3600-4225_00 TRS Manual 3 Last Revision: 3/1/2022

CONTENTS

•CONTENTS .............................................................................................................................................3

•List of Figures & Tables............................................................................................................................5

1: Safety.........................................................................................................................................................................6

•1.1 Safety Symbols ..................................................................................................................................6

•1.2 Safety Considerations ........................................................................................................................6

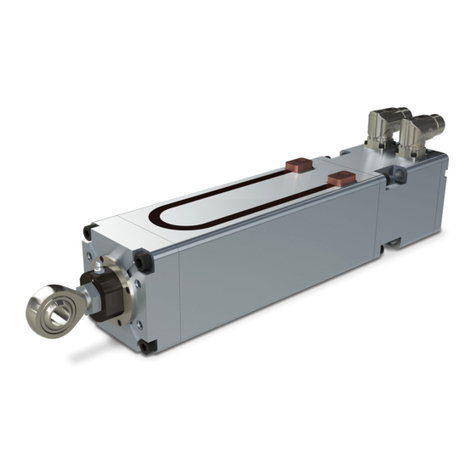

2: TRS Product Overview...............................................................................................................................................8

•2.1 General Description............................................................................................................................8

•2.2 Product Features................................................................................................................................8

•2.3 Installation..........................................................................................................................................9

•2.4 Identification Label .............................................................................................................................9

•2.5 Manufacturer ......................................................................................................................................9

3: TRS Actuator Product Configuration........................................................................................................................10

•3.1 Tolomatic TRS Actuator Series Configuration..................................................................................10

•3.2 Standard Configurations and Options ..............................................................................................10

•3.2.1 Motor (Gearhead) Mounting..........................................................................................................12

•3.2.2 Actuator Mounting .........................................................................................................................12

•3.2.3 Carrier Style Choices ....................................................................................................................12

4: TRS Mechanical Installation.....................................................................................................................................13

•4.1 General Operation............................................................................................................................13

•4.2 Loads and critical speed...................................................................................................................13

•4.3 Mechanical Installation.....................................................................................................................13

•4.4 Motor Installation..............................................................................................................................14

•4.4.1 Reverse Parallel (RP) Configuration ............................................................................................14

•4.4.2 Inline (LMI) Configuration..............................................................................................................17

•4.5 Actuator Mounting ............................................................................................................................17

•4.5.1 Standard Bottom Mounting............................................................................................................17

•4.5.2 Toe Clamp Mounting.....................................................................................................................18

•4.5.3 “Carrier-To-Carrier” Mounting........................................................................................................18

•4.5.4 Switch Mounting............................................................................................................................19

5: TRS Operation and Start up Considerations............................................................................................................20

•5.1 Back Driving.....................................................................................................................................20

•5.2 Homing.............................................................................................................................................20