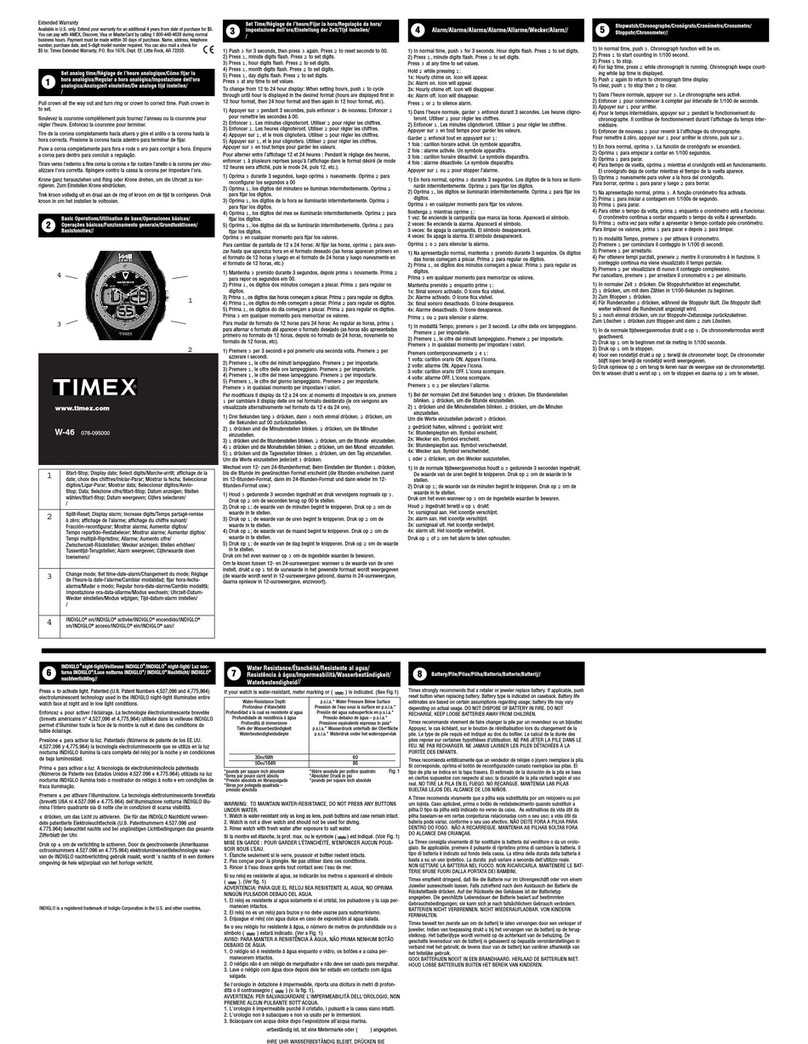

The

TIMEX®

Model

260

Movement

ACTUAL

SIZE

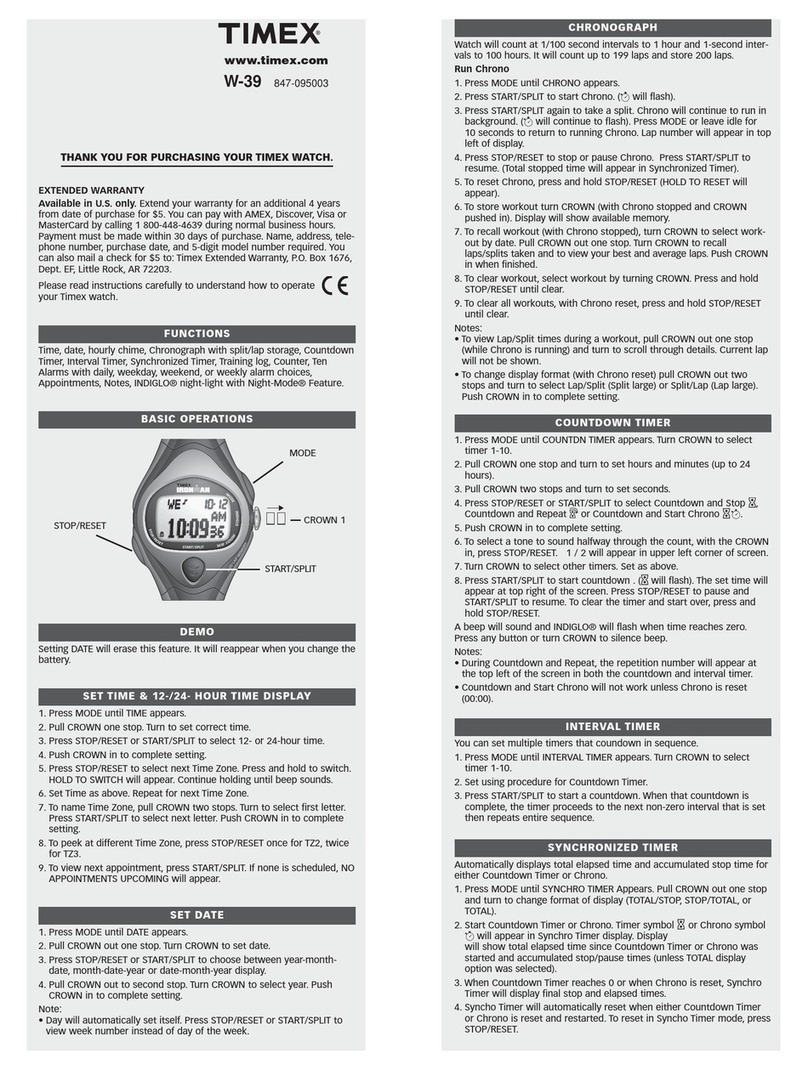

The

Timex Model

260

is--en

11-3/4

by

12-3/4

ligne electric watch movement

featuring a high frequency balance system.

The

Model

260

is

powered

by

a Timex Type

"A"

energy cell which provides

power for

at

least one year.

The

Model

260

operates

at

a

rate

of

28,800

beats

per hour. The

rate

can

be

checked on all conventional watch

rate

recorders having a

setting

of

28,800

beats

per hour

or

on some recorders using a

setting

for

14,400

or

21,600

beats

per

hour.

To

observe

the

operation of

the

Model

260,

follow

the

instructions detailed

on

page

253

.8 through

253

.14 for

the

Model

253

movement.

Tne

Timex code number

appears

on

the

edge of the dial.

The

Code number shows the

catalog

number, movement number,

and

year of

manufacture

for

the

watch (see Page 1.1 of

the

Timex Service Manual for

explanation) .

CAUTION: Since watch contains

permanent

magnets, no

attempt

should be

made

to

demagnetize

the watch.

260

.1