Tolomatic RSX User manual

RSX

EXTREME FORCE

ROD-STYLE

ACTUATOR

MANUAL

INSTALLATION, OPERATION

AND MAINTENANCE

LINEAR SOLUTIONS MADE EASY

LINEAR SOLUTIONS MADE EASY

2171-4007_02_RSX_MANUAL

Information furnished is believed to be accurate and reliable. However, Tolomatic

assumes no responsibility for its use or for any errors that may appear in this

document.

Tolomatic reserves the right to change the design or operation of the equipment

described herein and any associated motion products without notice. Information in

this document is subject to change without notice.

Copyright © 2022 Tolomatic, Inc. All rights Reserved.

All brand and product names are trademarks of their respective owners. Information

in this document is believed to be accurate at time of publication.

202203100833

Original Instructions - English

Translations will be supplied in other community languages as required by

customers

Tolomatic User Manual: RSX Extreme Force Electric Rod-Style Linear Actuator

• 3 •

Contents

SAFETY................................................................................6

1.1 Safety Symbols........................................................................6

General ..............................................................................6

Safety Symbols.........................................................................6

1.2 Safety Considerations ...................................................................7

Proper and Safe Use of Product.............................................................7

Requirement Regarding Personnel...........................................................8

RSX PRODUCT OVERVIEW .................................................................9

2.1 General Description ....................................................................9

2.2 Product Features ......................................................................9

RSX PRODUCT CONFIGURATION OVERVIEW ..................................................10

3.1 RSX Series Standard Configurations and Options ..............................................10

3.2 RSX Configurations and Options Ordering Codes ..............................................10

3.3 Motor (Gearhead) Mounting Options........................................................11

3.4 Actuator Mounting Options ..............................................................11

3.5 Rod End Options......................................................................12

3.6 Extended Thrust Rod...................................................................12

3.7 Extended Tie Rods ....................................................................12

3.8 IP67 Ingress Protection .................................................................13

3.9 Position Sensors .....................................................................13

MECHANICAL INSTALLATION OF RSX ACTUATORS .............................................14

4.1 General Operation.....................................................................14

4.2 Alignment and Side Loading .............................................................14

4.3 Mechanical Installation .................................................................15

4.4 Lifting and Moving ....................................................................15

4.5 Motor Installation .....................................................................17

4.5.1 Reverse Parallel Configuration ..........................................................17

4.5.2 Inline Configuration ..................................................................20

4.6 Options ............................................................................21

4.6.1 Front Flange Mount ..................................................................21

4.6.2 Trunnion Mount . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

4.6.3 Mounting Plates.....................................................................22

4.6.4 Rear Clevis Mount ...................................................................23

4.6.5 Extended Tie Rod Mounting ............................................................24

4.6.6 Rod End ..........................................................................24

Tolomatic User Manual: RSX Extreme Force Electric Rod-Style Linear Actuator

• 4 •

4.6.7 Rod Clevis.........................................................................25

RSX OPERATION AND STARTUP............................................................26

5.1 Back Driving.........................................................................26

5.2 Homing ............................................................................26

5.3 Breather/Purge Port Operation............................................................26

RSX REPAIR AND MAINTENANCE ..........................................................27

6.1 Seal Cartridge Replacement .............................................................27

6.2 Roller Screw Lubrication ................................................................28

In order to re-lubricate the Roller Screw: .....................................................28

6.3 Storage Recommendations ..............................................................29

6.4 Replacement Parts & Repairs ............................................................29

APPENDIX A ...........................................................................30

A.1 Specifications........................................................................30

A.1.1 Performance and Mechanical Specifications ..............................................30

A.1.2: Actuator Sizing ...................................................................30

A.1.3: Critical Speed....................................................................30

A.1.4: Roller Screw Life .................................................................30

APPENDIX B ...........................................................................31

B.1 Troubleshooting Procedure ..............................................................31

APPENDIX C ...........................................................................32

C.1 Warranty ...........................................................................32

Limited Warranty ......................................................................32

Limitation of Liability ....................................................................33

Product Return Procedure ................................................................33

End of Life . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

APPENDIX D ...........................................................................34

D.1 Declaration of Incorporation .............................................................34

Tolomatic User Manual: RSX Extreme Force Electric Rod-Style Linear Actuator

• 5 •

List of Figures and Tables

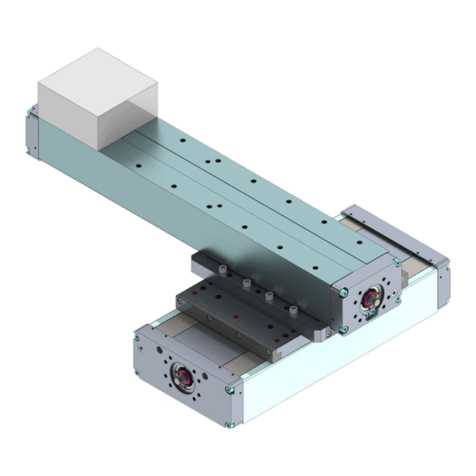

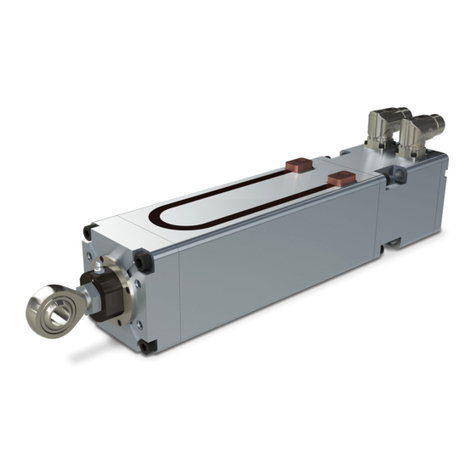

Figure 2-1: RSX actuator with RP (Reverse Parallel)

motor mount............................... 9

Figure 2-2: RSX actuator major components ....... 9

Figure 3-1 RSX ordering codes and descriptions ... 10

Figure 3-2 RSX front flange option.............. 11

Figure 3-3 RSX mounting plates option .......... 11

Figure 3-4 RSX rear clevis mount option on reverse

parallel motor mount actuator ................. 11

Figure 3-5 RSX trunnion mount option........... 12

Figure 3-6 RSX rod clevis option ............... 12

Figure 3-7 RSX external thread option ........... 12

Figure 3-8 RSX extended tie rods option ......... 13

Figure 3-9 RSX position sensors ............... 13

Figure 4-1 Lift RSX properly using hoist and eyebolts 16

Figure 4-2 Lift RSX properly without eyebolts ...... 16

Figure 4-3 RSX RP motor and pulley ............ 17

Figure 4-4 RSX belt pulley diagram ............ 18

Figure 4-5 RSX motor coupler for LMI (inline) motor

mounting ................................ 20

Figure 4-6 RSX front flange option.............. 21

Figure 4-7 RSX trunnion mount option........... 22

Figure 4-8 RSX mounting plates option .......... 22

Figure 4-9 RSX rear clevis mount option on reverse

parallel motor mount actuator ................. 23

Figure 4-10 RSX extended tie rod mount option .... 24

Figure 4-11 RSX rod clevis option .............. 25

Figure 6-1 RSX seal cartridge exploded view ...... 27

Figure 6-2 RSX lubrication access cover

exploded view............................. 28

Table 4-1 RSX actuator weights (add stroke per unit

weight to base actuator weight)................ 15

Table 4-2 RSX motor pulley set screw torque

requirements ............................. 17

Table 4-3 RSX belt tension specifications......... 18

Table 4-4 RSX motor fasteners torque requirements. 19

Table 4-5 RSX reverse parallel cover fasteners torque

requirements ............................. 19

Table 4-6 RSX motor coupler set screw torque

requirements ............................. 20

Table 4-7 RSX motor fasteners torque requirements. 20

Table 4-8 RSX front flange fasteners torque

requirements ............................. 21

Table 4-9 RSX trunnion diameter and tolerance .... 22

Table 4-10 RSX mounting plates torque

requirements ............................. 23

Table 4-11 RSX rear clevis mount diameter and

tolerance ................................ 23

Table 4-12 RSX extended tie rod mounting torque

requirements ............................. 24

Table 4-13 RSX pilot holes diameter and tolerance.. 24

Table 4-14 RSX rod end torque requirements...... 24

Table 4-15 RSX rod clevis bore diameter and

tolerance ................................ 25

Table 4-16 RSX rod clevis width and tolerance..... 25

Table 4-17 RSX rod clevis torque requirements .... 25

Table 5-1 RSX breather/purge port thread size..... 26

Table 6-1 RSX seal cartridge torque requirements .. 27

Tolomatic User Manual: RSX Extreme Force Electric Rod-Style Linear Actuator

• 6 •

General

Read completely through the applicable sections of the manual before the equipment/unit is

unpacked, installed or operated. Pay careful attention to all of the dangers, warnings, cautions and

notes stated in the manual.

Serious injury to persons or damage to the equipment may result if the information in the manual is

not followed.

Safety Symbols

Items that are specifically marked DANGER, WARNING, CAUTION, PROHIBITIVE, MANDATORY ACTION,

or NOTE! are arranged in a hierarchical system and have the following meaning:

DANGER!

Indicates a very hazardous situation which, if not avoided, could result in death or serious injury. This

signal word is limited to the most extreme situations.

WARNING!

Indicates a potentially hazardous situation which, if not avoided, could result in death or serious

injury.

CAUTION!

Indicates a potentially hazardous situation which, if not avoided, this situation may result in property

damage or minor or moderate injury.

PROHIBITED ACTION

Indicates Prohibited Action

MANDATORY ACTION

Indicates Mandatory Action

NOTE!

Information that requires special attention is stated here.

1.1 Safety Symbols

Safety1

Tolomatic User Manual: RSX Extreme Force Electric Rod-Style Linear Actuator

• 7 •

1: SAFETY

1.2 Safety Considerations

Proper and Safe Use of Product

Device Damage Prevention

To prevent permanent damage to the device, proper care should be taken not to exceed published

voltage, current, temperature, and load/force ratings. In addition, proper mechanical assembly and

proper wiring should be verified and safety measures checked before applying power to the complete

equipment package.

Personal Safety

During normal operation the actuator can become hot, especially the appropriately marked electric

motor housing, which is electrically coupled to the actuator. In addition, the case ground of the

appropriately marked electric motor should be tied to an earth ground to prevent the presence of

case voltage.

During normal operation, the actuator rod travels in and out creating a possible pinch point.

Proper guarding and signage must be used prevent entry into possible pinch zones and contact with

hot surfaces. It is highly recommended to display proper safety notices and implement proper safety

measures to prevent contact with hot surfaces.

Handling and Unpacking

When unpacking and handling the actuator, care should be taken not to drop the actuator as this can

damage the connectors, internal electronics, or cause misalignment of the actuator feedback device.

Damage the internal mechanical components may cause poor performance or render the actuator

non-functional. Since this is an electromechanical device, proper ESD measures should be taken to

avoid static electricity from contacting the signal and power lines of the device. as this can damage

the internal mechanical components rendering the actuator damaged or non-functional.

Packing and Transport

NOTE!

Package actuator to prevent damage during transport. Also make sure the actuator is clean, dry and

protected from moisture.

Modifications to the Equipment

WARNING!

The manufacturer takes no responsibility whatsoever if the equipment is modified or if the equipment

is used in any way beyond performance specifications. Unauthorized modifications or changes to the

equipment are strictly forbidden and void all warranties.

Tolomatic User Manual: RSX Extreme Force Electric Rod-Style Linear Actuator

• 8 •

1: SAFETY

Requirement Regarding Personnel

NOTE!

All personnel must be completely informed regarding all safety regulations and the function of the

equipment.

Risk Area and Personnel

When installed, pinch points are generated capable of damaging forces. The risk area surrounding

the actuator must either be guarded or clearly marked, including display signage in accordance with

all applicable national and international legal requirements. The risk area must be protected by a

safety system that stops the equipment if anyone enters the risk area. Personnel who enter the risk

area must be authorized, trained and qualified for the different tasks inside the risk area.

Tolomatic User Manual: RSX Extreme Force Electric Rod-Style Linear Actuator

• 9 •

Figure 2-1: RSX actuator with RP (Reverse Parallel) motor mount

RSX series is a family of roller screw driven high force mechanical rod style linear actuators

manufactured by Tolomatic Inc. to customer specified stroke length and mounting provisions

for customer specified motor (gearhead) and are intended for use in general purpose industrial

applications.

The product family includes the following models: RSX080, RSX096, RSX096P and RSX128.

The actuators have hard coat anodized aluminum construction with steel tie rods and thrust rod.

An appropriately marked electric motor or a motor (gearhead) assembly is coupled with the input shaft

of the actuator to create linear motion. The motor (gearhead) may be installed by the customer at their

facility or by Tolomatic.

2.2 Product Features

Actuator Body

Lube Access Cover

“Breather” Port

Tie Rods

Head

Seal Cartridge

Rod End

Thrust Rod

Bearing Block

RP Motor Mount

LMI Motor Mount

“Breather” Port

Lube Access Cover

Seal

Cartridge

RP

(Reverse Parallel

Motor Mount)

LMI

(Inline Motor Mount)

Figure 2-2: RSX actuator major components

RSX Product Overview2

2.1 General Description

Seal Cartridge

Tolomatic User Manual: RSX Extreme Force Electric Rod-Style Linear Actuator

• 10 •

3.1 RSX Series Standard Configurations and Options

RSX series includes four actuator models: RSX080, RSX096, RSX096P and RSX128

• Each of the RSX actuator models is available in a number of different motor mounting

configurations

• Each of the RSX actuator models is available with a number of different mounting options:

• Each of the RSX actuator models is available with a number of different rod end options:

• Each of the RSX actuator models is available with a choice of positioning sensors (switches)

• Each of the RSX actuator models is available with extended length tie rods

• Each of the RSX actuator models is available with extended length thrust rod

• Each of the RSX actuator models is available with IP67 ingress protection

NOTE For performance data and specifications please refer to the Tolomatic RSX Product

Brochure 2171-4001.

3.2 RSX Configurations and Options Ordering Codes

NOTE See Tolomatic RSX Product Brochure 2171-4001 for complete information on ordering

codes. Please use 3D CAD files (available at www.tolomatic.com) for critical dimensions.

Figure 3-1 RSX ordering codes and descriptions

RSX Product Configuration Overview3

Tolomatic User Manual: RSX Extreme Force Electric Rod-Style Linear Actuator

• 11 •

3: PRODUCT CONFIGURATION OVERVIEW

3.3 Motor (Gearhead) Mounting Options

• Each of the RSX actuators is available in Reverse Parallel or Inline motor (gearhead)

mounting configuration;

• Timing belt reduction drive in the Reverse Parallel configuration is available with

1:1 or 2:1 reduction ratio;

• Motor (gearhead) can be installed by the Customer at their facility or at Tolomatic.

3.4 Actuator Mounting Options

All of the RSX actuators are available with the following mounting options:

• Front Flange mount;

080 & 096 Size

128 Size

Figure 3-2 RSX front flange option

• Mounting Plates.

Figure 3-3 RSX mounting plates option

RSX080, RSX096 and RSX128 models are available with:

• Clevis mount (Reverse Parallel configuration only);

RP HOUSINGRP HOUSING

Side View Top View

Figure 3-4 RSX rear clevis mount option on reverse parallel motor mount actuator

Tolomatic User Manual: RSX Extreme Force Electric Rod-Style Linear Actuator

• 12 •

3: PRODUCT CONFIGURATION OVERVIEW

• Trunnion mount.

Figure 3-5 RSX trunnion mount option

3.5 Rod End Options

RSX080, RSX096 and RSX128 models are available with the following rod end options:

• Rod Clevis;

Side View Top View

Figure 3-6 RSX rod clevis option

• Rod End with male Imperial mounting thread.

Figure 3-7 RSX external thread option

3.6 Extended Thrust Rod

All of the RSX actuator models are available with a thrust rod of extended length per customer

specifications.

3.7 Extended Tie Rods

All of the RSX actuator models are available with extended tie rods that could be used to mount the

actuator to any wall with a set of through holes by protruding the tie rods into the holes and securing

the actuator with 4 jam nuts from the other side. If this option is used it is strongly recommended

that the actuator is properly aligned. A pilot hole for the alignment of the actuator is provided to avoid

any side loading (see section 4.2.).

Tolomatic User Manual: RSX Extreme Force Electric Rod-Style Linear Actuator

• 13 •

3: PRODUCT CONFIGURATION OVERVIEW

Figure 3-8 RSX extended tie rods option

3.8 IP67 Ingress Protection

All of the RSX actuator models are available with optional IP67 ingress protection, when additional

sealing gaskets and washers are used when mounting the motor (gearhead) as well as between

mating parts of Reverse Parallel or Inline motor mounting kits.

3.9 Position Sensors

All of the RSX actuator models are available with Reed, Solid State PNP or Solid State NPN position

sensors with a choice of Normally Open or Normally Closed logic, and with “Quick Disconnect”

Connectors or flying leads. Please see Tolomatic RSX Product Brochure 2171-4001 for specifications

and dimensional information.

19

7

8

9

10

15

14

16

17

6

5

4

32

1

12

13

14

11

18

(PCD)

Clevis Mount Kit

(MP2)

Mounting Plate Kit

(XT)

Extended

Tie Rod Kit

(CLV)

Rod End

Clevis Kit

Figure 3-9 RSX position sensors

Tolomatic User Manual: RSX Extreme Force Electric Rod-Style Linear Actuator

• 14 •

WARNING!

Prior to installation and commissioning of this equipment this Manual and all accompanying

manufacturer documents and manuals MUST be completely read by the appropriate personnel. All

warnings must be given special attention.

4.1 General Operation

RSX series linear actuators function by translating the rotary motion of externally mounted electric

motor into linear motion of the thrust rod using a planetary roller screw mechanism. The travel

coordinates, linear speed, acceleration and force are typically controlled by a servo drive.

The relationship between the rotary motion of the motor and the linear motion of the actuator

corresponds to the following relationships:

Linear Force (N) = [motor torque (Nm)/1000 x 2 x π x reduction ratio x screw efficiency]

/ screw lead (mm)

Linear Force (lbf) = [motor torque (lbf-in) x 2 x π x reduction ratio x screw efficiency]

/ screw lead (in)

CAUTION!

Care should be taken not to exceed the physical travel limits of the actuator. Exceeding the specified

stroke will cause the actuator to reach mechanical end of stroke internally. Although protected by the

end of stroke bumpers, reaching internal end of stroke at speeds and torque greater than those used

to home (less than 25mm/sec and low torque) may physically damage the screw and the internal

components of the actuator.

4.2 Alignment and Side Loading

Alignment of the actuator with regard to the application axis of motion and the direction of the force

is essential to its proper functioning. Misalignment creates side loads on the thrust rod, leading

to rod binding, uneven roller nut loading and premature wear of rod seals, leading to excessive

heat generation and reduced service life of the actuator. RSX series actuators must not be used in

applications where side loading occurs. Loads must be aligned with the line of motion of the thrust

rod. Where necessary rod alignment couplers may be used.

Mechanical Installation of RSX Actuators4

Tolomatic User Manual: RSX Extreme Force Electric Rod-Style Linear Actuator

• 15 •

4: MECHANICAL INSTALLATION

4.3 Mechanical Installation

1. Open the crate and remove packaging material

2. Carefully remove linear actuator from the crate *Consider the weight of the actuator.

Depending on the configuration, the actuator can weight over 227 kg (500 lb)

3. Visually inspect the actuator for damage

4. Notify the carrier of any shipping damage immediately

5. Move the actuator to its position.

6. If the actuator is mounted in a vertical or inclined position include safety measures to

prevent load from falling in the case of screw failure or loss of power

7. Ensure sufficient clearance around the actuator to allow for airflow and cooling

8. Follow installation mounting instructions for each configuration.

4.4 Lifting and Moving

CAUTION!

Special care must be taken when lifting and moving the RSX actuators. Depending on the size

and configuration RSX actuators can represent heavy and awkward loads. Lifting equipment with

appropriate capacity must be used, and safe hoisting practices must be employed.

RSX

SIZE

WEIGHT

BASE ACTUATOR

PER UNIT

kg kg per mm

LMI

RP1 ST RP1HT RP2 ST RP2 HT

080 35.17 42.16 42.12 0.031

096 65.64 73.18 75.29 73.65 74.16 0.041

096P 68.86 80.22 79.10 0.043

128 176.61 207.70 208.46 0.079

lb lb per in

080 77.54 92.94 92.85 1.72

096 144.71 161.34 165.98 162.38 163.49 2.31

096P 151.82 176.85 174.40 2.40

128 389.37 457.91 459.58 4.40

Table 4-1 RSX actuator weights (add stroke per unit weight to base actuator weight)

Tolomatic User Manual: RSX Extreme Force Electric Rod-Style Linear Actuator

• 16 •

4: MECHANICAL INSTALLATION

Special care must be taken when lifting and moving the RSX actuators. Depending on the size

and configuration RSX actuators can represent heavy and awkward loads. Lifting equipment with

appropriate capacity must be used, and safe hoisting practices must be employed.

Lift properly using hoist and eyeboltsLift properly using hoist and eyebolts

Figure 4-1 Lift RSX properly using hoist and eyebolts

RSX080 is not equipped with lifting eyebolts and may be lifted by securing straps around the

bearing block next to the motor mount and the thrust rod next to the front head.

NOTE For an RSX080 equipped with an RP (reverse parallel) motor mount, during lifting the

reverse parallel housing must be oriented vertically pointing upwards (as shown in Figure 4-1).

Lifting without eyeboltsLifting without eyebolts

Figure 4-2 Lift RSX properly without eyebolts

Tolomatic User Manual: RSX Extreme Force Electric Rod-Style Linear Actuator

• 17 •

4: MECHANICAL INSTALLATION

4.5 Motor Installation

4.5.1 Reverse Parallel Configuration

When the motor (gearhead) is installed by the Customer at their facility, RSX actuator is shipped with

6 socket head cap screws holding the Reverse Parallel Cover “hand tight” and the motor (gearhead)

fasteners and the timing pulley separate.

To install the motor (gearhead):

a.RSX080 and RSX096 use timing pulleys that are mounted directly onto the motor (gearhead)

shaft. RSX128 uses a Taper Lock bushing and pulley set.

b.Assemble the timing pulley on the motor (gearhead) shaft using the motor (gearhead) key

and secure with fasteners tightened to the torque values given below:

Figure 4-3 RSX RP motor and pulley

TORQUE

MODEL REDUCTION

RATIO

NUMBER OF

SET SCREWS

SET SCREW

SIZE (Nm) (lbf-ft)

RSX080 RP1/RP2 4 M6 8.5* 6*

RSX096 RP1/RP2 4 M8 20* 15*

RSX096P RP1/RP2 4 M8 20* 15*

RSX128 RP1 2 5/8-11 UNC 32 24

RP2 2 7/16-14 UNC 90 67

Table 4-2 RSX motor pulley set screw torque requirements

*Thread adhesive is recommended.

c.Install the motor (gearhead) on the Reverse Parallel Plate (with fasteners not tight)*;

d.Tension the timing belt using the following instruction

1.Locate the belt over the pulleys and slide the drive pulley over the motor shaft. Tighten the

pulley to the motor shaft.

2.Verify that there is clearance between the inside of the RP case and each pulley. Verify that

the pulleys are aligned to each other.

3.Tension the belt by pulling the motor away from the drive shaft with the appropriate force

from the “Total Belt Tension” column in the chart below. Tighten the motor fasteners while

this force is applied to the motor.

Tolomatic User Manual: RSX Extreme Force Electric Rod-Style Linear Actuator

• 18 •

4: MECHANICAL INSTALLATION

Tension Specs Sonic Tension Method Force Deflection Method

Belt Span Tension

Force

Natural

Frequency Mass Width Span Deflection Deflection Force

lbf NHz lb/in g/m in mm in mm in mm lbf N

RSX080

RP1 HT1 120 ± 20 534 ± 89 153 0.408 4.7 1.42 36 7.24 184 0.11 2.8 9 ± 2 40 ± 9

RP2 HT1 120 ± 20 534 ± 89 157 0.408 4.7 1.42 36 7.05 179 0.11 2.8 9 ± 2 40 ± 9

RSX096

RP1 ST1 220 ± 20 979 ± 89 190 0.408 4.7 1.42 36 7.87 200 0.12 3.0 16 ± 2 71 ± 9

HT1 220 ± 20 979 ± 89 145 0.408 4.7 2.44 62 7.87 200 0.12 3.0 16 ± 2 71 ± 9

RP2 ST1 220 ± 20 979 ± 89 197 0.408 4.7 1.42 36 7.60 193 0.12 3.0 16 ± 2 71 ± 9

HT1 220 ± 20 979 ± 89 150 0.408 4.7 2.44 62 7.60 193 0.12 3.0 16 ± 2 71 ± 9

RSX128

RP1 HT1 250 ± 20 1,112 ± 89 110 0.408 4.7 2.44 62 11.024 280 0.17 4.3 19 ± 2 84.5 ± 9

RP2 HT1 250 ± 20 1,112 ± 89 111 0.408 4.7 2.44 62 11.087 282 0.17 4.3 19 ± 2 84.5 ± 9

Table 4-3 RSX belt tension specifications

4.Validate the span tension of the belt using either a sonic tension meter or force deflection

method.

a.Sonic tension meter

i. Enter the mass, width, and span from the table above into the tension meter.

ii. Test the belt using the

manufacturers recommendations

iii. Compare the span tension to

the target in the “Span Tension Force”

b.Force deflection method

i. At the center of the span,

measure the force required to deflect

the belt the distance called out in

the “Deflection” column in the table above. The measured force should fall within the

deflection force tolerance noted in the “Deflection Force” column.

1.Ensure one pulley is free to rotate.

2.The deflection force needs to be evenly applied across the entire belt width. Use a piece of

steel or angle iron across the belt width and deflect the belt evenly.

e.Tighten the motor fasteners to the following torque values:

Span Length, t

Force

Deflection Max.

1/64" per inch of span

(0.40 mm per 25.4 mm of span)

Figure 4-4 RSX belt pulley diagram

Tolomatic User Manual: RSX Extreme Force Electric Rod-Style Linear Actuator

• 19 •

4: MECHANICAL INSTALLATION

SCREW

SIZE

TORQUE

(Nm) (lbf-ft)

M6 10 7

M8 25 18

M10 50 35

M12 85 60

M14 135 100

M18 275 200

Table 4-4 RSX motor fasteners torque requirements

f.Tighten the Reverse Parallel Cover fasteners to the following minimum torque values**:

MODEL FASTENER

SIZE

TORQUE

(Nm) (lbf-ft)

RSX080 M12 85 60

RSX096 M16 200 150

RSX096P M16 200 150

RSX128 M24 675 500

Table 4-5 RSX reverse parallel cover fasteners torque requirements

*If equipped with IP67 option verify that the gasket is installed between the motor (gearhead)

and the plate, and the sealing washers are used on the motor fasteners.

**If equipped with IP67 option verify that the Reverse Parallel cover gasket is properly seated

inside the machined recess of the Reverse Parallel plate.

Tolomatic User Manual: RSX Extreme Force Electric Rod-Style Linear Actuator

• 20 •

4: MECHANICAL INSTALLATION

4.5.2 Inline Configuration

When the motor (gearhead) is installed by the Customer at their facility, RSX actuator is shipped with

the motor (gearhead) fasteners and the coupling half separate.

To install the motor (gearhead):

a.Assemble the coupling half on the motor (gearhead) shaft using the motor (gearhead) key

(see the drawing) and secure with fasteners tightened to the torque values given below

(thread adhesive is recommended):

Figure 4-5 RSX motor coupler for LMI (inline) motor mounting

MODEL NUMBER OF

SET SCREWS SET SCREW SIZE TORQUE

(Nm) (lbf-ft)

RSX080 25/16-18 UNC 20 15

RSX096 25/16-18 UNC 20 15

RSX096P 25/16-18 UNC 20 15

RSX128 23/8-16 UNC 34 25

Table 4-6 RSX motor coupler set screw torque requirements

Carefully align the coupling half with the mating half on the actuator’s drive shaft and move

the motor (gearhead) in until it is fully seated on the LMI motor plate. If equipped with IP67

option verify that the gasket is installed between the motor (gearhead) and the plate.

b.Tighten the motor fasteners to the following torque values*:

SCREW

SIZE

TORQUE

(Nm) (lbf-ft)

M6 10 7

M8 25 18

M10 50 35

M12 85 60

M14 135 100

M18 275 200

Table 4-7 RSX motor fasteners torque requirements

*If equipped with IP67 option verify that the sealing washers are used on the motor fastener

Table of contents

Other Tolomatic Controllers manuals

Tolomatic

Tolomatic IMA Series User manual

Tolomatic

Tolomatic ACS Manual

Tolomatic

Tolomatic TRS Series User manual

Tolomatic

Tolomatic MXP16P Series User manual

Tolomatic

Tolomatic BCS10 Operator's manual

Tolomatic

Tolomatic ServoWeld CSW Owner's manual

Tolomatic

Tolomatic SmartActuator Series User manual

Tolomatic

Tolomatic IMA-S Series User manual

Tolomatic

Tolomatic ACS Manual

Tolomatic

Tolomatic 3604-9651 Manual