Safety instructions, guarantee and liability

Page 2 of 26

2 Safety instructions, guarantee and liability

2.1 Common

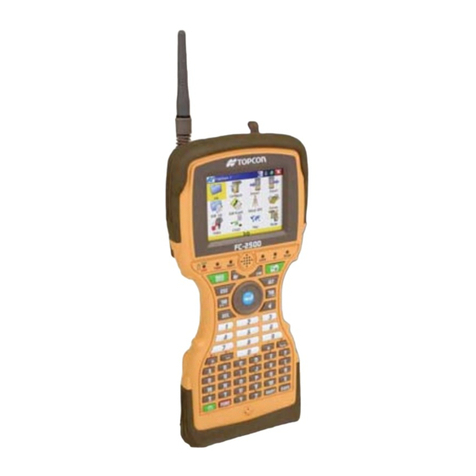

Read this operating manual before commissioning the OPUS A8. Keep this

operating manual where it is accessible to all users at anytime. Every person who is

assigned to commission or operate the OPUS A8 must have read and understood

the operating manual and the safety instructions in particular!

This operating manual contains instructions that must be complied with for your

personal safety and in order to avoid damage to property. Failure to follow these

safety instructions could result in fire, electric shock, or other injury or damage to

OPUS A8 or other property.

2.2 Qualified Personnel

This operating manual is intended for technically qualified personnel, who have the

appropriate skills in the area of measurement, control, and regulating technology.

Precise knowledge of all safety instructions and warnings contained in this operating

manual, as well as problem-free technical implementation of these instructions and

warnings are the prerequisites for hazard-free installation, commissioning, safe

operation, and maintenance, of the operator panel. Consequently it is strictly

required that all measures be performed by qualified personnel.

Qualified personnel, in accordance with the safety and warning instructions

contained in this operating manual are personnel, who

are familiar with CANbus systems, related protocols and network designs that

fulfill all legal requirements of the intended application, so that they are able to

program the OPUS operator panel accordingly

have gained knowledge of the programming related concepts by education or

trainings. Using the Projektor Tool a Projektor Tool training by Wachendorff

needs to be attended. Using CODESYS© a CODESYS©-training needs to be

attended, either held by Wachendorff or 3S.

are familiar with the safety concepts of automation technology, either as

project design personnel

or as operating personnel who have been instructed in how to handle the

automation technology, and who are familiar with the section of this manual

which deals with operation.

or who, as commissioning, and service personnel have been trained to repair

this type of automation technology, or who are authorized to commission,

ground, and label electrical circuits and devices, or systems, in accordance

with technical safety standards.

All persons who are involved in project planning, installation and operating the OPUS

A8 must be familiar with automation technology safety concepts, and they must be

qualified in accordance with the guidelines listed above.