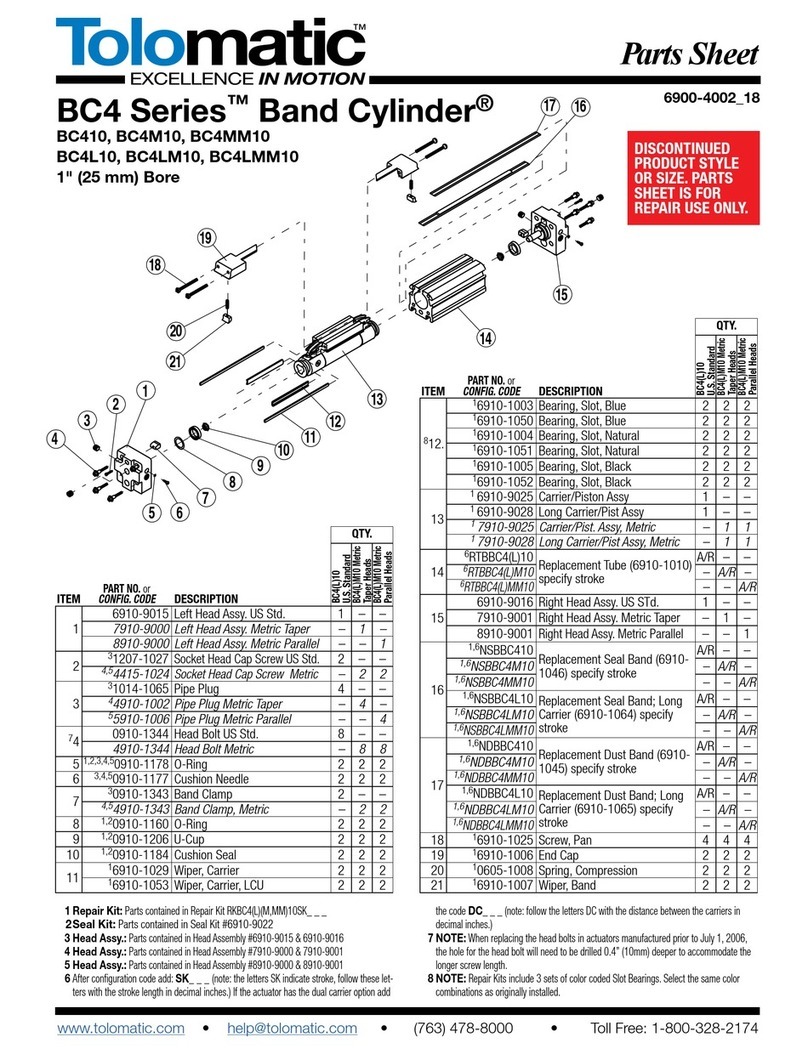

Parts Sheet #0510-4003_13_BC212ps BC212 Instructions – 2

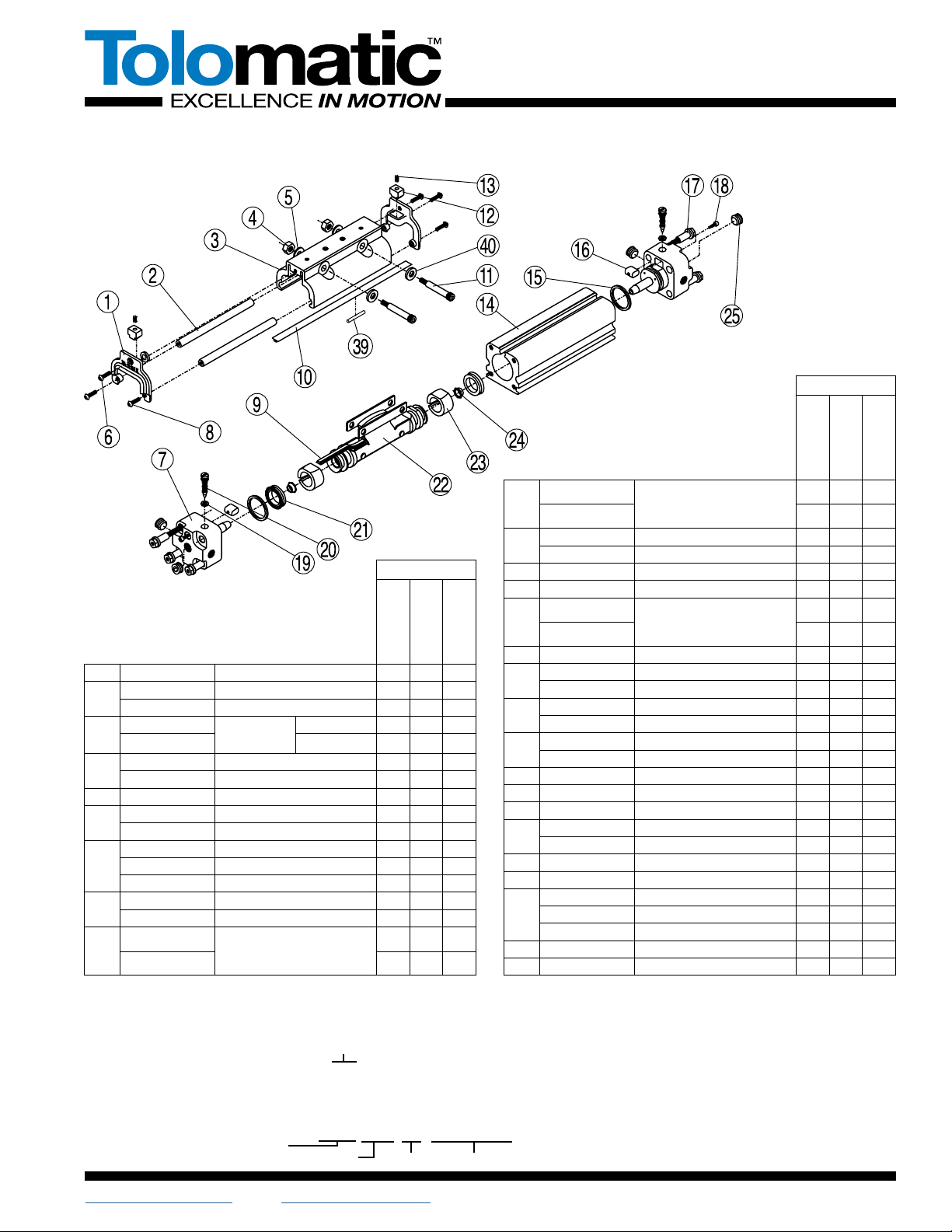

CYLINDER DISASSEMBLY INSTRUCTIONS

1. Remove Band Cylinder from machinery.

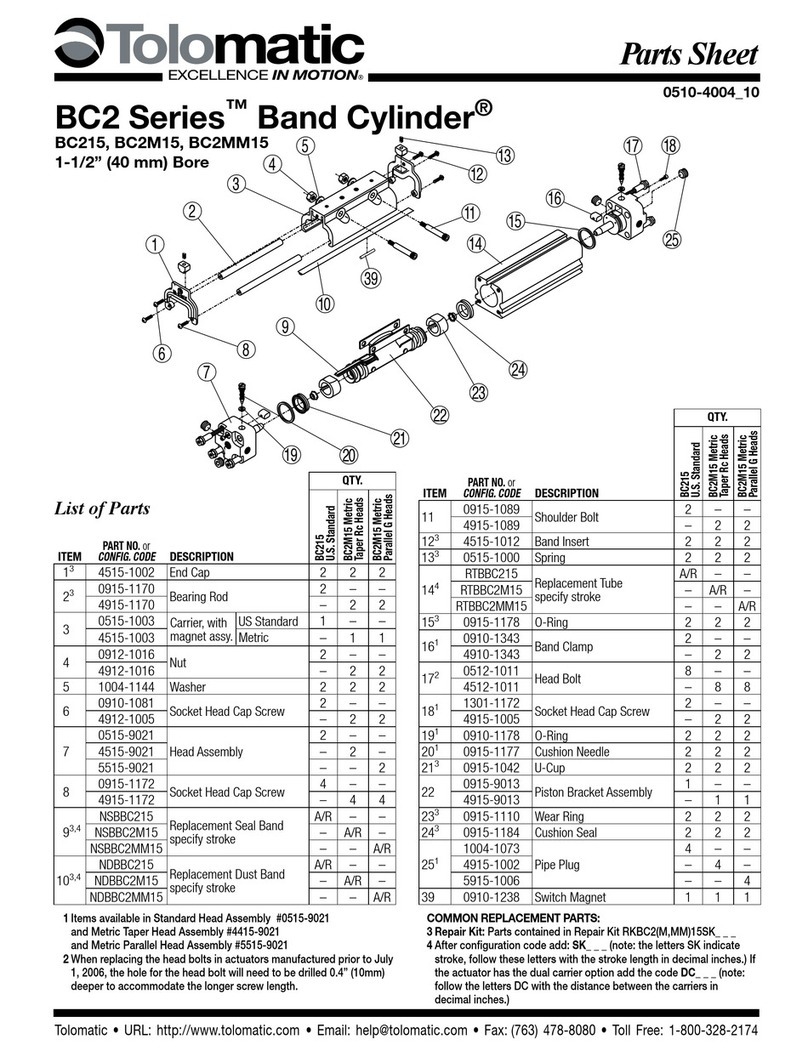

2. Loosen Screw(18).

3. Remove any foot mounting hardware if present then remove

the four Head Bolts(17) to free Cylinder Heads(7).

4. Remove the three Screws(6, 8) , Nuts(4), End Caps(1) and

Bearing Rods(2). Then remove the Shoulder Bolts(11) to free

the Carrier Bracket(3),

5. Slide Piston Bracket Assembly(22) to end of tube.

6. Remove top Dust Band(10) by lifting one end and drawing it

back across the entire length of the cylinder.

7. Remove the inner Sealing Band(9) by passing a screwdriver

or similar tool through the slot in the cylinder tube to

dislodge the band from the tube.(Take care in doing this

step to make certain that NO SCRATCHES ARE MADE in

the tube bore or slot.)

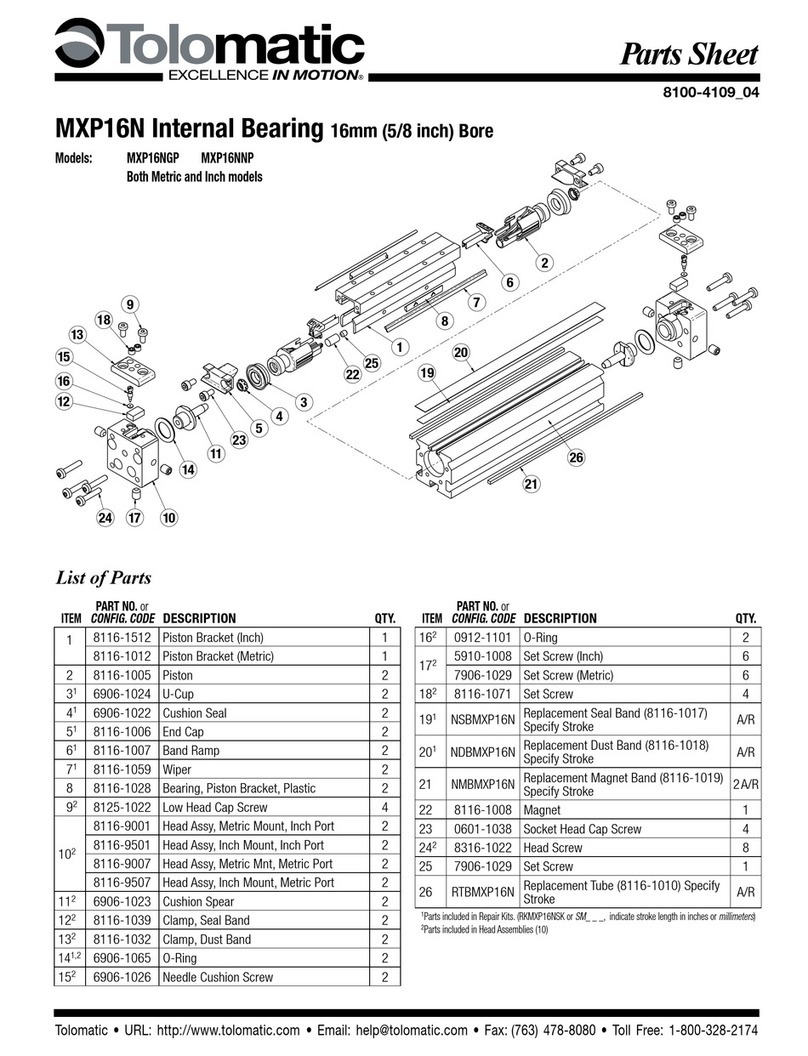

CYLINDER ASSEMBLY INSTRUCTIONS

1. CLEAN AND LUBRICATE

Thoroughly clean all components, particularly the tube bore

slot and bands. Thoroughly lubricate the tube a thin, uniform

layer of Magnalube-G®grease. Do not use SAE-grade

30-weight non-detergent oil.

2. READY INNER SEALING BAND

Lubricate rubber strip on both sides of new Sealing Band(9)

with grease. Insert Band into cylinder Tube(14) by passing it

sideways through slot in Tube. With rubber portion facing up,

center band in Tube so equal lengths of Band extend out

both ends.

CAUTION: Metal edges of Sealing Band are sharp. Exercise

caution to avoid injury to yourself or the Band and Tube when

inserting.

3. INSTALL PISTON BRACKET ASSEMBLY

Install new lubricated U-Cups(21)(seal lips facing out) and

Cushion Seals(24)(small end facing out) onto Piston-Bracket

Assembly(22). Install Wear Rings(23) on Piston with the

thinner edge and widest part of the flat inward, lining up the

wider flat portion with the band ramp and narrower flat with

the flat on the Piston. Place generous amounts of grease

around bore of Tube(14) on one end. Fill indentations on both

sides of Piston with grease and install Piston-Bracket

Assembly into Tube(14) by feeding Sealing Band(9) between

Piston and Bracket. Insert Piston into the greased end of Tube

and slide the length of the Tube to seat the Sealing Band in its

groove. Wipe excess grease from end.

NOTE: If Tube and Piston were greased properly, excess

grease should be present as Piston exits end of tube.

4. TRIM SEALING BAND

With a razor blade, remove rubber from extended band until

flush with the end of tube. With tin snips, trim band to length

indicated on table below.(Tolerance of +/- .032")

Cylinder Size Trim Length From Tube

1-1/4"(32 mm) .531"(14.86 mm)

5. INSTALL HEADS

Install new lubricated O-Rings(15) onto each Head(7). Insert

Head into Tube using a slight rocking motion until head is flush

with end of Tube. Apply Magnalube-G to threads of Head

Bolts(17) and install into head. Torque Bolts to requirements

shown below.(†When replacing the head bolts in

actuators manufactured prior to July 1, 2006, the hole for

the head bolt will need to be drilled 0.4" [10mm] deeper

to accommodate the longer screw length.) Repeat above

procedures for second head.

Cylinder Size In.-Lbs. Torque

1-1/4"(32 mm) 100-110(11.29-12.43 Nm)

6. INSTALL UPPER DUST BAND

With a razor blade, remove any rubber residue on the solid

steel surface of cleaned Dust Band(10). Place Dust Band in

slot on top of Tube(14). Remove rubber from one end of Band

flush with the end of the tube. With tin snips, trim Dust Band

to trim length requirements in Step 4. Insert trimmed Dust

Band into Head(7) positioning band above Band Clamp(16)

and tighten Screw(18). Grasp other end of Dust Band(10)

and carefully pull back out of Tube slot and back over cylinder

Head with affixed Band end. Lubricate Dust Band by filling

grooves along both sides of rubber strip with grease. Press

Dust Band back into groove in Tube.

7. INSTALL CARRIER

Position Carrier(3) on Piston-Bracket Assembly(22). Install

Shoulder Bolts(11), Washers(5) and Nuts(4) with screw

heads on port side of cylinder. Install Bearing Rods(2) in

Carrier and place End Caps(1) on Tube. Install Band

Insert(12) into pocket on End Cap(curved portion towards

carrier). Insert Spring(13) into hole of Band Insert(12).

Compress Spring and slide End Cap up to Carrier. Fasten

with Screws(6 and 8). Repeat for other end.

8. REMOVE SLACK AND AFFIX FREE END OF BAND

Work slack from Bands by moving the Carrier from the Head

with Bands secured to the opposite Head. Remove excess

rubber from free end keeping it flush with end of Tube. Cut to

trim length as before. Secure free end of Band by inserting

Band above Band Clamp(16) and tighten Screw(18).

9. CHECK ASSEMBLY

Run the Carrier Bracket(3) back and forth along the full

stroke to make certain that the cylinder is properly assem-

bled before applying air.

10. REMOUNT

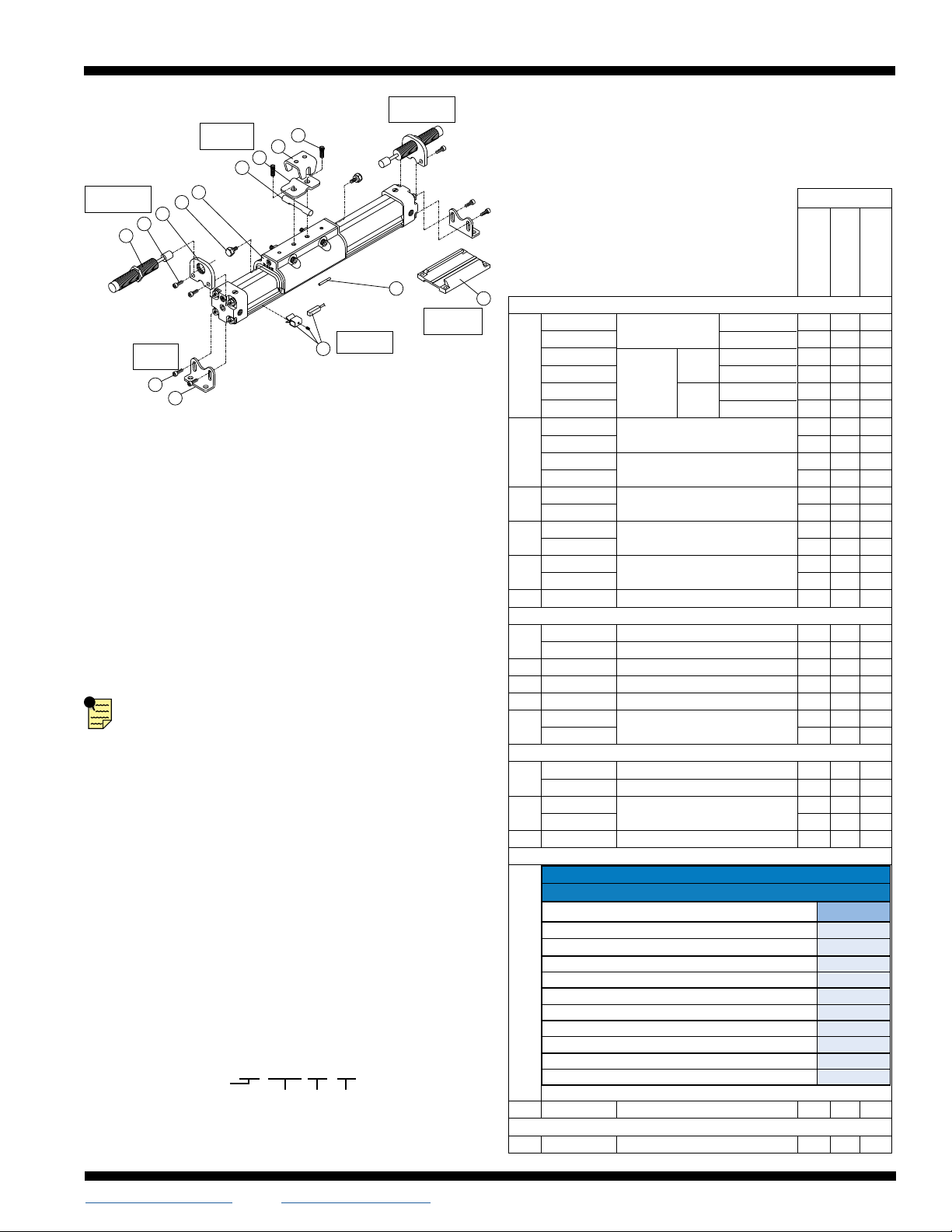

OPTIONAL ACCESSORY ASSEMBLY INSTRUCTIONS

1. SHOCK ABSORBERS

On assembled cylinder, screw Impact Bolts(29) into top of

carrier End Cap with Loctite #242. Secure Shock

Brackets(28) to cylinder Heads(7) with Socket Head Cap

Screws(27) and Loctite #242. Screw the Shock Absorber(26)

into the Shock Bracket(28). Adjust the Shock Absorber

nearest the carrier to bottom out the shock at its fullest stroke.

Back out the shock one full turn and tighten the Jam Nut.

Adjust the other Shock Absorber in the same manner.

2. TUBE SUPPORTS

Follow cylinder assembly instructions through steps 4. Before

installing second cylinder Head(7) in step 5., slide Tube

Support(40) onto cylinder Tube(14).

3. FOOT MOUNTS

On assembled cylinder, insert Screws(35) through holes in

Foot Mount Bracket(36) and install in holes on cylinder

Heads(7).

4. FLOATING MOUNT

Completely assemble cylinder. Place Pin(31), flat side

towards Carrier(3), and between the two center holes.

Place Floating Mount Clamp(32) over Pin(31) and secure to

the Carrier(3) with Screws(34) and Loctite® #242. Place

Floating Mount Bracket(33) over Pin(31) and hold in place

with a rubber band.