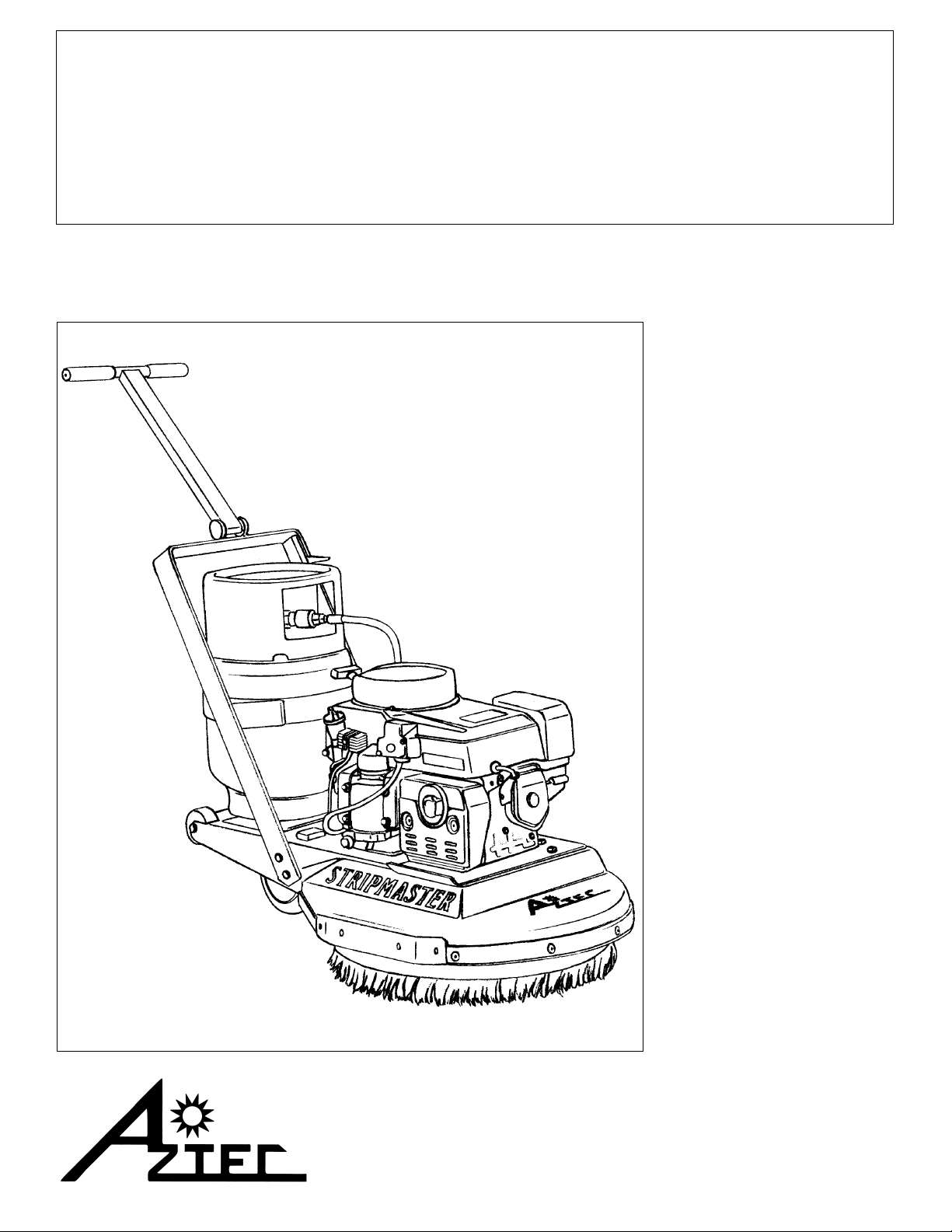

STRIPMASTER INFORMATION

I. ENGINE

A. See engine manual for maintenance schedule.

•Consult local laws regarding used oil.

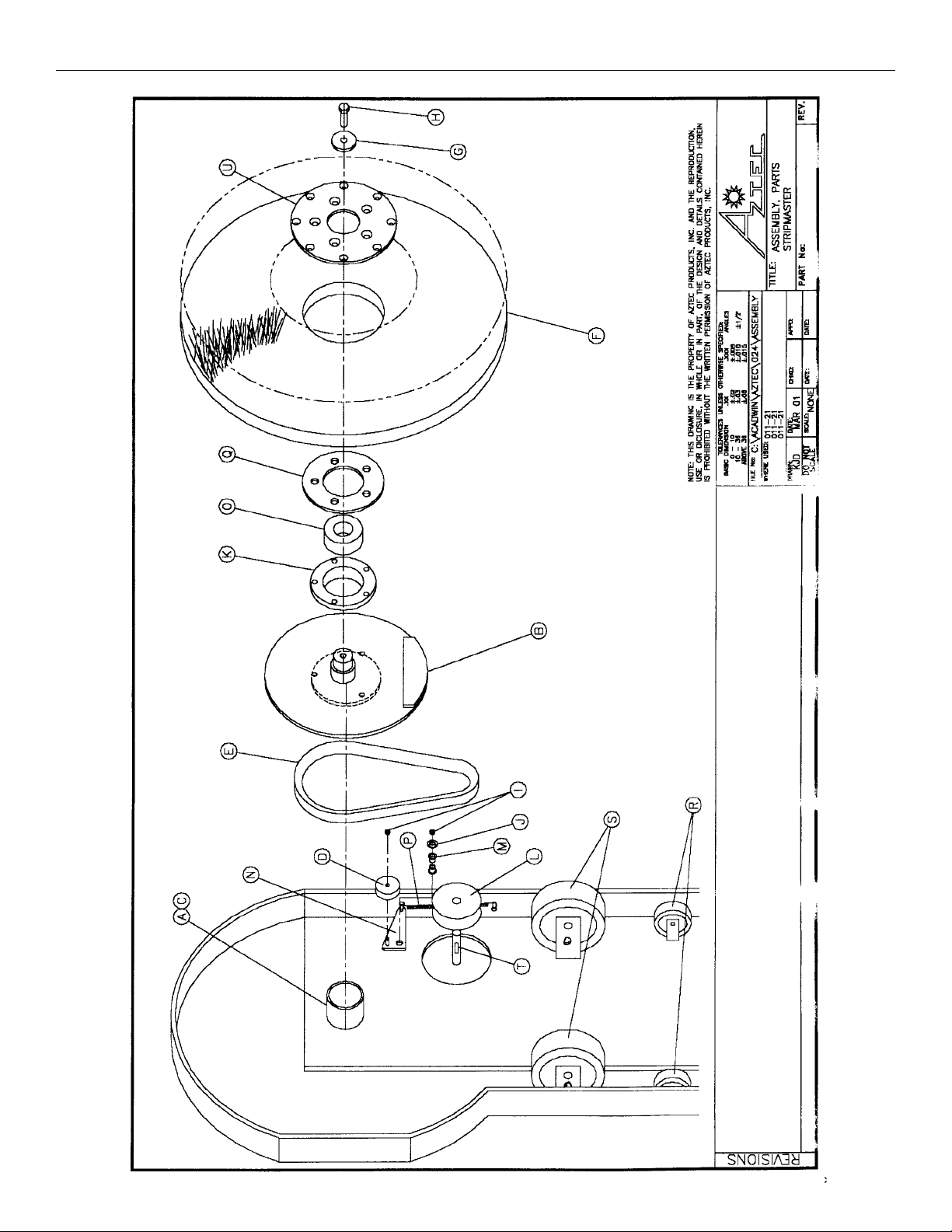

II. BRUSH, BELT, IDLER PULLEY, OR DRIVE

SHAFT REPLACEMENT:

A. Adjust the handle to enable the buffer to stand on

rear wheels. Never turn machine on its side.

•Handle must be in shipping (forward) position to

insure stability in the “tilt back” position. A

second person should aide in the lift and to

secure the buffer while being serviced.

•Do not use handle when attempting to tilt

back machine for service or cleaning. Handle

is designed for control during operation — Do not

use excessive vertical pressure.

B. Remove brush nut & brush centering device.

C. Remove brush. (Replace if worn.)

D. Remove idler pulley. (Replace if worn.)

E. Remove belt(s). (Replace if worn.)

F. To remove driveshaft unit: Remove retaining bolt &

clip—pull driveshaft out of housing—use of a slide

hammer may assist in removal (Do not pry with

crow bar). While drive shaft is removed, spin bearings.

If roughness is felt, bearing replacement may be

necessary.

G. To reassemble, reverse order of all steps taken above.

NOT ALL OF THESE STEPS WILL BE NECESSARY FOR

ALL JOBS, BUT IF THEY ARE, THE ENTIRE JOB CAN

BE COMPLETED QUICKLY WITH A FEW TOOLS.

III. LUBRICATION INSTRUCTIONS:

A. Refer to engine manufacturer’s owner’s manual and

comply completely with the lubrication instructions.

Any evidence of under -lubrication will make a

claim against the manufacturer invalid.

B. Thoroughly clean air filter each time engine oil is changed.

C. Keep a good service log on each machine with the

date, hour meter reading, type(s) of service performed.

This will assist you and Aztec in spotting weaknesses

in our respective areas of responsibility.

IV. ENGINE MAINTENANCE METER

A. This meter is used to perform preventive maintenance

which benefits you with increased fuel economy, less

down time and longer engine life. It is simple to

operate because of its functional and user friendly

design and has a function for every application, detailed

as follows:

HOUR METER: Records actual running time of

engine. Non-erasable.

B. TACHOMETER: Tells you what RPM your engine is

running at for maximum power and efficiency. Reads

up to 6,000 RPM Do not run in excess of 3400 RPM.

RETURN GOODS POLICY

As an Aztec customer, you are aware that the equipment

we design and build is both innovative and unique. Since

this is true, in order to trouble-shoot our equipment, we

rely heavily on returned defective or failed parts so that

we can examine first-hand the causes of failure. While

this may at first seem to be an inconvenience, ultimately

you benefit from safer and better designed machine

components. Please give us the opportunity to serve

you better by following these RGA (Returned Goods

Authorization) rules.

1. We maintain the serial number, date of shipment or

sale, and customer name on each piece of equipment

sold. If you were the purchaser, please reference that

information on your request for replacement or repair.

If you purchased the equipment through a distributor,

please contact them first. If you are not satisfied,

contact Aztec and give us the Distributor name,

purchase date, and the serial number of the product.

2. Order the replacement part from your distributor or

Aztec Products by calling 800-331-1423 during

normal business hours (8:30-5:00 Eastern Time).

We will ship warranted parts at our expense.

3. When dealing with Aztec ask for an RGA number

when you are ordering the replacement part. Return

the failed part to us within 30 days, freight prepaid,

exactly as it was at the time of failure. Our inspection

and evaluation will attempt to determine the probable

cause of failure.

4. If our inspection reveals that the failed part was

defective, we will credit your account for the entire

amount of the part including your cost of return

freight. When incomplete parts are returned for credit,

STRIPMASTER PG. 3