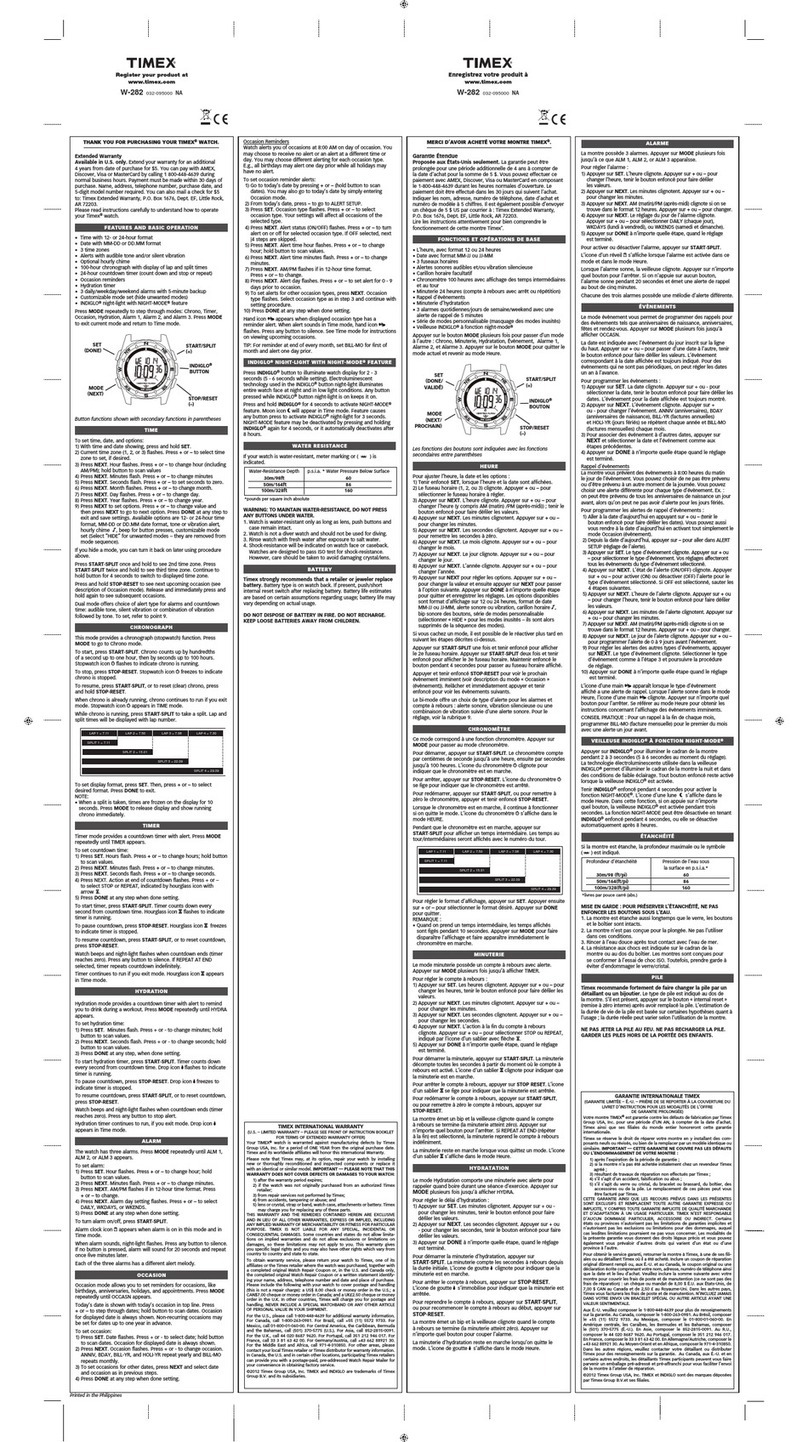

Timex W-282 User manual

Timex

Timex KIDS User manual

Timex

Timex Performance Watch User manual

Timex

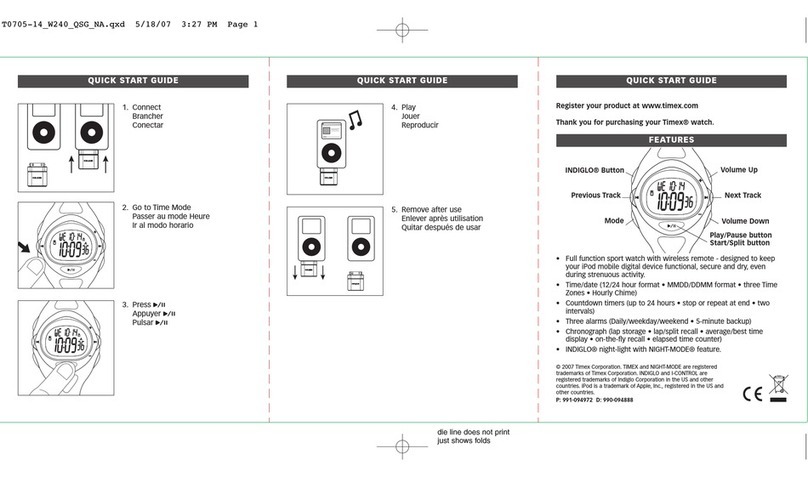

Timex i-Control User manual

Timex

Timex Marathon User manual

Timex

Timex 714-095005-01 User manual

Timex

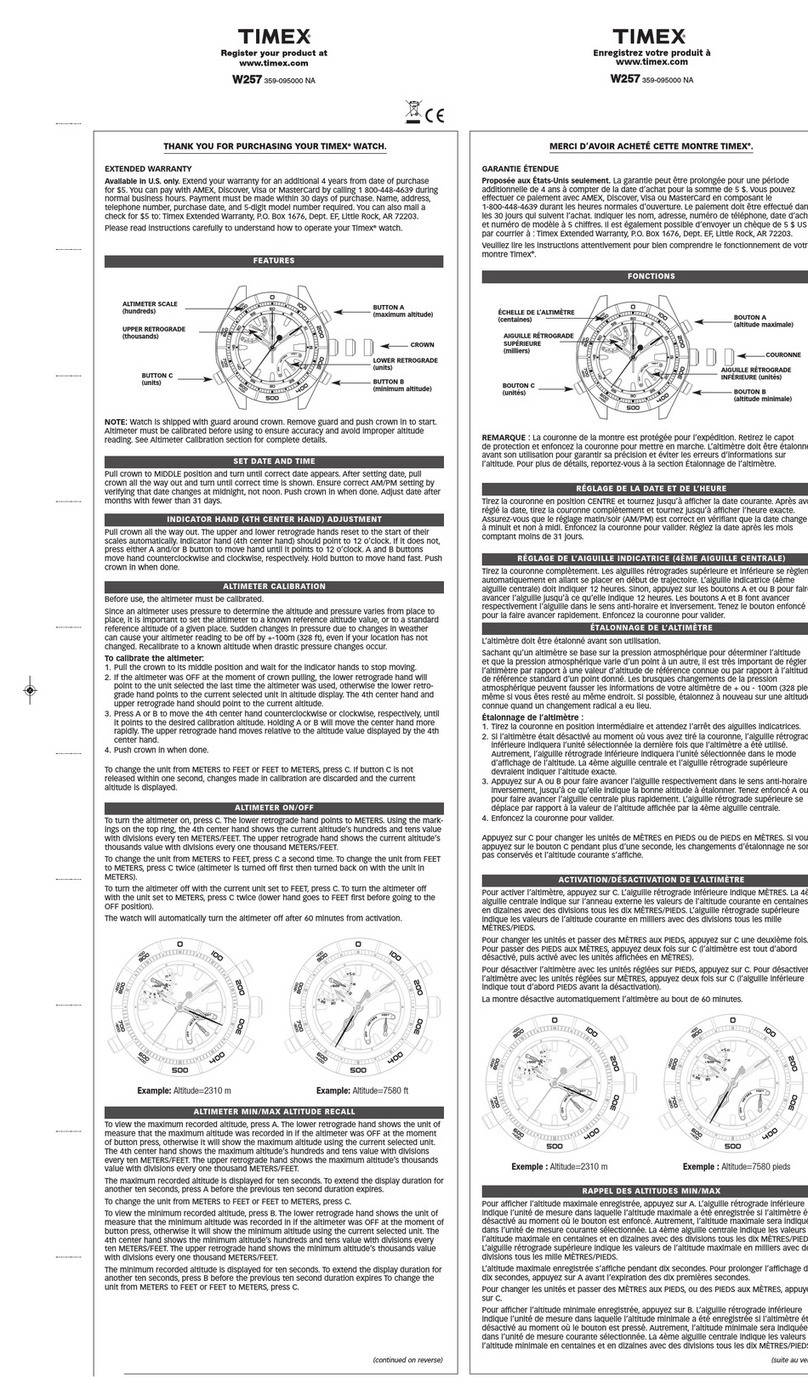

Timex w257 User manual

Timex

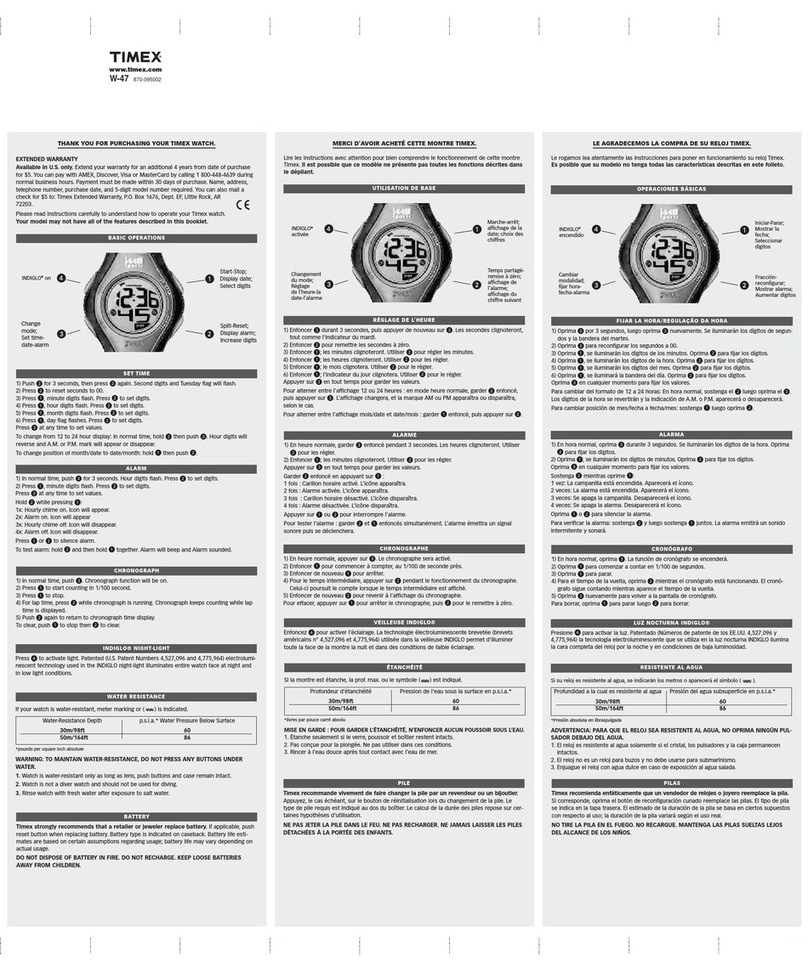

Timex W47 User manual

Timex

Timex W-106 User manual

Timex

Timex Expedition User manual

Timex

Timex Global Trainer W260 User manual

Timex

Timex Expedition WS4 User manual

Timex

Timex Ironman Run User manual

Timex

Timex 131-095000 User manual

Timex

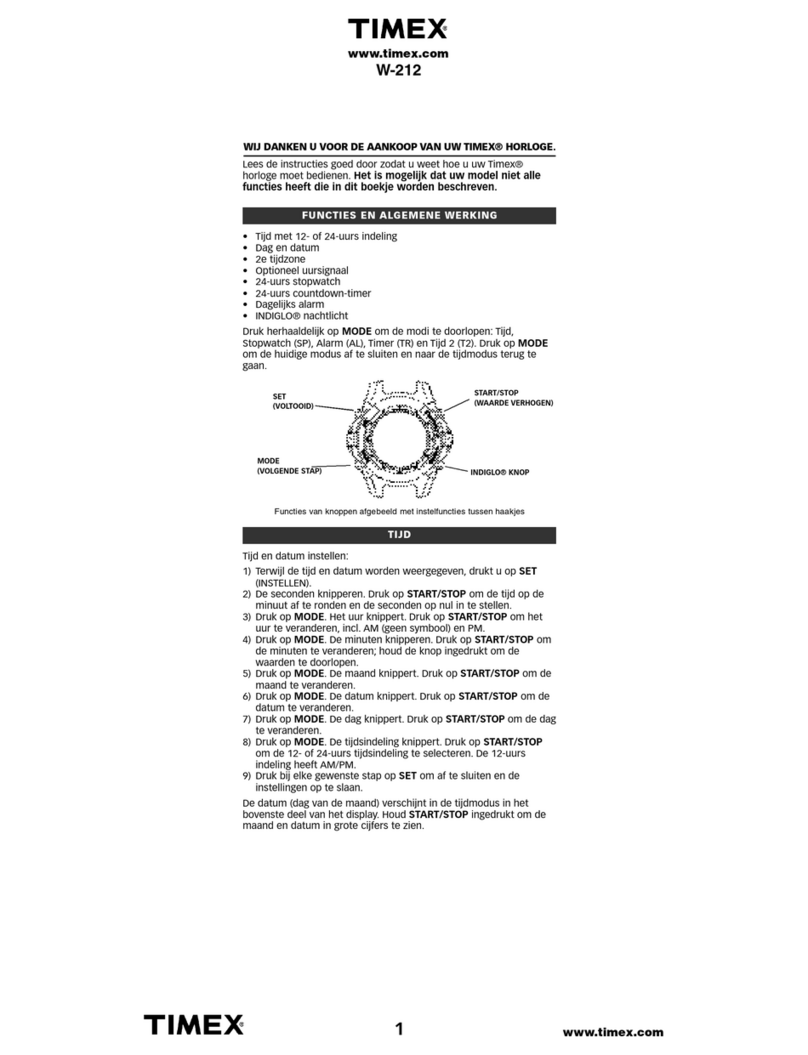

Timex W212 User manual

Timex

Timex Acclaim User manual

Timex

Timex Metropolitan+ User manual

Timex

Timex IronMan Run x50+ User manual

Timex

Timex UFC KNOCKOUT User manual

Timex

Timex Ironman User manual