TLV CV-COS-20 User manual

172-654741MA-01 (CV-COS-20/CV-COS-20D) 7 October 2021

Electro-Pneumatic Control Valve

with Built-in Separator and Steam Trap

CV-COS-20/CV-COS-20D

(for Valve Unit)

Copyright © 2021 by TLV CO., LTD.

All rights reserved

172-654741MA-01 (CV-COS-20/CV-COS-20D) 7 Oct 2021

1

Contents

Introduction .......................................................................1

Safety Considerations.......................................................2

Specifications....................................................................4

Configuration.....................................................................5

Installation.........................................................................9

Maintenance....................................................................13

Disassembly/Reassembly...............................................14

Troubleshooting...............................................................25

TLV EXPRESS LIMITED WARRANTY...........................26

Service ............................................................................28

Options............................................................................29

Introduction

Thank you for purchasing the TLV electro-pneumatic control valve with built-in

separator and steam trap CV-COS-20/CV-COS-20D.

This product has been thoroughly inspected before being shipped from the

factory. When the product is delivered, before doing anything else, check the

specifications and external appearance to make sure nothing is out of the

ordinary. Also be sure to read this manual carefully before use and follow the

instructions to be sure of using the product properly.

If detailed instructions for special order specifications or options not contained

in this manual are required, please contact TLV for full details.

The TLV electro-pneumatic control valve with built-in separator and steam

trap is a revolutionary product that combines a digital positioner, a diaphragm-

type actuator, a separator and a steam trap. Steam-using equipment can

achieve its intended efficiency only if the steam being used is very dry. Using

steam in which matter such as condensate, scale or types of grease is

entrained can not only result in problems with the steam-using equipment and

in lowered productivity, but can also lead to shortened service life for and

malfunction of the control valve. The CV-COS-20/CV-COS-20D are control

valves that offer a solution for these problems by supplying high-quality steam

to the process and offering maximum productivity.

This instruction manual is intended for use with the model(s) listed on the front

cover. It is needed not only for installation, but also for subsequent

maintenance, disassembly/reassembly and troubleshooting. Please keep it in

a safe place for future reference.

For details of the actuator and the electro-pneumatic digital positioner, refer to

the respective instruction manuals issued by the manufacturer.

172-654741MA-01 (CV-COS-20/CV-COS-20D) 7 Oct 2021

2

Safety Considerations

Read this section carefully before use and be sure to follow the instructions.

Installation, inspection, maintenance, repairs, disassembly, adjustment and valve

opening/closing should be carried out only by trained maintenance personnel.

The precautions listed in this manual are designed to ensure safety and prevent

equipment damage and personal injury. For situations that may occur as a result

of erroneous handling, three different types of cautionary items are used to

indicate the degree of urgency and the scale of potential damage and danger:

DANGER, WARNING and CAUTION.

The three types of cautionary items above are very important for safety: be sure

to observe all of them as they relate to installation, use, maintenance and repair.

Furthermore, TLV accepts no responsibility for any accidents or damage

occurring as a result of failure to observe these precautions.

Symbols

Indicates a DANGER, WARNING or CAUTION item.

Indicates an urgent situation which poses a threat of death or

serious injury

Indicates that there is a potential threat of death or serious injury

Indicates that there is a possibility of injury or equipment / product

damage

NEVER apply direct heat to the float.

The float may explode due to increased internal pressure, causing

accidents leading to serious injury or damage to property and

equipment.

Install properly and DO NOT use this product outside the

recommended operating pressure, temperature and other

specification ranges.

Improper use may result in such hazards as damage to the

product or malfunctions that may lead to serious accidents. Local

regulations may restrict the use of this product to below the

conditions quoted.

DO NOT use the product in excess of the maximum operating

pressure differential.

Such use could make discharge through the steam trap

impossible (blocked).

Use hoisting equipment for heavy objects (weighing

approximately 20 kg (44 lb) or more).

Failure to do so may result in back strain or other injury if the

object should fall.

DO NOT use only the actuator eye bolt when hoisting or

lifting the assembled product.

Failure to observe this precaution may lead to product damage.

Continued on the next page

DANGER

WARNING

CAUTION

WARNING

CAUTION

172-654741MA-01 (CV-COS-20/CV-COS-20D) 7 Oct 2021

3

Take measures to prevent people from coming into direct

contact with product outlets.

Failure to do so may result in burns or other injury from the

discharge of fluids.

When disassembling or removing the product, wait until the

internal pressure equals atmospheric pressure and the

surface of the product has cooled to room temperature.

Disassembling or removing the product when it is hot or under

pressure may lead to discharge of fluids, causing burns, other

injuries or damage.

Be sure to use only the recommended components when

repairing the product, and NEVER attempt to modify the

product in any way.

Failure to observe these precautions may result in damage to the

product and burns or other injury due to malfunction or the

discharge of fluids.

Do not use excessive force when connecting threaded pipes

to the product.

Over-tightening may cause breakage leading to fluid discharge,

which may cause burns or other injury.

Use only under conditions in which no freeze-up will occur.

Freezing may damage the product, leading to fluid discharge,

which may cause burns or other injury.

Use only under conditions in which no water hammer will

occur.

The impact of water hammer may damage the product, leading to

fluid discharge, which may cause burns or other injury.

Make sure the power supply is OFF before carrying out work

on the wiring or inspections involving disassembly.

If such work is carried out with the power on, there is a danger

that equipment may malfunction or electric shock may occur,

leading to injury or other accidents.

Make sure that wiring work requiring a special license is

carried out by qualified personnel.

If carried out by unqualified personnel, overheating or short

circuits leading to injury, fires, damage or other accidents may

occur.

When using this product, NEVER stand close to, or leave

tools anywhere near, moving parts, such as the shaft.

Contact with moving parts or objects becoming caught in moving

parts could lead to injury or damage or other accidents.

CAUTION

172-654741MA-01 (CV-COS-20/CV-COS-20D) 7 Oct 2021

4

Specifications

Install properly and DO NOT use this product outside the recommended

operating pressure, temperature and other specification ranges.

Improper use may result in such hazards as damage to the product or

malfunctions which may lead to serious accidents. Local regulations

may restrict the use of this product to below the conditions quoted.

CAUTION

DO NOT use the product in excess of the maximum operating pressure

differential; such use could make discharge impossible (blocked).

CAUTION

Use only under conditions in which no freeze-up will occur. Freezing

may damage the product, leading to fluid discharge, which may cause

burns or other injury.

CAUTION

Refer to the product nameplate for detailed specifications.

Valve Section

Actuator Section

*Maximum allowable pressure (PMA) and maximum allowable temperature (TMA) are

PRESSURE SHELL DESIGN CONDITIONS, NOT OPERATING CONDITIONS.

**Valve No. is displayed for products with options. This item is omitted from the

nameplate when there are no options.

Model

NominalDiameter

Maximum Allowable*

Pressure*

Maximum Operating

Pressure

Maximum Allowable

Temperature (TMA)*

Maximum Operating

Temperature (TMO)

Valve No.**

Serial No.

Operating Direction

Model

NominalDiameter

Maximum Allowable

Pressure*

Maximum Operating

Pressure

Maximum Allowable

Temperature (TMA)*

Maximum Operating

Temperature (TMO)

Valve No.**

Serial No.

Spring Range Pressure supplied to

Positioner

Valve Material

Valve Characteristic

Stroke Cv Value

172-654741MA-01 (CV-COS-20/CV-COS-20D) 7 Oct 2021

5

Configuration

CV-COS-20

Sizes 15 to 50 mm (1/2to 2 in)

No.

Description

A*

B*

C*

D*

1

Main Body

2

Separator Body

3

Trap Cover

4

Separator Screen

5

Separator

6

Wave Spring

7

Separator Body Gasket

8

Separator Body Bolt

9

Float Cover

10

Float

11

Float Cover Bolt

12

Washer

13

Trap Cover Gasket

14

Trap Valve Seat Gasket

15

Trap Valve Seat

16

Trap Cover Bolt

17

Valve Bonnet

18

Stem Connector Nut

19

Locknut

20

Guide Bushing

21

Stuffing Box V-ring

Packing

22

Stuffing Box Washer

23

Stuffing Box Spring

24

Plug

25

Valve Bonnet Gasket

26

Valve Bonnet Bolt

27

Valve Bonnet Nut

28

Valve Seat

29

Nameplate

30

Travel Indicator Scale

31

Stem Bracket Clamp

32

Actuator Stem

33

Fixing Nut

*Replacement parts are available only in

the following kits:

A = Maintenance Kit

B = Repair Kit

C = Repair Kit for Trap Valve Seat

D = Float

Actuator

Section

Positioner

Section

Valve Section

Eye Bolt

Actuator area

700 cm2(1.08 in2) only

172-654741MA-01 (CV-COS-20/CV-COS-20D) 7 Oct 2021

6

CV-COS-20

Sizes 65 to 100 mm (21/2to 4 in)

No.

Description

A*

B*

C*

D*

1

Main Body

2

Separator Body

3

Trap Cover

4

Separator Screen

5

Separator

6

Wave Spring

7

Separator Body Gasket

8

Separator Body Bolt

9

Float Cover

10

Float

11

Float Cover Bolt

12

Washer

13

Trap Cover Gasket

14

Trap Valve Seat Gasket

15

Trap Valve Seat

16

Trap Cover Bolt

17

Valve Bonnet

18

Stem Connector Nut

19

Locknut

20

Guide Bushing

21

Stuffing Box V-ring

Packing

22

Stuffing Box Washer

23

Stuffing Box Spring

24

Plug

25

Valve Bonnet Gasket

26

Valve Bonnet Bolt

27

Valve Bonnet Nut

28

Valve Seat

29

Nameplate

30

Travel Indicator Scale

31

Stem Bracket Clamps

32

Actuator Stem

33

Fixing Nut

34

Baffle Nut

35

Baffle

*Replacement parts are available only in

the following kits:

A = Maintenance Kit

B = Repair Kit

C = Repair Kit for Trap Valve Seat

D = Float

172-654741MA-01 (CV-COS-20/CV-COS-20D) 7 Oct 2021

7

CV-COS-20D (Optional)

Sizes 15 to 50 mm (1/2to 2 in)

No.

Description

A*

B*

C*

D*

1

Main Body

2

Separator Body

3

Trap Cover

4

Separator Screen

5

Separator

6

Wave Spring

7

Separator Body Gasket

8

Separator Body Bolt

9

Float Cover

10

Float

11

Float Cover Bolt

12

Washer

13

Trap Cover Gasket

14

Trap Valve Seat Gasket

15

Trap Valve Seat

16

Trap Cover Bolt

17

Valve Bonnet

18

Stem Connector Nut

19

Locknut

20

Guide Bushing

21

Stuffing Box V-ring

Packing

22

Stuffing Box Washer

23

Stuffing Box Spring

24

Plug

25

Valve Bonnet Gasket

26

Valve Bonnet Bolt

27

Valve Bonnet Nut

28

Valve Seat

29

Nameplate

30

Travel Indicator Scale

31

Stem Bracket Clamps

32

Actuator Stem

33

Fixing Nut

*Replacement parts are available only in

the following kits:

A = Maintenance Kit

B = Repair Kit

C = Repair Kit for Trap Valve Seat

D = Float

Actuator

Section

Positioner

Section

Valve Section

172-654741MA-01 (CV-COS-20/CV-COS-20D) 7 Oct 2021

8

CV-COS-20D (Optional)

Sizes 65 to 100 mm (21/2to 4 in)

No.

Description

A*

B*

C*

D*

1

Main Body

2

Separator Body

3

Trap Cover

4

Separator Screen

5

Separator

6

Wave Spring

7

Separator Body Gasket

8

Separator Body Bolt

9

Float Cover

10

Float

11

Float Cover Bolt

12

Washer

13

Trap Cover Gasket

14

Trap Valve Seat Gasket

15

Trap Valve Seat

16

Trap Cover Bolt

17

Valve Bonnet

18

Stem Connector Nut

19

Locknut

20

Guide Bushing

21

Stuffing Box V-ring

Packing

22

Stuffing Box Washer

23

Stuffing Box Spring

24

Plug

25

Valve Bonnet Gasket

26

Valve Bonnet Bolt

27

Valve Bonnet Nut

28

Valve Seat

29

Nameplate

30

Travel Indicator Scale

31

Stem Bracket Clamps

32

Actuator Stem

33

Fixing Nut

34

Baffle Nut

35

Baffle

*Replacement parts are available only in

the following kits:

A = Maintenance Kit

B = Repair Kit

C = Repair Kit for Trap Valve Seat

D = Float

Actuator

Section

Positioner

Section

Valve Section

Eye Bolt

Actuator area

700 cm2(1.08 in2) only

172-654741MA-01 (CV-COS-20/CV-COS-20D) 7 Oct 2021

9

Installation

Install properly and DO NOT use this product outside the recommended

operating pressure, temperature and other specification ranges.

Improper use may result in such hazards as damage to the product or

malfunctions which may lead to serious accidents. Local regulations

may restrict the use of this product to below the conditions quoted.

CAUTION

Use hoisting equipment for heavy objects (weighing approximately

20 kg (44 lb) or more). Failure to do so may result in back strain or other

injury if the object should fall.

CAUTION

DO NOT use only the actuator eye bolt when hoisting or lifting the

assembled product. Failure to observe this precaution may lead to

product damage.

CAUTION

Take measures to prevent people from coming into direct contact with

product outlets. Failure to do so may result in burns or other injury from

the discharge of fluids.

CAUTION

Do not use excessive force when connecting threaded pipes to the

product. Over-tightening may cause breakage leading to fluid

discharge, which may cause burns or other injury.

CAUTION

Installation, inspection, maintenance, repairs, disassembly and adjustment and valve

opening/closing should be carried out only by trained maintenance personnel.

Check to make sure that the piping where the product is to be installed is constructed

properly. If the piping is not correctly constructed, the valve may not perform optimally.

1. Blowdown

Before installing the product, be sure to blow down all piping

thoroughly.

If this is not possible, perform a blowdown using the bypass valve.

Blowdown is especially important for newly installed piping or

after the system has been shut down for a long period of time.

2. Installing the actuator section

The eye bolt welded onto the upper part of the diaphragm

housing is for mounting and removing the actuator. Do not lift the

assembled product using only the eye bolt.

(See Fig. 1)

3. Installing the control valve

Lift the assembled product using hoisting equipment such as cranes

and forklifts. Do not lift the assembled product using only the eye

bolt. (See Fig. 2)

Fig. 1

Hoisting the

actuator

Fig. 2

Hoisting the

control valve

172-654741MA-01 (CV-COS-20/CV-COS-20D) 7 Oct 2021

10

4. Removing any protective caps and seals

Before installation, be sure to remove all protective seals and caps. (Found in

three locations, on the product inlet and outlets.)

CV-COS-20

CV-COS-20D

5. Installation angle

Install the product so that the arrow mark on the valve body points horizontallyin

the direction of steam flow, and it should be installed horizontally in the piping

with the actuator at the top. Allowable inclination is 10 degrees in the fore-aft

direction and 15 degrees in the plane perpendicular to the steam flow line.

CV-COS-20

CV-COS-20D

6. Piping support

Install the product, paying attention to avoid excessive load, bending and

vibration. Support the inlet and outlet pipes securely.

CV-COS-20

CV-COS-20D

① ②

③

① ②

③

172-654741MA-01 (CV-COS-20/CV-COS-20D) 7 Oct 2021

11

7. Maintenance space

Leave sufficient space for maintenance, inspection and repair. (Units: mm)

CV-COS-20

CV-COS-20D

8. Trap outlet pipe

For ease of maintenance, installation of a union connection is recommended

for the trap outlet pipe.

Connect the outlet pipe to a condensate return line, or

extend it to a trench. In the case of the latter, make

sure the end of the pipe is above the waterline. (Dirt

and water may be sucked up by the vacuum formed

during trap closure and system shutdown.) If the end

must be underwater, make sure the piping has a

small hole, as shown in the drawing below.

9. Accessories

Always install a shut-off valve, pressure gauge and bypass lines at both inlet and

outlet. Ball valves, which will not retain condensate, are recommended for inlet

and outlet shut-off valves. The bypass pipe should be at least 1/2 of the size of

the inlet (primary side) pipe.

10. Installation environment

Check the installation environment to make sure that the ambient temperature

does not exceed the actuator ambient temperature limit and that no corrosive

gasses are present.

11. Installing the shut-off valve

Though the product adequately performs the function of a shut-off valve initially,

extended use will result in a drop in its performance as an isolation valve. Be sure

to install a separate shut-off or automatic valve if complete isolation is needed.

400

(16)

400

(16)

400

(16)

400

(16)

300

(12)

100

(4)

100

(4)

100 (4)

300

(12)

100

(4)

100

(4)

100 (4)

110 to 190 (41/2to 71/2)

Small hole

15 mm

(1/2in)

172-654741MA-01 (CV-COS-20/CV-COS-20D) 7 Oct 2021

12

12. Installing the safety valve

When installing a safety valve, be sure not to install it between the control valve

and the shut-off valve. It must be installed near the equipment it is to protect,

on the outlet side of the shut-off valve.

13. Avoid foreign matter and water hammer

Do not install in locations in the piping where foreign matter accumulates or

where impact from water pressure (water hammer) occurs.

14. Piping gaskets

Be careful that the piping gaskets do not protrude outside the inner bore of the

flange. The type of medium being used and the temperature must be taken into

account in order to select a gasket of a suitable material.

15. Air line blowdown/purge

Before connecting the air lines for the motive air that is to be piped to the

actuator, blow out the air in the lines to purge any dirt, foreign matter, oil or water

from inside of the piping.

16. Quality of motive air

Supply to the actuator only clean air that does not contain water, oil or foreign

matter.

To prevent malfunction due to contamination of the air supply, installation of the

optional air filter regulator (5 µm filter) and mist separator (0.3 µm filter) as a set

is recommended.

If air quality results in operation failure, the entire actuator unit (including the

integrated positioner) must be replaced.

If there is a problem in operation, determine the cause using the “Troubleshooting”

section in this manual.

Safety Valve

Safety Valve

172-654741MA-01 (CV-COS-20/CV-COS-20D) 7 Oct 2021

13

Maintenance

Take measures to prevent people from coming into direct contact with

product outlets. Failure to do so may result in burns or other injury from

the discharge of fluids.

CAUTION

When disassembling or removing the product, wait until the internal

pressure equals atmospheric pressure and the surface of the product

has cooled to room temperature. Disassembling or removing the

product when it is hot or under pressure may lead to discharge of fluids,

causing burns, other injuries or damage.

CAUTION

Be sure to use only the recommended components when repairing the

product, and NEVER attempt to modify the product in any way. Failure to

observe these precautions may result in damage to the product or burns

or other injury due to malfunction or the discharge of fluids.

CAUTION

Operational Check

An inspection of the following items should be done on a daily basis to determine

whether the product is operating properly or has failed. Periodically (at least

biannually) the operation should also be checked.

In the event of failure (malfunction), also refer to the "Troubleshooting" section for

remedies.

Inspection Item

Inspection Points

Remedy for Failure (Malfunction)

Leakage from valve

(when the valve is

closed)

Visual inspection orstethoscope

inspection; is the outlet side pressure

or temperature elevated, or is there

the sound of the medium flowing?

Adjust the zero/span; if that does

not solve the problem, replace

with a new valve plug & stem

and valve seat

Leakage from gland

area

Visual inspection; is fluid leaking

from the gap between the guide

bushing and the valve stem, or

are there signs it has leaked

previously?

Coat the guide bushing and the

valve stem with grease; if that

does not solve the problem,

replace with new V-ring packing

Leakage from the

gaskets between

any pressurized

parts

Visual inspection; is fluid leaking

from the gasket areas on

pressurized parts?

Apply additional tightening (refer

to recommended torque) or

replace with new gaskets

Leakage from

pressurized parts

such as body and

valve bonnet

Visual inspection; is fluid leaking

from pressurized parts such as

the body or valve bonnet?

Replace any pressurized parts at

leak locations

Leakage from the

trap area

Visual inspection or stethoscope

inspection; is live steam being

discharged from the trap outlet

piping, or can the sound of a

steam leak be heard?

Clean the sealing surface of the

trap valve seat or replace the

valve seat

Parts Inspection

When parts have been removed, use the following table to inspect the parts and

replace any that are found to be defective.

Inspection Item

Gasket(s): Check for warping and damage (Graphite gaskets MUST be replaced if

disassembled)

Stuffing Box V-ring Packing: Check for warping or damage

Valve Plug & Stem, Valve Seat: Check for damage or scratches

Separator Screen: Check for clogging and corrosion

Trap Valve Seat: Check for scratches, dents, etc.

Float: Check for scratches, dents, etc.

172-654741MA-01 (CV-COS-20/CV-COS-20D) 7 Oct 2021

14

Disassembly/Reassembly

When disassembling or removing the product, wait until the internal

pressure equals atmospheric pressure and the surface of the product

has cooled to room temperature. Disassembling or removing the

product when it is hot or under pressure may lead to discharge of fluids,

causing burns, other injuries or damage.

CAUTION

Be sure to use only the recommended components when repairing the

product, and NEVER attempt to modify the product in any way. Failure to

observe these precautions may result in damage to the product or burns

or other injury due to malfunction or the discharge of fluids.

CAUTION

Use the following procedures to remove components. Use the same procedures in

reverse to reassemble. (Installation, inspection, maintenance, repairs, disassembly,

adjustment and valve opening/closing should be carried out only by trained

maintenance personnel.)

For details of the actuator and the electro-pneumatic digital positioner, refer to the

respective instruction manuals issued by the manufacturer.

Refer to “Disassembling/Reassembling the Valve and Actuator Sections” on the

following page when removing the actuator section.

Consult the table of tightening torques when mounting the actuator section on the

valve section.

NOTE: Be sure to coat all threaded portions of the valve seat and bolts with anti-seize.

Removing/Reattaching the Actuator (Positioner)

Part

During Disassembly

During Reassembly

Stem Bracket Bolt

Loosen stem bracket bolts and

remove the stem bracket clamps

connecting the actuator stem and

stem connector nut

Consult the table of tightening

torques and tighten to the proper

torque

―

When an input signal is sent to

the positioner, the actuator stem

will ascend.

―

Fixing Nut

Remove the fixing nut connecting

the actuator and the valve bonnet

while keeping the actuator stem in

the raised position

Consult the table of tightening

torques and tighten to the proper

torque

Fixing Nut

Stem Bracket Clamps

Valve Bonnet

172-654741MA-01 (CV-COS-20/CV-COS-20D) 7 Oct 2021

15

Detaching/Reattaching the Stem Connector Nut and Locknut

Part

During Disassembly

During Reassembly

Locknut,

Stem Connector

Nut

Loosen the locknut by holding the

stem connector nut with a

spanner

DO NOT disassemble with the

valve plug in contact with the valve

seat, make sure that the valve plug

is slightly suspended

Do not supply air to the actuator at

a pressure of 0.6 MPaG (85 psig, 6

barg) or more.

Consult the table of tightening

torques and tighten to the proper

torque

If the instructions given are not

followed when reassembly is

carried out, malfunctions such as

insufficient lift (insufficient flow

capacity) and/or insufficient closing

force (valve leakage) may result:

give the proper attention to the

adjustment procedure

NOTE: Be careful not to pinch your fingers between the valve stem and actuator stem!

Stem Connector Nut

Locknut

172-654741MA-01 (CV-COS-20/CV-COS-20D) 7 Oct 2021

16

Instructions for Reverse Action (Air to Open, Fail Closed) Stroke Adjustment

1. Make sure that the valve plug is securely seated in the valve seat. (Fig. 1)

2. Supply the maximum air pressure (0.33 MPaG (48 psig, 3.3 barg)) of the spring

range (e.g. 0.09 to 0.33 MPaG (13 to 48 psig, 0.9 to 3.3 barg)) to the actuator.

(Refer to the nameplate, drawing or specification data sheet (SDS) for the spring

range.)

With the actuator stem raised, screw the locknut and stem connector nut into the

guide bushing as far as possible without touching the valve stem. (Fig. 2)

3. Supply the lower limit air pressure (0.09 MPaG (13 psig, 0.9 barg)) of the spring

range (e.g. 0.09 to 0.33 MPaG (13 to 48 psig, 0.9 to 3.3 barg)) to the actuator.

The actuator stem will descend. (Fig. 3)

NOTE: Be careful not to pinch your fingers.

4. Turn the stem connector nut until it comes into contact with the actuator stem,

and turn the stem connector nut a further 1/4 turn to contact the actuator stem.

Make sure that the valve plug is seated in the valve seat.

Hold the stem connector nut with a spanner and tighten the locknut with a

proper torque. (Fig. 4)

5. Shut off the air supply to the actuator.

NOTE: Be careful not to pinch your fingers.

6. Secure the stem connector nut and the actuator stem with the stem bracket

clamps. Make sure to adjust the stem bracket clamps to 0% (fully closed) on the

travel indicator scale. (Fig. 5)

Fig. 1

Fig. 2

Fig. 3

Fig. 4

Fig. 5

Actuator Stem

Valve Stem

Locknut

Stem

Connector Nut

Actuator Stem

ascends

Actuator Stem

descends

NOTE:

Be careful

not to pinch

your fingers

Stem

Connector Nut

Locknut

Stem Bracket Clamps Travel Indicator Scale

Travel Indicator Scale

Mounting Bolt

Travel Indicator Scale

Mounting Bolt

172-654741MA-01 (CV-COS-20/CV-COS-20D) 7 Oct 2021

17

Instructions for Direct Action (Air to Close, Fail Open) Stroke Adjustment

1.Make sure that the valve plug is securely seated in the valve seat. (Fig. 1)

2. Screw the locknut and stem connector nut onto the valve stem until they are just

short of coming into contact with the guide bushing. (Fig. 2)

3. Supply the upper limit air pressure (0.1 MPaG (15 psig, 1.0 barg)) of the spring

range (e.g. 0.02 to 0.1 MPaG (3 to 15 psig, 0.2 to 1.0 barg)) to the actuator. The

actuator stem will descend. (Fig. 3)

NOTE: Be careful not to pinch your fingers.

4. Turn the stem connector nut until it comes into contact with the actuator stem,

and turn the stem connector nut a further 1/4 turn to contact the actuator stem.

Make sure that the valve plug is seated in the valve seat. Hold the stem

connector nut securely in place with a tool such as a spanner and tighten the

locknut. (Fig. 4)

5. Shut off the air supply to the actuator.

NOTE: Be careful not to pinch your fingers.

6. Secure the stem connector nut and the actuator stem with the stem bracket

clamps. Make sure to adjust the stem bracket clamps to 100% (fully open) on

the travel indicator scale. (Fig. 5)

Fig. 1

Fig. 2

Fig. 3

Fig. 4

Fig. 5

Actuator Stem

Valve Stem

Locknut

Stem

Connector Nut

Actuator Stem

ascends

Actuator Stem

descends

NOTE:

Be careful

not to pinch

your fingers

Actuator Stem

ascends

Pull up the stem

connector nut and

the valve stem

Stem Bracket

Clamps Travel Indicator Scale

Travel Indicator Scale

Mounting Bolt

Travel Indicator Scale

Mounting Bolt

172-654741MA-01 (CV-COS-20/CV-COS-20D) 7 Oct 2021

18

Disassembling/Reassembling the Gland and its Components

In the procedure below, first partially loosen the guide bushing and then remove the

valve plug & stem before removing the other parts. (The procedure is most easily

performed if the bushing is loosened while it is attached to the valve body.)

Part

During Disassembly

During Reassembly

Guide Bushing

Remove with a socket wrench

Consult the table of tightening

torques and tighten to the proper

torque

Stuffing Box

V-ring Packing

Pull up and out

Make sure to reassemble the V-ring

packing in the proper orientation;

coat the groove with heat-resistant

silicon grease; reattach the V-ring

packing with the grooves facing

downward

Stuffing Box

Washer/

Stuffing Box

Spring

Pull up and out

Reinsert

Guide Bushing

Stuffing Box V-Ring Packing

Stuffing Box Washer

Stuffing Box Spring

Cut view of

Stuffing Box

V-Ring Packing

172-654741MA-01 (CV-COS-20/CV-COS-20D) 7 Oct 2021

19

Disassembling/Reassembling of the Valve Bonnet Section

Part

During Disassembly

During Reassembly

Nut

Remove with a socket

wrench

Consult the table of tightening torques and

tighten to the proper torque, making sure to

tighten evenly

Valve Bonnet

Pull up and off, being

careful not to damage the

valve plug or valve seat

Reattach, being careful not to damage the

valve plug or valve seat; insert the bonnet

securely into the gasket housing without tilting;

check to make sure that there is no catching or

biting when the valve plug is seated in the

valve seat, and that the valve plug is securely

seated in the valve seat

Valve Bonnet

Gasket

Remove the gasket and

clean sealing surfaces

Replace with a new gasket; make sure that the

gasket does not protrude from the housing in

the body; DO NOT coat with anti-seize

Nut

Valve Bonnet

Gasket

Valve Plug

Valve Bonnet

Section

Body Section

This manual suits for next models

1

Table of contents

Other TLV Control Unit manuals

Popular Control Unit manuals by other brands

Lincoln Electric

Lincoln Electric LACI Service schematic

Kohler

Kohler K-10970 Homeowner's guide

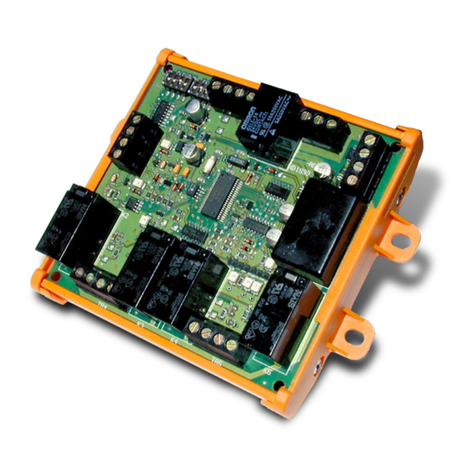

ICP DAS USA

ICP DAS USA tDS-700-T Series quick start

National Instruments

National Instruments NI 9375 Getting started guide

Timotion

Timotion TBB9 user manual

Texas Instruments

Texas Instruments 990 Maintenance manual

NIPPON VALVE CONTROLS

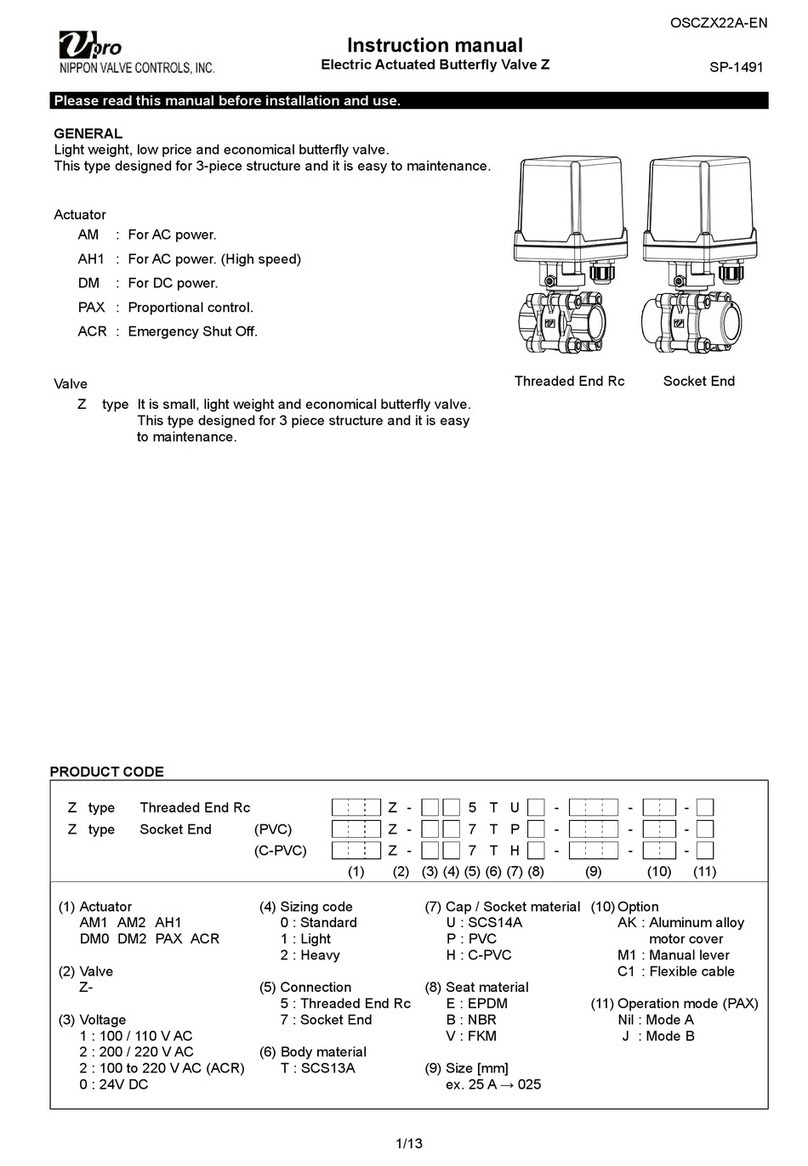

NIPPON VALVE CONTROLS SP-1491 instruction manual

Microhard Systems

Microhard Systems pMXDDL2450 operating manual

Emerson

Emerson FISHER CV500 instruction manual

Bosch

Bosch Rexroth IndraControl XFE 01.1 Series operating instructions

FarmTronics

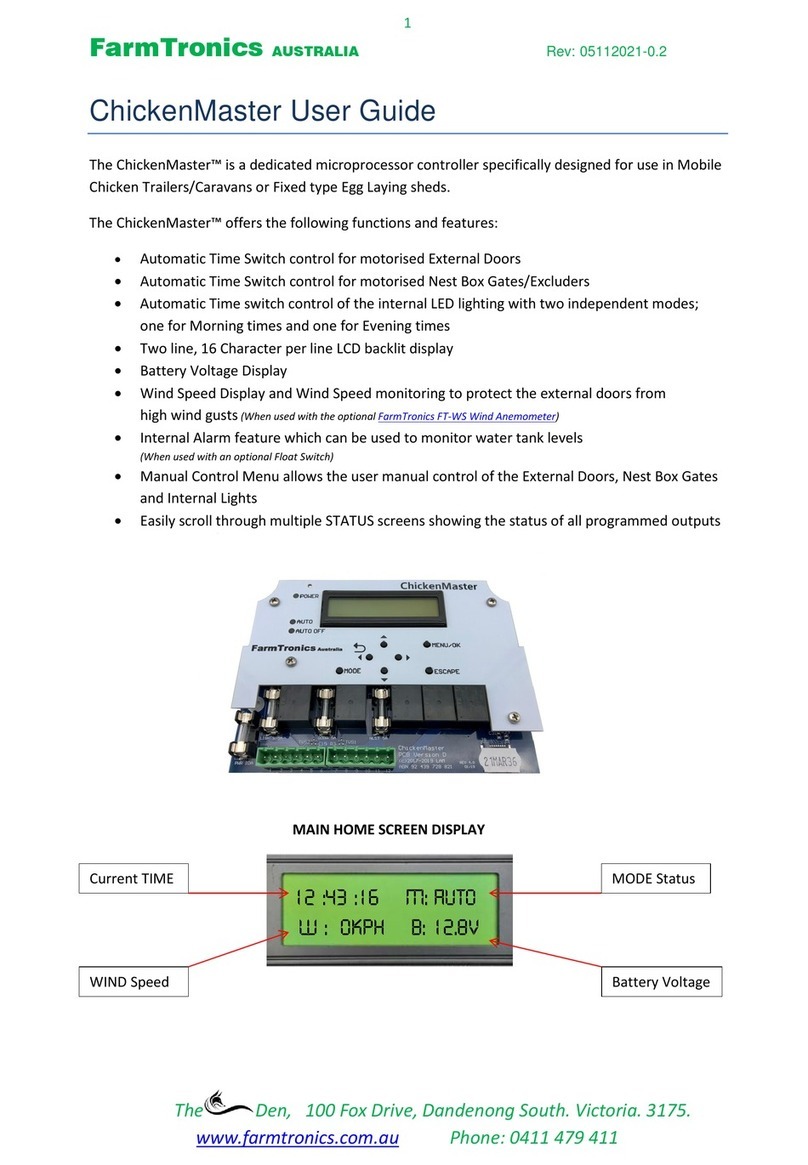

FarmTronics ChickenMaster user guide

Delma

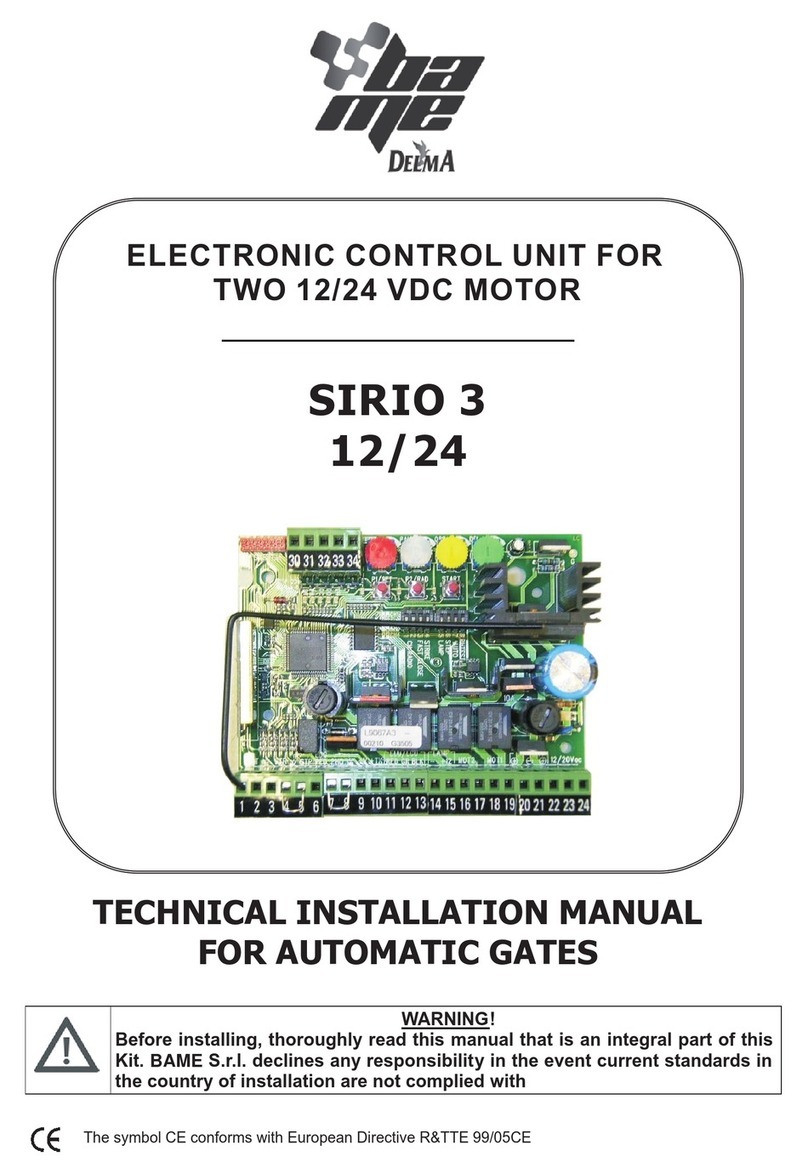

Delma SIRIO 3 Technical installation manual