4

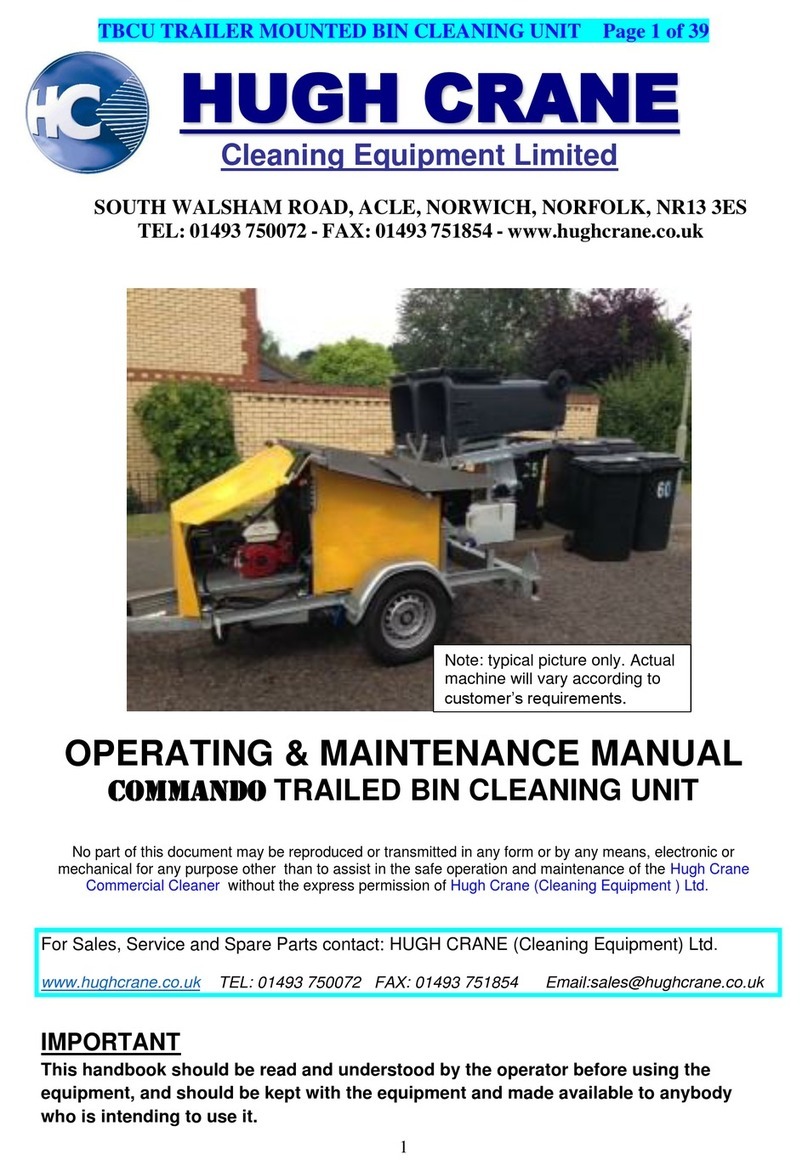

EN TORALIN®PROFESSIONAL PARTICULATE FILTER CLEANING MACHINE

Cleaning particulate lter. No Filter Disassembly Required!

Nowadays many modern diesel-powered vehicles have a built-in particulate lter. With the passing of time, soot parti-

cles build up for various reasons, which gradually leads to a clogged lter and hampered regeneration.

TORALIN oers garage owners a special, innovative method for cleaning the clogged particulate lter without disas-

sembling.

HOW IT WORKS:

The TORALIN® Diesel Particulate Filter Cleaner is directly sprayed into the particulate lter via the pressure sensor and

with help of the TORALIN Professional Particulate Filter Cleaning Machine. This loosens up all soot, ash and residue

particles or any other contaminants caught by the particulate lter and then easily burns them. The ushing liquid also

ensures that all the ash is removed. After the treatment, the particulate lter is as clean as new again.

DIRECTIONS:

General description

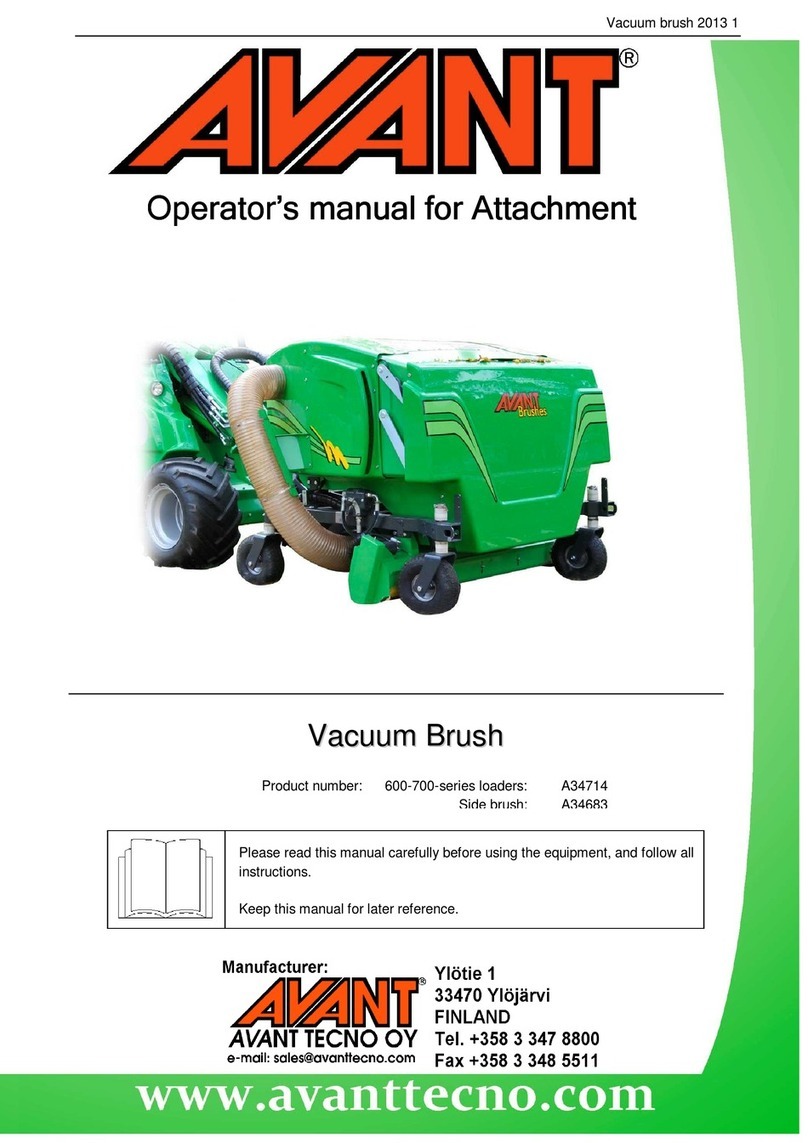

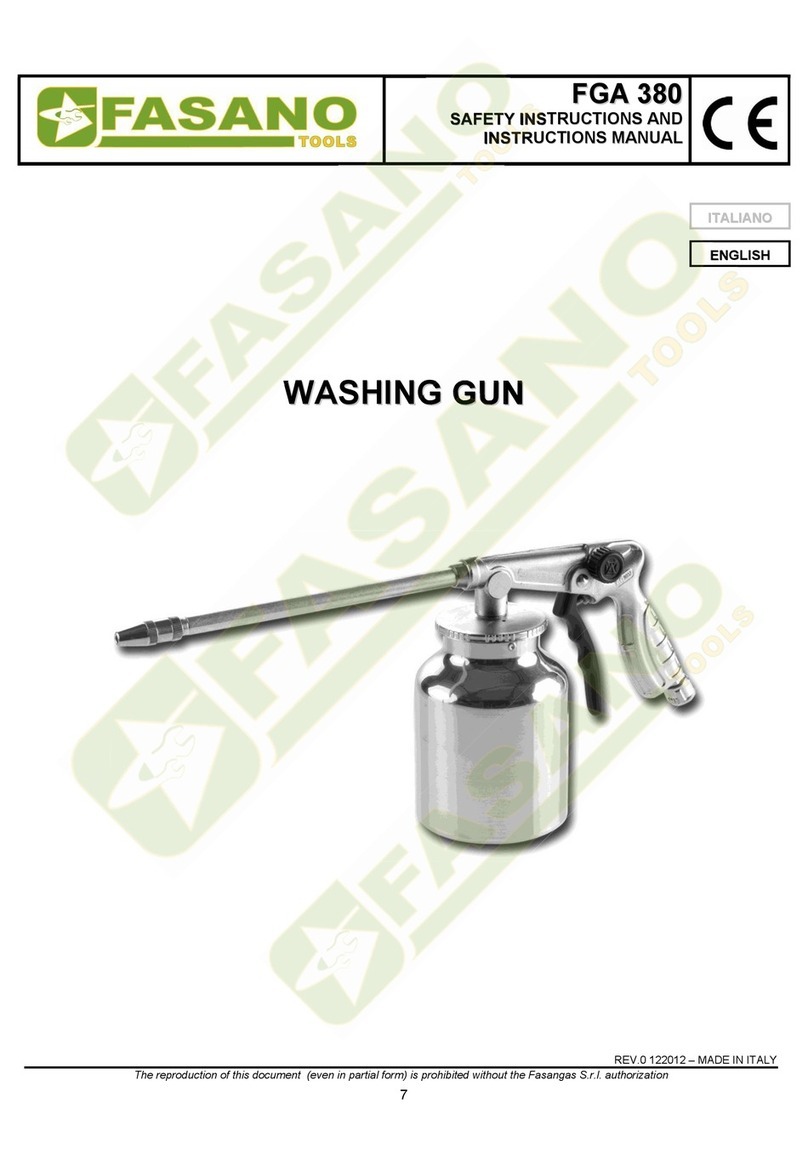

1 – TORALIN® Professional Particulate Filter Cleaning Machine

2 – Transparant supply hose

3 – Valve

4 – Connecting coupling for transparent supply hose

5 – Filling aperture

6 – Coupler for high-pressure compressor

WARNING: The TORALIN®Particulate Filter Cleaner and Particulate Filter Flushing Liquid are water-based pro-

ducts. It is strictly prohibited to ll these cleaners into to fuel tank or motor oil tank.

Step 1: Start the engine and let it work till the engine is warm.

Step 2: Prepare the TORALIN Cleaning machine for use. Connect the machine’s transparent supply hose 2to the

valve 3. (Fig. 2)

Step 3: Make sure the valve 3is closed. (Fig. 3)

Step 4: Now connect the supply hose 2 to the connecting coupling 4 of the machine. (Fig. 4)

Step 5: Add the contents of the “TORALIN Particulate Filter Cleaner” bottle (500 ml) to the tank of the machine via the ller

opening 5 and put the tank cap back on (Fig. 5). Do NOT use any other chemicals in this machine.

Step 6: Stop the engine when it has reached the desired temperature.

Step 7: Search for the front pressure sensor and release it. (Fig. 6)

Step 8: Connect the supply hose 2 of the TORALIN Cleaning Machine to the front exhaust sensor hose. (Fig. 7)

Step 9: Connect the machine to the high-pressure compressor via the coupler 6. Set the pressure at 2 bar. (Fig. 8)

Step 10: Open the valve 3to the supply hose 2. The TORALIN Diesel Particulate Filter Cleaner now transfers from the

machine into the particulate lter. This is visible in the transparent hose. (Fig. 9)

Step 11: After 1 minute, close the valve 3 again and allow the cleaner to soak in for 4-5 minutes. The Cleaner softens the

carbon particles and contaminants in the diesel particulate lter. Repeat step 10 2-3 times until all of the cleaner

is nished (Fig. 10). Now leave the cleaner to do its work for another 15 minutes.

Step 12: Disconnect the air hose. Close the valve 3 of the supply hose 2. (Fig. 11)

Step 13: Put the pressure sensor back into position.

Step 14: Start the engine and let it run at 3000-4000 revs for 5-7 minutes (Fig. 12). During the rst few minutes the car

should smoke considerably. Should this not be the case then an extra cleaner may be required.

Step 15: Turn o the engine, release the pressure sensor again and reconnect the machine’s supply hose 2.

Step 16: Add the contents of the bottle “TORALIN Particulate Filter Flush” (2 liters) to the tank of the TORALIN Cleaning

machine via the ller opening 5 and put back the tank 1cap. (Fig. 13)

Step 17: Start the engine and let it run up to 2000 rpm.

Step 18: Put a collection tray underneath the exhaust to catch the liquid/foam.

Step 19: Reconnect the air hose and then reopen valve 3on supply hose 2. Let the engine run up to 2000 rpm and

depress the accelerator pedal fully 2 or 3 times every minute. Continue this process until the entire Particulate

Filter Flush liquid is nished. (Fig. 14)

Step 20: Stop the engine. Disconnect the supply hose 2 and reconnect the front exhaust sensor hose.

Step 21: Start the engine and let it idle for 5 minutes. Then drive the car for 10 minutes at high revs. The treatment is now

nished. Possible error codes need to be reset.

Step 22: Drain the collection tray with uid with waste oil.

NOTE: If no foam/liquid appears from the tailpipe, drive 15 minutes at high speed and repeat the whole process again.