TMG 1260 User manual

Other TMG Greenhouse Kit manuals

TMG

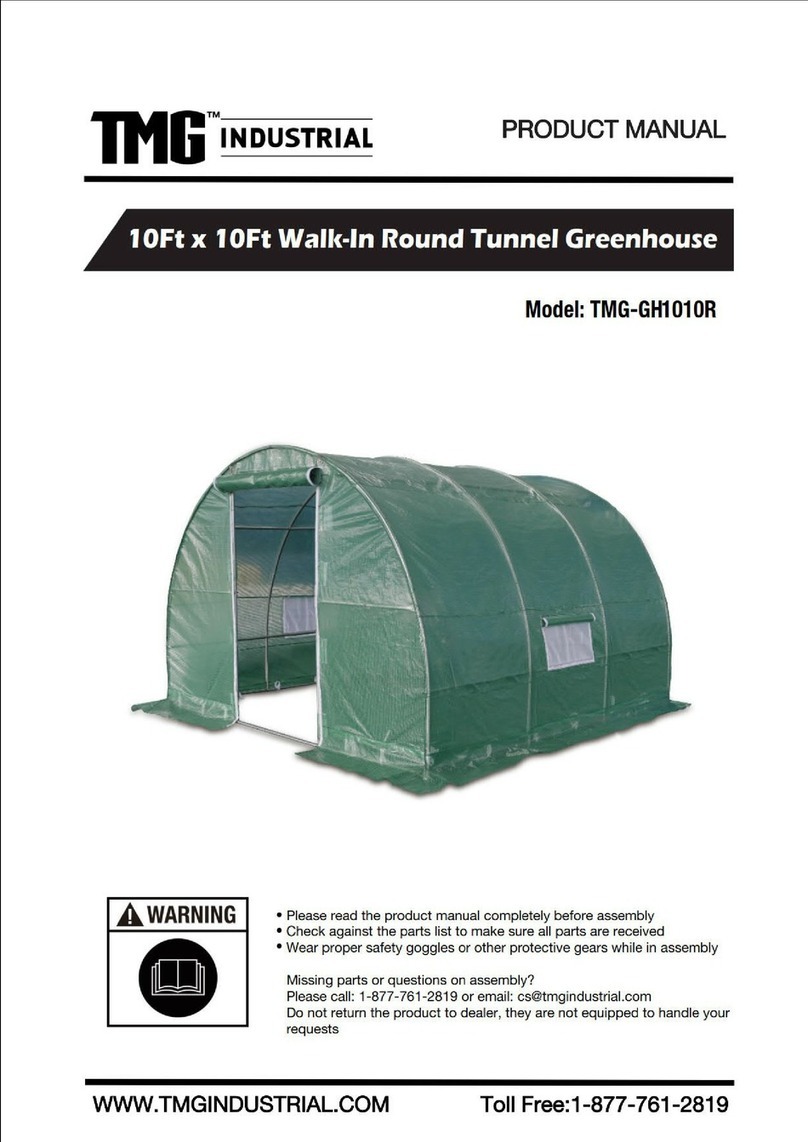

TMG TMG-GH1010R User manual

TMG

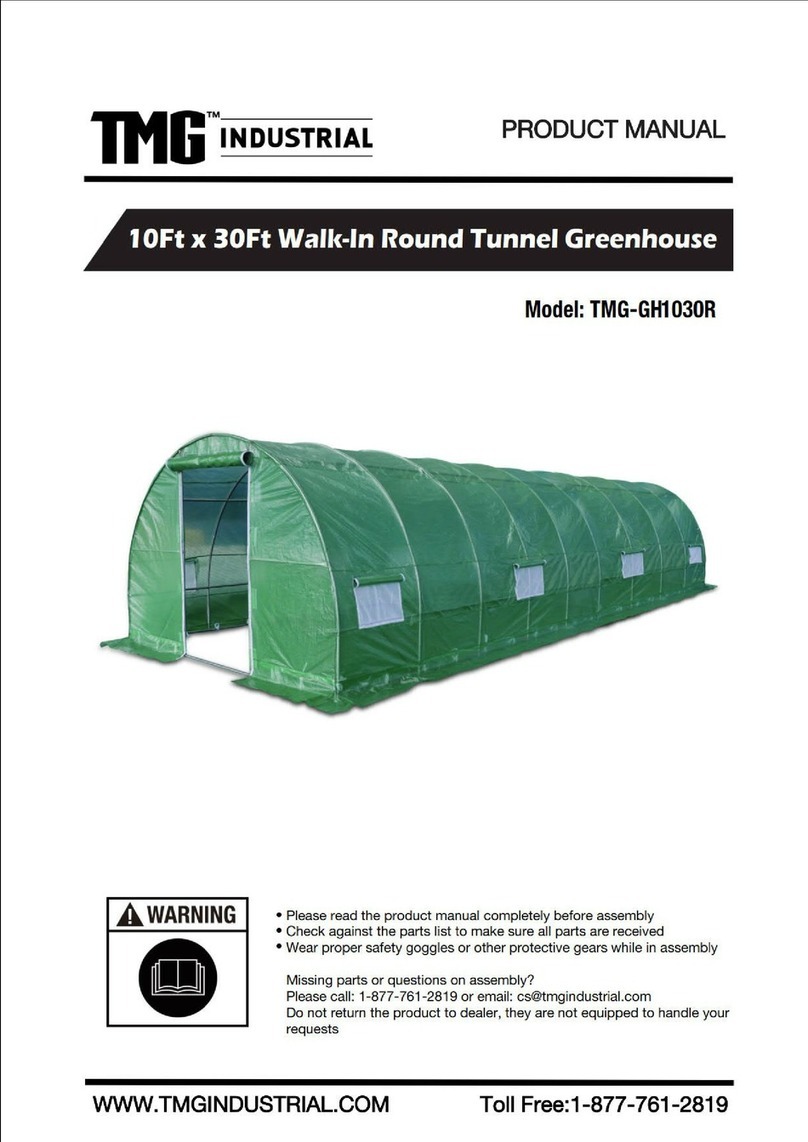

TMG TMG-GH1030R User manual

TMG

TMG TMG-GH813 User manual

TMG

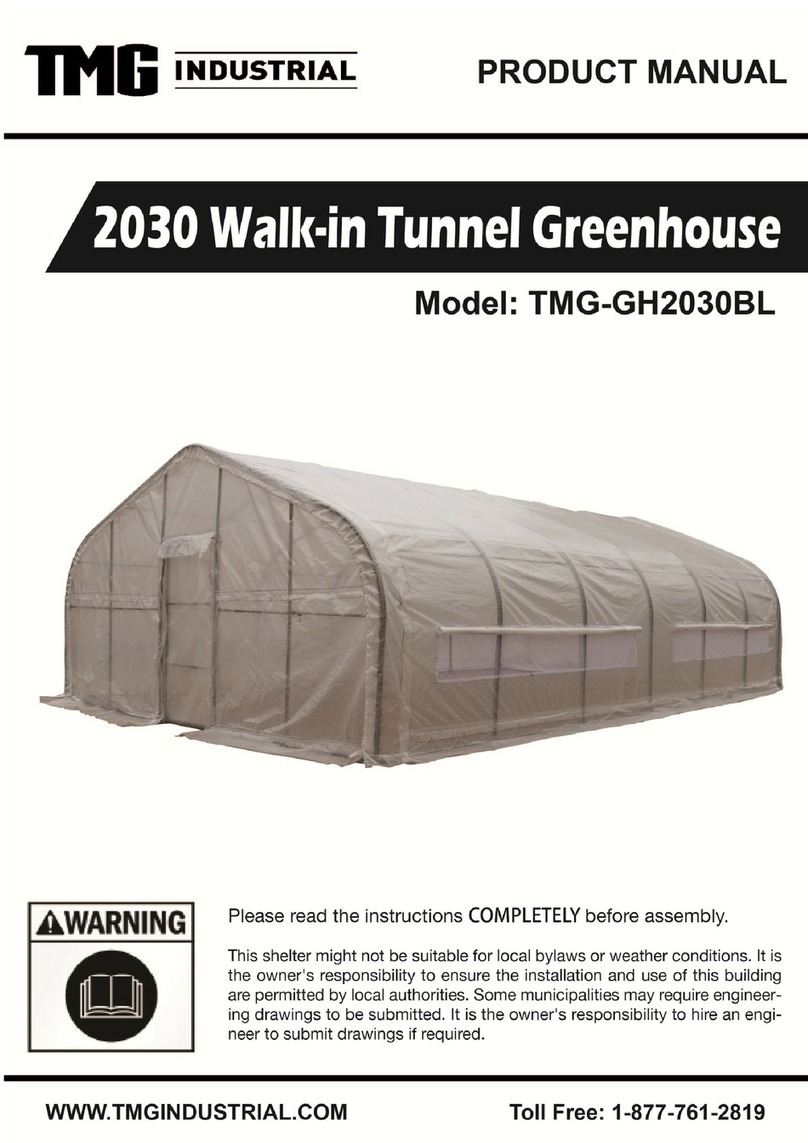

TMG TMG-GH2030BL User manual

TMG

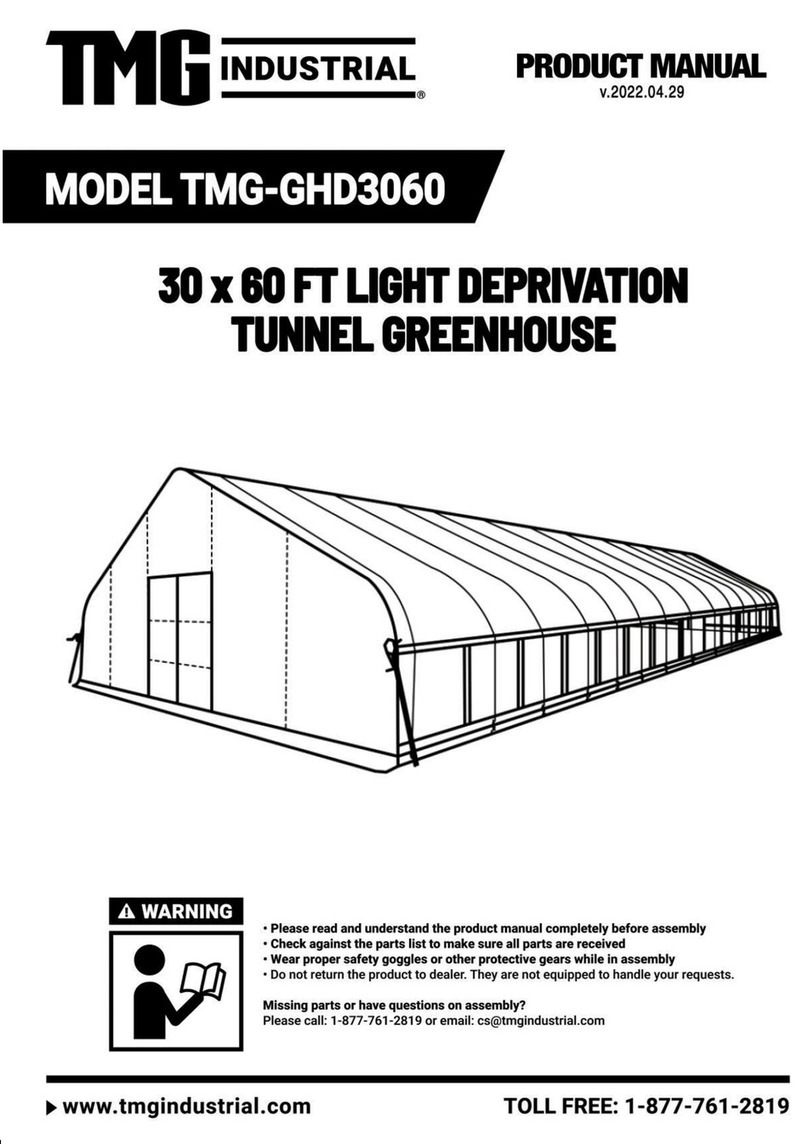

TMG TMG-GHD3060 User manual

TMG

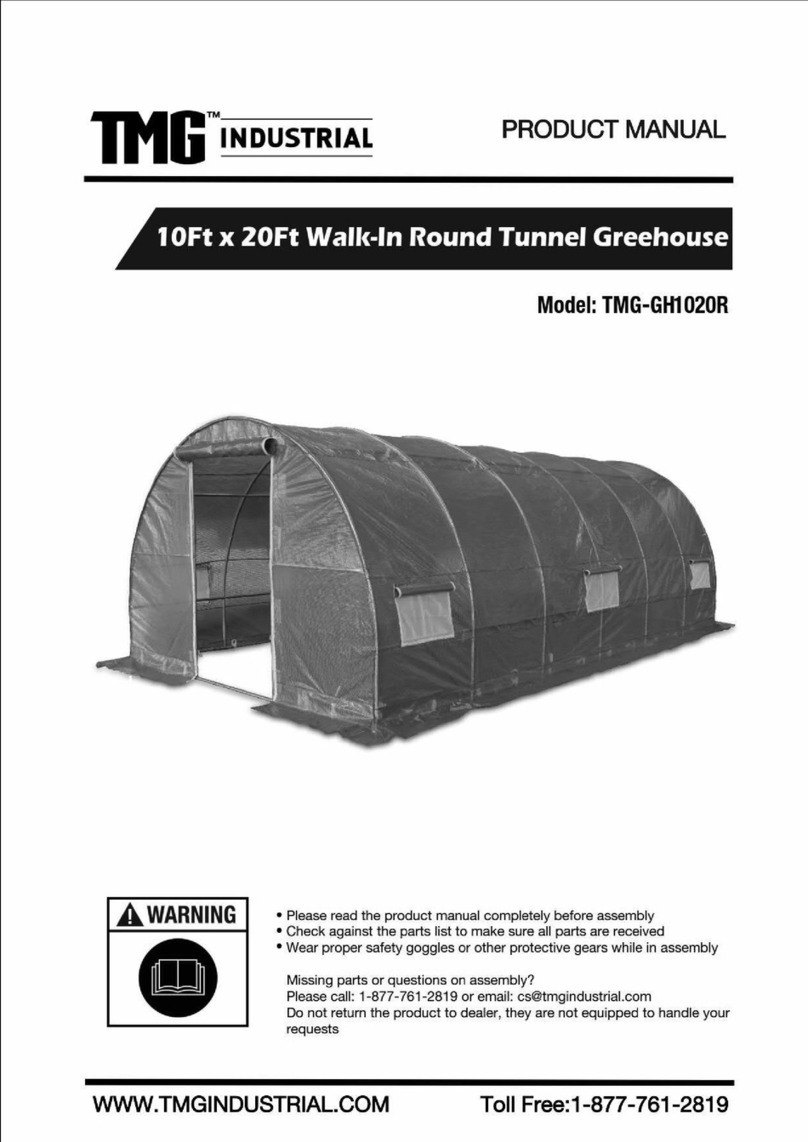

TMG TMG-GH1020R User manual

TMG

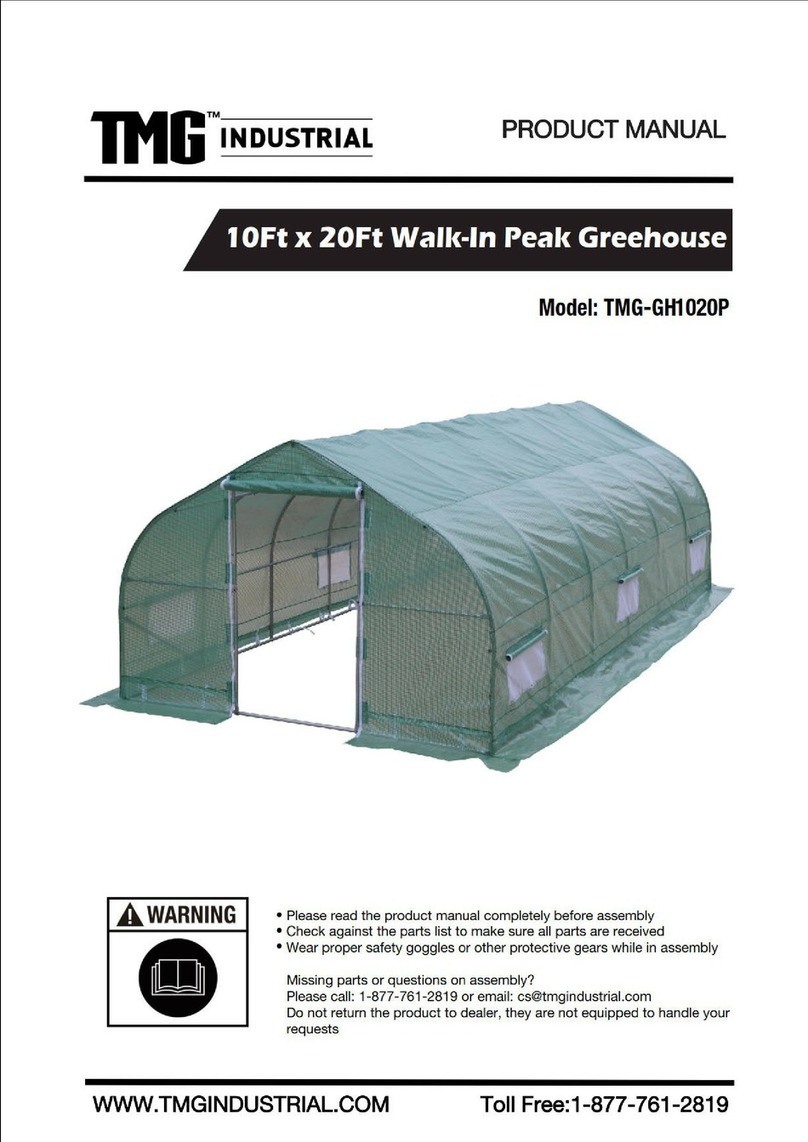

TMG TMG-GH1020P User manual

TMG

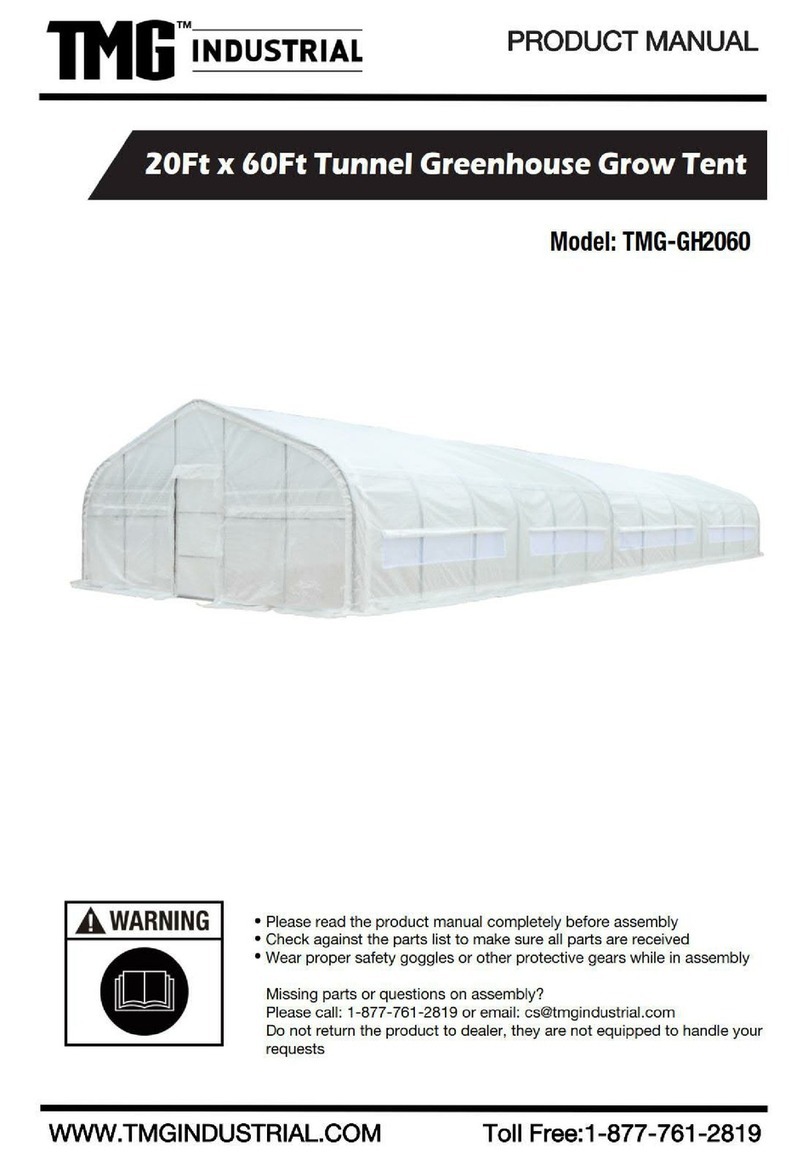

TMG TMG-GH2060 User manual

TMG

TMG INDUSTRIAL 25100 User manual

TMG

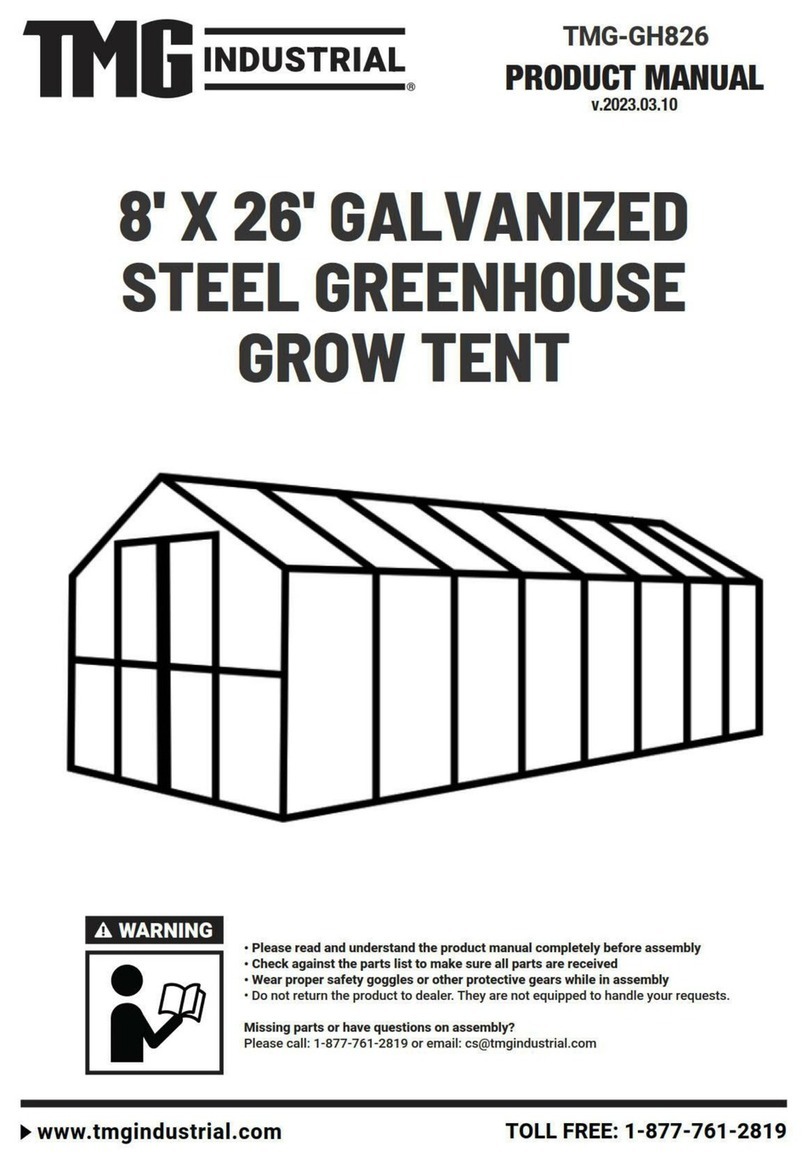

TMG TMG-GH826 User manual

Popular Greenhouse Kit manuals by other brands

ACD PRESTIGE

ACD PRESTIGE MR3 H manual

VegTrug

VegTrug Nursery manual

Riverstone Networks

Riverstone Networks Monticello 041315V Assembly instructions

STC

STC Easy Grow 6x12 Greenhouse Assembly instructions

CLIMA POD

CLIMA POD Spirit V7 Series Assembly instructions

Vitavia

Vitavia GAIA JUMBO Assembly instructions