Tolomatic User Guide: IMA-S Integrated Motor Rod-Style Actuator - Stainless Steel

• 14 •

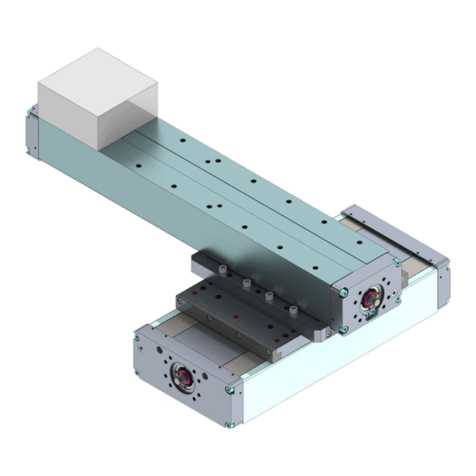

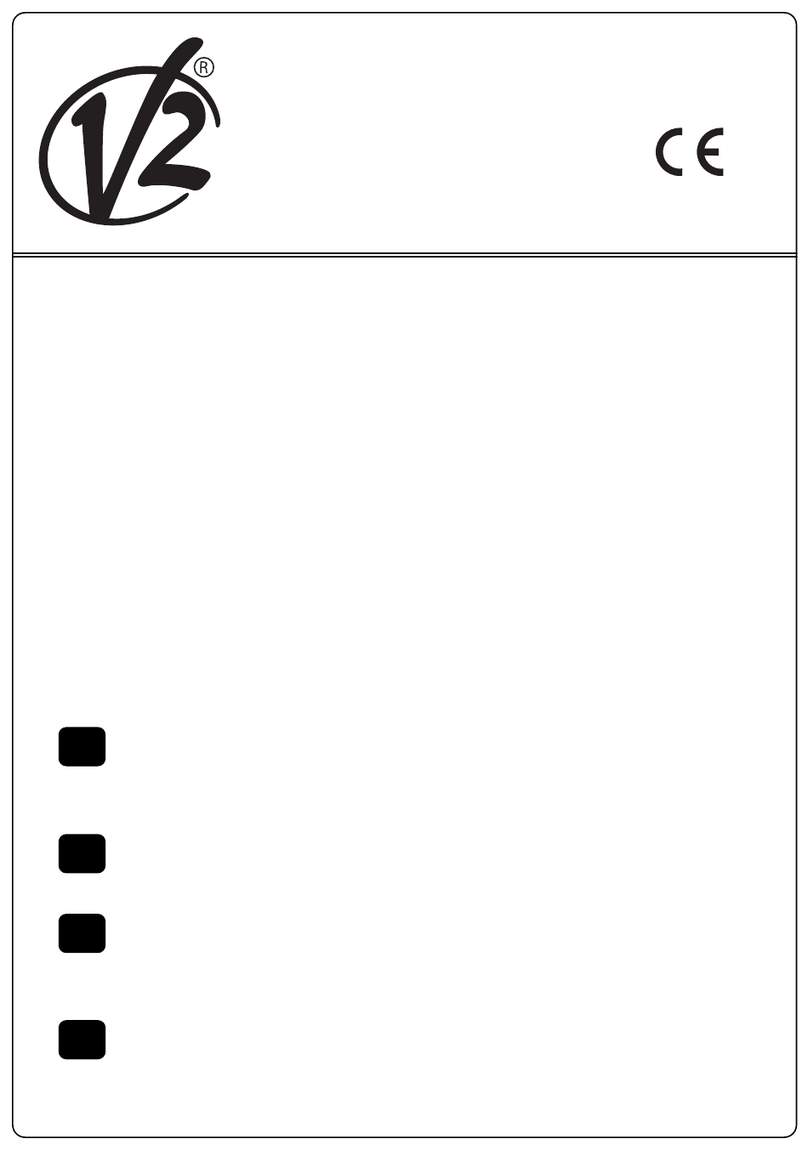

3.1 IMA-S Series Configuration

• Two sizes: 22 and 33

• Internal Anti-Rotation Option IMA-SA 33 (33 size only)

• Motor windings: 230 Vac & 460 Vac

• IP69K

• Feedback Choices:

- Multi-Turn Absolute Encoders (SICK HIPERFACE DSL,SICK HIPERFACE, Heidenhain EnDat2.2)

- Multi-turn Absolute Incremental

- Incremental Resolver

NOTE For performance data and specifications please refer to the IMA-S catalog #2700-

4014.

3.2 Standard Configurations and Options

NOTE Please see Tolomatic IMA-S Catalog 2700-4014 for complete information on ordering

codes. Use 3D CAD files (available at www.tolomatic.com) for critical dimensions.

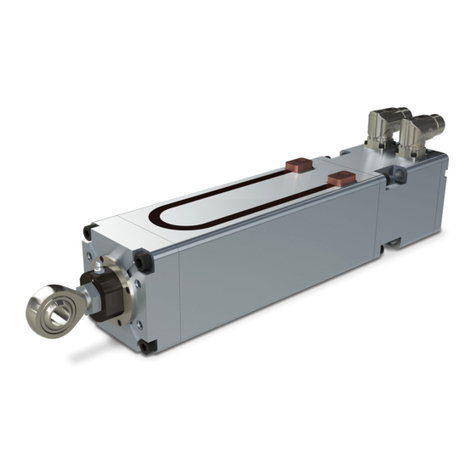

IMA-S - Hygienic Integrated Servo Actuator

www.tolomatic.com IMAS_15

BRAKE OPTION

NNO Brake

BBrake

MODEL

IMA-ST

Stainless IMA Standard

IMA-SA

Stainless IMA Anti-Rotate

CABLES

CR3

Tolomatic standard

3m flying lead cables,

power and feedback

CR5

Tolomatic standard

5m flying lead cables,

power and feedback

CR10

Tolomatic standard

10m flying lead cables,

power and feedback

For custom cable lengths please con-

tact Tolomatic. Lead times will vary.

MOUNTING OPTIONS

—Standard Face Mount

FFG Front Flange Mount

PCD Clevis Mount, Rear

PCDR Clevis Mount, Rear

(Rotated 90°)

ROD END OPTIONS

—Standard, female, inter-

nally threaded rod end

MET Male Externally Threaded

Rod End

OTHER OPTIONS*

HYG2 Hygienic Fasteners

HYG3 FDA Rod Wipers

*Order none, 1 or both

NUT / SCREW

Screw/Nut combinations available

22 33 33SA Description

BN05 BN05

—

Ball Nut, 5 mm lead

BN10 BN10

—

Ball Nut, 10 mm lead

—

BN20

—

Ball Nut, 20 mm lead

—

RN04 RN04

Roller Nut, 4 mm lead

—

RN05 RN05

Roller Nut, 5 mm lead

—

RN10 RN10

Roller Nut, 10 mm lead

MOTOR VOLTAGE

MV21* 230 Vac, Motor Voltage,

1 Stack Winding

MV41* 460 Vac, Motor Voltage,

1 Stack Winding

MV23 230 Vac, Motor Voltage,

3 Stack Winding

MV43 460 Vac, Motor Voltage,

3 Stack Winding

*NOTE: Not available for "SA"

Anti-Rotate actuators

STROKE LENGTH

SM

_ _ ._

Stroke, enter stroke

length in millimeters

NOTE: See page imas_7 for

stroke min. & max.

SIZE

22 22 Series Actuator

(Anti-Rotate not available)

33 33 Series Actuator

Ordering

MODEL SELECTION (MUST BE IN THIS ORDER)

OPTIONS (IN ANY ORDER)

Contact Tolomatic for Lead Time

Some feedback devices are not compatible with some

connectors. Contact Tolomatic for complete motor

connector & feedback combination information

MOTOR SERIES CONNECTORS FEEDBACK DEVICE

Cable + Allen Bradley VP Connector

CA2 A2

SICK Hiperface DSL

Allen Bradley Flying Lead

FA1 A1

SICK Hiperface

Allen Bradley Flying Lead

FA2 A2

SICK Hiperface DSL

Cable + Tolomatic Std. VP Connector

CT2 A2

SICK Hiperface DSL

Tolomatic Std. Flying Lead

FT1 D1

Incremental

MOTOR SERIES CONNECTORS FEEDBACK DEVICE

Tolomatic Std. Flying Lead

FT1 A1

SICK Hiperface

Tolomatic Std. Flying Lead

FT1 H1

Heidenhein Endat 2.2

Tolomatic Std. Flying Lead

FT1 R1

Resolver

Tolomatic Std. Flying Lead

FT2 A2

SICK Hiperface DSL

REPLACEABLE SEAL CARTRIDGE

Description IMA-ST22 IMA-ST33 IMA-SA33

Standard 2622-9070 2633-9070 2633-9070

Standard with Rear Clevis Mount (PCD_) 2622-9071 2633-9071 2633-9071

FDA Rod Wipers (HYG3) 2622-9072 2633-9072 2633-9072

FDA Rod Wipers (HYG3

with Rear Clevis Mount (PCD_) 2622-9073 2633-9073 2633-9073

IMAST

33

RN05

SM304.8

MV23

CT2A2

NFFG

HYG2

HYG3

CR5

Figure 3-1 IMA-S ordering codes and descriptions

IMA-S Product Configuration Overview3