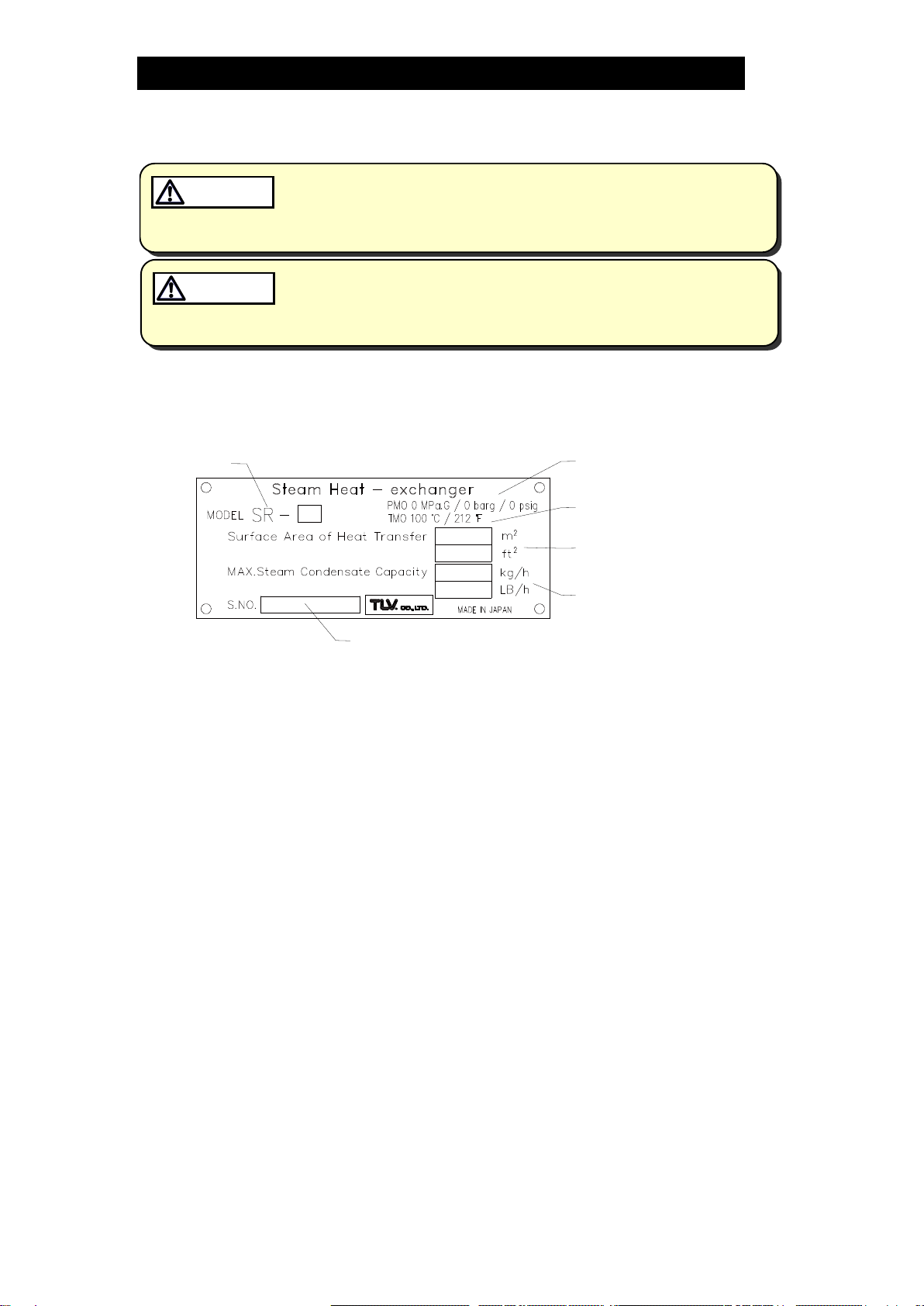

172-65207MA-08 (SR-3/SR-8) 8 Oct 2020

Operation

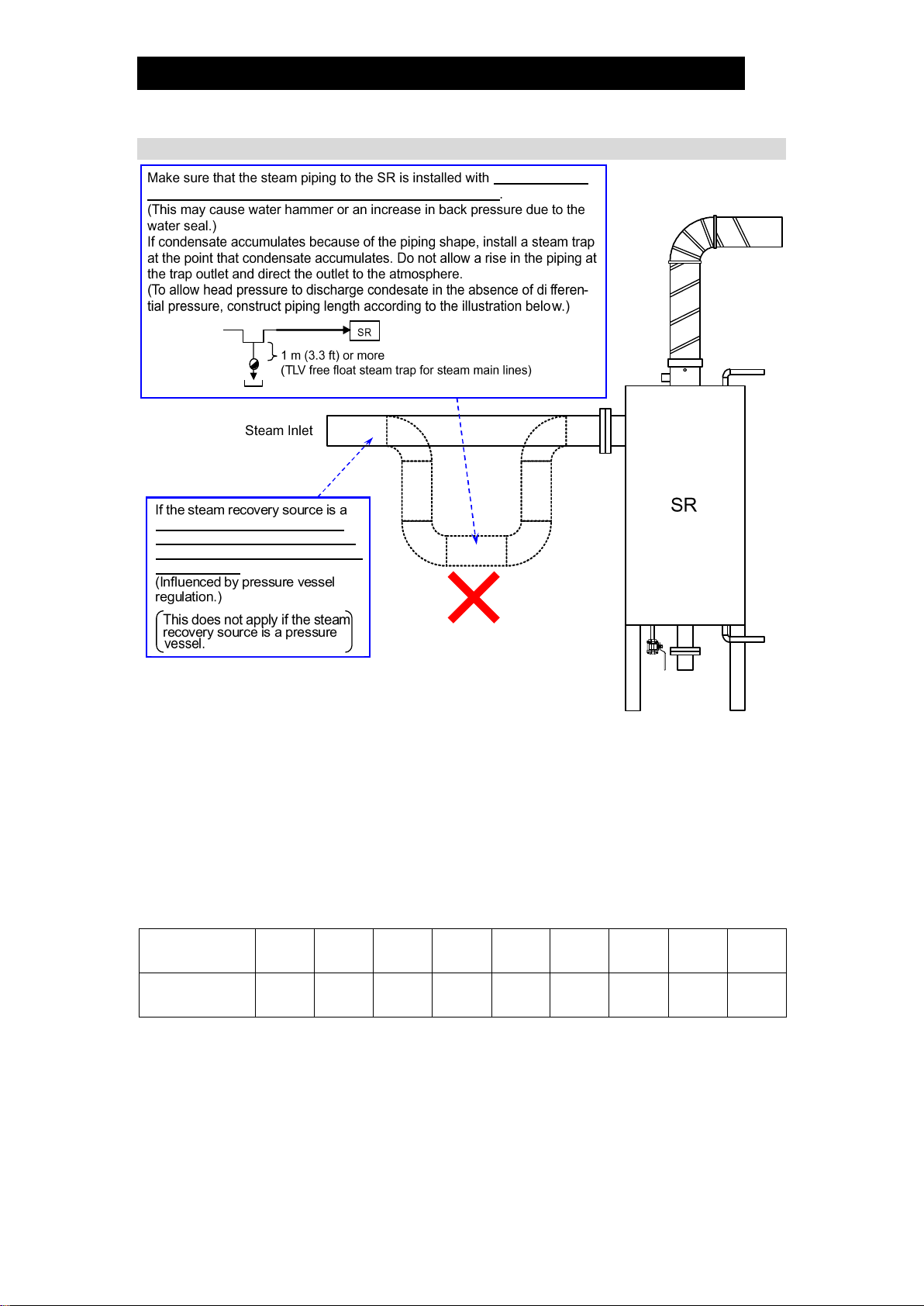

Install properly and DO NOT use this product outside the recommended

operating pressure, temperature and other specification ranges.

Improper use may result in such hazards as damage to the product or

malfunctions which may lead to serious accidents. Local regulations

may restrict the use of this product to below the conditions quoted.

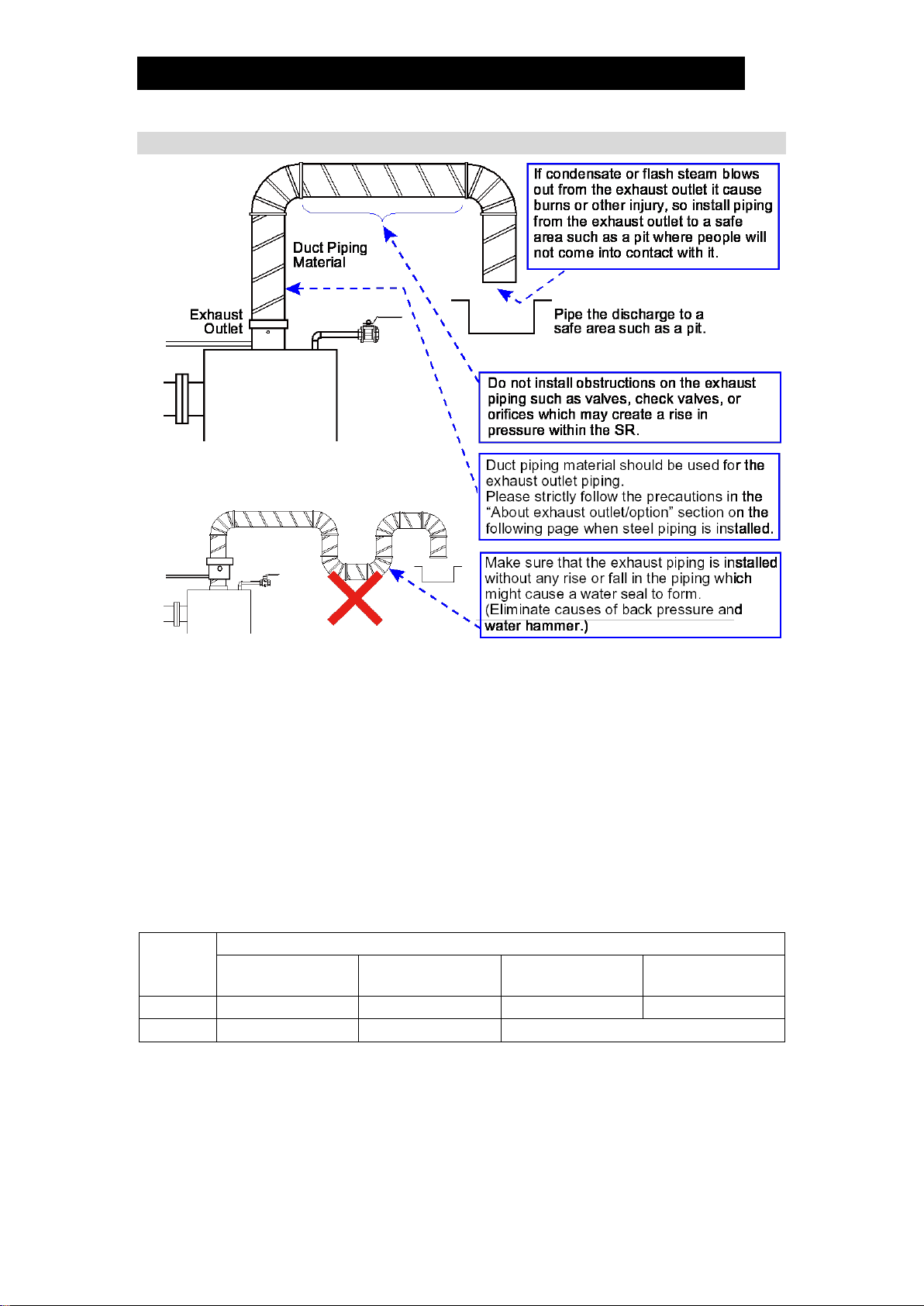

Take measures to prevent people from coming into direct contact with

product outlets. Failure to do so may result in burns or other injury from the

discharge of fluids.

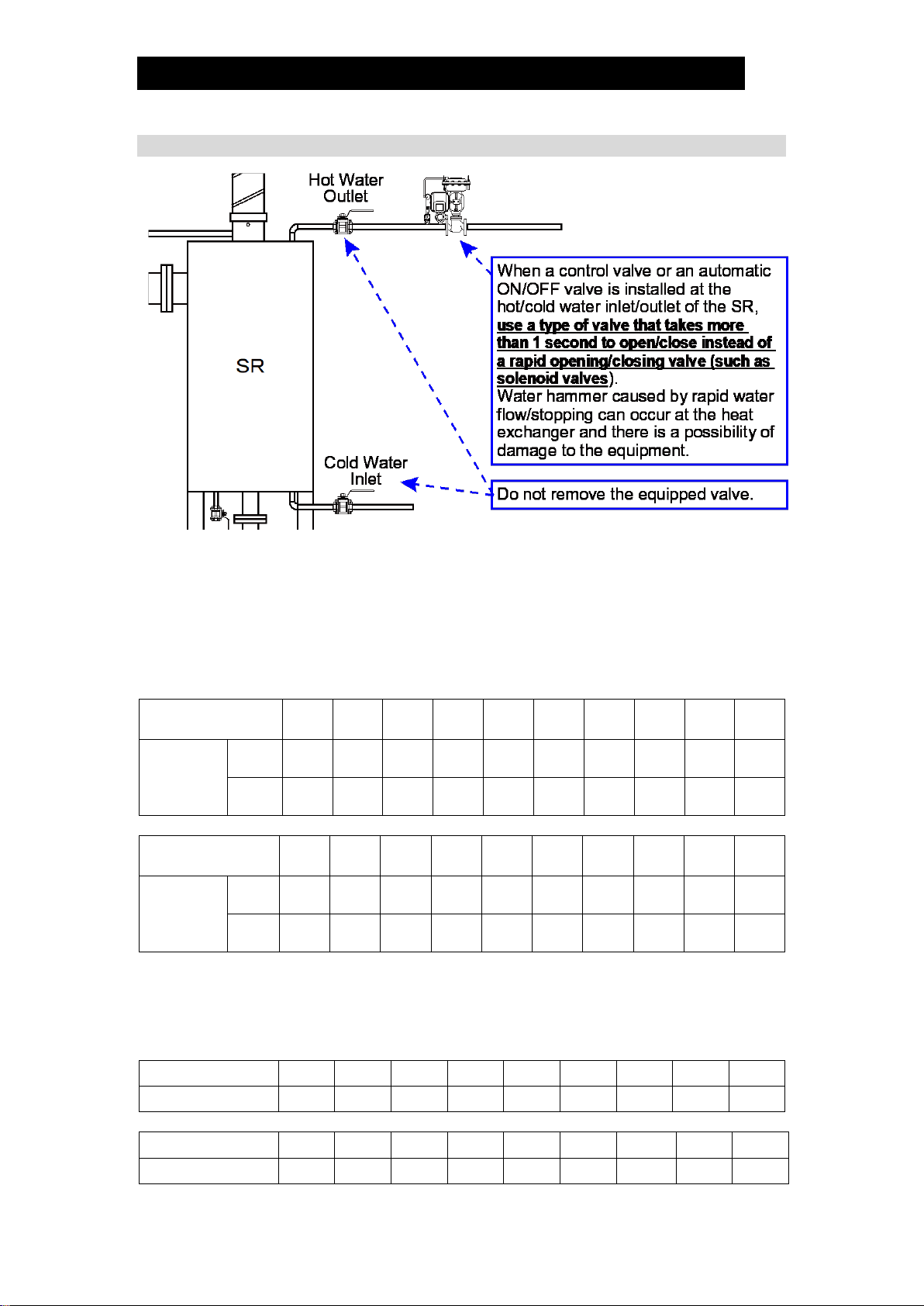

Operate valve slowly and carefully. Opening or closing valves too quickly

may cause water hammer to occur, the impact of which could cause

damage to equipment.

To be performed after installation and before initial operation

Make sure to flush the piping to remove welding slag, metal powder and filings.

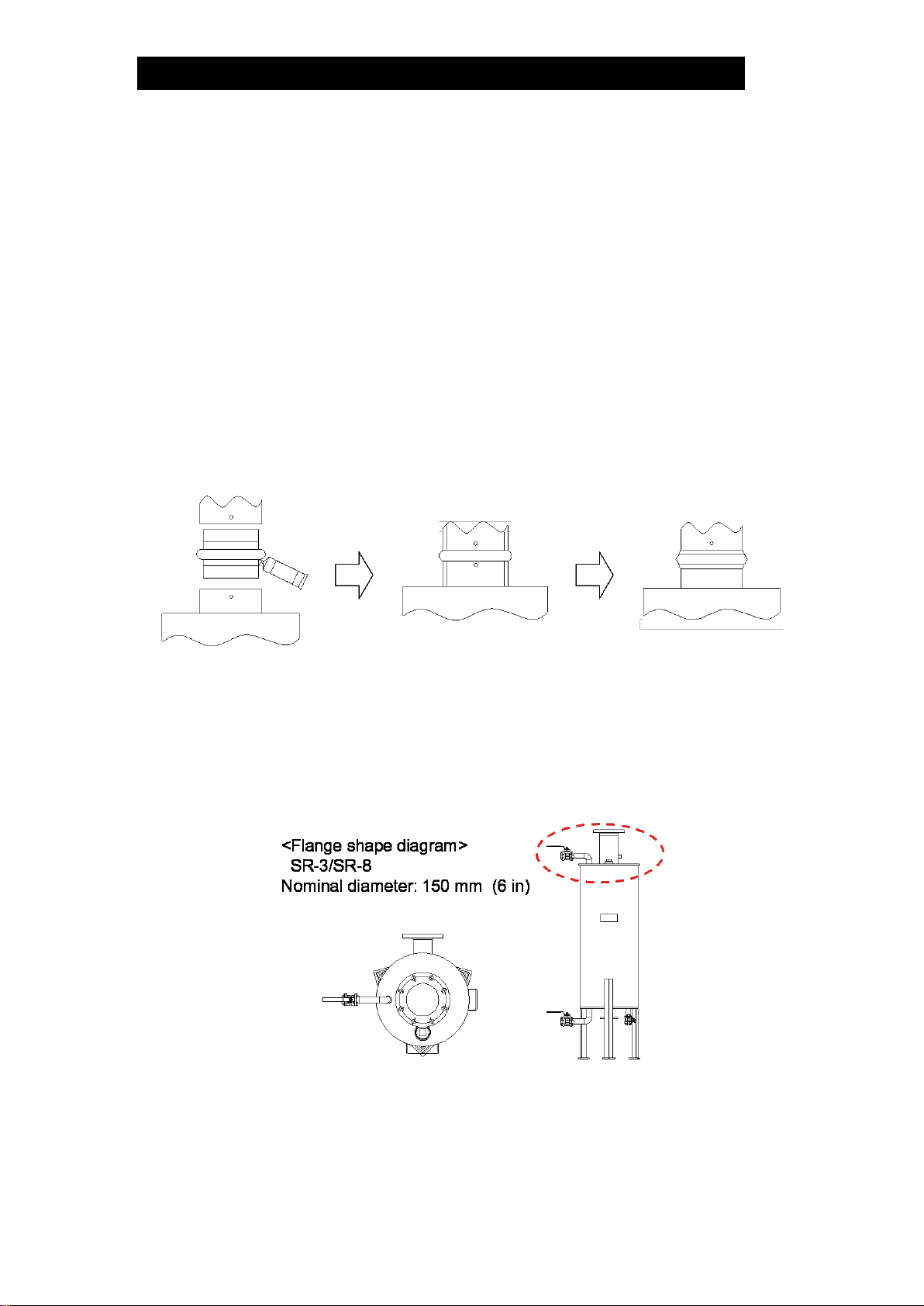

Make sure that flange bolts etc. are securely tightened before passing steam/

water through the SR.

When conducting the test operation, start with a low steam and water flow rate

and gradually increase the load to normal operating conditions.

If you start with a normal operating load at the outset and there is a leak

somewhere in the piping, there is a risk of steam or water blowing out.

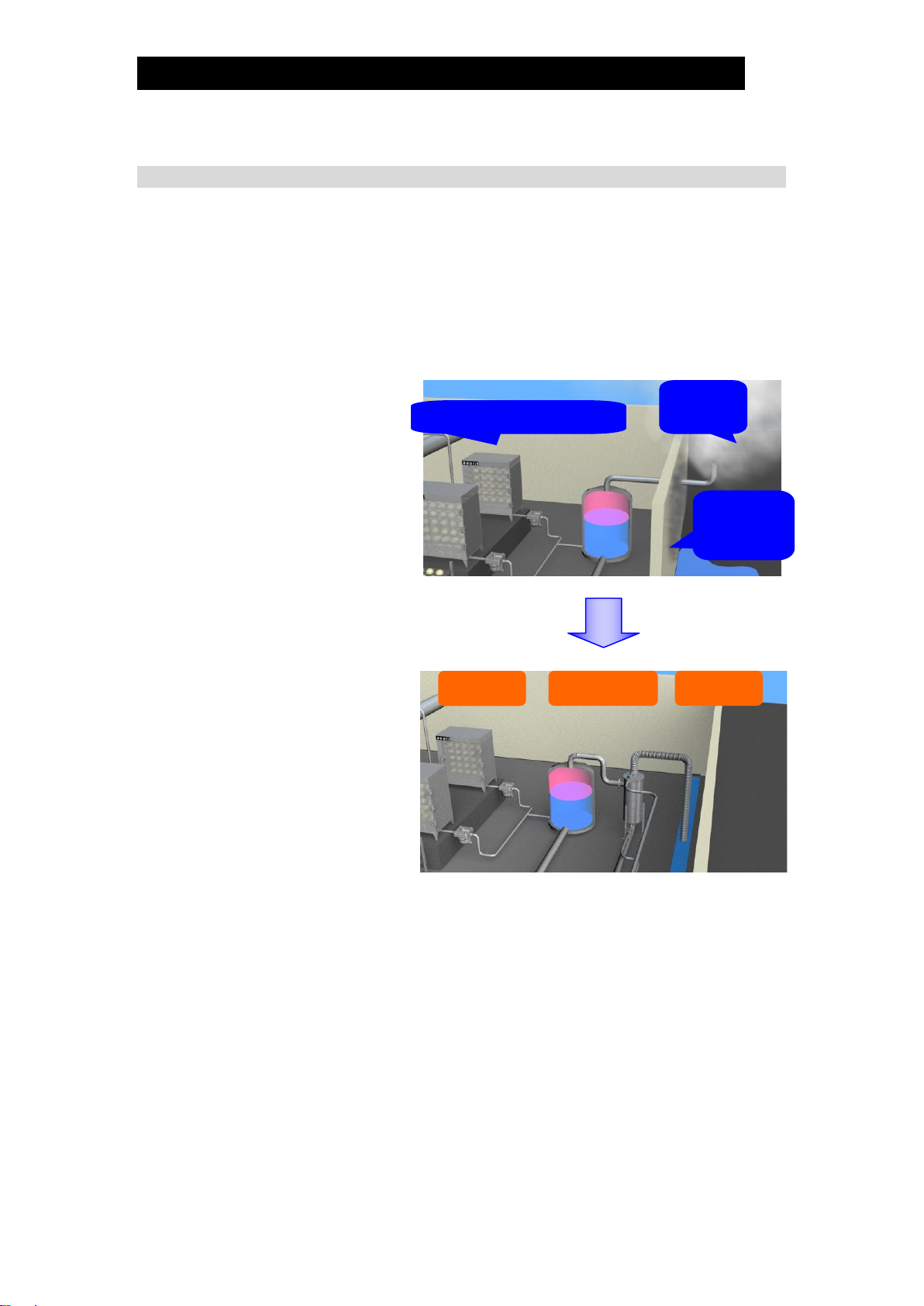

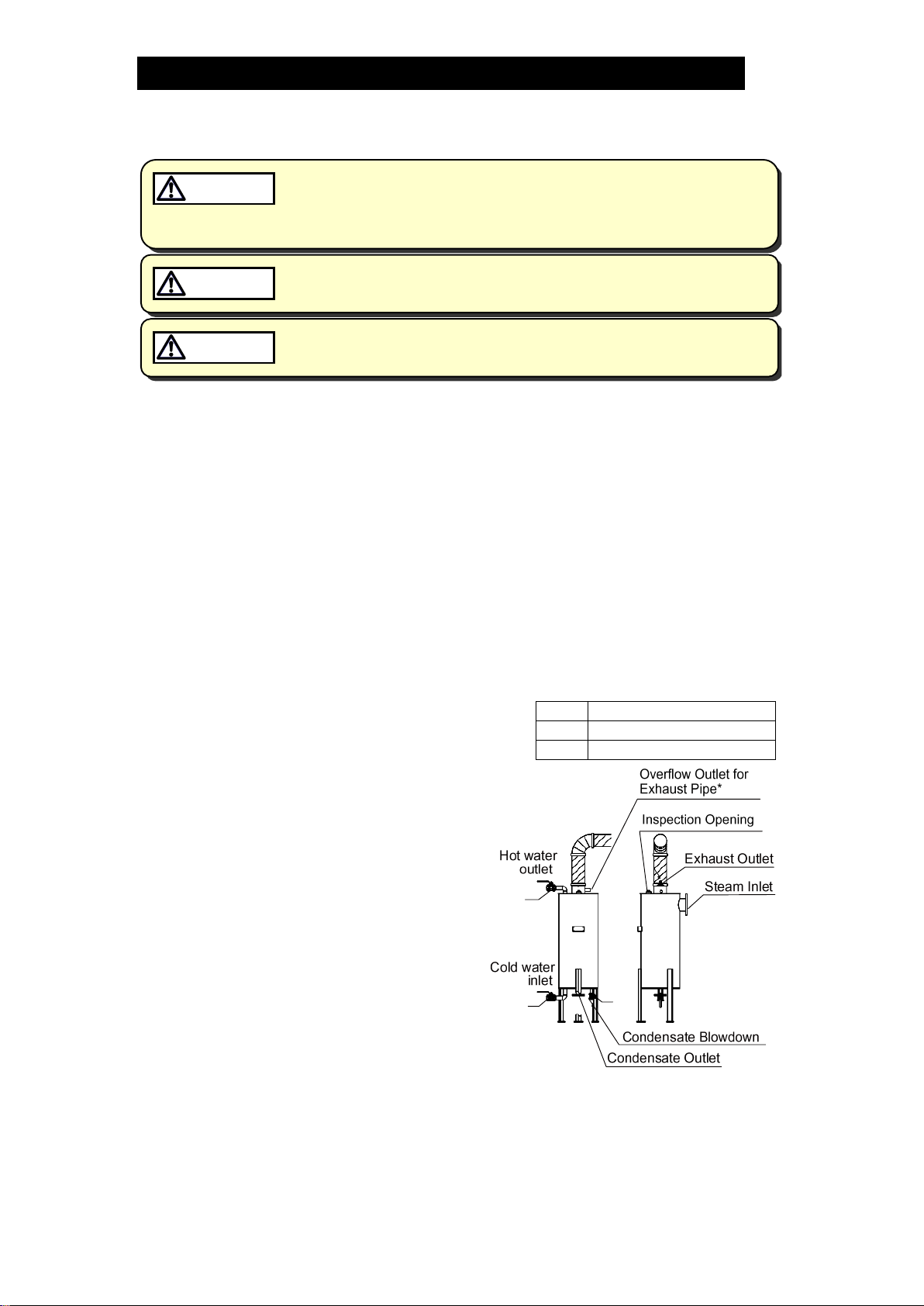

Startup

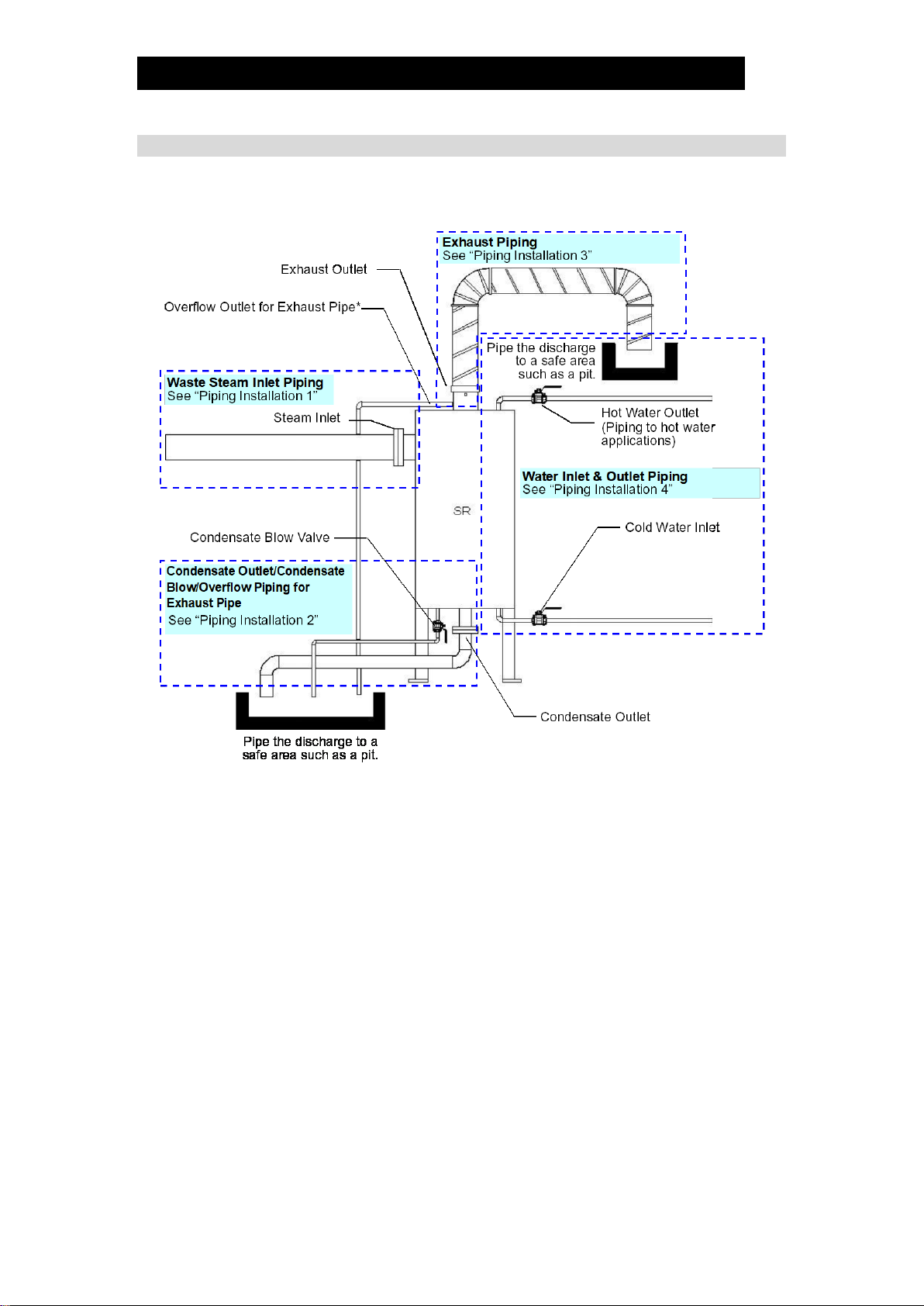

Make sure that the cold water inlet valve (A) and hot water outlet valve (B) are open

before supplying waste steam to the SR. If waste steam is supplied while the cold

water inlet valve (A) and hot water outlet valve (B) are closed, the pressure inside the

coil will increase due to volume expansion, which could damage the cold water inlet

valve (A) and hot water outlet valve (B).

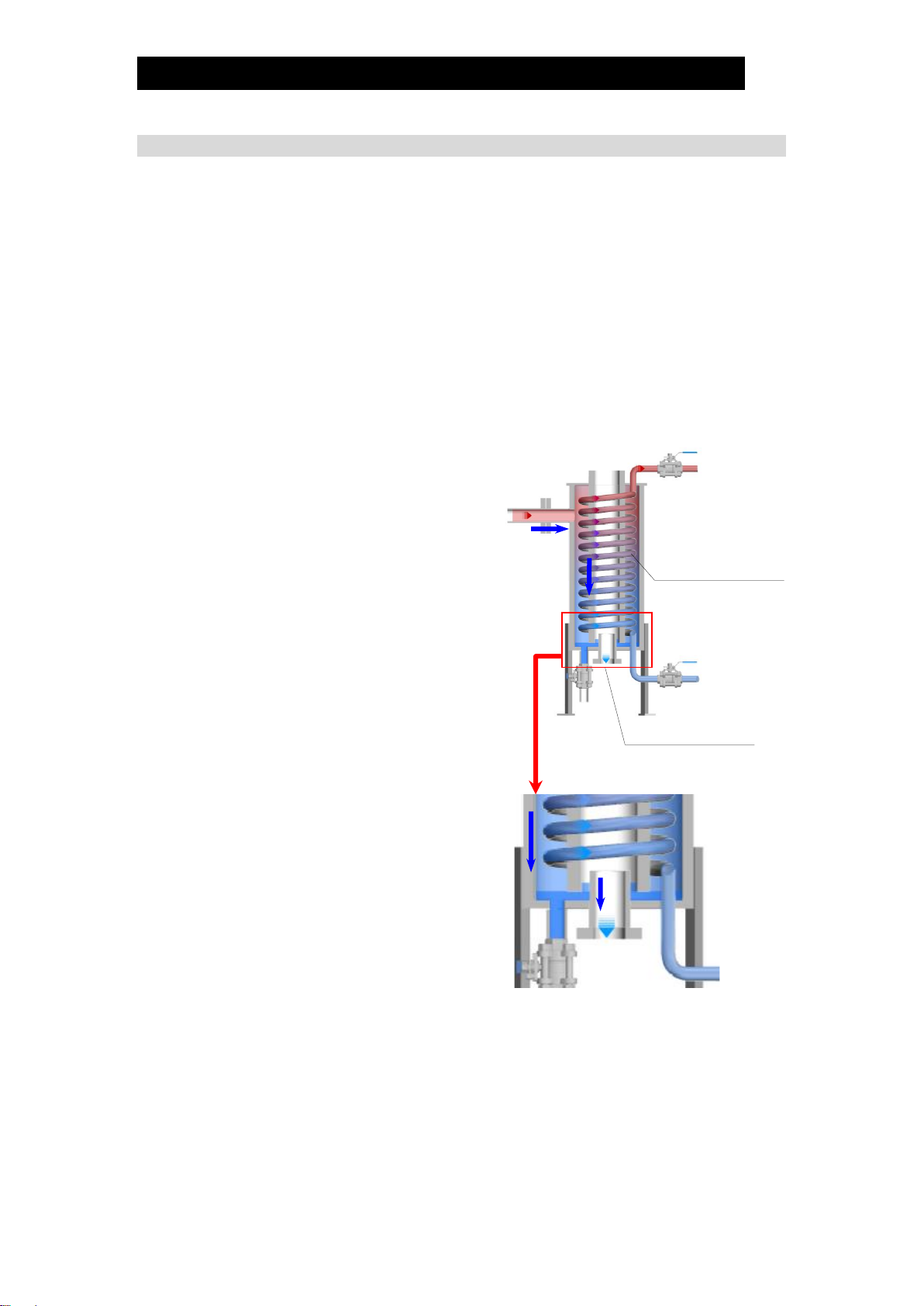

1. Make sure that the blow valve (C) in the base

of the SR is closed.

2. Open the cold water inlet valve (A) and the

hot water outlet valve (B), allowing water to

pass through the SR. In cases where either

TIC (temperature control of heated water) or

FIC (flowcontrol of heated water) is used,

start up the controls.

3. Open the condensate outlet valve, if any.

4. Open the steam inlet valve, if any.

5. Startup the equipment to allow waste

steam to enter the SR.

Make sure that there are no abnormal

discharges from the exhaust outlet or

overflow outlet for exhaust pipe*, such as

blowing steam or condensate. If there is

condensate blowing, or an abnormal

sound or vibration, halt operation immediately.

The first time you operate the SR, or when operating with the condensate blow valve

(C) open, waste steam may be discharged to the atmosphere through the exhaust

outlet or overflow outlet for exhaust pipe* immediately after initiating operation, due to

the lack of pooled condensate in the base to create an airtight water seal over the

condensate outlet. (if steam blow stops shortly then everything is normal)