Tolomatic Axidyne AXIOM PLUS PV Series User manual

ForSalesandSupport,ContactWalkerEMD•Toll-free:(800)876-4444•Tel:(203)426-7700•Fax:(203)426-7800•www.walkeremd.com

3600-4628_05

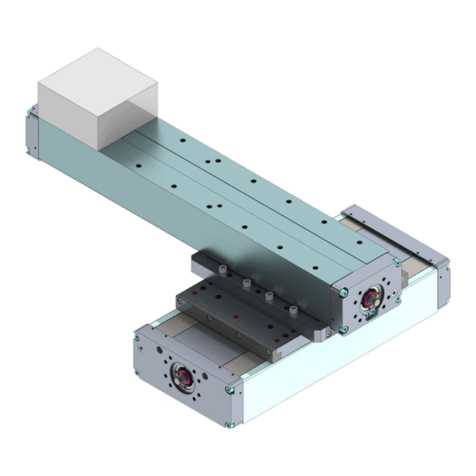

AXIOM® PLUS PV Series

Brushless Servo Controller/Drive

User Manual

TOL-O-MATIC, INC

Excellence in Motion®

ELECTRIC LINEAR MOTION PRODUCTS

NOW WITH

ANALOG

INPUT

ForSalesandSupport,ContactWalkerEMD•Toll-free:(800)876-4444•Tel:(203)426-7700•Fax:(203)426-7800•www.walkeremd.com

Product and Safety Notice

Use of Axiom Servo Drives

Axiom Plus systems are intended to be part of a controlled system or to operate in a stand-alone

configuration. Installation and operating instructions for all system components must be observed.

Unless otherwise specified, Axiom Plus systems are intended for use in a normal industrial environment.

Installation is to be in a suitable electrical cabinet capable of protecting the unit from exposure to excessive

moisture, corrosive agents or excessive ambient temperatures. Installation of the hardware must only be

attempted by skilled personnel and with adherence to the installation instructions in this manual. This unit

does not contain any user serviceable components. Should repair or replacement of a unit become

necessary, please contact the place of purchase for instructions.

Safety Notes

As with any electrical equipment, there are some possible hazards associated with the installation and use of

this hardware. Please observe the following precautions. Further specific Warnings and Cautions are listed

throughout this manual.

Installation and Maintenance: All installation and maintenance must be carried out by qualified personnel.

Generation: A mechanically driven motor will act as a generator. Because dangerous voltage levels may be

generated, motor to drive connections must be suitably guarded to protect against electrical shock hazards.

Cables: Use only Tol-O-Matic supplied cables, or cables deemed suitable for use by a competent person

familiar with the electrical and mechanical requirements of a given application.

Supply: Axiom Plus units must be connected to a permanent power source and fused according to the

instructions in this manual, in accordance with all local and national electrical codes.

Safety Requirements: The safe and proper installation and operation of this unit into a machine system is

the responsibility of the machine designer and should comply with all applicable local and national safety

requirements. In Europe, this is likely to include the Machinery Directive, the ElectroMagnetic Compatibility

Directive and the Low Voltage Directive. In the United States this will likely include the National Electrical

Code.

Mechanical Installation: Units must be installed inside an appropriate electrical cabinet providing

environmental controls and protection. The minimum requirements are outlined in this manual.

TOL-O-MATIC, INC.

3800 County Road 116, Hamel, MN 55340

Phone: (763) 478-8000 • Fax: (763) 478-8080 • Toll Free: 1-800-328-2174

Information furnished is believed to

be accurate and reliable. However,

Tol-O-Matic assumes no respons-

ibility for its use or for any errors

that may appear in this document.

Tol-O-Matic reserves the right to

change the design or operation of the

equipment described herein and any

associated motion products without

notice. Information in this document

is subject to change without notice.

ForSalesandSupport,ContactWalkerEMD•Toll-free:(800)876-4444•Tel:(203)426-7700•Fax:(203)426-7800•www.walkeremd.com

Contents....................................................................................................................i

List of Figures..........................................................................................................v

Introduction ............................................................................................................ix

Graphic Symbols andWarning Classifications ....................................................ix

Notices................................................................................................................x

Axiom Plus System Overview ..............................................................................xiii

Power Ratings ................................................................................................xiii

Interface Cables..............................................................................................xiv

Axiom Plus Features.............................................................................................xiv

Motor/Encoder Input.......................................................................................xv

Encoder Follower Input...................................................................................xv

Encoder Output...............................................................................................xv

Digital I/O.......................................................................................................xvi

Ac Input Power ...............................................................................................xvi

Drive and Motor Protection Circuitry...........................................................xvi

Agency Approvals ...........................................................................................xvi

Tol-O-Motion Axiom Plus Software...................................................................xvii

Chapter 1: Safety

Potential Hazards...............................................................................................1-1

Your Responsibilities..........................................................................................1-2

Safety Guidelines................................................................................................1-2

Chapter 2: Theory of Operation

Discussion of DriveTechnologies.....................................................................2-1

Three-Phase Brushless Motors .........................................................................2-1

Commutation.....................................................................................................2-2

Brushless Servo Drives .................................................................................2-3

Hall Commutated Drives...........................................................................2-3

Sine Commutated Drives..........................................................................2-4

Vector Drives............................................................................................2-5

Chapter 3: Unpacking, Inspection and Storage

Unpacking the Drive..........................................................................................3-1

Inspection Procedure.........................................................................................3-1

Storage ................................................................................................................3-1

Chapter 4: Physical Mounting of Drive

Physical Mounting of Drive...............................................................................4-2

Chapter 5: Power Connections and Fusing

GeneralWiring Guidelines ................................................................................5-1

Axiom Plus PV10, PV20, PV30............................................................................5-2

Chapter 6: Motor Encoder and Power Connections

GeneralWiring Guidelines ................................................................................6-1

Axiom Plus Systems ...........................................................................................6-2

Emergency Stop Connection.............................................................................6-3

i

Contents

ForSalesandSupport,ContactWalkerEMD•Toll-free:(800)876-4444•Tel:(203)426-7700•Fax:(203)426-7800•www.walkeremd.com

Chapter 7: Software Installation

Hardware and Software Requirements.............................................................7-1

Installation..........................................................................................................7-1

Chapter 8: Initial Check Out

Setup/Configuration Screen .............................................................................8-1

Commands,Setup and Configuration Mode..............................................8-3

Indexer Model Selection/Setup....................................................................8-3

Motor Model Selection/Setup.......................................................................8-4

Phasing Configuration.................................................................................8-4

Gains and Limits..........................................................................................8-5

Register Precision .........................................................................................8-5

ModBus Configuration ................................................................................8-6

Check Out Procedure ........................................................................................8-7

Chapter 9: I/O Connections

Inputs ................................................................................................................9-1

Analog Inputs .....................................................................................................9-6

Outputs...............................................................................................................9-9

Chapter 10: Regeneration Resistor Use and Sizing

Regeneration Resistor Use and Sizing............................................................10-1

Chapter 11: Final Checkout and Tuning

OnlineTuning and Diagnosis..........................................................................11-1

Command Menu,Online Tuning/Diagnosis Mode..................................11-1

Indexer Status,Fault,I/O ...........................................................................11-2

Oscilloscope................................................................................................11-3

Encoder Feedback Section .........................................................................11-4

Drive Diagnosis Screen .............................................................................11-4

DriveTuning Screen..................................................................................11-5

DriveTuning ....................................................................................................11-7

Auto Tuning ...............................................................................................11-7

Manual Tuning .........................................................................................11-8

Analog Input Gain and Offset .........................................................................11-8

Adjustments and Diagnostics .........................................................................11-8

Chapter 12: Programming

Programming Environment............................................................................12-2

Sequential Program Editor..............................................................................12-2

PRG Menu...................................................................................................12-3

Sequential Program Debugger..................................................................12-5

User Units...................................................................................................12-7

Sequential Program Listing.......................................................................12-8

Creating a Sequential Motion Program Instruction ................................12-9

Instruction Command Set.........................................................................12-10

Analog Input Position Mode .....................................................................12-12

Analog InputVelocity Mode.......................................................................12-13

Analog Position Conversion Factor...........................................................12-22

PLC Program Editor .........................................................................................12-28

PLC Menu ...................................................................................................12-28

CONTENTS

ii

ForSalesandSupport,ContactWalkerEMD•Toll-free:(800)876-4444•Tel:(203)426-7700•Fax:(203)426-7800•www.walkeremd.com

Creating / Editing a PLC Rung ..................................................................12-30

Operation Details Screen...........................................................................12-31

Default PLC Program.................................................................................12-44

Chapter 13: Communication/Protocol

ASCII Command ..............................................................................................13-1

RS232 Serial Communications Character Framing Settings...................13-1

Read /Write RegisterValue Using ASCII Commands Over RS232

Serial Port...................................................................................................13-1

Reading Indexer Internal Fault and Status Identification FlagWords ...13-5

Reading ProcessVariable/Diagnostic Registers.........................................13-6

Manipulation of PLC Flags Using ASCII Serial Port Commands............13-7

Scaling and Interpretation ofValues Stored in Axiom Plus Registers......13-9

General Analog Input Functionality Analog Register ..............................13-11

ModBus Communication Setting...................................................................13-12

Addressing of Slave Axiom Plus Devices ...................................................13-13

Mapping............................................................................................................13-14

Axiom Plus Registers into Modbus Registers.............................................13-14

Axiom Plus Discrete I/O and Flags into

ModBus 0X and 1X Memory Space............................................................13-20

Command stream Handling,Time-Separation of Commands,Etc........13-23

ModBus Commands Supported by Axiom Plus........................................13-24

Registers......................................................................................................13-29

Chapter 14: Examples

IndexerType Control of the Axiom Plus.........................................................14-1

PLC Program Listing .................................................................................14-1

Sequential Program Listing.......................................................................14-4

Chapter 15: Status and Fault Display

Normal Operation ...........................................................................................15-1

Status Codes .....................................................................................................15-1

Faults ................................................................................................................15-1

Fault and Status Codes .............................................................................15-2

Chapter 16: Maintenance & Troubleshooting

Maintenance ....................................................................................................16-1

Periodic Maintenance................................................................................16-1

Troubleshooting Guide....................................................................................16-2

Appendix A: Options and Accessories

Cables ...............................................................................................................A-1

Communications Cables.............................................................................A-1

Buffered Encoder Output / Auxiliary Encoder Cable .......................................A-1

Motor Cables................................................................................................A-2

iii

CONTENTS

ForSalesandSupport,ContactWalkerEMD•Toll-free:(800)876-4444•Tel:(203)426-7700•Fax:(203)426-7800•www.walkeremd.com

Appendix B: Specifications

Agency Approvals...............................................................................................B-1

Power ...............................................................................................................B-1

Command Sources ............................................................................................B-2

Serial Communication Port........................................................................B-2

Control Loops...............................................................................................B-2

Inputs and Outputs.....................................................................................B-2

Connectors ...................................................................................................B-2

Environmental.............................................................................................B-3

Motor Protection................................................................................................B-3

Regeneration Ratings ........................................................................................B-3

Power Dissipation..............................................................................................B-4

Appendix C: Motor Performance Data

Motor Drive Performance Curves for MRV Series Motor Drives...................C-1

Appendix D: Motor Dimension Drawings

Motor Dimension Drawings.............................................................................D-1

Appendix E: Warranty Information

Defective Equipment.........................................................................................E-1

Return Procedure...............................................................................................E-1

Product Support.................................................................................................E-2

Distributor & Representative Network.............................................................E-2

Application Engineers & Field Service .............................................................E-2

iv

ForSalesandSupport,ContactWalkerEMD•Toll-free:(800)876-4444•Tel:(203)426-7700•Fax:(203)426-7800•www.walkeremd.com

Figure Description Page

4.1 Axiom PV10 Mounting Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

4.2 Axiom PV20 and Axiom PV30 Mounting Dimensions. . . . . . . . . . . . . . . . . . . . 4-3

5.1 Axiom PV10/20/30 Single-Phase Drive Power Connections. . . . . . . . . . . . . . . 5-2

5.2 208/230 Vac Three-Phase; Axiom PV10/20/30

Three-Phase Power Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

6.1 PV10/20/30 Motor Power Cable Connections for MRV 2X, 3X, 5X. . . . . . . . . . 6-2

6.2 PV10/20/30 Motor Encoder Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

6.3 Emergency Stop Connection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

6.4 Drive Remains Powered . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

8.1 Tol-O-Motion Axiom Plus Setup Software Opening Screen. . . . . . . . . . . . . . . . 8-1

8.2 Setup and Configuration Screen. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-2

8.3 Register Precision Configuration Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-5

8.4 ModBus Configuration Window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-6

9.1 Axiom Plus Input Circuit Diagram. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-1

9.2 Axiom Plus Sinking Input Connected to Sourcing Switches

Using Internal Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-2

9.3 Axiom Plus Sinking Input Connected to Sourcing Switches

Using External Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-2

9.4 Axiom Plus Sinking Input Connected to Sourcing Output

Using Internal Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-3

9.5 Axiom Plus Sinking Input Connected to Sourcing Output

Using External Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-3

9.6 Axiom Plus Sourcing Input Connected to Sinking Switches

Using Internal Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-4

9.7 Axiom Plus Sourcing Input Connected to Sinking Switches

Using External Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-4

9.8 Axiom Plus Sourcing Input Connected to Sinking Outputs

Using Internal Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-5

9.9 Axiom Plus Sourcing Input Connected to Sinking Outputs

Using External Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-5

9.10 Front Panel Overlay. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-6

9.11 Single Ended and Differential Analog Input Connections . . . . . . . . . . . . . . . . . 9-6

9.12 Pullup/Pulldown Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-7

9.13 Axiom Plus Output Circuit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-9

9.14 Axiom Plus Sourcing Output Connected to Sinking Input

Using Internal Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-10

9.15 Axiom Plus Sourcing Output Connected to Sinking Input

Using External Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-10

9.16 Axiom Plus Sinking Output Connected to Sourcing Input

Using Internal Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-11

9.17 Axiom Plus Sinking Output Connected to Sourcing Input

Using External Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-11

v

List of Figures

ForSalesandSupport,ContactWalkerEMD•Toll-free:(800)876-4444•Tel:(203)426-7700•Fax:(203)426-7800•www.walkeremd.com

Figure Description Page

9.18

Axiom Plus Sinking Output Connected to Sourcing Opto22 Solid State Relays

. . 9-12

9.19 Axiom Plus Power Off Holding Brake Connection . . . . . . . . . . . . . . . . . . . . . . 9-12

10.1 Brake Connection & Regeneration Resistor Connections . . . . . . . . . . . . . . . 10-2

11.1 Tuning and Diagnosis Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-2

11.2 Drive-Stage Diagnosis Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-4

11.3 Drive-Stage Tuning Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-5

11.4 Tuning and Diagnostic Screen with Analog Input Calibration Function Active. 11-9

12.1 Sequential Program Display / Edit Screen. . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-2

12.2 Register Display Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-4

12.3 I/O Flag Table Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-4

12.4 Sequential Program Debugger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-5

12.5 Watched Registers & Flags. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-6

12.6 View / Edit Default Parameters Window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-7

12.7 Sequential Program Listing Screen. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-8

12.8 Icon Menu Window. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-8

12-9 Axis Motion Window. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-8

12-10 Absolute Position Move Window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-11

12.11 Sequential Instruction Form for Programming of Analog Absolute

Position Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-13

12.12 Sequential Instruction Form for Programming of Analog Absolute

Velocity Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-14

12.13 Set/Clear Multiple Flags . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-16

12.14 Program Control Window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-17

12.15 Branch on Analog Input Compare. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-18

12.16 Branch on Register Compare . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-19

12.17 Parameter Value Change Window. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-20

12.18 Axis Homing Routines Window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-21

12.19 Absolute Position Feedback Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-24

12.20 Register Manipulation Window. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-26

12.21 Increment/Decrement Count Register. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-27

12.22 PLC Menu and Programming Form Screen . . . . . . . . . . . . . . . . . . . . . . . . . . 12-28

12.23 PLC Programming Form Screen. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-30

12.24 Operation Details Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-31

12.25 Operation Selection Screen. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-32

12.26 One Shot Definition Screen. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-33

12.27 Register Comparison Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-34

12.28 Timer Definition Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-35

12.29 Counter Definition Screen. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-36

12.30 Operand Display / Selection / Comment Screen . . . . . . . . . . . . . . . . . . . . . . . 12-37

12.31 Indexer Control Flags Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-41

12.32 Default PLC Program Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-44

13.1 ModBus Configuration and Setup Screen. . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-12

LIST OF FIGURES

vi

ForSalesandSupport,ContactWalkerEMD•Toll-free:(800)876-4444•Tel:(203)426-7700•Fax:(203)426-7800•www.walkeremd.com

Figure Description Page

14.1 PLC Program Listing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14-2

14.2 PLC Program Listing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14-3

14.3 PLC Program Listing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14-4

14.4 Sequential Program Listing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14-5

14.5 Sequential Program Listing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14-6

14.6 Sequential Program Listing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14-7

14.7 Sequential Program Listing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14-8

A.1 RS-232 Communications Cable (P/N 3600-1172).............................................A-1

A.2 Encoder Output Cable (P/N 3604-1213)............................................................A-2

A.3 Tol-O-Matic MRV Motor Connector Pinouts......................................................A-4

C.1 MRV 11Y PV10 Single-Phase, Three-Phase Drive Performance Curves............C-1

C.2 MRV 21Y PV10 Single-Phase, Three-Phase Drive Performance Curves............C-2

C.3 MRV 22Y PV10 Single-Phase, Three-Phase Drive Performance Curves............C-2

C.4 MRV 23Y PV10 Single-Phase, Three-Phase Drive Performance Curves............C-3

C.5 MRV 24Y PV10 Single-Phase, Three-Phase Drive Performance Curves............C-3

C.6 MRV 31Y PV10 Single-Phase, Three-Phase Drive Performance Curves............C-4

C.7 MRV 31Z PV20 Single-Phase, Three-Phase Drive Performance Curves............C-4

C.8 MRV 32Y, PV20 Single-Phase, Three-Phase Drive Performance Curves...........C-5

C.9 MRV 32Z PV30 Single-Phase, Three-Phase Drive Performance Curves............C-5

C.10 MRV 33Y PV30 Single-Phase, Three-Phase Drive Performance Curves............C-6

C.11 MRV 33Z PV30 Single-Phase, Three-Phase Drive Performance Curves............C-6

C.12 MRV 51Z PV30 Single-Phase, Three-Phase Drive Performance Curves............C-7

D.1 MRV 11 Motor ..................................................................................................D-1

D.2 MRV 21/22/23/24 Motors..................................................................................D-1

D.3 MRV 31/32/33 Motors.......................................................................................D-2

D.4 MRV 51 Motor...................................................................................................D-2

vii

LIST OF FIGURES

ForSalesandSupport,ContactWalkerEMD•Toll-free:(800)876-4444•Tel:(203)426-7700•Fax:(203)426-7800•www.walkeremd.com

viii

ForSalesandSupport,ContactWalkerEMD•Toll-free:(800)876-4444•Tel:(203)426-7700•Fax:(203)426-7800•www.walkeremd.com

This manual provides step-by-step instructions for installing,

controlling, tuning and maintaining yourTol-O-Matic Axiom Plus

system. It details the hardware connections necessary to operate

this unit in each of its operating modes.

All Axiom series drives use Tol-O-Motion™ Axiom® setup software

installed on a personal computer running MicrosoftWindows® 95,

98, NT or XP operating system.The software utilizes a graphical user

interface, allowing point and click setup and tuning of the drive

when used withTol-O-Matic servo motors.

Graphic Symbols and Warning Classifications

Protective Conductor terminal (Earth ground)

Chassis terminal (Not a protective ground)

Risk of Electrical Shock symbol

The use of the following symbols and signal words is based on an

estimation of the likelihood of exposure to the hazardous situation

and what could happen as a result of exposure to the hazard.

DANGER,WARNING or CAUTION require accompanying

information notices to prevent potential personal injury and

equipment damage.

Classifications include:

DANGER! Indicates a very hazardous situation which, if not

avoided, could result in death or serious injury.This signal word is

limited to the most extreme situations.

WARNING! Indicates a potentially hazardous situation which, if not

avoided, could result in death or serious injury.

Caution! Indicates a potentially hazardous situation which, if not

avoided, may result in property damage or minor to moderate

injury.

!

ix

Introduction

ForSalesandSupport,ContactWalkerEMD•Toll-free:(800)876-4444•Tel:(203)426-7700•Fax:(203)426-7800•www.walkeremd.com

NOTICES

Danger Notices

DANGER! Adjustment, operation and service of this equipment

should only be performed by qualified electrical personnel familiar

with its operation and hazards. Read and understand this manual

before attempting installation or operation of this equipment.

Failure to observe this precaution could result in serious bodily

injury or loss of life.

DANGER! The user of this equipment is responsible for observing

all local, national and international codes. Proper grounding, wiring

practice, disconnects and overcurrent protection are of particular

importance. Failure to observe this precaution could result in

serious bodily injury or loss of life.

DANGER! Any shielded power cables must be grounded in at least

one place for safety. Failure to ground the shield of a shielded power

cable could result in potentially lethal voltages being present on the

shield and anything connected to it.

DANGER! The DC bus capacitors may retain a hazardous voltage

level for a period of time after input power has been removed. After

disconnecting power, wait for the time period listed on the front of

the unit before servicing. This allows the bus capacitors time to

bleed down to a safe voltage level. Failure to observe this precaution

could result in serious bodily injury or loss of life.

Warning Notices

WARNING! Always perform initial motor checkout with the motor

disconnected from the load. Remove keys or loose couplings from

the motor shaft to prevent injury from flying metal parts. Improper

wiring could result in unexpected motor movement. Be prepared to

remove power if improper motor movement occurs.

WARNING! Full DC bus voltage is present at the regeneration

resistor terminals. Treat them with the same respect and practice as

the power and motor drive connections.

INTRODUCTION

x

ForSalesandSupport,ContactWalkerEMD•Toll-free:(800)876-4444•Tel:(203)426-7700•Fax:(203)426-7800•www.walkeremd.com

WARNING! Large leakage currents exist in AC line filters.They must

be grounded properly before applying power. Filter capacitors retain

high voltages after power removal. Before handling the equipment,

voltages should be measured to determine safe levels prior to

handling the equipment. Failure to observe this precaution could

result in severe bodily injury.

WARNING! The circuits in the Axiom Plus are potential sources of

severe electrical shock. Follow all safety guidelines to avoid shock.

WARNING! Rotating motor shafts can cause extensive damage and

injury. Motors must be properly guarded during testing and in the

final installation.

WARNING! The user must provide an external, hard-wired

emergency stop circuit in addition to the controller circuitry. This

circuit must remove power from the system in case of improper

operation.The drive enable is not adequate for this purpose, as it

does not remove supply voltage from the unit and may not disable

the system in all circumstances. Uncontrolled machine operation

may result if this procedure is not followed. Failure to observe this

precaution could result in severe bodily injury.

WARNING! High voltage may be present on the terminals of the

unit. Remove power and disconnect the power cable before making

or removing any connection. Again mention wait for bus bleed-

down.

Caution Notices

Caution! Do not tin (solder) the exposed leads on cables.Tinned

leads will loosen in time and may come loose from their screw

terminal connections.

Caution! Ensure that encoder signals are connected properly.

Incorrect connection of encoder signals will result in a“run away”

motor condition and/or incorrect commutation.

Caution! Electronic components are subject to damage by static

electricity. Follow Electrostatic Discharge (ESD) practices while

handling components.

!

!

!

xi

ForSalesandSupport,ContactWalkerEMD•Toll-free:(800)876-4444•Tel:(203)426-7700•Fax:(203)426-7800•www.walkeremd.com

Caution! If the cabinet is ventilated, use filtered or conditioned air

to prevent the accumulation of dust and dirt on electronic

components.The air should be free of oil, corrosives, or electrically

conductive contaminates.

!

xii

ForSalesandSupport,ContactWalkerEMD•Toll-free:(800)876-4444•Tel:(203)426-7700•Fax:(203)426-7800•www.walkeremd.com

Axiom Plus System Overview

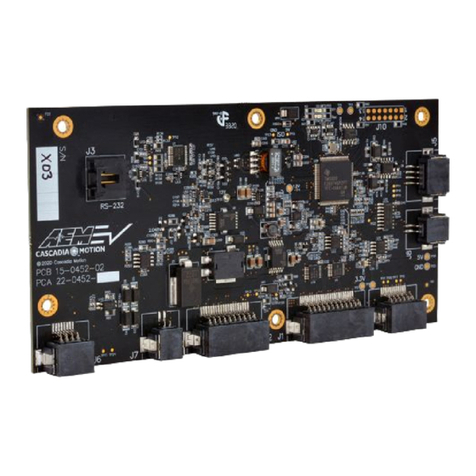

The Axiom Plus unit uses a high speed Digital Signal Processor (DSP)

to perform all calculations necessary for high bandwidth, digital

control of three-phase brushless servo motors. All tuning

parameters are set and stored digitally using theTol-O-Motion

Axiom Plus setup software. In addition, the unit includes a 1-1/2

axis controller function with user assignable I/O and an integrated

PLC.

With brushless motors, the Axiom Plus incorporates state-of-the-art

SpaceVector Commutation to give 12.5% better bus voltage

utilization than traditional sinusoidal commutation drives. This

allows for improved motor speed/torque performance over older

technology trapezoidal or sinusoidal motor drives.

In addition, the Axiom Plus implements a FluxVector, or field

oriented, current control algorithm. This allows for precise, high

bandwidth current control in each individual motor phase and

minimizes torque variations due to slight phase-to-phase

differences within a motor’s windings. It also minimizes non-torque

producing motor current for less motor heating and better speed/

torque performance than with traditional trapezoidal and sinusoidal

control algorithms.

POWER RATINGS

Three power levels of Axiom Plus are available.

• Axiom Plus PV10 with a continuous current rating of 5A and a

peak rating of 10A from a single or three phase power source.

• Axiom Plus PV20 with a continuous current rating of 10A and a

peak rating of 20A from a single or three phase power source.

• Axiom Plus PV30 with a continuous current rating of 15A and a

peak rating of 30A from a single or three phase power source.

The Axiom Plus system, when combined withTol-O-Matic MRV

series brushless servo motors, can provide continuous torque up to

75 lb-in (10.7 Nm), peak torque up to 150 lb-in (21.4 Nm) and speeds

up to 6000 RPM.

xiii

ForSalesandSupport,ContactWalkerEMD•Toll-free:(800)876-4444•Tel:(203)426-7700•Fax:(203)426-7800•www.walkeremd.com

INTERFACE CABLES

Standard motor power and encoder feedback cables, as well as

communications cables, are available to complete the motion

control system and provide reliable, trouble free start-up. For a

description of optional equipment, refer to Appendix A: Options

and Accessories.

Axiom Plus System Features

Sequential Motion Control - An easy to use sequential motion

control programming environment.

PLC Programming - Provides a method to create more complex

motion control programs than can be done with a sequential

controller alone.

State-of-the-Art SpaceVector Commutation - Provides 12.5% better

bus voltage utilization than traditional sinusoidal commutation

drives.

State-of-the-art FluxVector Motor Current Control - Allows higher

bandwidth control of torque producing current than traditional

Sinusoidal approach. FluxVector control also improves overall

efficiency by reducing harmonic currents in motor windings. Flux

Vector control is also known as field-oriented control.

High Performance Digital Signal Processor (DSP)Technology -

Allows for the implementation of advanced brushless motor control

algorithms.

Digital Current,Velocity and Position Calculations - Provide for high

bandwidth motor control while minimizing drift and aging

problems inherent in traditional analog drives.

Standard Features:

•

15 optically isolated inputs with 5-25Vdc range (if analog is not used)

• 8 optically isolated outputs with 5-25Vdc range

• One 14-bit analog input (±10Vac)-full differential – 12 optically

isolated inputs with 5-25Vdc range

• Built-in 24Vdc 400mA power supply

xiv

ForSalesandSupport,ContactWalkerEMD•Toll-free:(800)876-4444•Tel:(203)426-7700•Fax:(203)426-7800•www.walkeremd.com

• Built-in 1-1/2 axis programmable motion controller

• Built-in real-time scanned“PLC” for complex machine control tasks

• Encoder Follower input

• Designed for use withTol-O-Matic MRV series brushless motors.

• Pluggable terminal block connections for ease of Installation.

• Continuous output ratings of 5A, 10A and 15A.

• Peak output ratings of 10A, 20A and 30A. (3 sec. peak)

• Buffered encoder output.

• 115/208/230Vac input, 50/60Hz, single or three phase.

• Short-circuit protection.

• Overcurrent protection.

• Bus over-voltage shutdown.

• Internal bus current regeneration.

• Connection for additional external regeneration capacity.

• Motor and Drive thermal protection.

• Auto-Phasing: Requires no Hall Effect switches for phasing or

commutation.

• RS-232 communications, including ASCII and Modbus RTU

protocols

• Windows-based software for setup, tuning and diagnostics.

• Integral 3A brake relay.

• Front panel status and fault display indicators.

MOTOR/ENCODER INPUT

A single, motor-mounted optical encoder provides complete

commutation information as well as position and velocity feedback.

The input can accept a wide range of encoder line counts at

quadrature rates up to 4MHz.

ENCODER FOLLOWER INPUT

This input provides power (5Vdc) for an incremental quadrature (A

& B channel) differential output encoder and provides the input

command for all gearing functions.

ENCODER OUTPUT

The Axiom Plus incorporates a buffered encoder output signal for

connection to a motion controller. This is a 5Vdc differential signal.

xv

ForSalesandSupport,ContactWalkerEMD•Toll-free:(800)876-4444•Tel:(203)426-7700•Fax:(203)426-7800•www.walkeremd.com

I/O – INPUT OUTPUT

The Axiom Plus unit incorporates several dedicated discrete I/O

connections.

• Brake Relay Output - A 3A relay contact for connection to an

actuator or motor shaft-mounted“energize-to-release”-type brake.

• MotorTemp Input - Connection for a motor’s internal temperature

switch. This requires a normally closed (N.C.) connection. If this

connection is broken, the unit shuts down and displays the

appropriate fault on the fault indicator.

• Total of 15 Assignable Inputs / 5-25Vdc range

• Total of 8 Assignable Outputs

• I/O controlled from sequential motion program or“PLC”

• One ±10Vac analog input range

ANALOG INPUT

• 14-bit

• ±10 volt differential

• Scale and offset adjustments

• ±2 LSB’s accuracy over full scale input range

AC INPUT POWER

Axiom Plus units are powered directly from a single-phase or three-

phase ac main.The drive accepts nominal input voltages of 115Vac,

208Vac or 230Vac. The input range is switch selectable. The 115V

selection is for 115Vac operation. The 230V selection is for 208Vac or

230Vac operation.

Caution! Failure to make the correct switch selection for the

supplied voltage will result in the drive entering a fault condition

when power is applied. The drive will not operate until powered

down and switched correctly.

DRIVE AND MOTOR PROTECTION CIRCUITRY

• Seven-segment LED display provides drive status and fault codes

at a glance

• Over-temperature, short circuit and over-current protection for

the power output

• Peak and continuous current limits

!

xvi

ForSalesandSupport,ContactWalkerEMD•Toll-free:(800)876-4444•Tel:(203)426-7700•Fax:(203)426-7800•www.walkeremd.com

• Bus over-voltage and under-voltage

• Motor over-speed protection

• Watchdog timers provide fail-safe operation

AGENCY APPROVALS

The Axiom Plus is UL approved and CE certified.

Tol-O-Motion Axiom Plus Software

All drive/motor setup, tuning and programming is accomplished

with theTol-O-Motion Axiom Plus setup software. This is a

Windows-based graphical interface that communicates through the

drive’s RS-232 serial communications port. Windows 95, 98, NT and

XP are supported.

•The software allows easy selection of any Tol-O-Matic MRV series

brushless servo motor.

•The software provides a user friendly “on-screen” oscilloscope and

diagnostic screen for tuning and troubleshooting.

•The software incorporates a“point-and-click” editor for entering the

user’s sequential motion program and“PLC” ladder logic program.

• Digital auto-tuning allows easy setup. All tuning adjustments are made

via software to immediately set servo system compensation

parameters, thus eliminating time-consuming potentiometer

adjustment.

xvii

ForSalesandSupport,ContactWalkerEMD•Toll-free:(800)876-4444•Tel:(203)426-7700•Fax:(203)426-7800•www.walkeremd.com

xviii

This manual suits for next models

3

Table of contents

Other Tolomatic Controllers manuals

Tolomatic

Tolomatic RSX User manual

Tolomatic

Tolomatic IMA Series User manual

Tolomatic

Tolomatic 3604-9651 Manual

Tolomatic

Tolomatic MXP16P Series User manual

Tolomatic

Tolomatic ACS Manual

Tolomatic

Tolomatic TRS Series User manual

Tolomatic

Tolomatic SmartActuator Series User manual

Tolomatic

Tolomatic ServoWeld CSW Owner's manual

Tolomatic

Tolomatic BCS10 Operator's manual

Tolomatic

Tolomatic ACS Manual