▶W W W . T M G I N D U ST R I A L . C O M P 1 / 20 T o l l F r e e : 1 - 877-761-2819

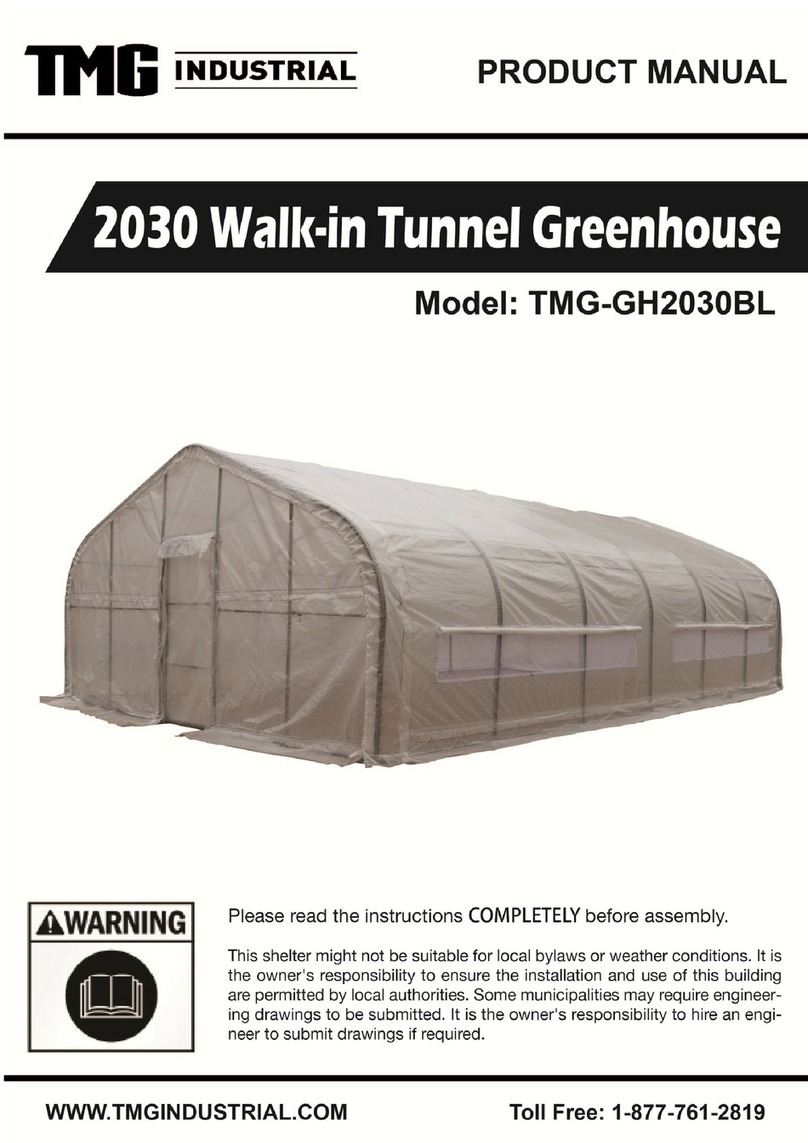

Main specifications

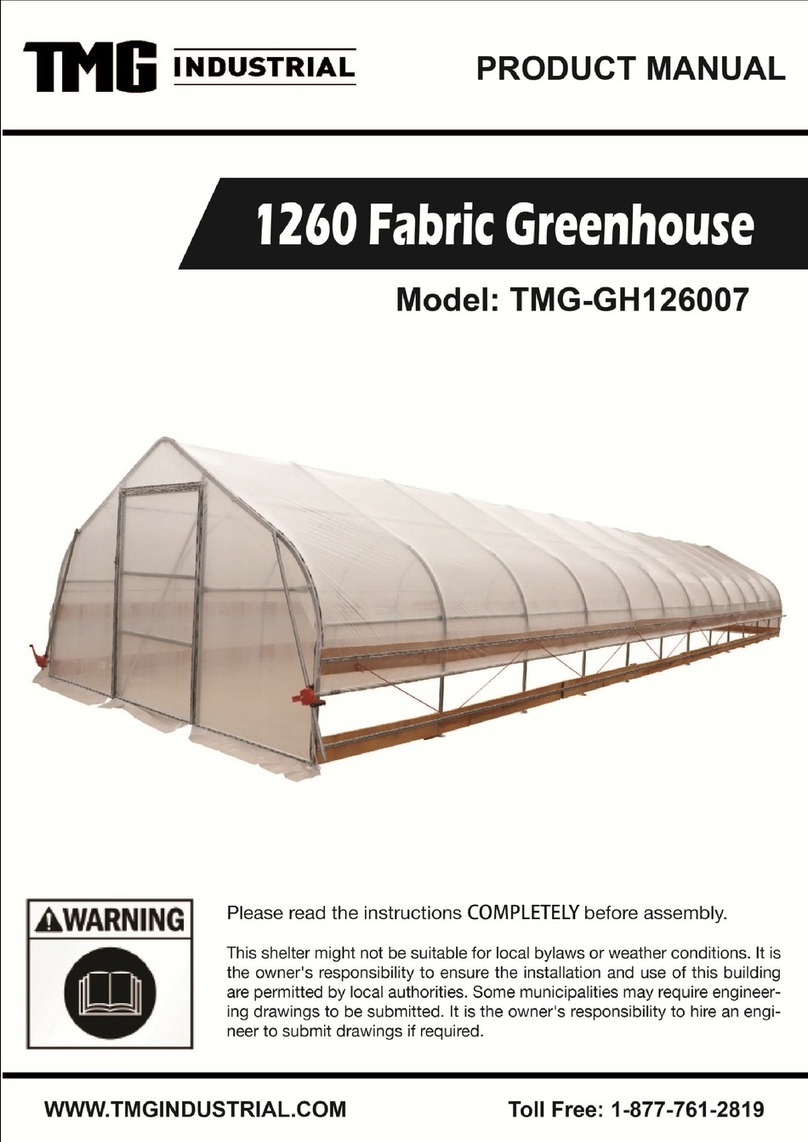

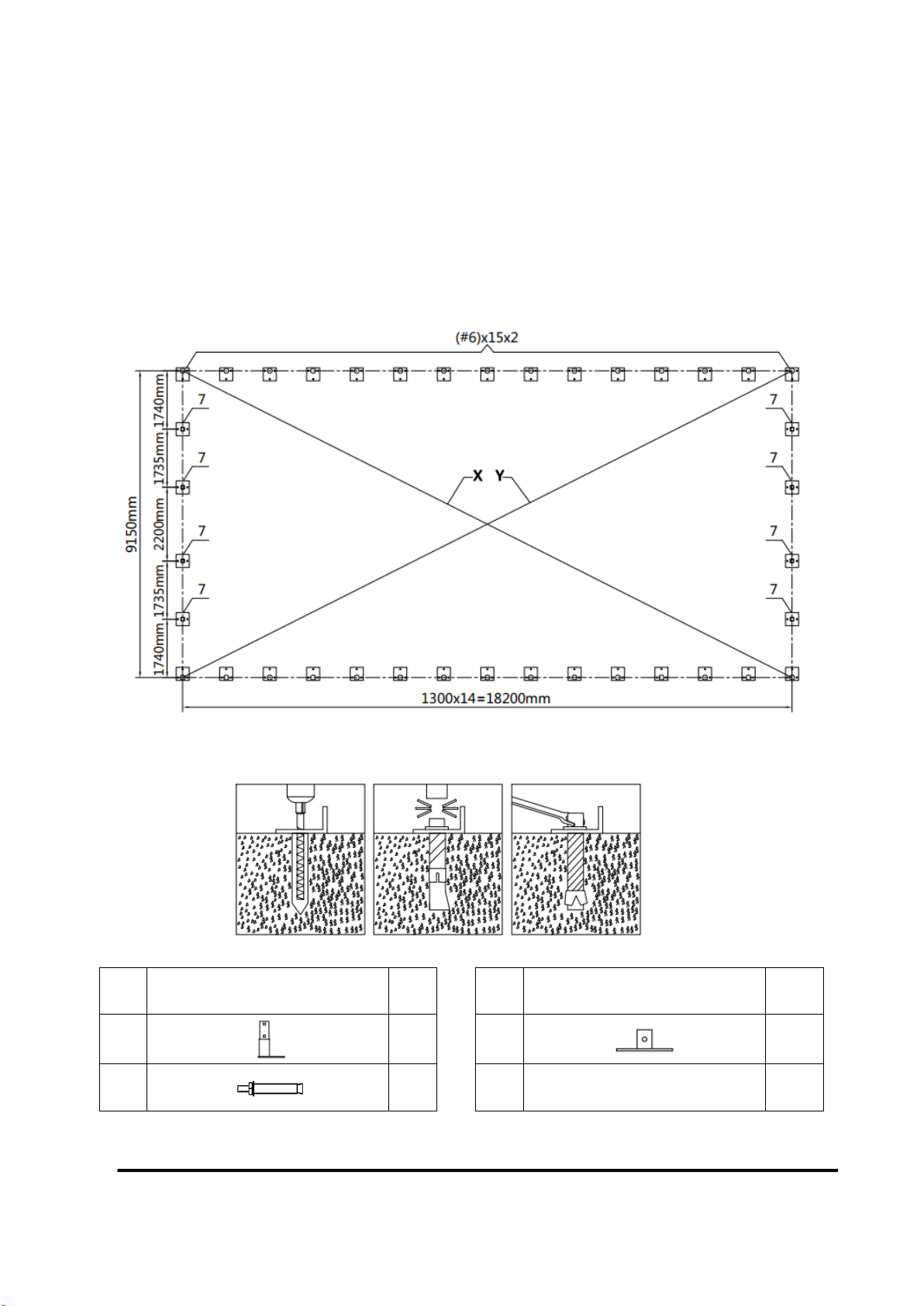

Assembly size : W9.15 x L18.2 x H3.66 (m) / W30 x L60 x H12 (ft)

Shoulder height : H1.6 (m) / 5ft

Door : W2.2 x H2 (m) / 7.2 x 6.6 (ft)

Prior to assembly

Please read the instructions carefully before installation. It is important to follow your

local safety regulations and industry standards during installation. Regulations may

include but are not limited to :

Safety helmets, protective eyewear, and clothing

Safety harnesses for all elevated workers

Proper ladder, cage, and safety operation

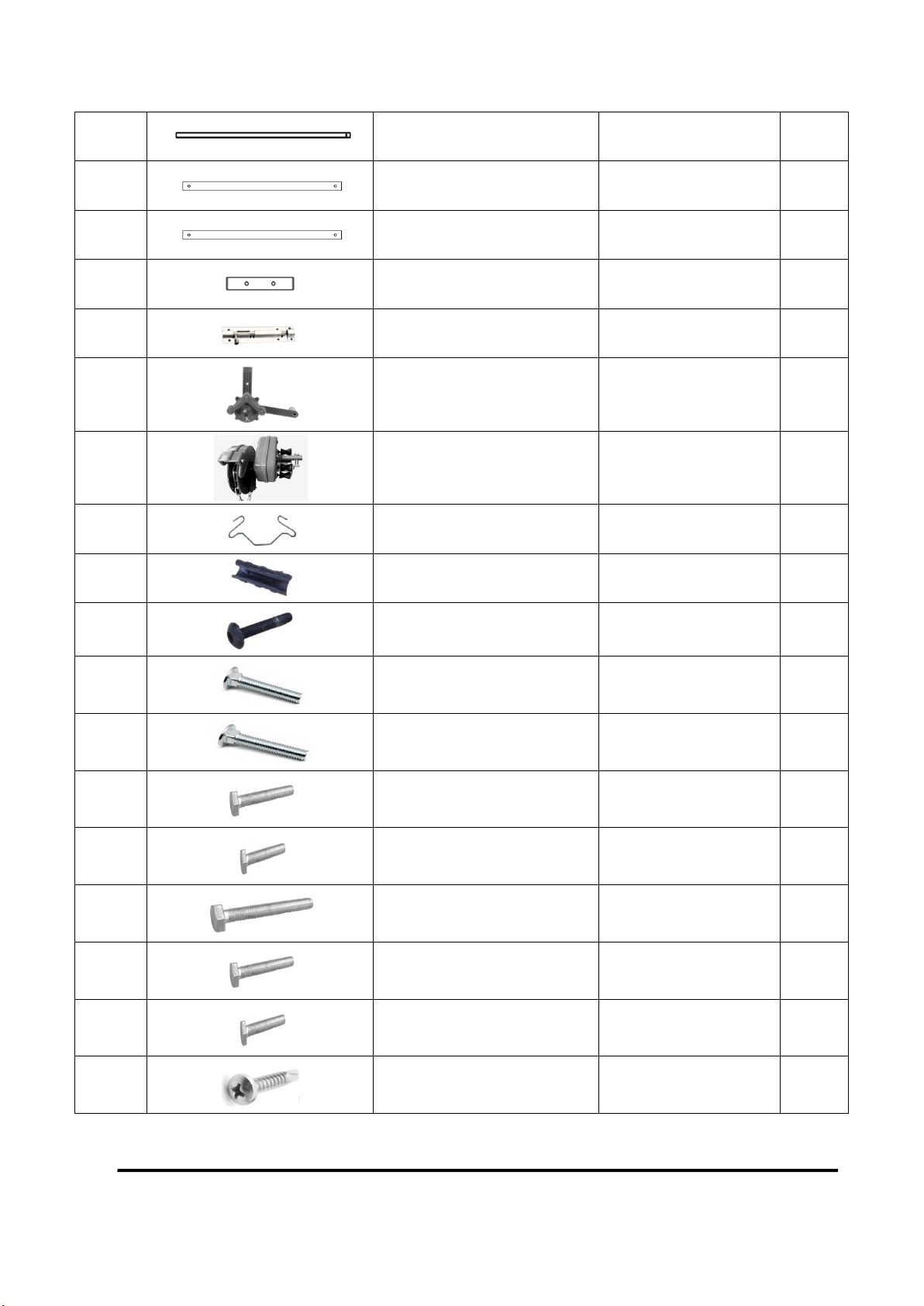

Check all components and parts before installation. All parts are marked with a part

number, please refer to the parts list to make sure you have all parts.

Choose a day with low or no wind to install, assembly is hard in heavy wind. Do not

make any alterations to the structure. Do not hang any weights on the frame during

installation, including parts. We are not responsible for any damages or injuries caused by

inappropriate installation, unauthorized modifications or extreme weather.

This building is not intended for human occupancy.

It is recommended to tape or add foam/rubber on the frame where joints connect and

where it touches the cover. This will help extend the life span of the cover.

Read the following item list carefully and count the number of items to ensure that all

parts are included prior to setup.