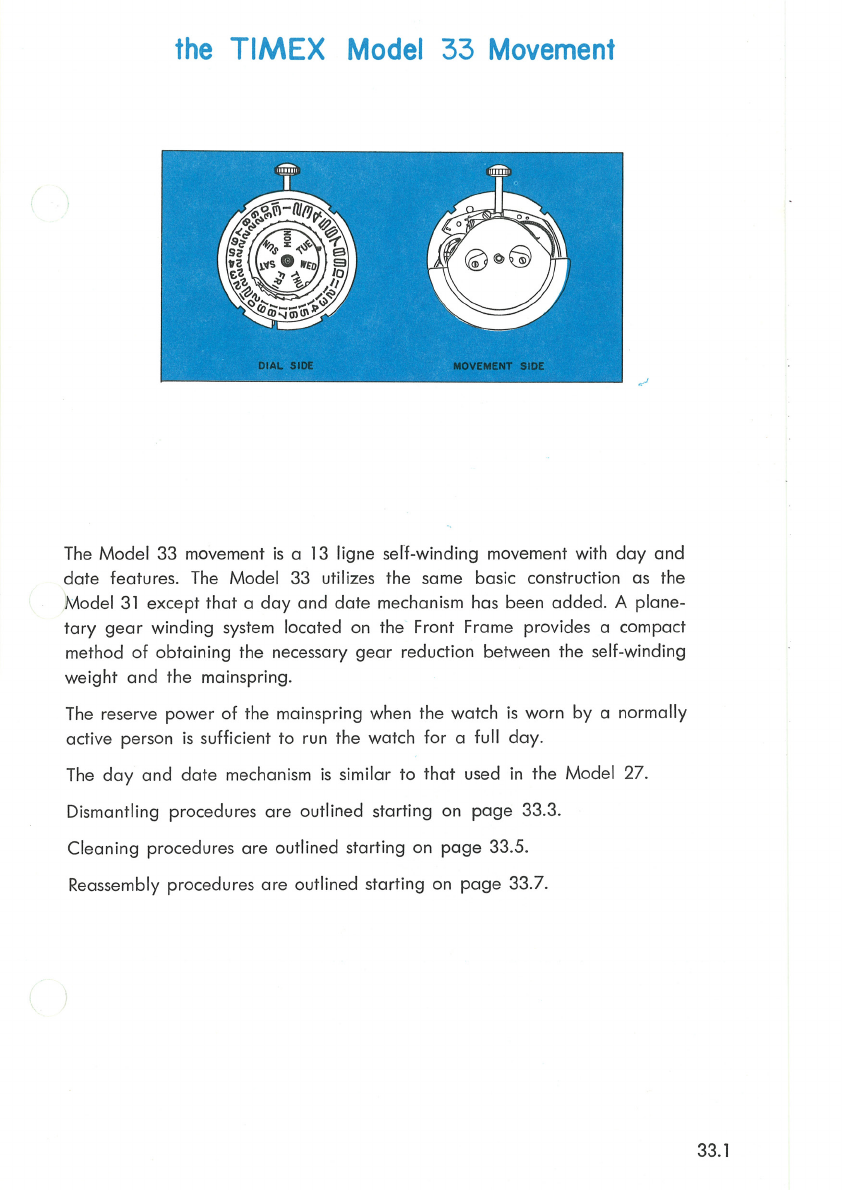

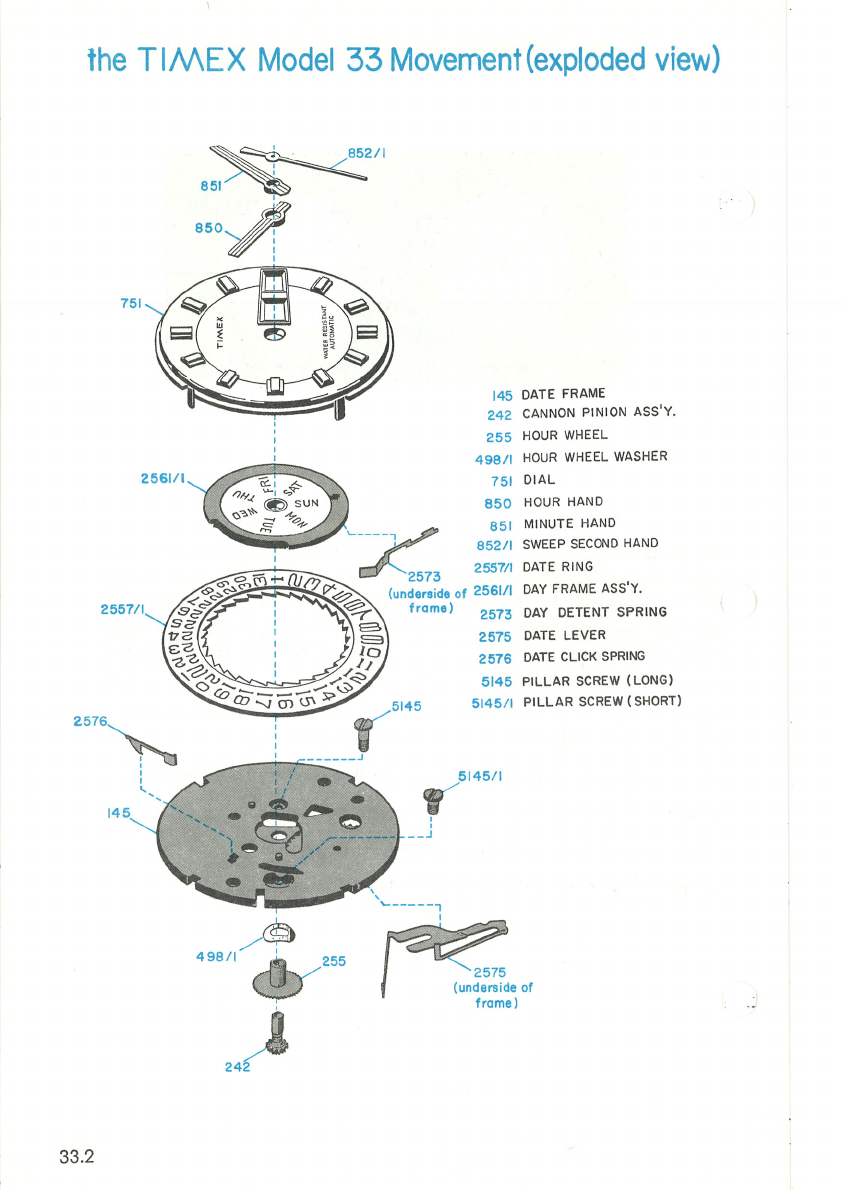

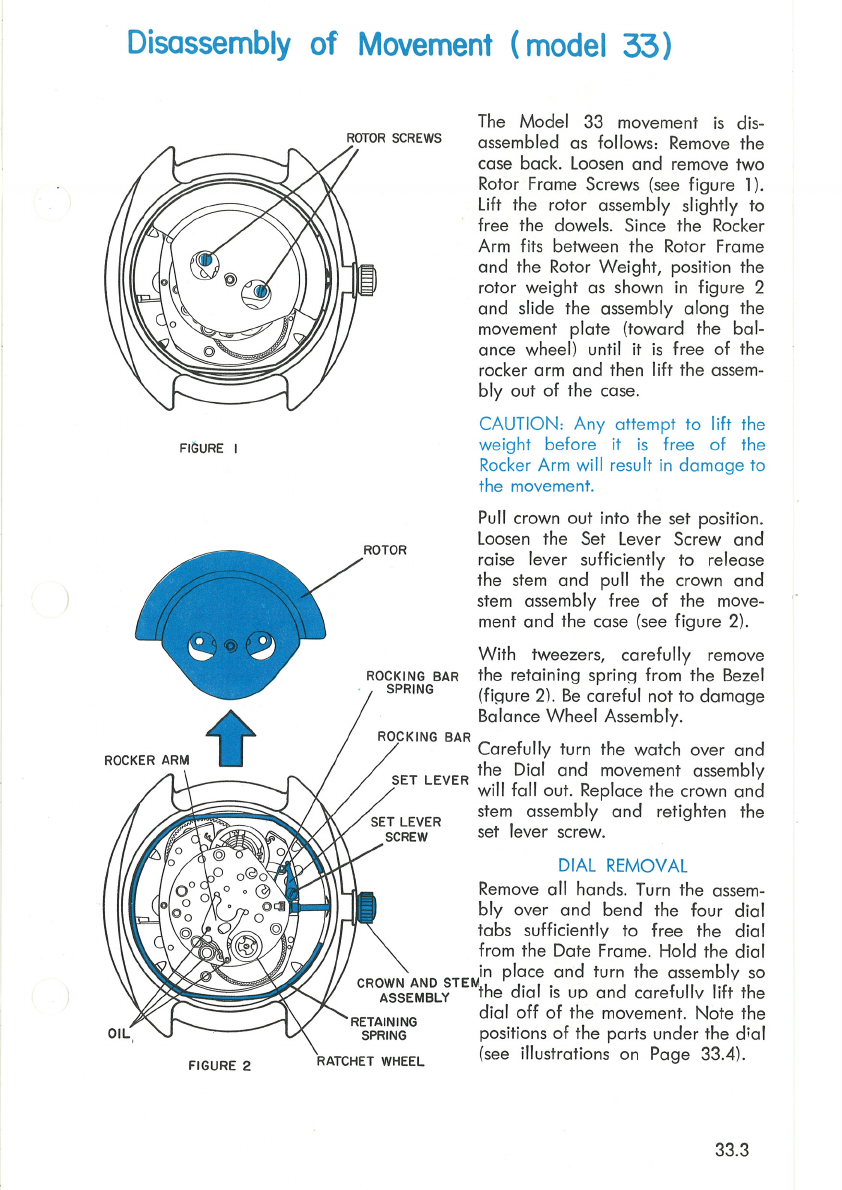

Timex 33 User manual

Other Timex Watch manuals

Timex

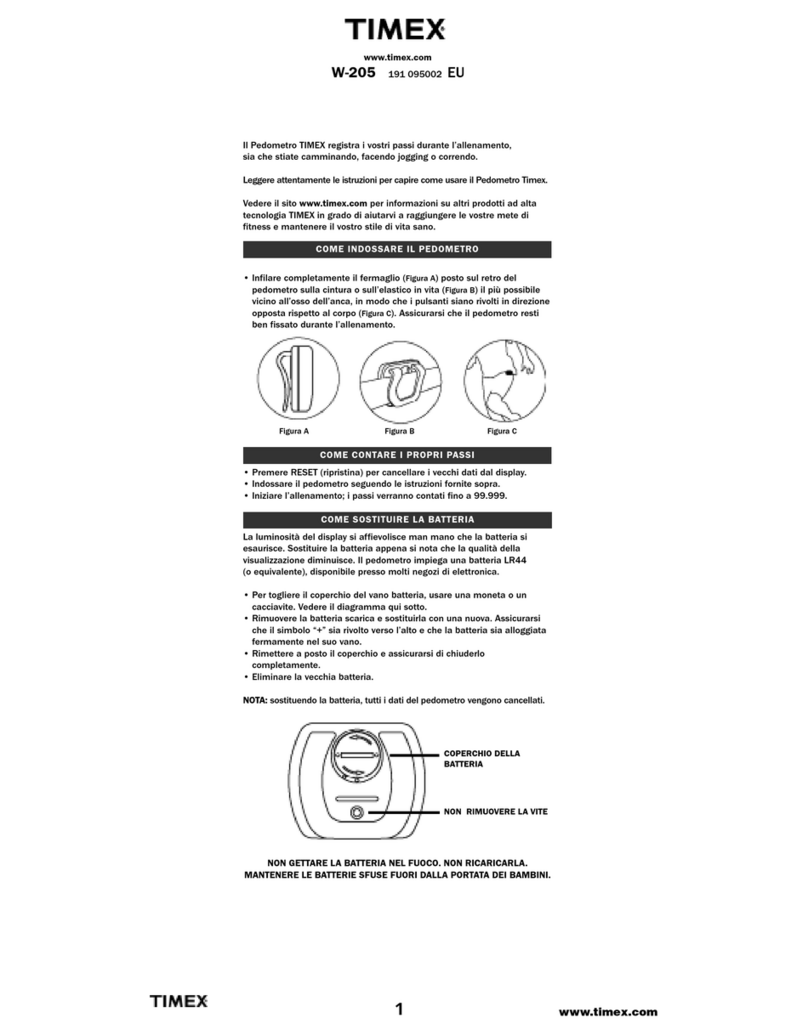

Timex W205 User manual

Timex

Timex Expedition User manual

Timex

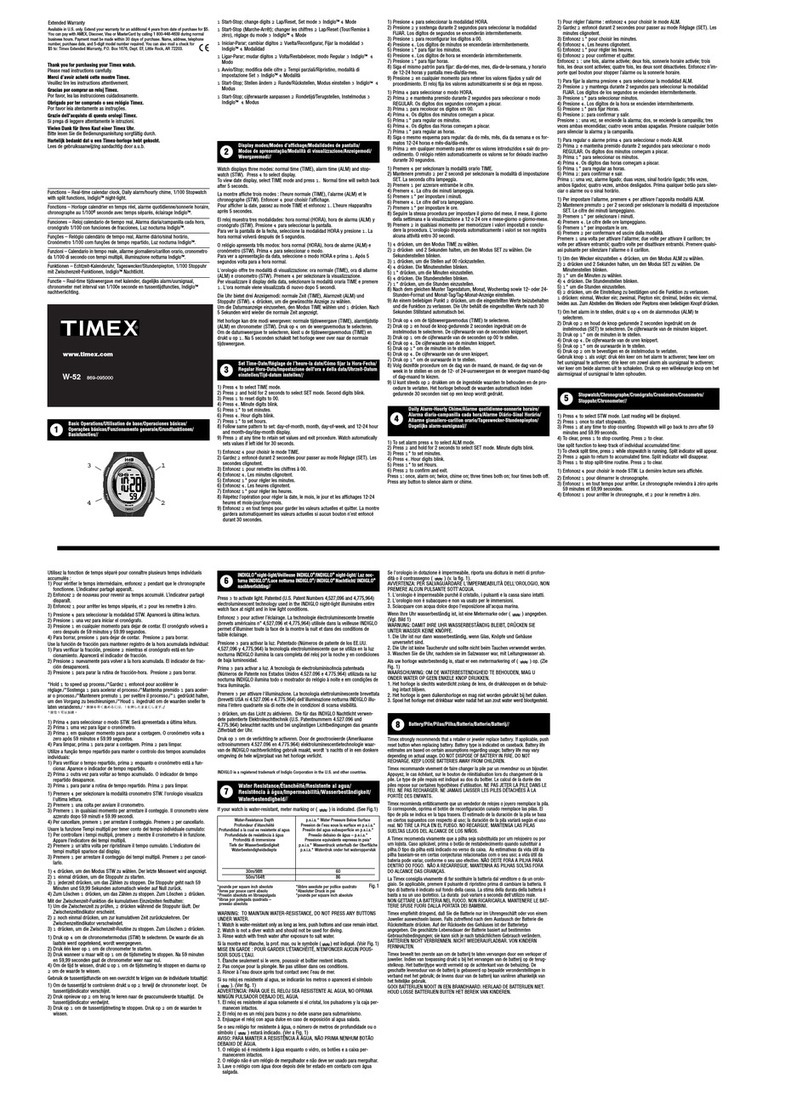

Timex W-52 User manual

Timex

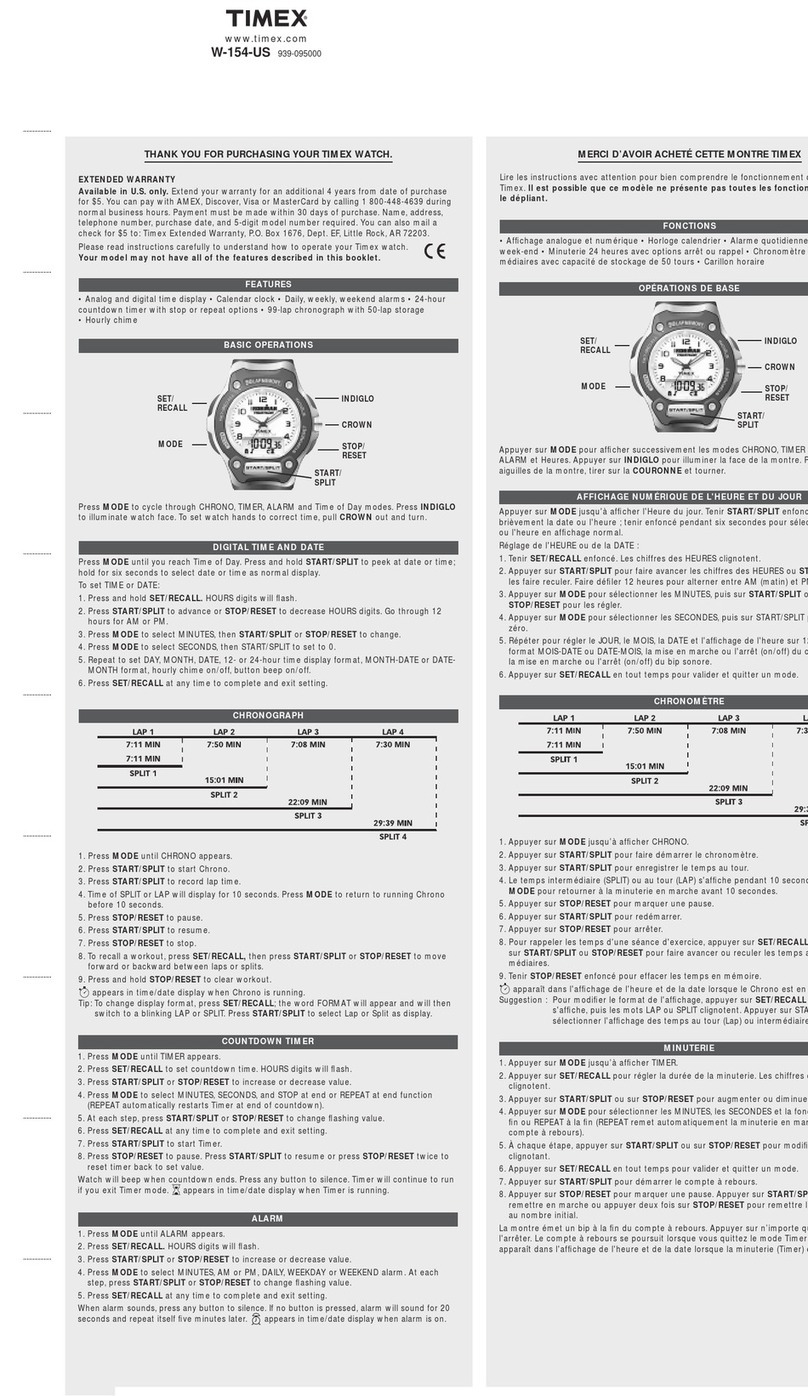

Timex 939-095000 User manual

Timex

Timex Ironman Run x20 GPS User manual

Timex

Timex Global trainer User manual

Timex

Timex Global Trainer W260 User manual

Timex

Timex Expedition WS4 User manual

Timex

Timex IronMan Run x50+ User manual

Timex

Timex W-162 User manual

Timex

Timex IronmanW-276 User manual

Timex

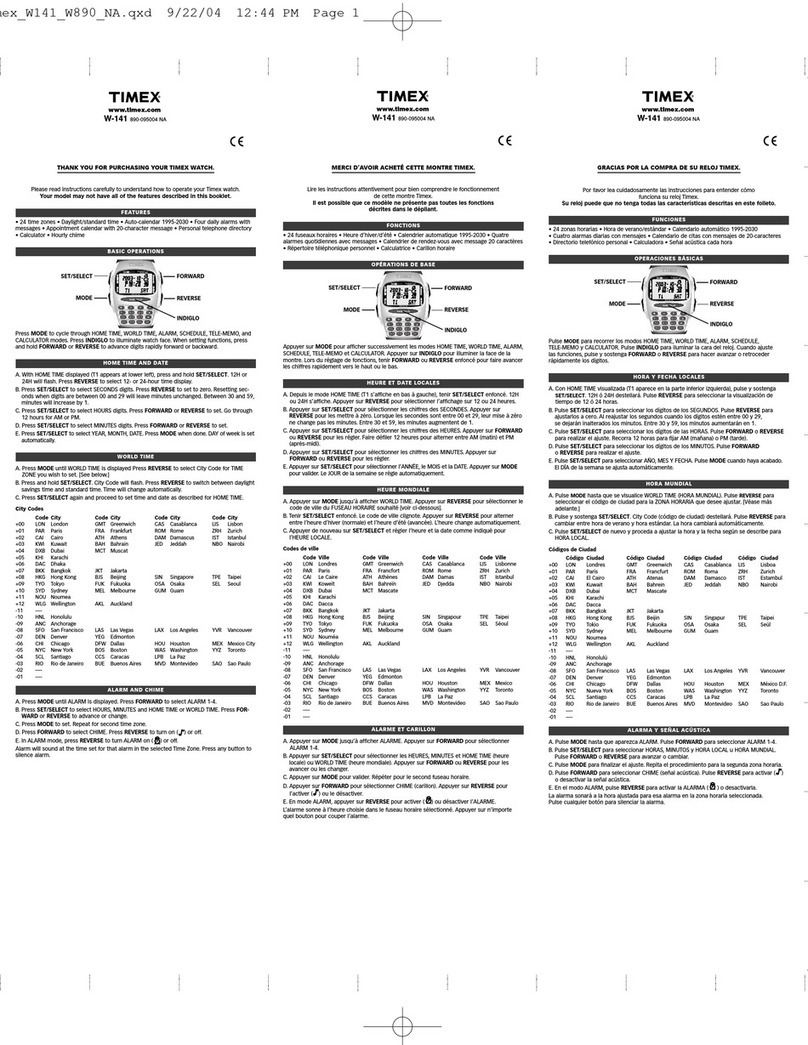

Timex W-141 User manual

Timex

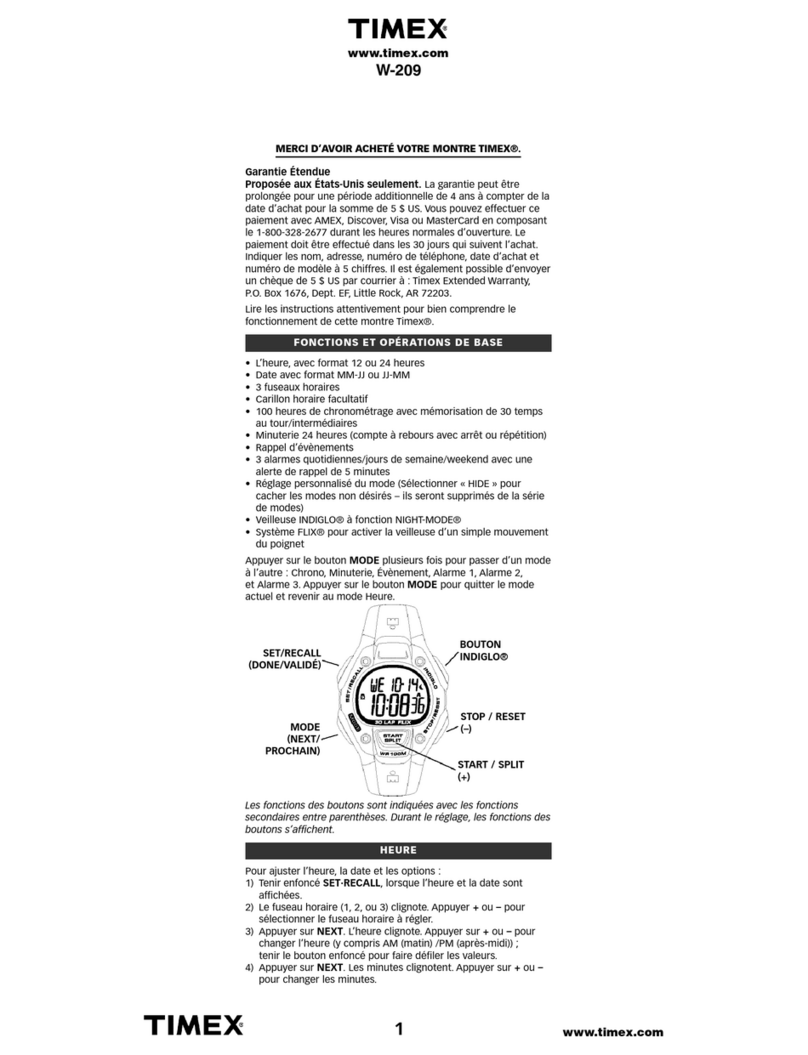

Timex W209 User manual

Timex

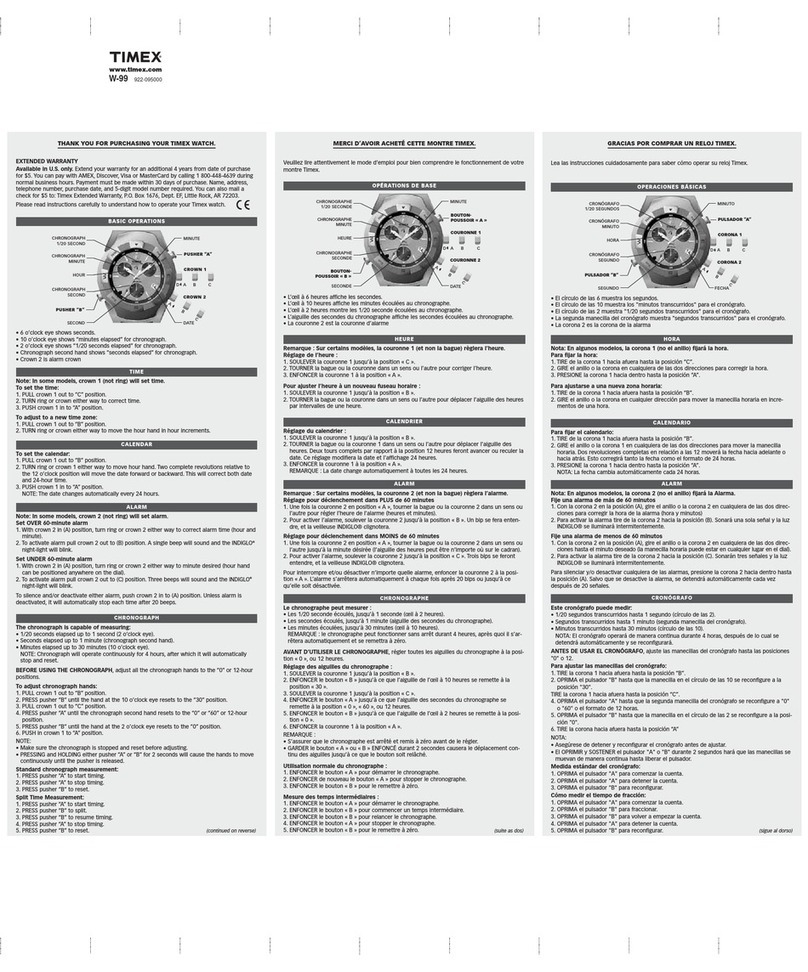

Timex W-99 User manual

Timex

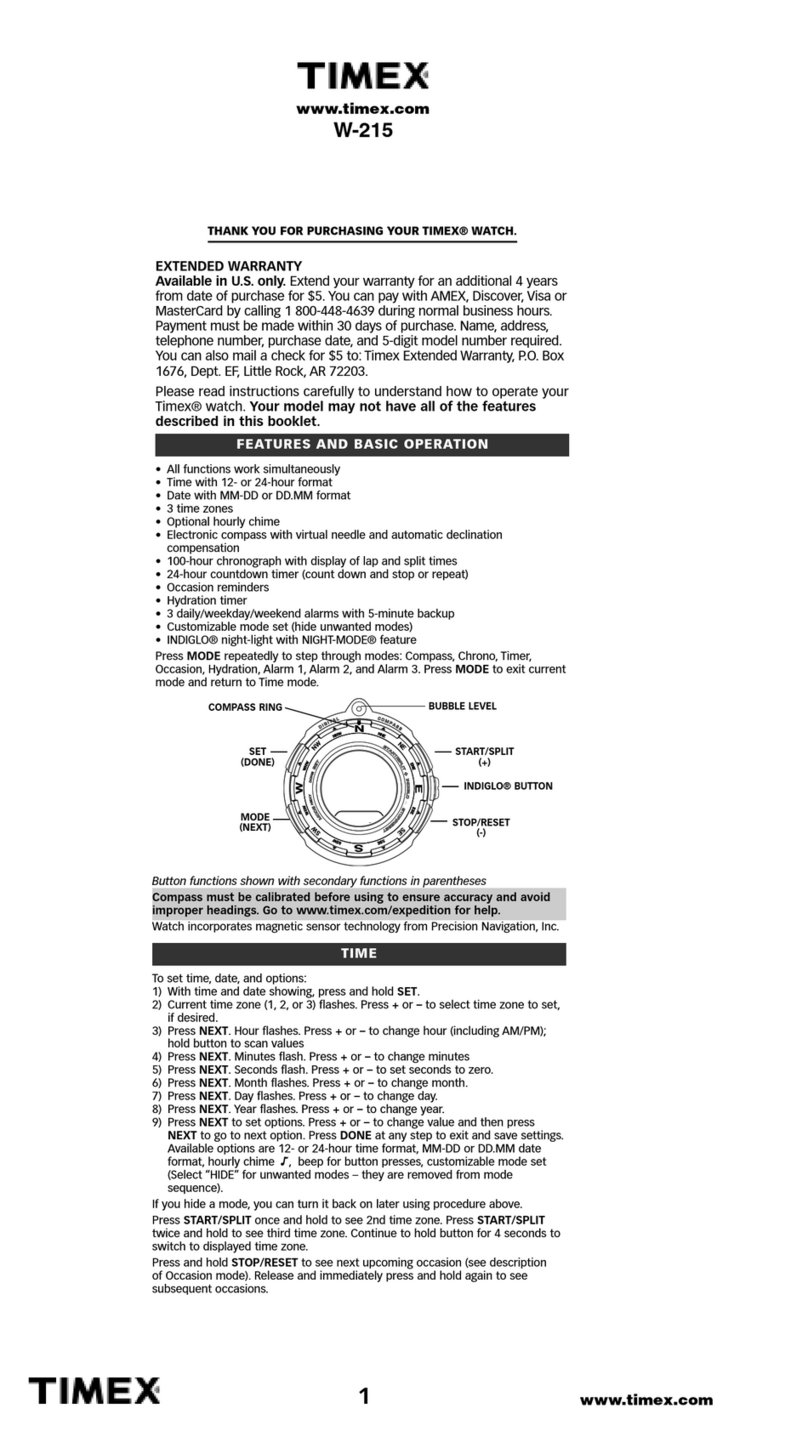

Timex w-215 User manual

Timex

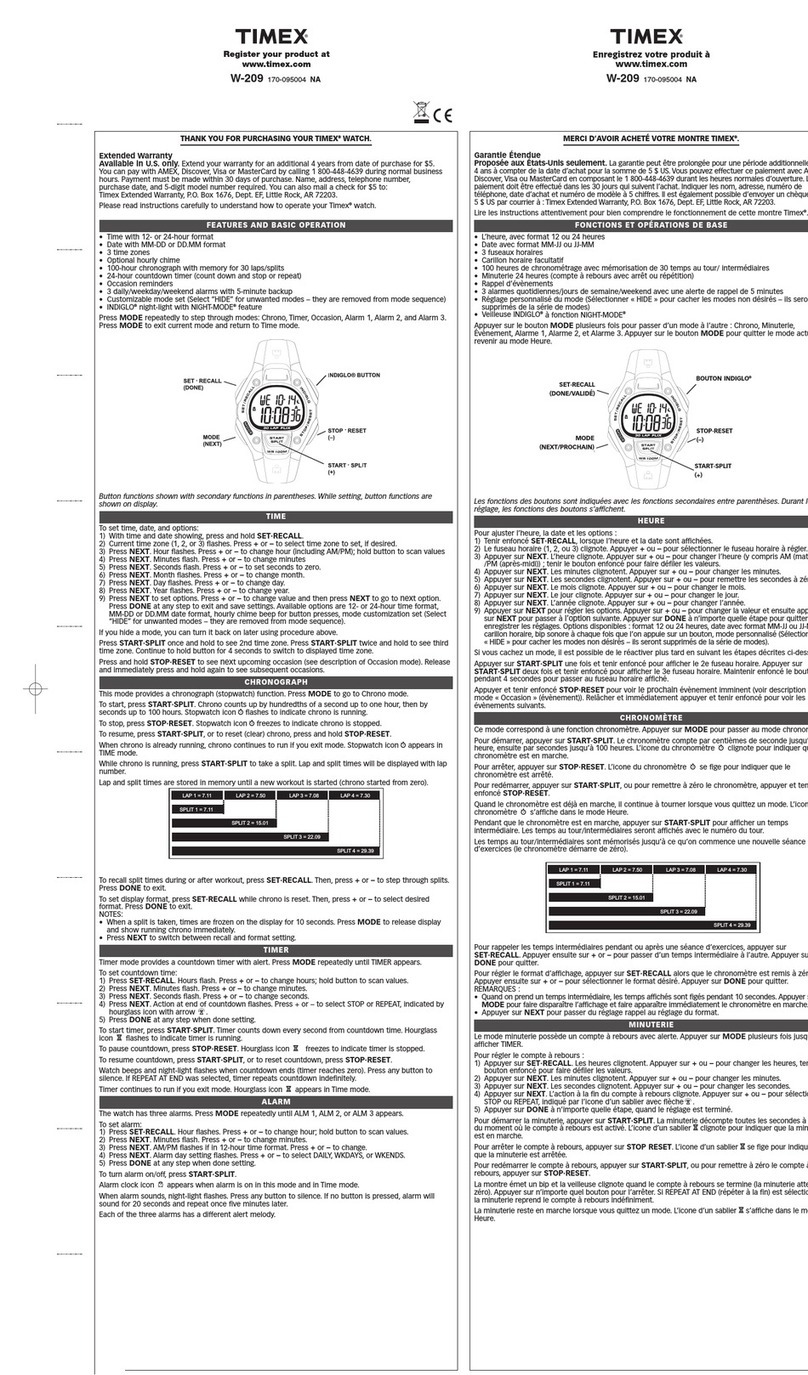

Timex 170-095004 NA User manual

Timex

Timex W231 User manual

Timex

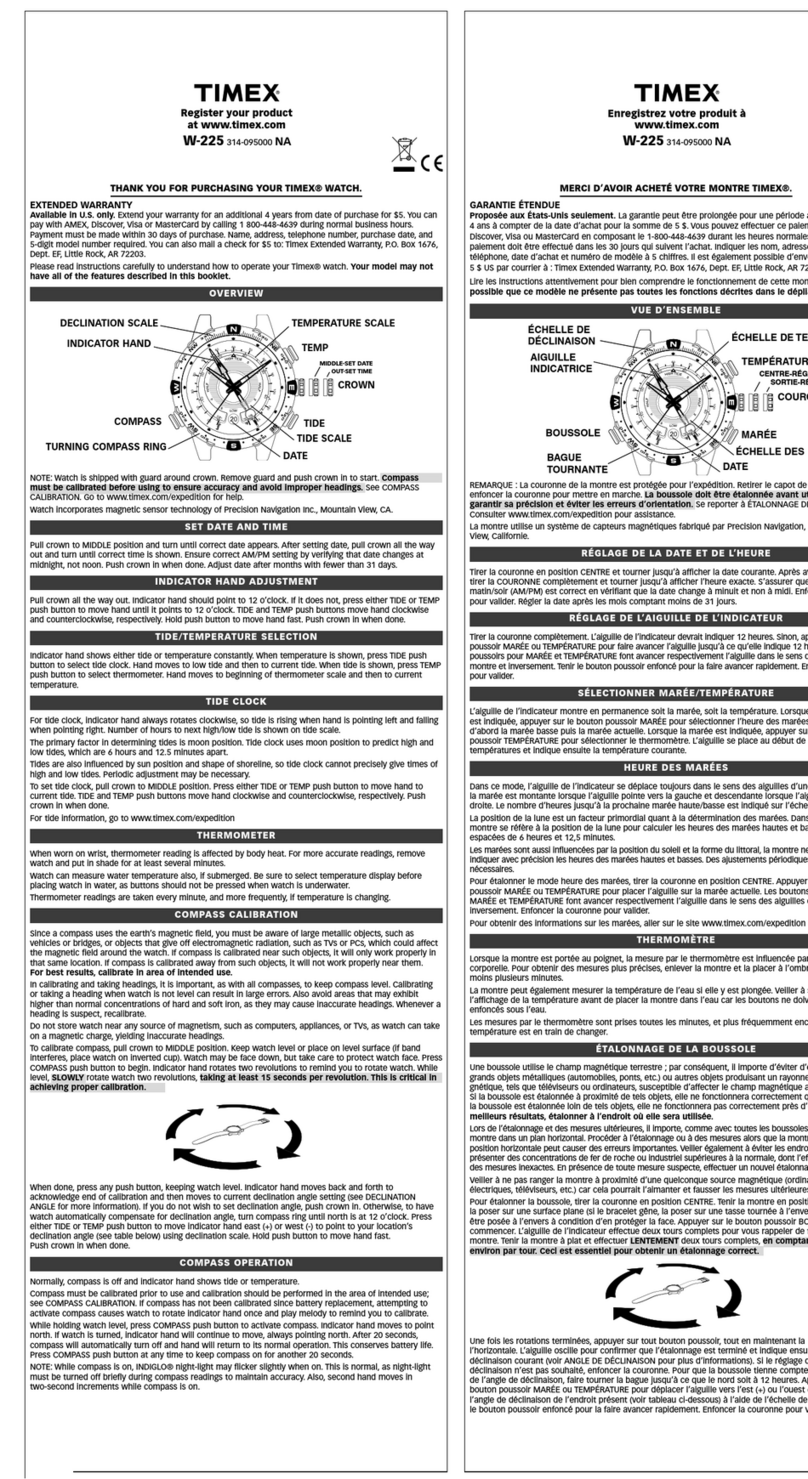

Timex W-225 User manual

Timex

Timex Ironman Triathlon User manual

Timex

Timex 100 Lap Ironman Triathlon with the FLIX User manual