3800 County Road 116, Hamel, MN 55340

http://www.Tolomatic.com • Email: Help@Tolomatic.com

Phone: (763) 478-8000 • Fax: (763) 478-8080 • Toll Free: 1-800-328-2174

© 2014 Tolomatic 201404170914

Information furnished is believed to be accurate

and reliable. However, Tolomatic assumes no

responsibility for its use or for any errors that

may appear in this document. Tolomatic reserves

the right to change the design or operation of the

equipment described herein and any associated

motion products without notice. Information in

this document is subject to change without notice.

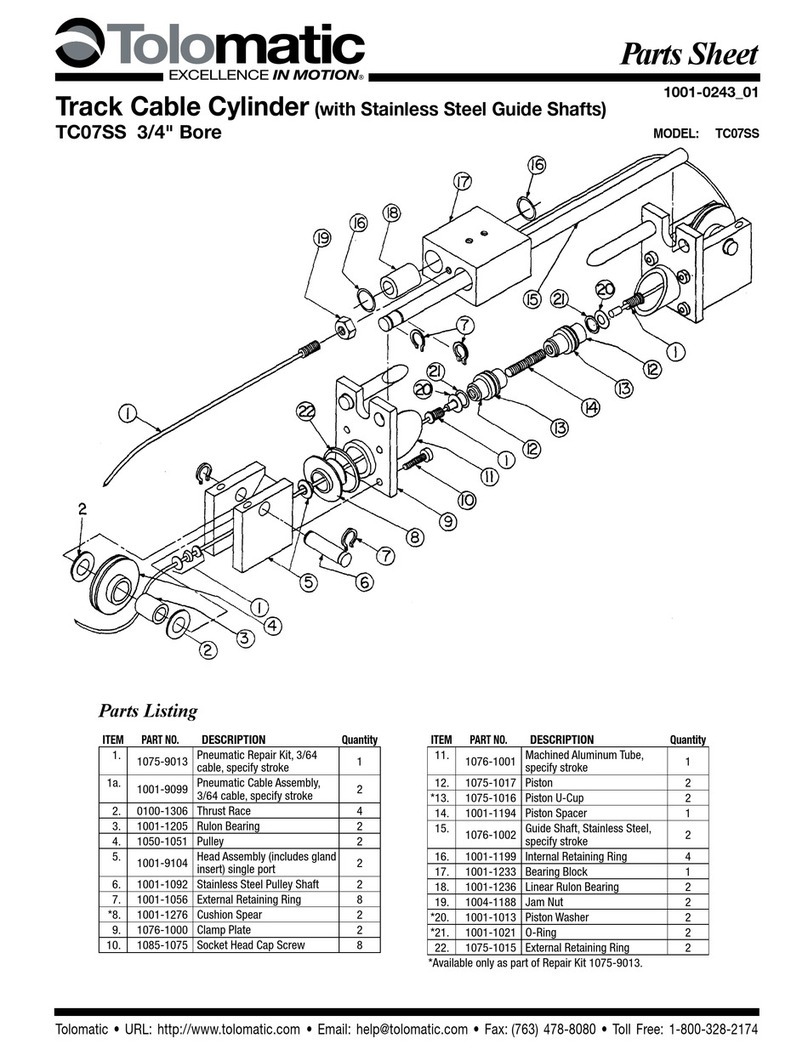

Parts Sheet #1001-0233_05_TC15ps

2 – Installation & Maintenance TC15

INSTALLATION

When unpacking a track cable cylinder, BE EXTRA CAREFUL NOT

TO SCRATCH OR MAR THE NYLON COVERING ON THE CABLE.

The cylinder may be mounted by use of the bolt holes in head.

When attaching the bearing block to a driven mechanism, be sure

it is in perfect alignment and that the load does not exceed the

specifications listed in the catalog.

PRETENSIONING INSTRUCTIONS

All track cable cylinders are shipped without being pretensioned.

They must be tensioned after mounting to insure the maximum

service life of the unit.

To pretension a track cylinder, remove one of the guide shafts to

gain access to the terminals to adjust the cable tension. Block the

load some distance from the end of travel to keep the cylinder from

bottoming. Next, apply pressure 15 to 20 percent higher than the

actual pressure required to move the load. When the load is stopped

externally before the piston bottoms, the relief valve or regulator

setting becomes the load pressure.

When pressurized, one cable will become tight while the other

becomes slack. Manually take up the slack in the cable. Release the

pressure and block the load from the other side. Repeat the manual

adjustment on the other cable. Release pressure and remove the

blocks. Reinstall the guide shaft which had been removed. Return

the regulator to its original setting.

Additional manual adjustment should not be needed initially, after

the cylinder has been pretensioned. It is suggested, however,

that the cable tension be checked periodically, from a preventive

maintenance standpoint.

Loctite®is a registered trademark of the Loctite Corporation, www.loctite.com

TO REBUILD CYLINDER

1. Remove the cylinder from machinery.

2. Remove the guide shafts, then disconnect

cables from bearing block and remove pulleys

on both ends of cylinder.

3.

Remove one head from cylinder by removing

the four cap screws.

4. Pull piston towards the removed head and

remove from the tube.

5. Disconnect cables from piston. (See Cable

Assembly/Disassembly Instructions at right.)

Then remove the other cylinder head from tube

and disengage cable from it.

6. Install new U-cups and O-rings on pistons.

7. See Cable Assembly/Reassembly Instructions

below. Always lubricate seals with oil when

installing.

8. Put one cable end through each cylinder head.

Reattach one head to tube and connect the end

of one cable to the piston. Then connect the

other cable to the piston.

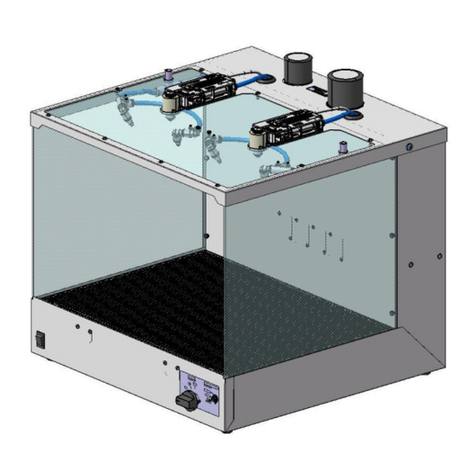

Figure 1.

Figure 2.

Figure 3.

9. Push piston back into tube by gently tucking in the U-cup. Mount

head back on cylinder with the cap screws. Replace pulleys and

connect cables to bearing block.

10. Pretension cables according to the pretensioning instructions.

11. Operate cylinder back and forth by hand several times to be sure

it is properly assembled before applying pressure.

12. Reinstall cylinder on machinery. Note: Apply (Blue) Locitie®#242

or equivalent to threaded cable terminal before connecting to the

piston.

If the cylinder identification tag is missing, measure the overall length

of cylinder, including the heads on both ends. Then refer to catalog

dimensional drawing to determine stroke length

SNAP IN/OUT CABLE ASSEMBLY INSTRUCTIONS

Your Tolomatic Track Cable Cylinder has been designed to allow

assembly and disassembly of cable assemblies from the cylinder

heads without the use of tools.

DISASSEMBLY: (Refer to Figure 1 & 2)

1. Holding onto cylinder Head (6), pull Piston Terminal (1) until

Bearing BlockTerminal (8) is against Washer (4).

2. Put a small amount of slack in Cable (7) as shown in Figure 2.

3. Impart a “snap” action to Piston Terminal (1).

4. With the imparting "snap" action, Washer (2) will release

allowing the removal of the complete cable assembly.

REASSEMBLY: (Refer to Figure 1 & 3)

1. Holding onto cylinder Head (6), string Bearing Block Terminal (8)

through Gland (5) until Washer (2), U-cup (3) and

Washer (4) are held flush against one another by

Piston Terminal (1).

2. Put a small amount of slack in Cable (7) as

shown in Figure 3.

3. Impart a “snap” action to Bearing Block

Terminal (8).

4. With the imparting snap action, Washer (2)

will snap into Gland (5).

5. Move the Cable (7) in the opposite direction

as shown in Figure 2, to verify if Washer (2)

is seated in Gland (5). If not, repeat steps

1-4.

MAINTENANCE

Cylinder should be kept as clean as possible

around the pulleys, glands, guide shafts, etc.

Always use air that is adequately lubricated with

SAE 10 or 20 non-detergent oil. Pulleys have

permanently lubricated bearings and require no

maintenance.

Your Tolomatic Track Cable Cylinder will give you

many cycles of trouble free service. However, should

a leak occur, a rebuilding kit can be obtained which

enables you to replace all seals in the cylinder to

return it to its proper operating condition.