Tolomatic ACS Manual

HARDWARE & INSTALLATION

GUIDE

LINEAR SOLUTIONS MADE EASY

LINEAR SOLUTIONS MADE EASY

3604-4183_02_ACS_STEP_HDW

ACS – Actuator Control Solutions

Stepper Drive/Controller and Motors

STEPPER

Tolomatic reserves the right to change the design or operation

of the equipment described herein and any associated motion

products without notice. Information in this document is

subject to change without notice.

201611181522

Tolomatic Hardware & Installation Guide: ACS Stepper Drive/Controller

• i •

Contents

List of Figures..................................................................................................iii

List of Tables....................................................................................................iv

Health and Safety Regulations.........................................................................v

Safety Symbols.............................................................................................v

EMC Wiring Guidelines.................................................................................vi

Proper and Safe Use of Product....................................................................vi

Handling and Unpacking.............................................................................. vii

Product Warnings........................................................................................ vii

1. Product Overview ................................................................................. 1_1

1.1 The ACS Drive/Controller for Actuator Control Solutions........................ 1_1

1.1.1 The ACS Drive Overview............................................................. 1_1

1.1.2 Optional Accessories................................................................. 1_2

2. Environment, Dimensions & Mounting ................................................ 2_1

2.1 Operating Environment....................................................................... 2_1

2.2 Dimensions ....................................................................................... 2_1

2.3 Mounting the ACS Drive .................................................................... 2_2

3. CD & USB Cable .................................................................................... 3_1

4. ACS Drive Setup.................................................................................... 4_1

4.1 ACS Drive and Actuator Basic Setup ................................................... 4_1

4.1.1 Setup Procedures ...................................................................... 4_2

5. Connections & Cables .......................................................................... 5_1

5.1 Connections & Cables Overview ......................................................... 5_1

5.2 Motor Power Connection and Cable.................................................... 5_1

5.3 Encoder Connection and Cable........................................................... 5_2

5.4 I/O Connection and Cable................................................................... 5_3

5.5 Input Power Connection ..................................................................... 5_5

5.6 Brake Output Connection ................................................................... 5_5

5.7 USB 2.0 Connection........................................................................... 5_6

5.8 RS-485 Connection ........................................................................... 5_6

5.8.1 RS-485 Cable Length................................................................ 5_6

5.8.2 RS-485 Grounding .................................................................... 5_7

5.9 Ethernet Connection........................................................................... 5_7

5.10 Cable Routing.................................................................................. 5_7

5.10.1 Ethernet Cable ........................................................................ 5_8

5.10.2 Ethernet Cable Length............................................................. 5_8

Tolomatic Hardware & Installation Guide: ACS Stepper Drive/Controller

• ii •

6. Specifications and Wiring .................................................................... 6_1

6.1 Digital Inputs.................................................................................... 6_1

6.1.1 Specifications............................................................................ 6_1

6.1.2 Typical Wiring Diagrams............................................................. 6_1

6.2 Digital Outputs................................................................................. 6_2

6.2.1 Specifications............................................................................ 6_2

6.2.2 Typical Wiring Diagrams............................................................. 6_3

6.3 Analog Input .................................................................................... 6_4

6.3.1 Specifications............................................................................ 6_4

6.3.2 Equivalent Circuit....................................................................... 6_4

6.4 Analog Output.................................................................................. 6_5

6.4.1 Specifications............................................................................ 6_5

6.4.2 Equivalent Circuit....................................................................... 6_5

6.5 Brake Output ................................................................................... 6_6

6.5.1 Specifications............................................................................ 6_6

6.5.2 Equivalent Circuit....................................................................... 6_6

6.6 Input Power ..................................................................................... 6_6

6.6.1 Drive Specifications ................................................................... 6_6

6.6.2 Typical Input Power Wiring ......................................................... 6_7

6.6.3 Power Supply Selection.............................................................. 6_7

6.6.4 Suggested Power Supplies......................................................... 6_8

7. I/O Timing Diagrams........................................................................... 7_1

7.1 I/O Timing Diagrams......................................................................... 7_1

7.1.1 Move Timing Rules .................................................................... 7_3

8. Move Select Logic............................................................................... 8_1

8.1 Move Select Logic Tables ................................................................. 8_1

9. LED Codes and Faults......................................................................... 9_1

9.1 LED Codes....................................................................................... 9_1

9.2 Fault Descriptions and Recovery ....................................................... 9_1

10. Troubleshooting................................................................................. 10_1

10.1.1 Troubleshooting the ACS Drive ................................................... 10_1

Appendix 1.................................................................................................A1_1

Motors.................................................................................................A1_1

Appendix 2.................................................................................................A2_1

Product Warranty .................................................................................A2_1

CONTENTS

Tolomatic Hardware & Installation Guide: ACS Stepper Drive/Controller

• iii •

List of Figures

Figure 2-1 ACS Drive Dimensions......................................................................... 2_1

Figure 2-2 Mounting the ACS Drive....................................................................... 2_2

Figure 4-1 ACS Drive and ERD Actuator Basic Setup ............................................. 4_1

Figure 5-1 Motor Power Connection on ACS Drive................................................. 5_1

Figure 5-2 Motor Power Cable 3604-1708 / 1709 / 1710 .................................... 5_2

Figure 5-3 Encoder Connection on ACS Drive........................................................ 5_2

Figure 5-4 Encoder Cable 3604-1768 / 1769 / 1969 ........................................... 5_3

Figure 5-5 I/O Connection on ACS Drive ............................................................... 5_3

Figure 5-6 I/O Cable 3604-1770 / 1771 .............................................................. 5_4

Figure 5-7 Input Power Connection....................................................................... 5_5

Figure 5-8 Brake Connection................................................................................ 5_5

Figure 5-9 Brake Cable........................................................................................ 5_6

Figure 5-10 USB 2.0 Connection............................................................................ 5_6

Figure 5-11 ACS 2-Wire RS485 with RJ45 Socket .................................................. 5_6

Figure 5-12 Resistors in Ground Wire to Limit Current............................................. 5_7

Figure 5-13 EtherNet/IP Connection for ACS Drive Programmability.......................... 5_7

Figure 5-14 Cable Routing for Top and Side Mounted Connectors ............................ 5_8

Figure 6-1 Digital Input Circuit.............................................................................. 6_1

Figure 6-2 Input Source (switched) Connection...................................................... 6_1

Figure 6-3 Input Source (PNP) Connection ............................................................ 6_2

Figure 6-4 Input Sink (switched) Connection ......................................................... 6_2

Figure 6-5 Input Sink (NPN) Connection ................................................................ 6_2

Figure 6-6 Output Circuit ..................................................................................... 6_3

Figure 6-7 Digital Output Sinking Connection ........................................................ 6_3

Figure 6-8 Digital Output Sourcing Connection...................................................... 6_3

Figure 6-9 Analog Input Equivalent Circuit............................................................. 6_4

Figure 6-10 Analog Output Equivalent Circuit .......................................................... 6_5

Figure 6-11 Brake Output Equivalent Circuit............................................................ 6_6

Figure 6-12 ACS Drive Logic and Main Power Supplies ........................................... 6_7

Figure 6-13 ACS Drive Single Supply – Main Power ................................................ 6_7

Figure 6-14 ACS Drive External Cutoff Switch for Emergency Stop ........................... 6_7

Figure 6-15 Unregulated Power Supply Configuration with Shunt Regulator .............. 6_9

Figure 6-16 Regulated Power Supply Configuration with Blocking Diode .................. 6_9

Figure 6-17 Regulated Power Supply with Blocking Diode and Shunt Regulator ........ 6_9

Figure 7-1 Input Requirement............................................................................... 7_1

Figure 7-2 System Startup Timing ........................................................................ 7_1

Figure 7-3 Jog Move Timing................................................................................. 7_1

Figure 7-4 Absolute & Incremental Move Timing.................................................... 7_2

Figure 7-5 Brake Subsystem Timing ..................................................................... 7_2

Tolomatic Hardware & Installation Guide: ACS Stepper Drive/Controller

• iv •

List of Tables

Table 2-1 ACS Drive Operating Conditions........................................................... 2_1

Table 3-1 CD and USB cable part numbers.......................................................... 3_1

Table 5-1 Motor Power Connection pinouts.......................................................... 5_1

Table 5-2 Motor Power Cable and Connector Parts .............................................. 5_2

Table 5-3 Encoder Connection pinouts ................................................................ 5_2

Table 5-4 Encoder Cable and Connector Parts ..................................................... 5_3

Table 5-5 I/O Connection pinouts ........................................................................ 5_4

Table 5-6 I/O Cable and Connector Parts............................................................. 5_4

Table 5-7 Input Power pinouts ............................................................................ 5_5

Table 5-8 Input Power Cable Parts ...................................................................... 5_5

Table 5-9 Brake Pinout....................................................................................... 5_5

Table 5-10 EtherNet/IP pinouts and Connections.................................................... 5_7

Table 5-11 Cable Wire Type versus Cable Length................................................... 5_9

Table 6-1 Opto-isolated Digital Input Specifications.............................................. 6_1

Table 6-2 Digital Output Specifications ................................................................ 6_3

Table 6-3 Analog Input Specifications.................................................................. 6_4

Table 6-4 Analog Output Specifications ............................................................... 6_5

Table 6-5 Brake Output Specifications................................................................. 6_6

Table 6-6 ACS Internal Drive Specifications ......................................................... 6_6

Table 6-7 Maximum Power Supply Current for Tolomatic Motors........................... 6_8

Table 8-1 4 Move Commands Mode Logic........................................................... 8_1

Table 8-2 8 Move Commands Mode Logic........................................................... 8_1

Table 8-3 16 Move Commands Mode Logic......................................................... 8_2

Table 9-1 LED Indicators..................................................................................... 9_1

Table 9-2 Safety Faults....................................................................................... 9_2

Table 9-3 Critical Faults...................................................................................... 9_2

Table 10-1 Troubleshooting Descriptions ............................................................. 10_2

Table A-1 Tolomatic Stepper Motor Specifications .............................................. A1_1

Table A-2 Tolomatic Stepper Motor Part Numbers .............................................. A1_1

Table A-3 Encoder Specifications ...................................................................... A1_1

Table A-4 NEMA11, 17, 23 Motor Connection pinouts........................................ A1_2

Table A-5 NEMA34 Motor Connection pinouts.................................................... A1_2

Table A-6 NEMA11, 17, 23 Encoder Connections and Connector pinouts............ A1_2

Table A-7 NEMA 34 - Encoder Connections and Connector pinouts .................... A1_2

Tolomatic Hardware & Installation Guide: ACS Stepper Drive/Controller

• v •

Health and Safety Regulations

Read through the applicable sections of the manual before the equipment is

unpacked, installed or operated. Pay attention to all of the dangers, warnings,

cautions and notes stated in the manual.

Serious injury to persons or damage to the equipment may result if the information

in the manual is not followed.

Safety Symbols

Items that are specifically marked DANGER!, WARNING!, CAUTION! or NOTE! are

arranged in a hierarchical system and have the following meaning:

DANGER!

Indicates a very hazardous situation which, if not avoided, could result in death or

serious injury. This signal word is limited to the most extreme situations.

WARNING!

Indicates a potentially hazardous situation which, if not avoided, could result in

death or serious injury.

CAUTION!

Indicates a potentially hazardous situation which, if not avoided, may result in

property damage, minor or moderate injury.

CAUTION!

Indicates hot surfaces. Avoid contact.

NOTE!

Information that requires special attention is stated here.

Tolomatic Hardware & Installation Guide: ACS Stepper Drive/Controller

• vi •

EMC Wiring Guidelines

Cable routing

It is recommended that the power and signal cables for the ACS Drive be routed as

far apart as possible to minimize system noise.

NOTE! The standard cables from Tolomatic are not flex rated and have a minimum

bend radii of 3.75 inches. Any repeated flexing or excessive bending can result in

broken conductors and intermittent faults.

Shielding and grounding

When cabling the system, high quality braided or foil with braided shielded cables

are recommended. The standard motor cables provided by Tolomatic have a braided

shield with drain wires. The metal angle bracket on the drive/controller is also

a case ground and should be tied to earth ground. To minimize EMI and ensure

system reliability, all shield drain wires from all cables should be tied to a common

earth ground.

Proper and Safe Use of Product

Protection circuits and external fuses

A fuse should be added to the input power line to protect the drive/controller and

power supply from any potential over current conditions that may occur. (See

Section 6: Specifications & Wiring)

Fail Safe Emergency Stop Recommendations

A fail safe e-stop is highly recommended to ensure equipment and personal safety.

The e-stop should provide a means to remove main power from the actuator to

cease and prevent any unwanted motion.

Device Damage Prevention

To prevent permanent damage to the device, proper care should be taken not to

exceed published voltage, current, temperature, and load ratings. In addition, proper

wiring should be verified and safety measures checked before applying power.

Personal Safety

During normal operation the motor can become hot. It is highly recommended to

display proper safety notices and implement proper safety measures to prevent

contact with hot surfaces.

HEALTH AND SAFETY REGULATIONS

WARNING!

The manufacturer takes no

responsibility whatsoever

if the equipment is

modified or if the

equipment is used in any

way beyond performance

specifications.

Unauthorized modifications

or changes to the

equipment are strictly

forbidden and void all

warranties.

WARNING!

Incorrect wiring can

feedback through the

USB port and damage

your computer. Use good

wiring practices to prevent

ground loops.

Tolomatic Hardware & Installation Guide: ACS Stepper Drive/Controller

• vii •

HEALTH AND SAFETY REGULATIONS

Handling and Unpacking

When unpacking and handling, care should be taken not to drop the drive/controller

as this can damage the connectors and internal electronics.

Product Warnings

The following precautions should be observed to prevent erratic behavior or

damage:

• Do not short circuit the motor power at the power connector. Doing so may

damage the drive power electronics. The motor/cable is part of the current

regulation circuitry. For a short occurring in a motor, the motor leads should

provide enough resistance and inductance to prevent dangerous peak currents

from occurring.

• Do not reverse bias the drive power.

• Do not apply voltages above the maximum rated voltage.

• Do not expose drive to conductive contaminants, moisture, or excessive

temperature.

• Do not disassemble or modify the drive/controller.

• Do not plug and unplug cables while the drive is energized.

Wiring for CE Compliance

• Use a braided shield motor cable such as Igus Chainflex CF140US-07-04.

• See Section 5-2 for motor cable description.

CAUTION!

Proper ESD measures

should be taken to avoid

static electricity from

contacting the signal and

power lines of the drive,

motor and encoder.

Protocols:

•EtherNet/IP • Modbus TCP

Tolomatic Hardware & Installation Guide: ACS Stepper Drive/Controller

• 1_1 •

Product Overview

1

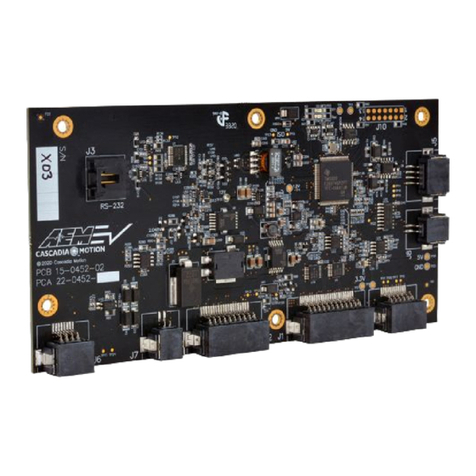

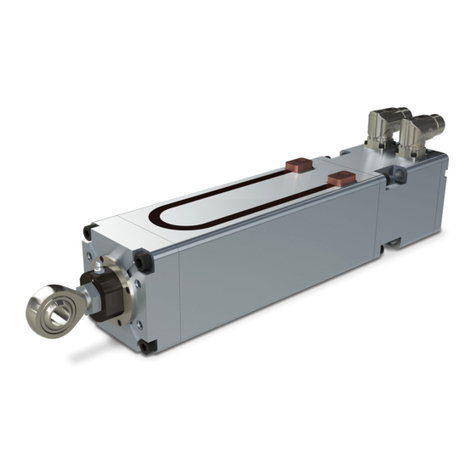

1.1 The ACS Stepper Drive/Controller for Actuator Control Solutions

Tolomatic’s ACS Drive/Controller is a stepper drive and controller intended for use

with electric actuators. Tolomatic's Motion Interface software allows the user to

select the compatible Tolomatic electric linear actuator of choice. The software

automatically sets most of the necessary parameters to create the desired motion

of the selected actuator reducing setup and programming time. (See Tolomatic

Motion Interface Software Manual 3600-4167 for more information).

Currently there are three ACS Drive/Controller choices:

• #3604-9665 - ACS Stepper Drive/Controller, Modbus RTU over RS485

- firmware 36043183UD.tol

• #3604-9666 - ACS Stepper Drive/Controller, EtherNet/IP (Analog Output)

- firmware 36043183UD.tol

• #3604-9667 - ACS Stepper Drive/Controller, Modbus TCP (Analog Output)

-firmware 36043183UD.tol

NOTE: They will collectively be referred to as ACS Drive throughout this guide

1.1.1 ACS Stepper Drive/Controller — Overview

MOTOR POWER

•10 - 52 VDC

Stepper Motors

COM PORT

BRAKE

•USB Com Port

•Active high/low

ACS POWER

•10 - 52 VDC Main Power

•10 - 52 VDC Keep-alive

Power

•24 VDC Brake Power

ETHERNET (OPTION)

DIGITAL I/0

ANALOG I/0

LED INDICATORS

RS485 COM PORT

DUAL PURPOSE HEAT SINK

FEEDBACK

•8 Digital Inputs

•4 Digital Outputs

•24 VDC Opto-Isolated

•Sourcing or Sinking

•Configurable Inputs

•0-10 VDC or 4-20mA

•1 Analog Input

•1 Analog Output (option)

•Modbus RTU (Base Model)

•Removes heat from drive

for optimal performance

• Panel mounting

•Motor Power & Fault

indicators

•For Digital Encoder

Tolomatic Hardware & Installation Guide: ACS Stepper Drive/Controller

• 1_2 •

1: PRODUCT OVERVIEW

ACS Drive/Controller (3604-9665) Capabilities

•

4, 8, or 16 move command modes (abso-

lute, incremental and jog or home with

analog output echoing position of actuator

from encoder) for infinite position capability

• Ability to reduce holding current for

energy savings

• End point correction

• Zone output based on position

• Force limiting capability

• Configurable digital I/O

(24 VDC Opto-Isolated)

(sourcing or sinking)

• Compatible with most

24/48 VDC stepper motors

• Analog position mode (0-10 VDC or 4-20

mA)

• Pneumatic mode replaces pneumatic

valve logic for simple motion

• ModBus RTU over RS485 provides infinite

positioning

•

Adjustable motion profile parameters

(velocity, accel/decel, force). Parameters are

independently configurable for each move

ACS Drive/Controller (3604-9666, 3604-9667) Additional Capabilities

• EtherNet mode provides infinite

positioning using EtherNet/IP and

Modbus TCP protocols

• Dual EtherNet port with internal switch for

easy daisy chaining

• Analog output for Analog Position Mode

1.1.2 Optional Accessories

Cable Options

Tolomatic offers a motor power cable

with drive and motor mating connectors,

an encoder cable with drive and encoder

connectors, and an I/O cable with drive

mating connector to flying leads. Cables are

available in 3, 5 or 10 meter lengths.

Disc and Cable

Tolomatic software is always available online

at www.tolomatic.com. For your convenience

a software CD and optional USB computer

connections are available:

Tolomatic Motion Interface Software CD

(3604-9526) and a USB Type B cable (3604-

1852)

Brake Cable

Tolomatic offers a 5-meter brake power cable

with drive and brake mating connectors

Tolomatic Hardware & Installation Guide: ACS Stepper Drive/Controller

• 2_1 •

Environment, Dimensions & Mounting

2

2.1 Operating Environment

The ACS Drive is designed to be operated in ambient conditions from 0° – 40°C

(32° – 104°F), and humidity from 0 – 90% non-condensing. There is no ingress

protection (IP) for the drive, so it is important to protect the drive from water and

other conductive contamination. In addition, proper ESD procedures should be

observed to prevent static discharge and damage to electronic components.

ACS Drive Operating Conditions

Ambient Temperature 77° F, 25° C Nominal

Operating Temperature 32°-104° F, 0°-40° C Non Freezing

Storage Temperature 32°-158° F, 0°-70° C

Humidity 0-90% non-condensing

Table 2-1: ACS Drive Operating Conditions

3.55 [90.2] (2) 0.80

[20.3]

(2)

5.80

[147.3]

4.29 [109.0] 0.88

[22.2]

(2)

0.12

[2.9]

TYP.

Ø.17

[4.3]

TYP.

1.38

[34.9]

PART #:

MODEL #:

www.tolomatic.com Made in U.S.A.

RoHS

COMPLIANT

Figure 2-1: ACS Drive Dimensions

WARNING!

Do not expose the drive to

conductive contaminants,

moisture, or exceed

temperature ratings.

2.2 ACS Drive Dimensions

Tolomatic Hardware & Installation Guide: ACS Stepper Drive/Controller

• 2_2 •

2: ENVIRONMENT, DIMENSIONS & MOUNTING

The drive/controller is intended to be mounted vertically (as shown in Figure 2-2) to

provide the vents with enough clearance on the top and bottom of the drive to allow

for air flow. The metal bracket should also be mounted to a metal surface for best

thermal dissipation. A 2-inch head space is recommended from the drive vents to

another surface to ensure the proper ambient temperature ratings are maintained.

It is recommended to have a minimum of 1-inch spacing between drives. This

spacing may be relaxed provided the ambient temperature is kept within limits and

the drive is mounted to a metal surface suitable enough to heat sink the drives.

Metal

Mounting

Surface

FLAT MOUNTBOOK MOUNT

Clearance

for Air

Vents

Clearance

for Air

Vents

Metal

Mounting

Surface

Figure 2-2 Mounting the ACS Drive

2.3 Mounting the ACS Drive

Tolomatic Hardware & Installation Guide: ACS Stepper Drive/Controller

• 3_1 •

CD & USB Cable

3

3.1 CD & USB Cable

Tolomatic offers a CD with Tolomatic Motion Interface software, drive firmware and

firmware upgrade utility. A USB type B cable is also available for connecting your

computer to the ACS drive.

ACS Drive Accessories

ITEM TOLOMATIC PART NUMBER

Tolomatic Motion Interface

Software CD 3604-9526

1 meter USB Cable 3604-1852

Table 3-1: CD and USB cable part numbers.

NOTE: The most current

version of software and

firmware is always available

at www.tolomatic.com

Tolomatic Hardware & Installation Guide: ACS Stepper Drive/Controller

• 4_1 •

4.1 ACS Drive and Actuator Basic Setup

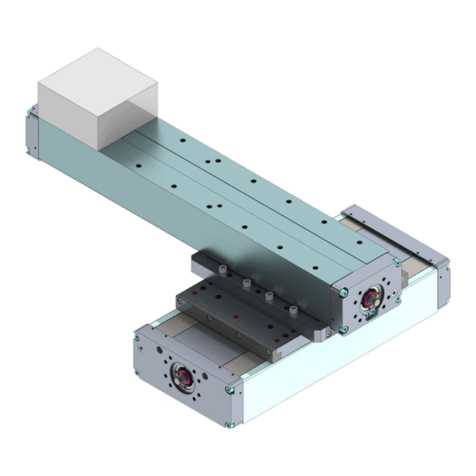

Figure 4-1 shows the simple setup of the ACS Drive, the Tolomatic ERD actuator

and the necessary cables and power source.

Figure 4-1: ACS Drive and ERD Actuator– Basic Setup

Please refer to the following sections and page numbers for cable part numbers

and wiring specifications:

Motor Power Cable: Section 5

Encoder Cable: Section 5

I/O Cable: Section 5

USB: Section 5

For recommended power supplies: Section 6

ACS Drive Setup

4

SUPPLIED

POWER SOURCE

10 to 52 VDC

USB Type B Cable

to PC

Customer Supplied Power Cable

to Power Input on Drive

I/O Cable from

Drive to PLC

Encoder Cable from

Drive to Motor Encoder

Motor Power

Cable from

Drive to Motor

Tolomatic Hardware & Installation Guide: ACS Stepper Drive/Controller

• 4_2 •

4: ACS DRIVE/CONTROLLER SETUP

4.1.1 Setup Procedures

1. Install drive/controller and actuator into appropriate fixtures.

2. Wire the power supply to the drive. See Section 6: Power Supply Selection.

3.

Wire

input

and

output

signals to the desired logic device. See Section 5:

Connections and Cables.

4. Attach motor and encoder cables.

5. Attach programming cable and install the Tolomatic Motion Interface software.

6. Configure ACS Drive.

7. Program the logic device.

Tolomatic Hardware & Installation Guide: ACS Stepper Drive/Controller

• 5_1 •

All cables for the ACS Drive can be ordered through Tolomatic with the exception of the

power supply. When using cables other than those provided by Tolomatic, reference the

cable mating connector style to ensure the proper cabling is supplied.

12345

Figure 5-1: Motor Power Connection on ACS Drive

ACS CONNECTOR

(ON-SHORE)

PIN NUMBERS

SIGNAL CABLE WIRE COLOR

MOTOR

CONNECTOR

(TYCO)

1Motor A- Black 6

2Motor A+ Green 3

3 Shield Shield 2

4Motor B+ Red 1

5Motor B- White 4

Table 5-1: Motor Power Connection pinouts

Connections & Cables

5

5.1 Connections and Cables Overview

5.2 Motor Power Connection and Cables

WARNING!

Do not connect or

disconnect motor cables

while the drive is powered.

MOTOR

CONNECTION

USB

COM PORT

ENCODER

CONNECTION

I/O

CONNECTION

RS485

COM PORT

POWER

CONNECTION

ETHERNET

PORTS

LED

INDICATORS

BRAKE

CONNECTION

Tolomatic Hardware & Installation Guide: ACS Stepper Drive/Controller

• 5_2 •

5: CONNECTIONS & CABLES

A

1.00 MAX.

[25.40 MAX.]

1.00

[25.40] 1.00

[25.40]

On Shore P/N: OSTTJ055153

SHRINK TUBING

01

1.00 MAX.

[25.40 MAX.]

TYCO P/N: 1586000-6

Figure 5-2: Motor Power Cable 3604-1708/ 1709 / 1710 / 2228 / 2229 / 2230

CABLE

TOLOMATIC

PART NO.

DRIVE MATING

CONNECTOR

MOTOR MATING

CONNECTOR

MOTOR

CONTACTS DIM. "A"

Motor Power:

3-meter

3604-1708 On Shore PN

OSTTJ055153

Tyco PN:

1586000-6

Tyco PN:

1586314-3

3 m

118"

Motor Power:

5-meter

3604-1709 On Shore PN

OSTTJ055153

Tyco PN:

1586000-6

Tyco PN:

1586314-3

5 m

197"

Motor Power:

10-meter

3604-1710 On Shore PN

OSTTJ055153

Tyco PN:

1586000-6

Tyco PN:

1586314-3

10 m

394"

34 Motor Power:

3-meter

3604-2228 On Shore PN

OSTTJ055153

Phoenix Contact:

1786200 None 3 m

118"

34 Motor Power:

5-meter

3604-2229 On Shore PN

OSTTJ055153

Phoenix Contact:

1786200 None 5 m

197"

34 Motor Power:

10-meter

3604-2230 On Shore PN

OSTTJ055153

Phoenix Contact:

1786200 None 10 m

394"

Table 5-2: Motor Power Cable and Connector Parts

NOTE: For CE compliance use a quality braided shield cable such as

Igus Chainflex CF140US-07-04. See Appendix 1 for motor pinout chart.

The ACS Drive has an encoder port that supports differential signal quadrature

encoders. Single ended encoders may be used with additional external circuitry. It is

highly recommended to use differential encoders as they are more resistant to signal

noise. The drive can supply +5VDC power to the feedback device up to 100mA.

1

214

13

1

214

13

Figure 5-3: Encoder Connection on ACS Drive

PIN NUMBERS SIGNAL CABLE WIRE COLOR

1ENC A+ Blue

2ENC A- Orange

3ENC B+ Yellow

4ENC B- Gray

5 NA NA

6 NA NA

9Signal Ground Black

12 +5VDC Red

13 Case Ground NA

Table 5-3: Encoder Connection pinouts

5.3 Encoder Connection and Cable

Tolomatic Hardware & Installation Guide: ACS Stepper Drive/Controller

• 5_3 •

5: CONNECTIONS & CABLES

1

2

3

4

5

9

1

2

12

3

MOLEX P/N:

51021-0600

JST P/N:

PHDR-14VS

6

BLK

BLU

ORG

RED

YEL

GRY 4

01

118.11 [3000.0]

MOLEX P/N: 51021-0600 JST P/N: PHDR-14VS

SHRINK TUBING

ALL CONDUCTORS ARE 20 AWG

USE OVERALL SHIELD WITH 20 AWG DRAIN WIRE

CONDUCTOR COLORS ARE UNIQUE

RoHS COMPLIANT

MUST BE RATED 60°C OR BETTER

COLOR OF JACKET IS GRAY

100V MIN WORKING VOLTAGE

CABLE TO BE TESTED FOR CONTINUITY AND SHORTS

BAG INDIVIDUALLY

Figure 5-4: Encoder Cable 3604-1768 / 1769 / 1969

FOR NEMA 11, 17, 23 MOTORS

CABLE

TOLOMATIC

PART NO.

DRIVE MATING

CONNECTOR

DRIVE MATING

CONTACTS

ENCODER MATING

CONNECTOR

ENCODER MATING

CONTACTS

Encoder:

3-meter 3604-1768 JST PN:

PHDR-14VS

JST PN:

SPHD-001T-P0.5

Molex PN:

51021-0600

Molex PN:

50079-8100

Encoder:

5-meter 3604-1769 JST PN:

PHDR-14VS

JST PN:

SPHD-001T-P0.5

Molex PN:

51021-0600

Molex PN:

50079-8100

Encoder:

10-meter 3604-1969 JST PN:

PHDR-14VS

JST PN:

SPHD-001T-P0.5

Molex PN:

51021-0600

Molex PN:

50079-8100

FOR NEMA 34 MOTORS

CABLE

TOLOMATIC

PART NO.

DRIVE MATING

CONNECTOR

DRIVE MATING

CONTACTS

ENCODER MATING

CONNECTOR

ENCODER MATING

CONTACTS

Encoder:

3-meter 3604-1971 JST PN:

PHDR-14VS

JST PN:

SPHD-001T-P0.5

Molex PN:

15-04-5104

Molex Inserts PN:

14-60-0058

Encoder:

5-meter 3604-1972 JST PN:

PHDR-14VS

JST PN:

SPHD-001T-P0.5

Molex PN:

15-04-5104

Molex Inserts PN:

14-60-0058

Encoder:

10-meter 3604-1973 JST PN:

PHDR-14VS

JST PN:

SPHD-001T-P0.5

Molex PN:

15-04-5104

Molex Inserts PN:

14-60-0058

Table 5-4: Encoder Cable and Connector Parts

NOTE: See Appendix 1 for encoder pinout chart

1

2

29

30

1

2

29

30

Figure 5-5: I/O Connection on ACS Drive

JST #PHDR-30VS

PIN NUMBERS SIGNAL CABLE WIRE COLOR

1Input ISO 1 Red/Black/White

2Input ISO 2 Orange/Green

3Input ISO 3 Red/White

4Input ISO 4 Green/White

5Input ISO 5 Blue/White

6Input ISO 6 White/Black/Red

7Input ISO 7 White/Red

5.4 I/O Connection and Cable

Tolomatic Hardware & Installation Guide: ACS Stepper Drive/Controller

• 5_4 •

5: CONNECTIONS & CABLES

8Input ISO 8 Orange/Red

9Input ISO COM Green/Black

10 Output 1 - Red/Black

11 Output 1 + White

12 Output 2 - White/Black

13 Output 2 + Blue

14 Output 3 - Blue/Black

15 Output 3 + Orange

16 Output 4 - Orange/Black

17 Output 4 + Red

20 Case Ground Shield

23 *Step Input Blue/Red *Not yet supported

24 *Direction Input Red/Green by software

25 NA Green

26 NA Black/Red

27 Analog Out GRN/Black/White

28 Analog In Black/White/Red

29 Signal Ground Black

30 Signal Ground Black/White

Table 5-5: I/O Connection pinouts

1

2

3

4

5

JST P/N:

PHDR-30VS

6

RED/BLK/WHT

9

7

12

11

8

16

29

27

24

23

13

17

14

15

28

26

20

25

30

ORG/GRN

RED/WHT

GRN/WHT

BLU/WHT

WHT/BLK/RED

WHT/RED

ORG/RED

GRN/BLK

WHT

WHT/BLK

BLU

BLU/BLK

ORG

ORG/BLK

RED

RED/BLK

BLU/RED

10

RED/GRN

GRN/BLK/WHT

BLK/WHT/RED

BLK

BLK/WHT

GRN

BLK/RED

118.11 [3000.0]

JST P/N: PHDR-30VS

SHRINK TUBING FLYING LEADS

ALL CONDUCTORS ARE 20 AWG

USE OVERALL SHIELD WITH 20 AWG DRAIN WIRE

CONDUCTOR COLORS ARE UNIQUE

RoHS COMPLIANT

MUST BE RATED 60°C OR BETTER

COLOR OF JACKET IS GRAY

100V MIN WORKING VOLTAGE

CABLE TO BE TESTED FOR CONTINUITY AND SHORTS

BAG INDIVIDUALLY

1.00 MAX.

[25.40 MAX.]

4.00 [101.6]

1.00

[25.40] 1.00

[25.40]

Figure 5-6: I/O Cable 3604-1770 / 1771

CABLE TOLOMATIC

PART NO.

DRIVE MATING CONNECTOR DRIVE MATING CONTACTS

I/O: 3-meter 3604-1770 JST PN: PHDR-30VS JST PN: SPHD-001T-P0.5

I/O: 5-meter 3604-1771 JST PN: PHDR-30VS JST PN: SPHD-001T-P0.5

Table 5-6: I/O Cable and Connector Parts

Other manuals for ACS

1

Table of contents

Other Tolomatic Controllers manuals

Tolomatic

Tolomatic BCS10 Operator's manual

Tolomatic

Tolomatic ACS Manual

Tolomatic

Tolomatic TRS Series User manual

Tolomatic

Tolomatic ServoWeld CSW Owner's manual

Tolomatic

Tolomatic MXP16P Series User manual

Tolomatic

Tolomatic RSX User manual

Tolomatic

Tolomatic SmartActuator Series User manual

Tolomatic

Tolomatic IMA-S Series User manual

Tolomatic

Tolomatic Axidyne AXIOM PLUS PV Series User manual

Tolomatic

Tolomatic 3604-9651 Manual