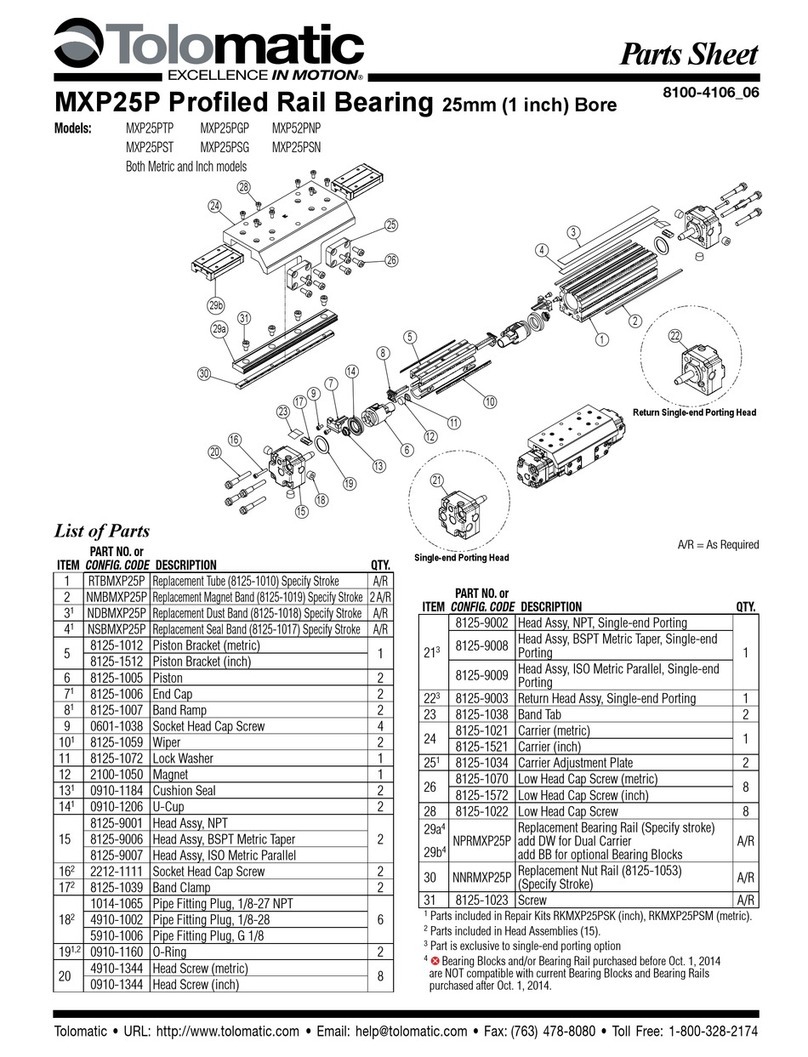

Parts Sheet #0600-4002_10 LS10, LSMM10 Disassembly and Assembly Instructions – 3

TOLOMA

TIC

•

URL:

http://www

.tolomatic.com

•

Email:

[email protected] •

Fax:

(763)

478-8080

•

T

oll

Free:

1-800-328-2174

REED SWITCHES

NOTE: Form A Reed Switches should not be used in TTL logic circuits.

A voltage drop caused by the L.E.D. indicator will result. For applications

where TTL circuits are used, please contact the factory.

WARNING: An ohmmeter is recommended for testing Reed Switches.

NEVER use an incandescent light bulb as a high current rush may

damage the switch.

Reed and TRIAC switches are only recommended for signalling position,

not directly powering soleniods. For shifting a solenoid, a relay or

resistor is recommended between it and the Reed Switch. Switch

ratings must not be exceeded at any time.

NOTE: The side of the switch with the groove indicates the sensing

surface. This must face toward the magnet.

NOTE: For Hall Effect Switch Magnet, be sure the S pole of the magnet

(indicated with black dot) is facing toward the switch (down).

clear underside of Carrier (#6). Use Screws (#1) to hold End

Cap (#2) in place.

13. Place Band Wedges (#11) between Bands (#12,#13) at both

ends of cylinder.

14. Install new O-Rings (#23,#24) on Head Assemblies (#8) and install

Head Assemblies to cylinder. If using Square Nuts (#16) be sure

they are installed in Tube/Base before Heads are installed.

15. Install Screws (#25) and tighten Head Assemblies in place.

16. Push Carrier (#6) to one end and tighten Set Screw in Head

Assembly on that end. Push Carrier (#6) to the other end of the

Slide Cylinder to take out any slack in Bands (#12,#13) and tighten

Set Screw (#26) in Head Assemblies (#8).

17. Run Carrier (#6) back and forth along the full stroke to make

certain the Slide is properly assembled.

18. Remount the completed Slide Cylinder.

SHAFT AND BEARING REPLACEMENT

INSTRUCTIONS

Note: Shaft alignment is critical to assure proper function of the slide

cylinder.

1. Remove Slide Cylinder from machinery.

2. Loosen two Set Screws (#26) in Head Assembly (#8) on one end of

Cylinder.

3. Remove four screws (#25), and Head Assembly (#8) from same end

of Cylinder.

4. Remove Screws (#21) from one shaft (#22).

5. Slide Shaft (#22) out of Carrier (#6).

6. Remove and replace Set Screws (#5) and Bearing (#14) from open

side of Carrier (#6). Use Loctite #242 on Set Screws (#5) and screw

them into Carrier (#6) until they bottom out on bearings (#14), then

back them out one half turn.

7. Slide new Shaft (#22) through Bearings (#14). Replace Screws (#21)

loosely, use Loctite #242 on Screws (#21).

8. Hold Top Dust Band (#13) at open end of Cylinder and slide Carrier

(#6) to opposing end.

9. Tighten Screws (#21) below Carrier (#6) to 40 inch-pounds

minimum.

10. To align Shaft (#22) properly, slide carrier over next Screw (#21)

and tighten to 15 inch-pounds minimum. Repeat this until all

Screws (#21) are tight.

11. Repeat steps 5 through 11 for second Shaft (#22).

12. Place Band Wedge (#11) between Bands (#12,#13) at open end of

Cylinder.

13. Be sure O-rings are on Head Assembly (#8) and install Head

Assembly (#8) to Cylinder. If using Square Nuts (#16) be sure they

are installed in Tube/Base (#17) before Head is installed.

14. Install four Screws (#25) and tighten to 70-80 inch-pounds.

15. Position Carrier (#6) to the end of Cylinder with non-removed Head

Assembly (#8). Push Carrier (#6) back to other end to remove any

slack from Bands (#12,#13) and tighten Set Screws in Head

Assembly (#8).

16. Run Carrier back and forth along the full stroke to make certain the

Slide is properly assembled before applying air.

17. Remount the completed Slide Cylinder.

Loctite® is a registered trademark of the Loctite Corporation, www.loctite.com

Magnalube®-G is a registered trademark of the Carleton-Stuart Corporation, www.magnalube-g.com

Viton® is a registered trademark of the E.I. Du Pont de Newmours Co., www.dupont.com.

Description QTY

RT

Switch, Reed, Form A, 5M Wire

AR

RM

Switch, Reed, Form A, Male Connect

AR

BT

Switch, Reed, Form C, 5M Wire AR

BM

Switch, Reed, Form C, Male Connect AR

CT

Switch, Triac, 5M Wire AR

CM

Switch, Triac, Male Connect AR

TT

Switch, Hall, Sourcing, 5M AR

TM

Switch, Hall, Sourcing, Male Connect AR

KT

Switch, Hall, Sinking, 5M AR

KM

Switch, Hall, Sinking, Male Connect AR

0610-9100 Rail and Rail Hardware (specify stroke) AR

SWITCH AND HARDWARE LISTING

OPTIONAL ACCESSORIES

Shock Absorber (Shock absorbers are sold individually.)

DESCRIPTION PART NO.

1"/25mm Light Duty 0610-9022

1"/25mm Heavy Duty 0610-9023

Inductive DC Proximity Sensors (also sold individually.)

DESCRIPTION PART NO.

DC 10-24 NPN NO Sink 0610-1023

DC 10-24 PNP NO Source 0610-1024

NOTE: NO=Normally Open

Note: Linear Slide is shown with Optional

Shock Absorbers.

.93"

1.05"

TOLOMATIC

TOLOMATIC

.08"

.37"

1.31"

SENSING SURFACE

SENSING SURFACE

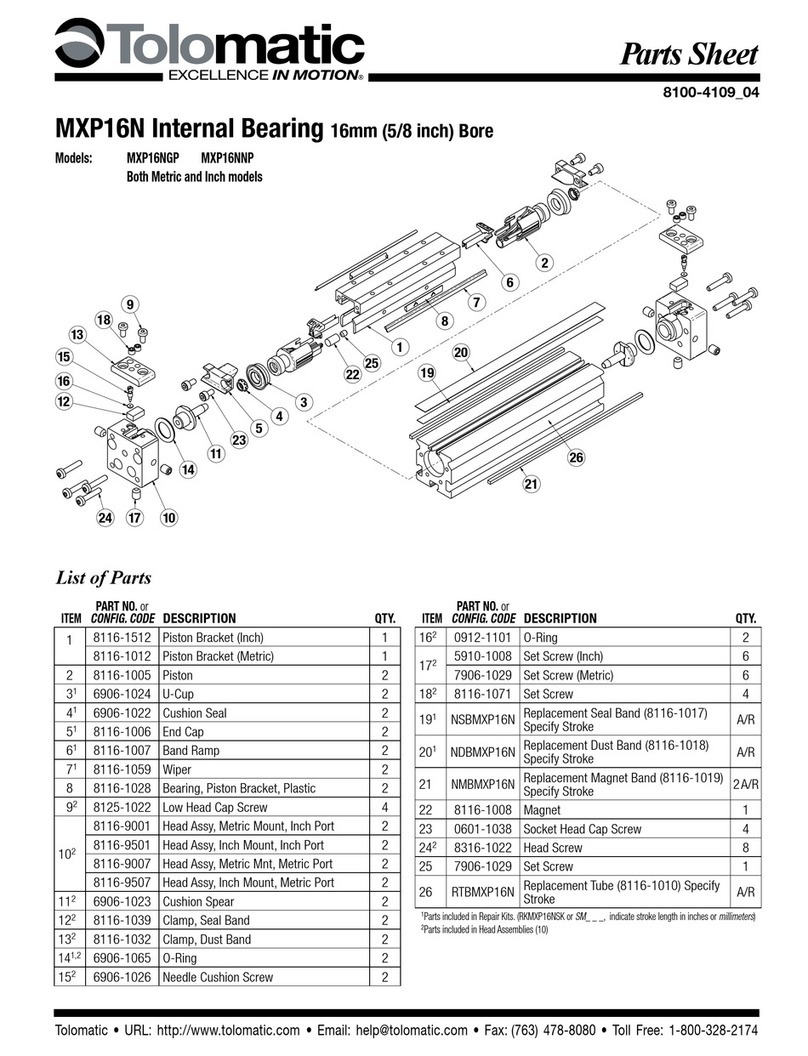

PART NO. or

CONFIG. CODE

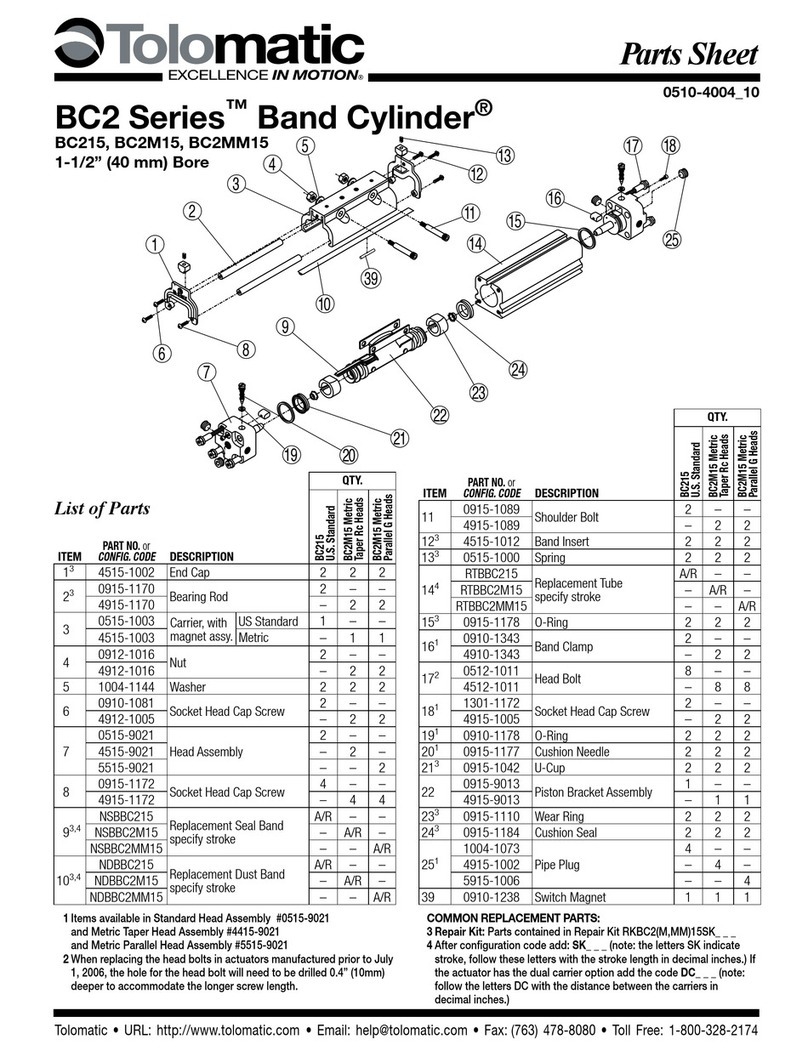

ITEM