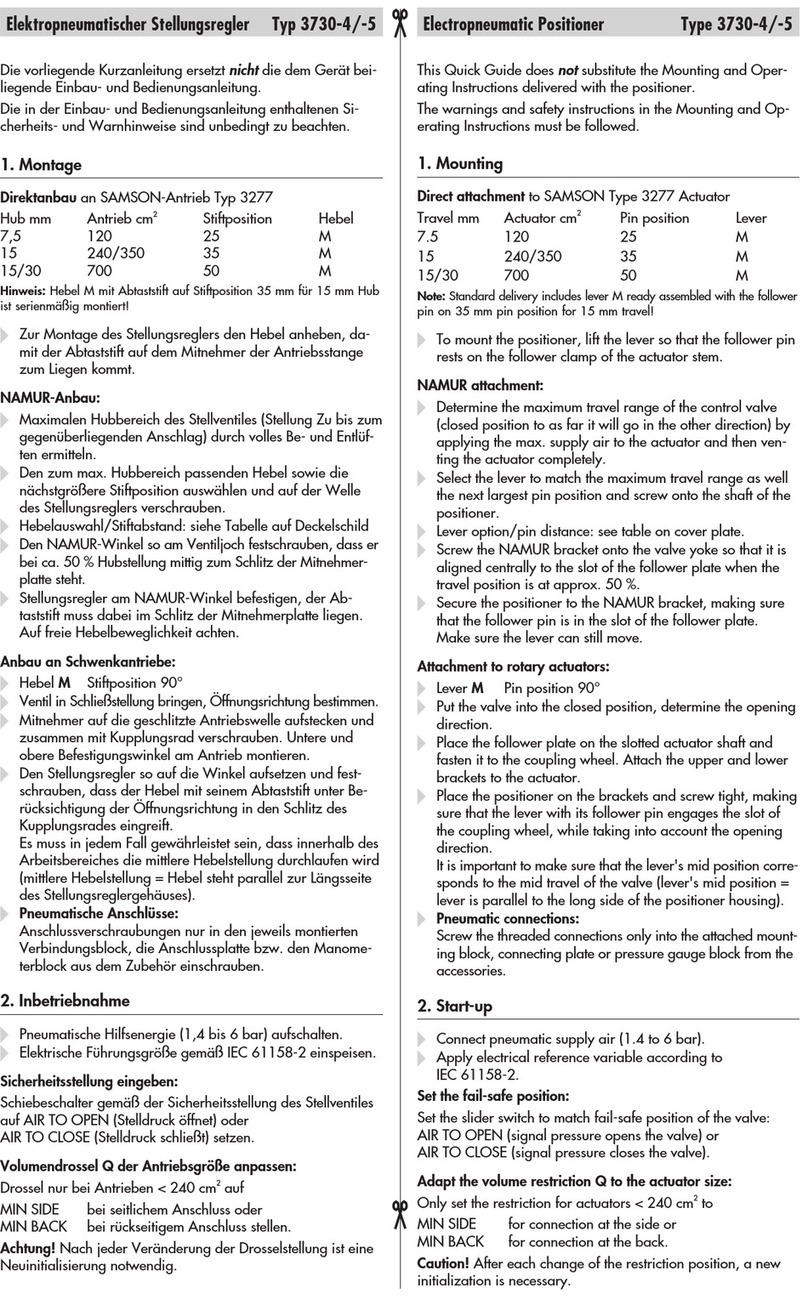

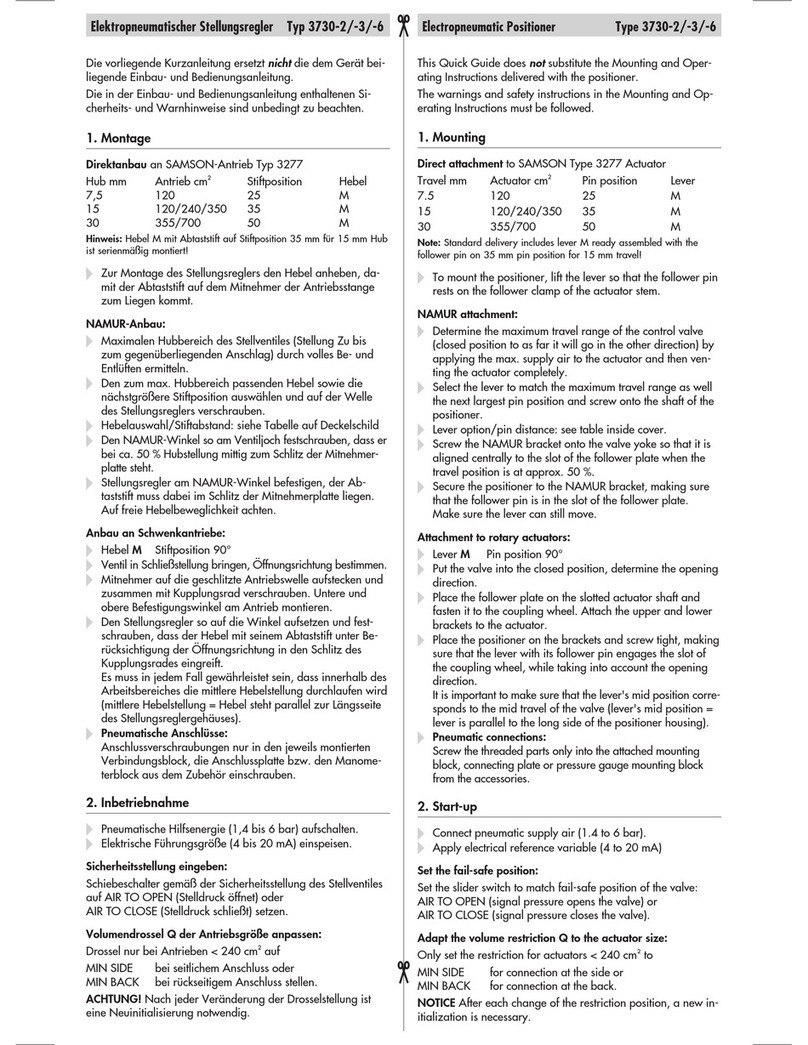

2 Attachment to actuators

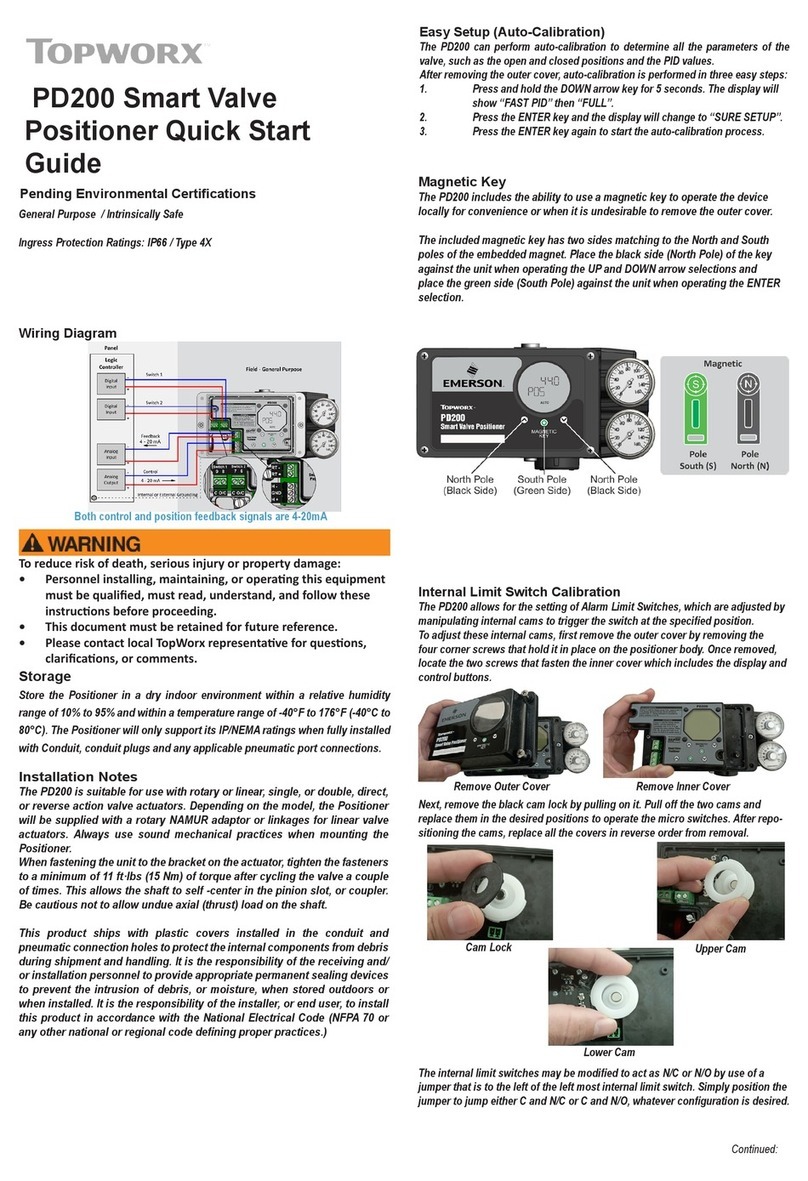

The positioner is attached directly to the ac-

tuator yoke using the two screws inside the

housing. The rubber profile serves as a seal

between positioner housing and yoke.

The following accessories are required to

mount the positioner: clamp, cover plate and

a plug with seal.

The required mounting kit is listed in the ta-

ble on page 12.

For attachment to 120 cm² actuators

(Fig. 3), remove the filter installed in the side

signal pressure connection. The connection

(output 36) must be sealed by a plug with

seal (see accessories).

The signal pressure is routed over the signal

pressure hole at the back of the housing di-

rectly through the yoke into the associated

diaphragm chamber.

When attaching the positioner to the yoke,

make sure that the seal containing a filter is

installed in the side hole of the yoke.

How the signal pressure is supplied to the

actuator depends on whether the positioner

is attached on the left or right side of the

yoke. For this purpose, the corresponding

symbol on the switchover plate must be

aligned with the mark (point) on the yoke.

If, in addition to the positioner, a solenoid

valve or a similar device is to be attached to

the actuator, the signal pressure hole at the

back of the positioner housing must be

sealed. To do so, remove the screw installed

(parking position) in the hole below the sig-

nal pressure hole and screw it into the signal

pressure hole.

In this case, the signal pressure must be

routed from the signal pressure connection

(output) to the actuator using a connecting

plate. The switchover plate is no longer

used.

Note: Switchover and connecting plates are

accessories for the 120 cm² actuator. For

details, see table on page 12.

For attachment to 240 and 350 cm² actua-

tors (Fig. 2), the signal pressure must be

supplied to the signal pressure connection of

the actuator using the appropriate hook-up.

The required hook-up kit is listed in the table

on page 12.

Furthermore, the signal pressure hole on the

back of the positioner housing has to be

sealed. To do so, remove the screw installed

in the hole below the signal pressure hole

(parking position) and screw it into the sig-

nal pressure hole (see Fig. 3).

2.1 Determinng the direction of

action

The positioner's direction of action also de-

termines its attachment position on the actu-

ator, either on the left or right side of the

yoke as illustrated in Figs. 3 and 2. The po-

sition of the booster (12) must be arranged

accordingly on the positioner.

When the input signal (reference variable)

increases, the signal pressure pst may either

increase (direct action >>) or decrease (re-

verse action <>). The same applies when the

input signal decreases. For direct action >>,

the signal pressure decreases, whereas it in-

creases for reverse action <>.

8EB 8385 EN

Attachment to actuators