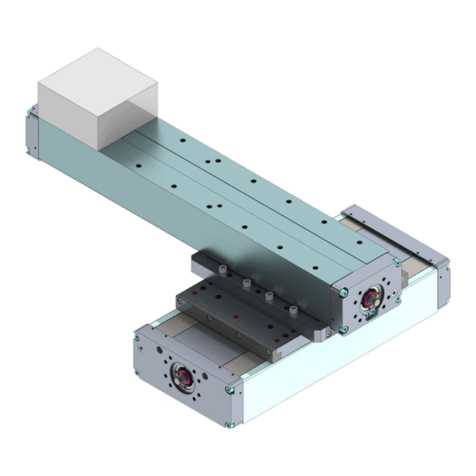

Tolomatic BCS10 Operator's manual

Tolomatic • URL: http://www.tolomatic.com • Email: [email protected] • Fax: (763) 478-8080 • Toll Free: 1-800-328-2174

Parts Sheet

3600-4011_18_BCS10ps

Model & Size

RTB _CS10 ____ SK_____ MR___

RTB BCS10 SN01 SK21.25 MRS23

*Replacement tube for BCS ordering method:

EXAMPLE:

Replacement Tube

RLS _CS10 ____ SK_____ MR___

RLS BCS10 SN01 SK21.25 MRS23

†Configurated code is the preferred ordering method:

EXAMPLE:

Replacement Lead Screw Motor CodeStroke LengthNut Style & Size

A/R = As Required

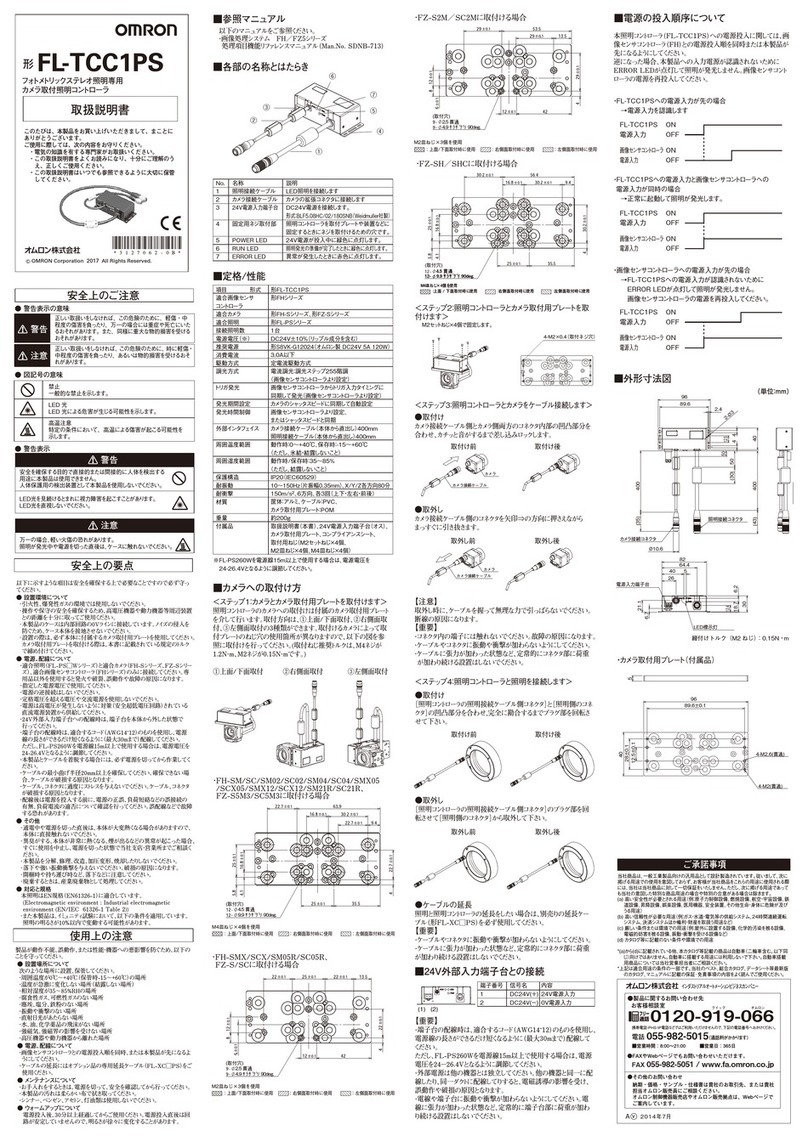

1

2

4

5

6

7

8

10

9

11

12

13

15

16

17

18

19

21

22

23

24

25

26

20

27

28 29

14

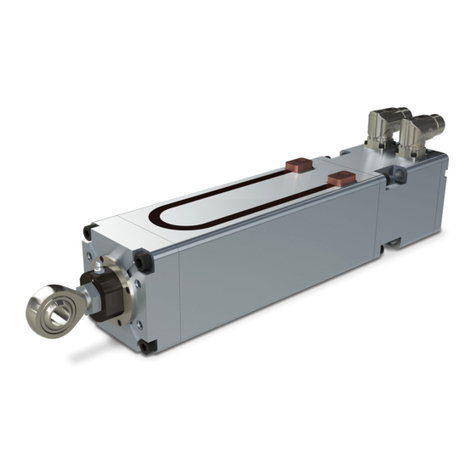

BCS10 Cylinder-Style

Screw-Drive Actuators

1-INCH

MODELS:

SN02 SN02(RP) SNA02

SNA02(RP) BNL08 BNL08(RP)

BN08 BN08(RP) SN01

SN01(RP) BN05 BN05(RP)

BCS10 MCS10

ITEM PART NO. DESCRIPTION

SN02

SN02RP(23 FRAME)

SN02RP(34 FRAME)

SNA02

SNA02RP(23 FRAME)

SNA02RP(34 FRAME)

BNL(L)08§

BN(L)08RP (23 FRAME)§

BN(L)08RP (34 FRAME)§

SN01

SN01RP(23 FRAME)

SN01RP(34 FRAME)

SN05

SN05RP(23 FRAME)

SN05RP(34 FRAME)

BN(L)08§

BN(L)08RP (23 FRAME)§

BN(L)08RP (34 FRAME)§

SN12

SN12RP (23 FRAME)

SN12RP (34 FRAME)

SN12

SN12RP (23 FRAME)

SN12RP (34 FRAME)

¡10910-1344 HEAD BOLT 8 8 8 8 8 8 8 8 8 8 8 8 8 8 8

4910-1344 HEAD BOLT 8 8 8 8 8 8 8 8 8

2. 0910-1482 NUT 5/16-24 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1

4510-1104 NUT M8 X 1.0 1 1 1 1 1 1 1 1 1

4. 4510-1060 BALL BEARING,RADIAL 2 2 2 2 2 2 2 2 2 2 2 2 2 2 2 2 2 2 2 2 2 2 2 2

5. 0910-1382 HEAD,MACHINED 2 2 2 2 2 2 2 2 2 2 2 2 2 2 2

4510-1058 HEAD,MACHINED 2 2 2 2 2 2 2 2 2

†**6.

**

**

§**

§**

§**

**

**

**

**

**

**

**

**

**

**

**

**

0910-1385 LEAD SCREW, SN02 LMI A/R A/R

0510-1361 LEAD SCREW, SN02 RP(23 FRAME) A/R A/R

0510-1365 LEAD SCREW, SN02 RP(34 FRAME) A/R A/R

0910-1409 LEAD SCREW, BN(L)08 LMI A/R A/R

0510-1360 LEAD SCREW, BN(L)08 RP(23 FRAME) A/R A/R

0510-1364 LEAD SCREW, BN(L)08 RP(34 FRAME) A/R A/R

0910-1437 LEAD SCREW, SN01 LMI A/R

0510-1362 LEAD SCREW, SN01 RP(23 FRAME) A/R

0510-1366 LEAD SCREW, SN01 RP(34 FRAME) A/R

0510-1071 LEAD SCREW, SN05 LMI A/R

0510-1363 LEAD SCREW, SN05 RP(23 FRAME) A/R

0510-1367 LEAD SCREW, SN05 RP(34 FRAME) A/R

4510-1044 LEAD SCREW, SN12 LMI A/R

4510-1131 LEAD SCREW, SN12 RP(23 FRAME) A/R

4510-1134 LEAD SCREW, SN12 RP(34 FRAME) A/R

4510-1042 LEAD SCREW, SN25 LMI A/R

4510-1132 LEAD SCREW, SN25 RP(23 FRAME) A/R

4510-1135 LEAD SCREW, SN25 RP(34 FRAME) A/R

7. 0910-1430 BALL NUT 1 1 1

4510-1036 BALL NUT 1 1 1

8. 0910-1384 NUT BRACKET 1 1 1

4510-1048 NUT BRACKET 1 1 1

§Contact fac-

tory when

ordering a

replacement

low backlash

(BNL) Ball

Screw and Nut

** Specify

stroke when

ordering

# Available

with Repair

Kit #0510-

9130

¡When replac-

ing the head

bolts in actua-

tors manufac-

tured prior to

July 1, 2006,

the hole for

the head bolt

will need to be

drilled 0.4"

(10mm) deep-

er to accom-

modate the

longer screw

length.

Tolomatic • URL: http://www.tolomatic.com • Email: [email protected] • Fax: (763) 478-8080 • Toll Free: 1-800-328-2174

2 – Parts List BCS10/MCS10 Parts Sheet #3600-4011_18_BCS10ps

Drawing repeated for reference

BCS10 MCS10

ITEM PART NO. DESCRIPTION

SN02

SN02RP(23 FRAME)

SN02RP(34 FRAME)

SNA02

SNA02RP(23 FRAME)

SNA02RP(34 FRAME)

BNL(L)08§

BN(L)08RP (23 FRAME)§

BN(L)08RP (34 FRAME)§

SN01

SN01RP(23 FRAME)

SN01RP(34 FRAME)

SN05

SN05RP(23 FRAME)

SN05RP(34 FRAME)

BN(L)08§

BN(L)08RP (23 FRAME)§

BN(L)08RP (34 FRAME)§

SN12

SN12RP (23 FRAME)

SN12RP (34 FRAME)

SN12

SN12RP (23 FRAME)

SN12RP (34 FRAME)

*,** 9.

*,**

0510-1120 TUBE, MACHINED A/R A/R A/R A/R A/R A/RA/R A/R A/R A/R A/R A/R A/R A/R A/R

4510-1009 TUBE, MACHINED A/R A/R A/R A/R A/R A/R A/R A/RA/R

10.

0510-9051 NUT BRACKET ASSEMBLY 1 1 1

0510-9052 NUT BRACKET ASSEMBLY 1 1 1

0510-9053 NUT BRACKET ASSEMBLY 1 1 1

0510-9054 NUT BRACKET ASSEMBLY 1 1 1

4510-9044 NUT BRACKET ASSEMBLY 1 1 1

4510-9045 NUT BRACKET ASSEMBLY 1 1 1

11. 4510-1059 CUP,RETAINING RING 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1

12. 0510-1019 RING,RETAINING 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1

13. 0510-1012 PLUG 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1

0515-1012 PLUG 1 1 1 1 1 1 1 1 1

14. 0912-1066 SHCS 1/4-20 X 1.75 LONG 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1

4915-1173 SHCS M6 X 1.0 X 40 LONG 1 1 1 1 1 1 1 1 1

**#15.

0912-9000 (NDBB(M)CS10SK_) DUST BAND A/R A/R A/R A/R A/R A/RA/R A/R A/R A/R A/R A/R A/R A/R A/R A/R A/R A/R A/R A/R A/R A/R A/R A/R

16. 0910-1172 SHCS 6-32 X .50 LONG 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4

4520-1046 SLHCS M4 X 0.7 X 16 LONG 4 4 4 4 4 4 4 4 4

17. 0515-1049 SET SCREW, 8-32 X .25 LONG 2 2 2 2 2 2 2 2 2 2 2 2 2 2 2

0610-1046 SET SCREW, M4 X 0.7 X 6 LONG 2 2 2 2 2 2 2 2 2

18. 0520-9015 BAND CLAMP ASSEMBLY 2 2 2 2 2 2 2 2 2 2 2 2 2 2 2

4515-9023 BAND CLAMP ASSEMBLY 2 2 2 2 2 2 2 2 2

19. 0520-1028 BAND CLAMP SLUG 2 2 2 2 2 2 2 2 2 2 2 2 2 2 2 2 2 2 2 2 2 2 2 2

20. 0910-1172 SHCS 6-32 X .50 LONG 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4

4910-1172 SBHCS M4 X 0.7 X 16 LONG 4 4 4 4 4 4 4 4 4

21. 0910-1290 SBHCS 8-32 X .38 LONG 2 2 2 2 2 2 2 2 2 2 2 2 2 2 2

4910-1003 SLHCS M4 X 0.7 X 8 LONG 2 2 2 2 2 2 2 2 2

# 22. 4510-1002 END CAP,CARRIER 2 2 2 2 2 2 2 2 2 2 2 2 2 2 2 2 2 2 2 2 2 2 2 2

# 23. 4515-1012 BAND INSERT 2 2 2 2 2 2 2 2 2 2 2 2 2 2 2 2 2 2 2 2 2 2 2 2

#24.4520-1012SPRING 222222222222222222222222

# 25. 0910-1170 BEARING,ROD 2 2 2 2 2 2 2 2 2 2 2 2 2 2 2

4910-1170 BEARING,ROD 2 2 2 2 2 2 2 2 2

26. 0510-1025 CARRIER,MACHINED 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1

4510-1049 CARRIER,MACHINED 1 1 1 1 1 1 1 1 1

27. 0912-1016 NUT 1/4-20 2 2 2 2 2 2 2 2 2 2 2 2 2 2 2

4510-1050 NUT M6 X 1.0 2 2 2 2 2 2 2 2 2

28.1004-1144WASHER 222222222222222222222222

29. 2006-1063 SFHCS 10-24 X .38 LONG 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1

4410-1016 SFHCS M5 X 0.8 X 10 LONG 1 1 1 1 1 1 1 1 1

RTB _CS10 ____ SK_____ MR___

RTB BCS10 SN01 SK21.25 MRS23

*Replacement tube for BCS ordering method:

EXAMPLE:

Replacement Tube

RLS _CS10 ____ SK_____ MR___

RLS BCS10 SN01 SK21.25 MRS23

†Configurated code is the preferred ordering method:

EXAMPLE:

Replacement Lead Screw Motor CodeStroke LengthNut Style & Size

A/R = As Required

§Contact fac-

tory when

ordering a

replacement

low backlash

(BNL) Ball

Screw and Nut

** Specify

stroke when

ordering

# Available

with Repair

Kit #0510-

9130

¡When replac-

ing the head

bolts in actua-

tors manufac-

tured prior to

July 1, 2006,

the hole for

the head bolt

will need to be

drilled 0.4"

(10mm) deep-

er to accom-

modate the

longer screw

length.

1

2

4

5

6

7

8

10

9

11

12

13

15

16

17

18

19

21

22

23

24

25

26

20

27

28 29

14

Tolomatic • URL: http://www.tolomatic.com • Email: [email protected] • Fax: (763) 478-8080 • Toll Free: 1-800-328-2174

Parts Sheet #3600-4011_18_BCS10psParts Sheet #3600-4011_18_BCS10ps BCS10/MCS10 Instructions – 3

Christo-Lube® is a registered trademark of Lubrication Technology, Inc., www.lubricationtechnology.com

Loctite® is a registered trademark of the Loctite Corporation, www.loctite.com

INTRODUCTION

Begin with a clean work area. Be sure all parts are present and

have no visual damage or defects. The following tools are recom-

mended for proper disassembly and assembly (exact wrench

sizes will vary depending upon cylinder size):

Tin Snips

Allen Wrench Set

Open-end or Box Wrenches and/or Sockets

DISASSEMBLY INSTRUCTIONS

1. REMOVE CARRIER: Remove Bolts (#14), Washers (#28) and

Nuts (#27). Remove Carrier (#26) from Bracket (#8) by removing

Screw (#29). Remove Spring (#24), Band Insert (#23), and End

Cap (#22) by removing Screws (#20 and 21) at each end of

Carrier. Remove Bearing Rods (#25). Remove carrier (#26).

2. REMOVE DUST BAND: Loosen Clamp Slug (#19) holding Band

by loosening Set Screw (#17). Remove two Screws (#16) securing

Band Clamp Assembly (#18). Remove Band Clamp

Assembly (#18) from top of Slug, then remove Clamp Slug from

top of Band (next to Head). IMPORTANT NOTE: Edges of Dust

Band are SHARP — Use caution when handling to avoid injury!

Carefully pull the Dust Band (#15) from the Tube (#9) and through

the Nut Bracket Assembly (#10)

3. DISASSEMBLE UNIT.

Remove the four Bolts (#1) from both heads (5). Remove the

lock nut (2) from the “live side” of the lead screw. Remove the

“live side” head w/ bearing (4). Remove the Plug (#13) from the

“dead side” head. Push ring cup (#11) to expose Retaining

Ring (#12) and remove retaining ring from groove of Lead

Screw (#6). Remove ring cup and head w/ bearing. Slide lead

screw w/ nut bracket (#8) and Ball Nut (#7) out of Machined

Tube (#9).

A. Ball Nut Style: DO NOT REMOVE NUT BRACKET w/

BALL NUT FROM LEAD SCREW (balls will fall out).

B. Plastic Nut Style: Remove nut bracket w/ lead screw

nut from lead screw.

4. HEAD SUB-ASSEMBLY: If necessary, carefully remove

Bearings (#4) from both Heads (#5).

5. SUB-ASSEMBLIES:

Ball Nut Style: Caution is required if removal of nut is neces-

sary. Contact the factory for available parts and procedures.

Plastic Nut Style: Plastic nuts are factory pressed into the Nut

Bracket and cannot be removed. If nuts are worn, a new Nut

Bracket Assembly must be ordered.

ASSEMBLY INSTRUCTIONS

1. AREA PREPARATION: Ensure all parts are present and have

no visual damage or defects.

2. PREPARE HEAD SUB-ASSEMBLY: Carefully install Bearings (#4) in

both Heads (#5).

3. ASSEMBLE UNIT:

A. Ball Nut Style: Grease Lead Screw (#6) with Mobil HP

Multi-purpose grease. Install Lead Screw in machined

tube. Place Head (#5) on “dead” end of Lead Screw (non-

threaded end). Secure with Ring Cup (#11) and Snap

Ring (#12). NOTE: Make sure the Snap Ring is properly

seated in groove on the Lead Screw, then pull Ring Cup

over Snap Ring. Install second Head, and Nut (#2). Snug up,

but do not tighten the four Bolts (#1) on each Head. Place

an End Plug (#13) in the “dead” side Head.

B. Plastic Nut Style: Grease Screw (#6) with Christolube®

MCG405, assemble Nut Bracket to Screw with the Nut

end facing the “live” end (threaded end) of the Screw.

Install Screw in machined tube. Place Head on “dead”

end of Screw (non-threaded end). Secure with Ring Cup

(#11) and Snap Ring (#12). NOTE: Make sure the Snap

Ring is properly seated in groove on the lead Screw, then

pull Ring Cup over Snap Ring. Install second Head and

Nut (#2). Snug up, but do not tighten the four Bolts (#1)

on each Head. Place an End Plug (#13) in the “dead”

side Head.

4. INSTALL CARRIER: Thread one end of Band (#15) through

slot in Bracket (#8) and press down on Band (#15) to seat in

tube. Place Carrier (#26) on Tube and align with Nut Bracket.

Install Bearing Rods (#25). Secure Spring (#24), Band

Insert (#23), and End Cap (#22) in place by tightening

Screws (#20 and 21) with Loctite #242 to each end of Carrier.

Secure Carrier in Bracket by tightening Screws (#29) with

Loctite #242. Install Bolts (#14), Washers (#28) and Nuts (#27).

Snug up the bolts only. NOTE: “Snug” means no noticeable

end play by hand. If a wrench is applied to either end, both

ends will turn.

5. ALIGN HEADS: Place Carrier next to each Head then tighten

the four Head Bolts (#1) to assure proper alignment of Head

and Carrier. (¡When replacing the head bolts in actuators manu-

factured prior to July 1, 2006, the hole for the head bolt will

need to be drilled 0.4" [10mm] deeper to accommodate the

longer screw length.)

HEAD TORQUE REQUIREMENTS

Cylinder Size In-Lbs of Torque

1" 70-80

1-1/2" 100-110

2" 180-195

6. TRIM AND SECURE DUST BAND: Locate on one Head a

Slug (#19) and Band Clamp Assembly (#18). (NOTE: Width of

Slug should match dust Band width.) Tighten with Screw (#16)

and Loctite #242. Insert one end of Dust Band (#15) under

Band Clamp assembly and Slug until it is tight to the Head.

Install Set Screw (#17) into Band Clamp assembly and tighten

against Slug.

With tin snips, cut the end of the Band so it nearly butts to the

other Head. Place Clamp Slug (#19) on top of Band (next to

Head), then place Band Clamp Assembly (#18) over Slug.

Tighten to Head with two Screws (#16) and Loctite #242. Install

Set Screws (#17).

7. TEST PROCEDURE: The torque required to rotate the Lead

Screw (#6) should not exceed the following limits.

MAXIMUM BREAKAWAY REQUIREMENTS:

Cylinder Size Torque

1" 25 ounce-inches

1-1/2" 30 ounce-inches

2" 45 ounce-inches

Check and/or readjust unit to conform to specification

requirements. Retest.

8. CLEAN UNIT THOROUGHLY BEFORE INSTALLING.

Tolomatic • URL: http://www.tolomatic.com • Email: [email protected] • Fax: (763) 478-8080 • Toll Free: 1-800-328-2174

Parts Sheet #3600-4011_18_BCS10ps

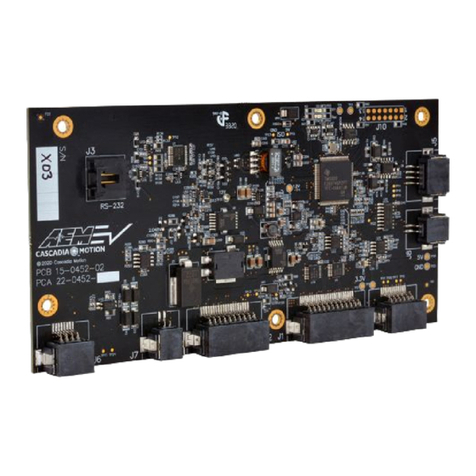

4 – In-Line Mounting Parts List BCS10/MCS10

2

1

IN-LINE MOUNTING

IN-LINE MOUNTING WITH

GEARHEAD

ITEM PART NO. DESCRIPTION

MRB2XX

MRS 2XX

MRB34X

MRS34X

MRV2XX W/O SN01

MRV21X W/ SN01 (SN25)

GHK W/ MRB2XX

GHK W/ MRS2XX

GHJ30,31 W/ MRB3X

GHJ30,31 W/ MRS3X

GHJ20,21 W/ MRV2XX

GHJ20,21W/MRV2XX W/

SN01 (SN25)

1. 3410-9202 Motor Adapter Kit 1 1 1 1

3410-9149 Motor Adapter Kit 1 1 1 1

3410-9201 Motor Adapter Kit 1 1 1 1

4410-9202 Motor Adapter Kit - metric 1 1 1 1

4410-4149 Motor Adapter Kit - metric 1 1 1 1

4410-9201 Motor Adapter Kit - metric 1 1 1 1

2. 3600-9204 Coupler 1 1 1 1

3600-9213 Coupler 1 1 1 1

3600-9206 Coupler 1 1

3600-6163 Coupler 1 1

4520-9103 Coupler - metric 1 1 1 1

4520-9107 Coupler - metric 1 1

4520-9106 Coupler - metric 1 1

3600-6181 Coupler - metric 1 1

4520-9107 Coupler - metric 1 1

ITEM PART NO. DESCRIPTION

ALL BCS10

MODLES

FLOATING MOUNT

30. 0510-1009 Pin 1

31. 0910-1196 Clamp 1

32. 0910-1195 Bracket 1

33. 0910-1199 Screw 2

SWITCHES

34. SEE PAGE 6

35. 0910-1238 Switch Magnet 1

TUBE SUPPORTS

36. 4510-1010 Bracket 1

Inline Motor Mount

Tube Supports, Floating Mounts and Switches

Disassembly and Assembly Instructions

TUBE SUPPORTS

Follow cylinder assembly instructions through steps 5. Before

installing second cylinder Head (#5) in step 6, slide Tube

Support (#36) onto cylinder Tube (#9).

FLOATING MOUNT

Completely assemble cylinder. Place Pin (#30) flat side towards

Carrier (#26) and between the two center holes. Place Floating

Mount Clamp (#31) over Pin (#30) and secure to the Carrier

(#26) with Screws (#33) and Loctite® #242. Place Floating

Mount Bracket (#32) over Pin (#30) and hold in place with a

rubber band.

SWITCHES

On assembled cylinder, Secure Switch to open port side of

cylinder with a Hardware Kit (#34) clamp and screw. Cycle the

carrier over the Switch by hand to ensure that the carrier does

not hit the switch. See page 6 for additional switch information.

35

36

30

31

32

33

34

BCS10 OPTIONS

FLOATING

MOUNT

TUBE

SUPPORTS

SWITCHES

(Also see drawing on page 1)

Tolomatic • URL: http://www.tolomatic.com • Email: [email protected] • Fax: (763) 478-8080 • Toll Free: 1-800-328-2174

Parts Sheet #3600-4011_18_BCS10psParts Sheet #3600-4011_18_BCS10ps BCS10/MCS10 Reverse Parallel Mounting – 5

BCS10 MCS10

1:1 RATIO 2:1 RATIO 1:1 RATIO 2:1 RATIO

ITEM PART NO. DESCRIPTION

MRV21,22,23,24

MRS231,232,MRB21

MRB31,32

MRS341,342,343

MRV21,22,23,24

MRS231,232,MRB21

MRB31,32

MRS341,342,343

MRV21,22,23,24

MRS231,232,MRB21

MRB31,32

MRS341,342,343

MRV21,22,23,24

MRS231,232,MRB21

MRB31,32

MRS341,342,343

1. 3420-1640 SHCS, M5 X 0.8, 50 MM LONG, LOW HEAD, SST 1 1 1 1 1 1 1 1

3420-1639 SHCS, M5 X 0.8, 55 MM LONG, LOW HEAD, SST 1 1 1 1 1 1 1 1

2. 0601-1618 COVER, BCS10/B3S10-23 FRAME 1 1 1 1 1 1 1 1

0602-1618 COVER, BCS10/B3S10-34 FRAME 1 1 1 1 1 1 1 1

3. 0510-1109 BEARING, BALL, RADIAL, Ø.250 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1

4. 0510-1112 TIMING BELT, 11.00-1/5-3/8 1 1 1 1 1 1 1 1

0510-1113 TIMING BELT, 13.00-1/5-3/8 1 1 1 1 1 1 1 1

5. 0520-1067 CLAMP COLLAR, Ø.688 1 1 1 1 1 1 1 1

6. 0515-1191 PULLEY, 18 TEETH, .38 WIDTH 1 1 1 1 1 1 1 1

0510-1110 PULLEY, 36 TEETH, .38 WIDTH 1 1 1 1 1 1 1 1

7.

3420-1255 PULLEY, 18 TEETH, .38 WIDTH 1 1 1 1 1 1 1 1

0515-1191 PULLEY, 18 TEETH, .38 WIDTH 1 1 1 1

0515-1192 PULLEY, 18 TEETH, .38 WIDTH 1 1 1 1

8. 0510-1111 TRANTORQ, Ø.250 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1

9. 0510-1111 TRANTORQ, Ø.250 1 1 1 1

0515-1181 TRANTORQ, Ø.375 1 1 1 1

10. 3410-1229 BHCS, TORX, 10-24, 0.50, BLK 4 4 4 4 4 4 4 4

3420-1644 SHCS, M5 X 0.8, 12 MM LONG, LOW HEAD 4 4 4 4 4 4 4 4

11. 0601-1053 PLATE, MOTOR, 23 FRAME 1 1 1 1 1 1 1 1

0602-1057 PLATE, MOTOR, 34 FRAME 1 1 1 1 1 1 1 1

12. 0601-1608 HOUSING, BCS10/B3S10-23 FRAME 1 1 1 1 1 1 1 1

0602-1608 HOUSING, BCS10/B3S10-34 FRAME 1 1 1 1 1 1 1 1

13. 0601-1625 SCREW, #6 X .25, SELF-TAPPING, SST 8 8 8 8 8 8 8 8 8 8 8 8 8 8 8 8

14. 0601-1602 END CAP 2 2 2 2 2 2 2 2

0602-1602 END CAP 2 2 2 2 2 2 2 2

15. 2212-1098 SHCS, M5 X 0.8, 20 MM LONG, SST 4 4 4 4

2212-1099 SHCS, M5 X 0.8, 25 MM LONG, SST 4 4 4 4 4 4 4 4 4 4 4 4

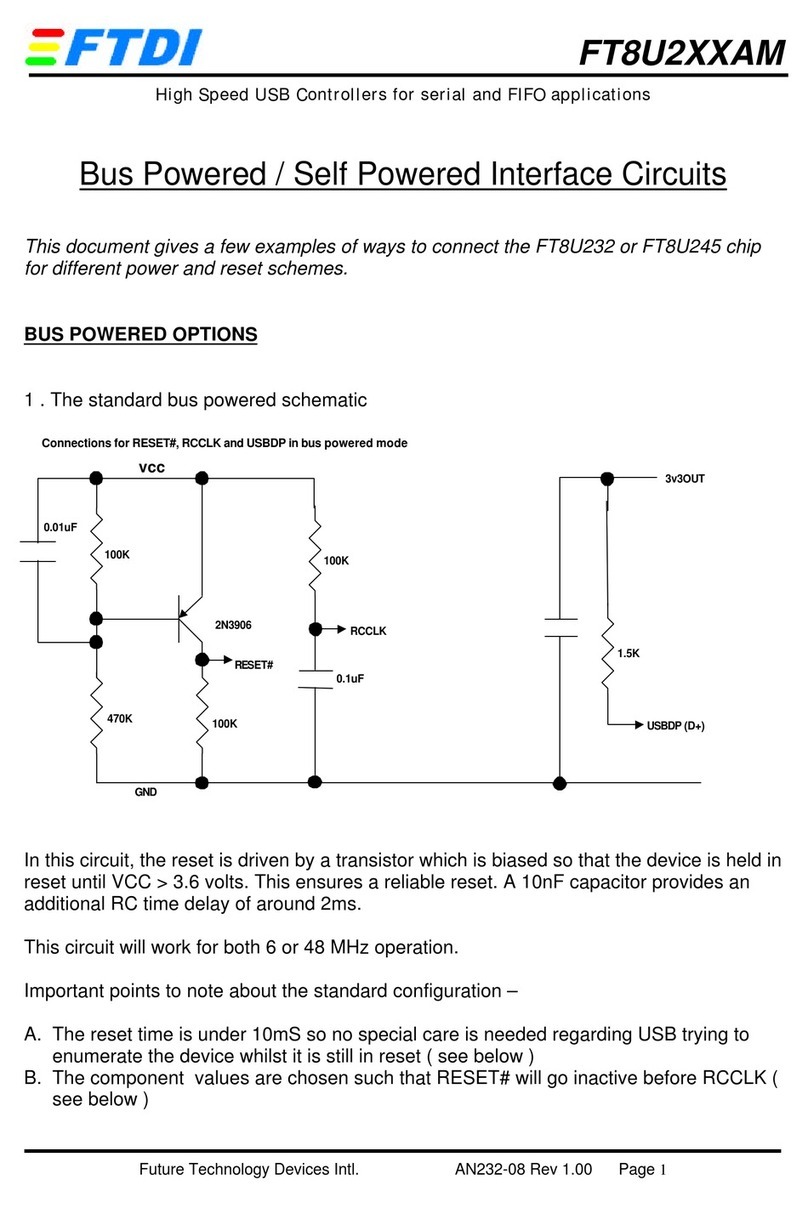

REVERSE PARALLEL DISASSEMBLY INSTRUCTIONS

1. Remove End Cap’s (#14). Release tension on belt by breaking loose the

motor screws (#15).

2. Remove RP Cover (#2).

3. Remove both drive pulley (#7) and driven pulley (#6) from their respective

shafts. The belt (#4) will come off with the pulley’s.

4. Remove motor screws (#15) from the motor plate (#11), to remove the motor

from the RP Housing.

5. Remove the RP Housing (#12) from the head by removing screws (#10).

REVERSE PARALLEL ASSEMBLY INSTRUCTIONS

*Apply Loctite #242 to all screws upon installation

1. Install RP Housing (#12) to the head with cap screws (#10). Do not fully tight-

en the screws at this time and verify that the RP Housing can move with

respect to the head.

2. Temporarily install the cover (#2) with bearing (#3) onto the RP Housing posi-

tioning the bearing over the leadscrew shaft. Hold the cover in place while

tightening all of the screws (#10) that hold the RP Housing to the head.

3. Remove the cover (#2) and finish tightening all screws attaching the RP

Housing to the head.

4. Install the motor to the RP Housing with screws (#15). Do not tighten the

screws at this time.

5. Locate the belt (#4) over the pulleys and slide the drive (#7) and driven (#6)

pulleys over their respective shafts. Tighten each pulley to it’s shaft with

either trantorque or collar clamp. If trantorque, utilize torque wrench to apply

appropriate torque. 1/2" hex on trantorque apply 75 in-lbs. 5/8" hex on tran-

torque apply 100 in-lbs.

6. Verify that there is clearance between the inside of the RP Housing and each

pulley. Verify that the pulleys are aligned to each other.

7. Position the cover (#2) in mating slot of the RP Housing and install the SHCS

(#1) to hold in place. Take care not to overtighten. If the cover is deflected it

can interfere with the leadscrew.

8. Tension the belt by pulling the motor away from the drive shaft with appropri-

ate force from chart below. Tighten the motor screws while this force is

applied to the motor.

Motor Frame Tension Force

MRB23, MRS17/23 10 lbs

MRV23, MRS34 20 lbs

MRV34, MRB34 30 lbs

9. Install both end caps (#14) with the screws (#13) to finalize assembly.

10

15

8

6

3

4

2

1

579

11

14

12

13

3800 County Road 116, Hamel, MN 55340

http://www.Tolomatic.com • Email: Help@Tolomatic.com

Phone: (763) 478-8000 • Fax: (763) 478-8080 • Toll Free: 1-800-328-2174

8

© 2017 Tolomatic 201708081451

Information furnished is believed to be accurate

and reliable. However, Tolomatic assumes no

responsibility for its use or for any errors that may

appear in this document. Tolomatic reserves the

right to change the design or operation of the

equipment described herein and any associated

motion products without notice. Information in

this document is subject to change without notice.

6 – Switches BCS10/MCS10 Parts Sheet #3600-4011_18_BCS10ps

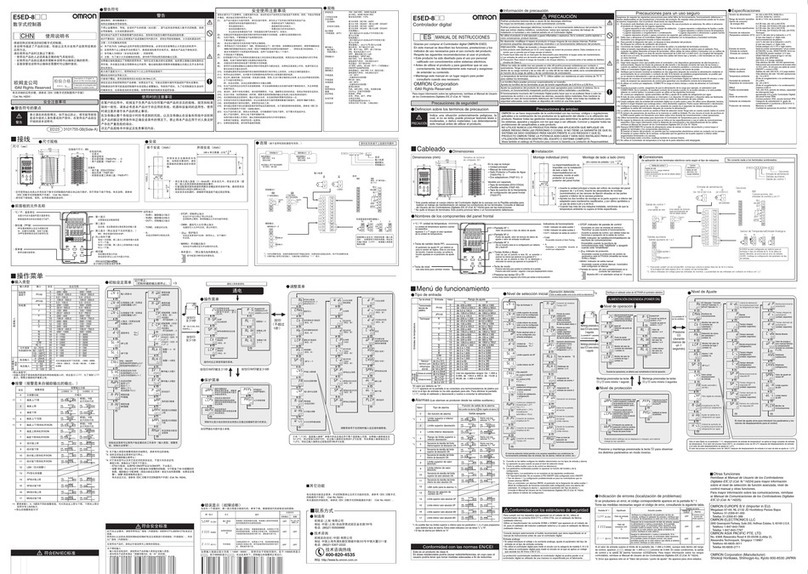

PERFORMANCE

THE NOTCHED

FACE OF THE

SWITCH INDICATES

THE SENSING

SURFACE AND

MUST FACE

TOWARD THE

MAGNET.

THE NOTCHED

GROOVE IN THE

ACTUATOR

INDICATES THE

GROOVE TO

INSTALL THE

SWITCH. CONTACT

TOLOMATIC IF

SWITCHES ARE

REQUIRED ON

ANOTHER SIDE OF

ACTUATOR.

0

50

100

150

200

0100 200 300 400 500

VOLTAGE A.C. or D.C.

CURRENT D.C (mA)

REED FORM A

R

E

E

D

F

O

R

M

C

TEMP. vs CURRENT, DC REED VOLTAGE DERATING, DC REEDTEMP. vs CURRENT, AC REED

0

100

200

300

400

500

600

020406080 100 120 140 160

LOAD CURRENT (mA)

OPERATING TEMPERATURE (F)

REED FORM C

REED FORM A

0

200

400

600

800

1000

020406080 100 120 140 160

LOAD CURENT (mA)

OPERATING TEMPERATURE (F)

TRIAC

RT & RM DC REED, FORM A

BT & BM DC REED, FORM C

CT & CM AC REED, TRIAC

TT & TM HALL-EFFECT, SOURCING, PNP

KT & KM HALL-EFFECT, SINKING, NPN

REED

SWITCH

LOAD

BROWN

BLUE

(-) (-)

(+)(+)

REED

SWITCH

LOAD

BROWN

BLUE

(-)

(-)

(+)(+)

OR

AC

COM

LOAD

INPUT

TRIAC

SWITCH

120V

ac

Max.

MOV

BROWN

BLUE

REED

SWITCH

COMMON

NORMALL

Y CLOSED

NORMALLY OPEN

BROWN

BLACK

BLUE

HALL-EFFECT

SOURCING

SWITCH

BLACK

LOAD

BROWN

BLUE (-)

(+)

(-)

(+)

HALL-EFFECT

SINKING

SWITCH

BROWN

BLACK

BLUE (-)

(+)

(-)

(+)

LOAD

WIRING DIAGRAMS INSTALLATION INFORMATION

Some actuators may

require switch mount-

ing on a specific side

of the assembly. Call

Tolomatic for details.

Female Connector 5M

SWITCHES

There are 10 sensing choices: DC reed, form A (open) or form C (open or

closed); AC reed (Triac, open); Hall-effect, sourcing, PNP (open); Hall-effect,

sinking, NPN (open); each with either flying leads or QD (quick disconnect).

Commonly used to send analog signals to PLC (programmable logic

controllers), TLL, CMOS circuit or other controller device. These switches are

activated by the actuator’s magnet.

Switches contain reverse polarity protection. QD cables are shielded; shield

should be terminated at flying lead end.

If necessary to remove factory installed switches, be sure to reinstall on the

same of side of actuator with scored face of switch toward internal magnet.

**

WARNING

: Do not exceed power rating (Watt = Voltage X Amperage). Permanent damage to sensor will occur.

*QD = Quick Disconnect; Male coupler is located 6" [152mm} from sensor,

Female coupler to flying lead distance is 197" [5m] also see Cable Shielding specification above

REPLACEMENT OF QD SWITCHES MANUFACTURED BEFORE JULY 1, 1997:

It will be necessary to replace or rewire the female end coupler.

CAUTION: DO NOT OVER TIGHTEN SWITCH HARDWARE WHEN INSTALLING!

CURRENT

Quick disconnect

Wiring

BROWN

BLACK

BLUE

+

-

SIGNAL

OLD

Quick disconnect

Wiring

BROWN

BLACK

BLUE

+

-

SIGNAL

†Shielded from the female quick disconnect coupler to the flying leads. Shield should be terminated at flying lead end.

§

Maximum current 500mA (not to exceed 10VA) Refer to Temperature vs. Current graph and Voltage Derating graph

§§

Maximum current 250mA (not to exceed 3VA) Refer to Temperature vs. Current graph and Voltage Derating graph

Reed Switch Life Expectancy: Up to

200,000,000 cycles (depending on load cur-

rent, duty cycle and environmental conditions)

DC REED, AC REED (TRIAC)

AND HALL-EFFECT

QUICK-DISCONNECT

COUPLER - MALE END

QUICK-DISCONNECT

COUPLER - FEMALE END

SPECIFICATIONS

REED DC REED AC HALL-EFFECT DC

ORDER CODE

RT RM BT BM CT CM TT TM KT KM

LEAD 5m QD* 5m QD* 5m QD* 5m QD* 5m QD*

CABLE SHIELDING Unshielded Shielded† Unshielded Shielded† Unshielded Shielded† Unshielded Shielded† Unshielded Shielded†

SWITCHING LOGIC "A" Normally Open "C" Normally Open or Closed Triac Normally Open PNP (Sourcing) Normally

Open NPN (Sinking) Normally Open

MECHANICAL CONTACTS Single-Pole Single-Throw Single-Pole Double-Throw Single-Pole Single-Throw NO, These Are Solid State Components

COIL DIRECT Yes Yes Yes —

POWER LED None None None None None

SIGNAL LED Red Red Red

OPERATING VOLTAGE 200 Vdc max. 120 Vdc max. 120 Vac max. 5 - 25 Vdc

OUTPUT RATING — — 25 Vdc, 200mA dc

OPERATING TIME 0.6 msec max.

(including bounce)

0.7 msec max.

(including bounce) —< 10 micro sec.

OPERATING TEMPERATURE -40°F [-40°C] to 158°F [70°C] 0°F [-18°C] to 150°F [66°C]

RELEASE TIME 1.0 msec. max. — —

ON TRIP POINT — — 150 Gauss maximum

OFF TRIP POINT — — 40 Gauss minimum

**POWER RATING (WATTS) 10.0

§

3.0

§ §

10.0 5.0

VOLTAGE DROP 2.6 V typical at 100 mA NA — —

RESISTANCE 0.1 Ω Initial (Max.) — —

CURRENT CONSUMPTION —1 Amp at

86°F [30°C]

0.5 Amp at

140°F [60°C] 200 mA at 25 Vdc

FREQUENCY —47 - 63 Hz —

CABLE MIN.

BEND

RADIUS

STATIC 0.630" [16mm]

DYNAMIC Not Recommended

SWITCHES

There are 10 sensing choices: DC reed, form A (open) or form C (open or

closed); AC reed (Triac, open); Hall-effect, sourcing, PNP (open); Hall-effect,

sinking, NPN (open); each with either flying leads or QD (quick disconnect).

Commonly used to send analog signals to PLC (programmable logic

controllers), TLL, CMOS circuit or other controller device. These switches are

activated by the actuator’s magnet.

Switches contain reverse polarity protection. QD cables are shielded; shield

should be terminated at flying lead end.

If necessary to remove factory installed switches, be sure to reinstall on the

same of side of actuator with scored face of switch toward internal magnet.

**

WARNING

: Do not exceed power rating (Watt = Voltage X Amperage). Permanent damage to sensor will occur.

*QD = Quick Disconnect; Male coupler is located 6" [152mm} from sensor,

Female coupler to flying lead distance is 197" [5m] also see Cable Shielding specification above

REPLACEMENT OF QD SWITCHES MANUFACTURED BEFORE JULY 1, 1997:

It will be necessary to replace or rewire the female end coupler.

CAUTION: DO NOT OVER TIGHTEN SWITCH HARDWARE WHEN INSTALLING!

CURRENT

Quick disconnect

Wiring

BROWN

BLACK

BLUE

+

-

SIGNAL

OLD

Quick disconnect

Wiring

BROWN

BLACK

BLUE

+

-

SIGNAL

†Shielded from the female quick disconnect coupler to the flying leads. Shield should be terminated at flying lead end.

§

Maximum current 500mA (not to exceed 10VA) Refer to Temperature vs. Current graph and Voltage Derating graph

§§

Maximum current 250mA (not to exceed 3VA) Refer to Temperature vs. Current graph and Voltage Derating graph

Reed Switch Life Expectancy: Up to

200,000,000 cycles (depending on load cur-

rent, duty cycle and environmental conditions)

DC REED, AC REED (TRIAC)

AND HALL-EFFECT

QUICK-DISCONNECT

COUPLER - MALE END

QUICK-DISCONNECT

COUPLER - FEMALE END

SPECIFICATIONS

REED DC REED AC HALL-EFFECT DC

ORDER CODE

RT RM BT BM CT CM TT TM KT KM

LEAD 5m QD* 5m QD* 5m QD* 5m QD* 5m QD*

CABLE SHIELDING Unshielded Shielded† Unshielded Shielded† Unshielded Shielded† Unshielded Shielded† Unshielded Shielded†

SWITCHING LOGIC "A" Normally Open "C" Normally Open or Closed Triac Normally Open PNP (Sourcing) Normally

Open NPN (Sinking) Normally Open

MECHANICAL CONTACTS Single-Pole Single-Throw Single-Pole Double-Throw Single-Pole Single-Throw NO, These Are Solid State Components

COIL DIRECT Yes Yes Yes —

POWER LED None None None None None

SIGNAL LED Red Red Red

OPERATING VOLTAGE 200 Vdc max. 120 Vdc max. 120 Vac max. 5 - 25 Vdc

OUTPUT RATING — — 25 Vdc, 200mA dc

OPERATING TIME 0.6 msec max.

(including bounce)

0.7 msec max.

(including bounce) —< 10 micro sec.

OPERATING TEMPERATURE -40°F [-40°C] to 158°F [70°C] 0°F [-18°C] to 150°F [66°C]

RELEASE TIME 1.0 msec. max. — —

ON TRIP POINT — — 150 Gauss maximum

OFF TRIP POINT — — 40 Gauss minimum

**POWER RATING (WATTS) 10.0

§

3.0

§ §

10.0 5.0

VOLTAGE DROP 2.6 V typical at 100 mA NA — —

RESISTANCE 0.1 Ω Initial (Max.) — —

CURRENT CONSUMPTION —1 Amp at

86°F [30°C]

0.5 Amp at

140°F [60°C] 200 mA at 25 Vdc

FREQUENCY —47 - 63 Hz —

CABLE MIN.

BEND

RADIUS

STATIC 0.630" [16mm]

DYNAMIC Not Recommended

REPLACEMENT OF QD SWITCHES

MANUFACTURED BEFORE JULY 1, 1997:

It will be necessary

to replace or

rewire the

female end

coupler.

3. SWITCHES

NOTE: Form A Reed Switches should not be used in TTL logic cir-

cuits. A voltage drop caused by the L.E.D. indicator will result.For

applications where TTL circuits are used, please contact the factory.

WARNING: An ohmmeter is recommended for testing Reed

Switches. NEVER use an incandescent light bulb as a high current

rush may damage the switch.

Reed and TRIAC switches are only recommended for signalling

position, not directly powering solenoids. For shifting a solenoid, a

relay or resistor is recommended between it and the Reed Switch.

Switch ratings must not be exceeded at any time.

NOTE: For Hall Effect Switch Magnet, be sure the S pole of the mag-

net (indicated with black dot) is facing toward the switch (down).

Switch Ordering NOTES:

To order field retrofit switch and hardware kits for all Tolomatic actuators:

SW (Then the model and bore size, and type of switch required)

Example: SW BCS10 RT

(Hardware and Form A Reed switch with 5 meter lead for 1" size

BCS actuator)

Mounting hardware is required if replacing switch for any actuator

manufactured before 7/1/97

SWITCH KIT

34.

CONFIG. CODE ORDERING

Mounting Hardware & FE conn. included

CODE

DESCRIPTION

BT Switch Only, Reed, Form C, 5m

BM Switch Only, Reed, Form C, Male Conn.

RT Switch Only, Reed, Form A, 5m

RM Switch Only, Reed, Form A, Male Conn.

CT Switch Only, Triac, 5m

CM Switch Only, Triac, Male Conn.

KT Switch Only, Hall-effect, Sinking, 5m

KM

Switch Only, Hall-effect, Sinking, Male Conn.

TT Switch Only, Hall-effect, Sourcing, 5m

TM Switch Only, Hall-effect, Sourcing, Male Conn.

NOTE: When ordered by Config. Code Female connector & all mounting hardware

is

included

This manual suits for next models

1

Table of contents

Other Tolomatic Controllers manuals

Tolomatic

Tolomatic TRS Series User manual

Tolomatic

Tolomatic ServoWeld CSW Owner's manual

Tolomatic

Tolomatic IMA-S Series User manual

Tolomatic

Tolomatic ACS Manual

Tolomatic

Tolomatic MXP16P Series User manual

Tolomatic

Tolomatic ACS Manual

Tolomatic

Tolomatic IMA Series User manual

Tolomatic

Tolomatic Axidyne AXIOM PLUS PV Series User manual

Tolomatic

Tolomatic 3604-9651 Manual

Tolomatic

Tolomatic SmartActuator Series User manual