Tormach ATC User manual

USING THE TORMACH

TOOLING SYSTEM ATC

AUTOMATIC TOOL CHANGER

FOR THE PCNC 1100

Operator’s Manual

© 2013 Tormach®LLC. All rights reserved.

Questions or comments?

Please e-mail us at:

Tormach TTS ATC Manual:

UM10081_TTS_ATC_PCNC1100_1013A

1. Preface 2

1.1 Manual Overview 2

1.2 Safety 2

1.3 System Requirements 3

2. Preparaon 4

2.1 UnpackingandCheckingShipment 4

2.2 BeforeYouBegin 5

2.3 MounngtheATC 5

3. ElectricalInstallaon 7

4.1 AirLineConneconandRequirements 12

4. AirLines 12

5. SowareInstallaon 14

6. SystemValidaon 15

6.1 AlignToolTrayandSlots 16

7.1 FootPedalKit 20

7.2 FilterRegulatorLubricator(FRL) 20

7. OponalAccessories 20

7.3 PressureSensor 21

8. Operaon 23

8.1 GeneralTheoryofOperaon 23

8.2 Loading/UnloadingTools 23

8.3 AutomacTrayLoad/Unload 24

8.4 ManualTrayLoad/Unload 24

8.5 ToolTouch-oRoune 25

8.6 ATCBypass 25

9. Maintenance&Troubleshoong 26

9.1 Support 26

9.2 Maintenance 26

9.3 Troubleshoong 26

10. ExplodedView&PartsList 33

10.1 ATCCarousel 34

10.2 ATC1100ColumnMount 36

10.3 TTSATCActuator 38

10.4 ATCControlModuleAssembly 40

10.5 TTSATCPneumacSchemac 42

10.6 ATCElectrical 43

TABLE OF CONTENTS

PB 1

UM10081_TTS_ATC_PCNC1100_1013A UM10081_TTS_ATC_PCNC1100_1013A

1.1 Manual Overview

ThismanualisintendedforusersoftheTormachTooling

SystemAutomacToolChanger-anaccessorytothe

TormachPCNC1100mill.Readersareassumedtobe

familiarwiththeoperaonanddocumentaonfortheir

parcularmillingmachine.Forquesonsofageneral

nature(e.g.applyingtoolheightosetcompensaon)

pleaserefertothePCNC1100machinemanual.

TheTTSATCcanbeusedwithallexisngpartprograms

withoutmodicaon,regardlessofexisngtoolnumber

assignments.Forprogramsthatuse10toolsorfewerthe

ATCmaybeusedforalltoolchanges.Forpartprograms

requiringmorethan10tools,orforprogramsrequiring

specialtoolingnotappropriateforanATC,suchasa

reversingtappinghead,itcanbeusedinconjunconwith

manualchanges.Anytoolnumberbetween1and253

maybeassignedtoaposioninthetooltray–youarenot

connedtousingtoolnumbers1-10.Thisisconvenientif

youhaveatoollibraryalreadysetupwithtoolnumbers

andheightsmeasuredinyourtoolosettable.The

toolchangerrememberstoolsassignedtothetray,and

promptsformanualspindleinseronandremovalofnon-

assignedtoolsatappropriatemes.Toolsmaybeassigned

todierenttraynumberssothat,forinstance,onecan

dedicategroupsoftrayassignmentstospecicjobsthat

are run frequently.

AlltoolsarecalledfromGcodewithstandardM6

commands,orfrombuonsontheATCcontrolscreen.

1.2 Safety

Anymachinetoolispotenallydangerous,

especiallyautomatedtoolsundercomputer

control.BecauseTormachdoesnotknow

thedetailsofyourworkshoporotherlocal

condions,noresponsibilitycanbetakenfordamage

orinjurycausedbytheuseofthemillandATC.Itisthe

owner’sandoperatorsresponsibilitytounderstandthe

mill/ATCsystemintegraonandoperaonandtocomply

withanylegislaonandcodesofpracceapplicableto

countryorstate.Ifthereisanydoubt,seekguidancefrom

aprofessionallyqualiedexpertratherthanriskinjury.

ThesafetyofanyapplicaonusingtheATCisulmately

theresponsibilityofthoseperformingthesetupand

operaon.Pleasedonottakethisresponsibilitylightly

-usecommonsenseandreviewallinstruconsonthe

operaonandmaintenanceoftheATC

Operator Safety

• Whenusingelectrictools,machinesorequipment,

basicsafetyprecauonsshouldalwaysbefollowed

toreducetheriskofre,electricshock,andpersonal

injury.

• Readandunderstandthismanual.Donotoperatethe

ATCwithoutknowingthefunconofeverycontrol

key,buon,andalignmentandreferencingprocedure.

RefertothismanualorcontactTormachifanyfuncon

isnotunderstood.

• KeephandsclearoftheATCatallmesduringtool

changesorwhencommandinganyATCmoonfrom

theATCcontrolscreenofthemill’scontrolsoware.

• Avoidcontactwithmovingparts.Beforeoperangthe

millandATC,removealljewelryincludingwatchesand

rings,neckesandanyloose-ngclothing.Tieback

hair.

• Keephairawayfrommovingparts.

• Donotreachforthepart,toolorxturewhilerunning

apartprogram.

• Keepworkareaclean.Clueredareasinviteinjuries.

• WearANSIapprovedeyeproteconatallmes.

• Keepworkareawelllit.

• Keepthecomputerareaclearofcluer.

• Neveruselongerorlargertoolsthannecessary.

• DonotusetheATCorpowertoolsindamp,wetor

poorlylitlocaons.

• Donotusetoolsinthepresenceofammablegasesor

liquids.

• Useonlyidencalreplacementpartswhenservicing.

• TakeoglovesbeforeyouoperatetheATC.Glovesare

easilycaughtinmovingpartsorcungtools.

• Neveroperatewithunbalancedtooling.

• NeveroperatetheATCaerconsumingalcoholic

beveragesortakingstrongmedicaon.

• Protectyourhands.Stopthemachineandensurethat

thecomputercontrolisstoppedbeforeyou:

*Changetools;

*Changepartsoradjusttheworkpiece;

*Makeanadjustment;

• Keepworkareawelllit.Askforaddionallightif

needed.

• Alwaysuseproperfeedsandspeeds,aswellasdepth

andwidthofcut,topreventtoolbreakage.

• Usepropercungtoolsforthejob.

• Donotusedullordamagedcungtools.Theybreak

easilyandbecomedangerousprojecles.

• Becertaineveryoperatorunderstandstheoperaon

andsafetyrequirementsofthemillandATCbefore

operang.Itistheresponsibilityoftheownerof

1. PREFACE

23

UM10081_TTS_ATC_PCNC1100_1013A UM10081_TTS_ATC_PCNC1100_1013A

theATCtoprovideandensurepointofoperaon

safeguardingperOSHAstandards.

Electrical Safety

TheTormachToolingSystemATCoperateson

70VDC,fusedat8amps.Itispoweredfrom

theDCBusBoard(PN32005)insidethecontrol

cabinetofthemill.Neveroperatethe

machinetoolwiththecabinetdooropen.Nevermakeor

checktheseconneconswiththemillpoweredon.

PowertotheATCandotherdevicesinsidethecontrol

cabinetmayretaindangerousvoltagesaerexternal

powerhasbeenremoved.Donotmodifythese

conneconsinanyway.Ifunsureabouttheconnecons,

callTormachoraqualiedrepairtechnician.

1.3 System Requirements

TousetheTormachToolingSystemATC,yourmachine

mustmeetthefollowingrequirements:

• Youmustprovideacompressedairsourcecapableof

deliveringclean,dryairat95PSIand2CFM.

• TheTormachPowerDrawBar(PN31706)mustbe

installed

• ForPCNC1100machinesserialnumbers1325and

lower,youmusthavepreviouslyinstalledtheSpindle

DriveUpgradekit(PN31090)

• ForPCNC1100machinesserialnumbers999and

lower,youmusthavepreviouslyinstalledtheSeries3

upgradekit(PN32010)

Required Tools

• MetricAllenwrenchset

• Screwdrivers

• Boxwrenchesandlargecrescentwrench

• Hotgluegun

• 12”longwoodendowelorroundstock

23

UM10081_TTS_ATC_PCNC1100_1013A UM10081_TTS_ATC_PCNC1100_1013A

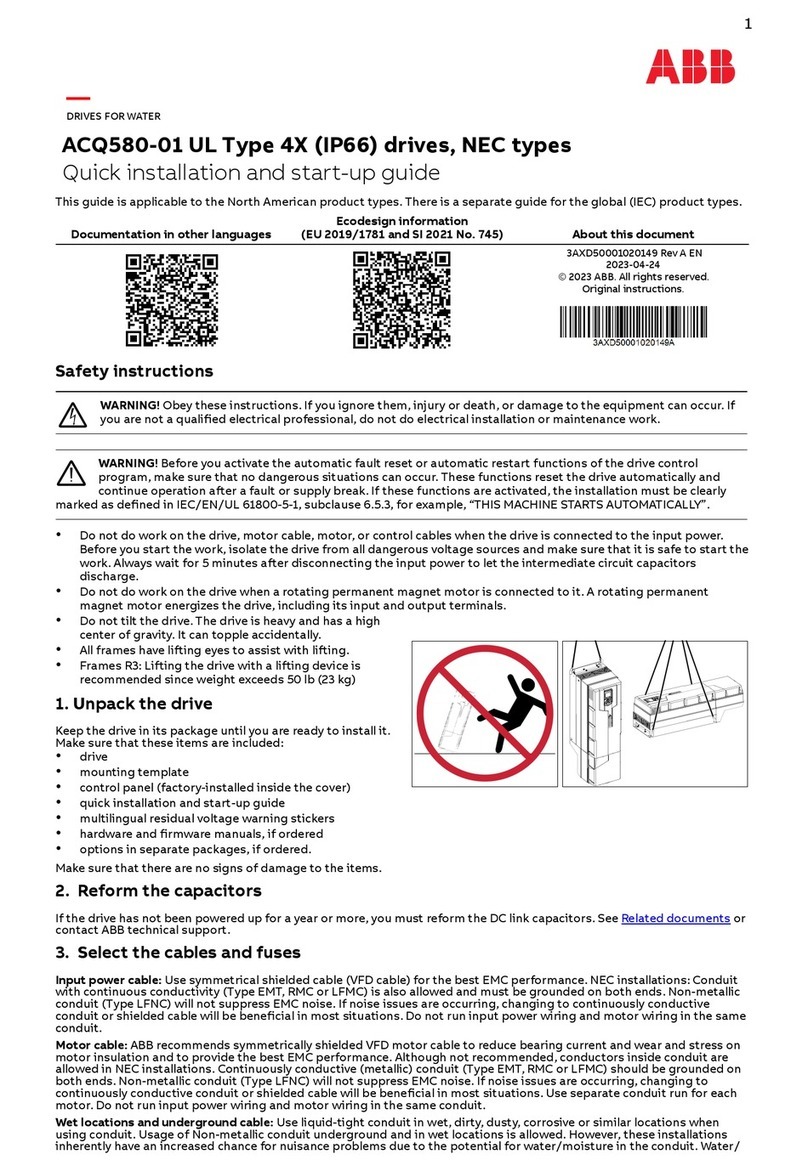

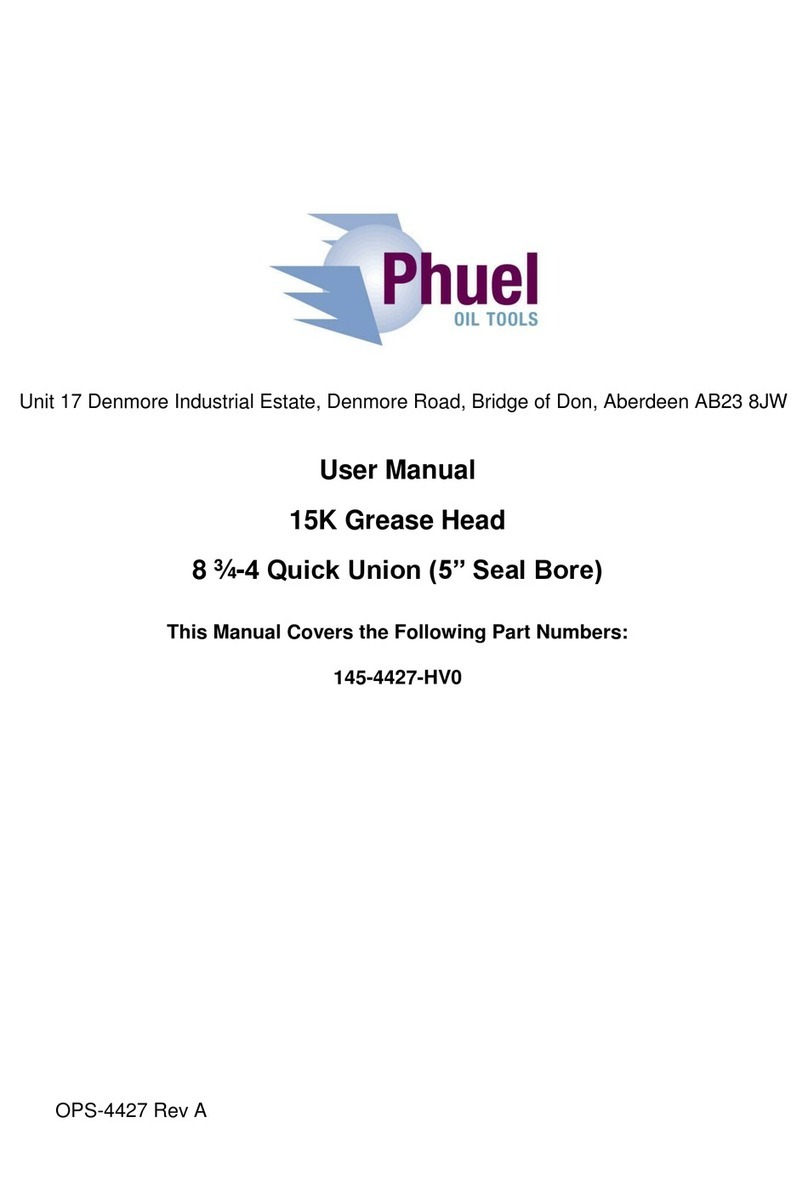

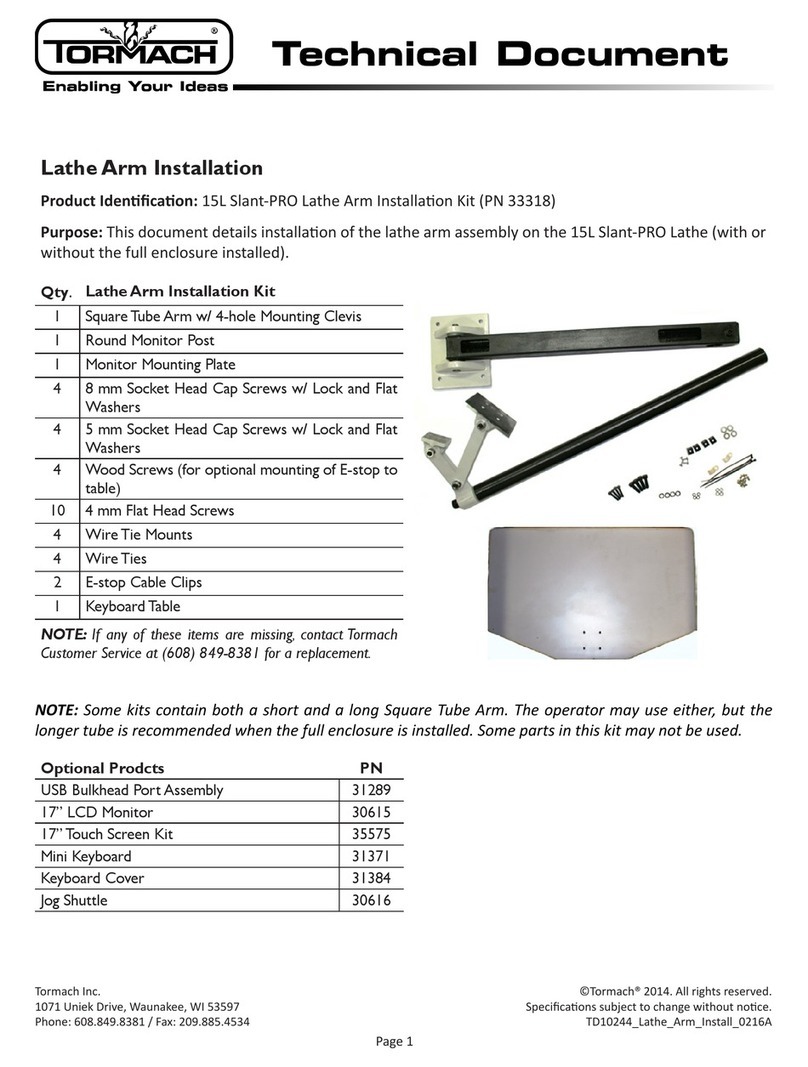

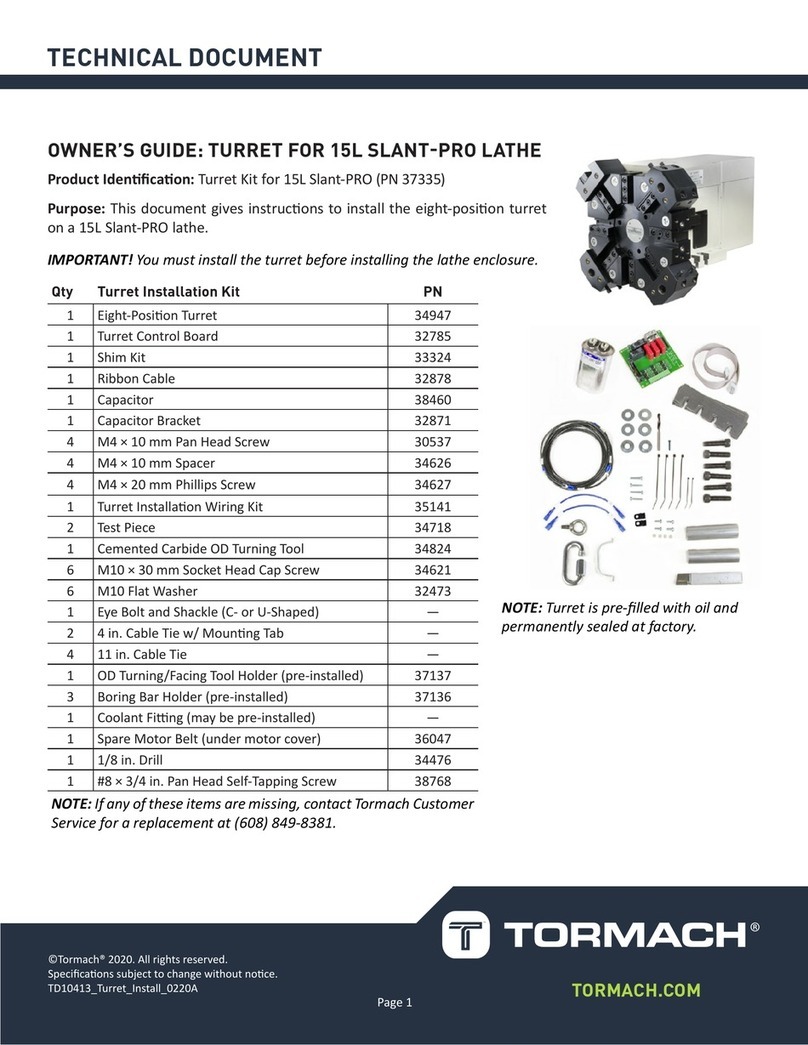

2.1 Unpacking and Checking

Shipment

Uponreceipt,carefullyunpacktheATCandinspectto

ensuredamagedidnotoccurintransitandalsotoaccount

forallparts.Ifanydamageisapparent,orpartsmissing,

pleasecontactTormachimmediately.

Withanassistant,litheATContoasturdysurfaceor

workbenchtoprepareitforuse.

11ATCassembly

24¼”airlines,onew/checkvalveandpushng

31ATCsquaretubemount

4 4hexstandoswithM8andM10studs

5 4angenutsandwashers

620nylonM6x16hexbolts

7 1USBcable

81ATCcommunicaonRJ-11cable(512-515)

91Mainpowercable(503,504)terminatedwith4pin

Molexandspades

10 1PDBpowercable(501,502)terminatedwithPDBcon-

nectorandspades

11 1VFDinterconnectwiringkit(532-535)

12 1coolanthosemounngplatew/fasteners

13 PowerDrawBarpowersupplyboard

14 1R8TTSexpandedcollet

15 Operator’sManual

16 SowareinstallaonCD

17 25X20glassfuses

Thefollowingitemsmayormaynotbeincludedbasedon

theageofyourmachineandpowerdrawbarinstallaon:

1. 1drawbarwith8Bellevillewashers

2. PowerDrawbarcontrolcircuitboard(ifrequiredbased

onageofyourpowerdrawbarinstallaon.)

3. DCBusBoard

Checktheseitems.NofyTormachofanydamageincurred

duringtransitormissingpartssoanyclaimscanbemade

withintheshippingcarrier’sdeadline.

2. PREPARATION

45

UM10081_TTS_ATC_PCNC1100_1013A UM10081_TTS_ATC_PCNC1100_1013A

2.2 Before You Begin

TheTormachToolingSystemATCisdesignedformachines

withthepowerdrawbar(PN31706)installed.PCNC1100

millingmachineswithserialnumbers1325andlower

willneedtohavethespindledriveupgrade(PN31090)

installedbeforeinstallingtheATC.PCNC1100machines

withserialnumbers999andlowerwillalsohavetohave

theSeries3upgradekit(PN32010)installedbefore

installingtheATC.

Allmachineswillneedtohavethepowerdrawbarinstalled

beforeinstallingtheATC.Seethepowerdrawbarmanual

(includedwiththepowerdrawbarpackageandontheATC

sowareCD)forpowerdrawbarinstallaoninstrucons.

PCNC1100machinesserialnumbers1999andlowerwill

needtoreplacetheoldDCBusBoard(PN30661)withthe

newbusboard(PN32005).

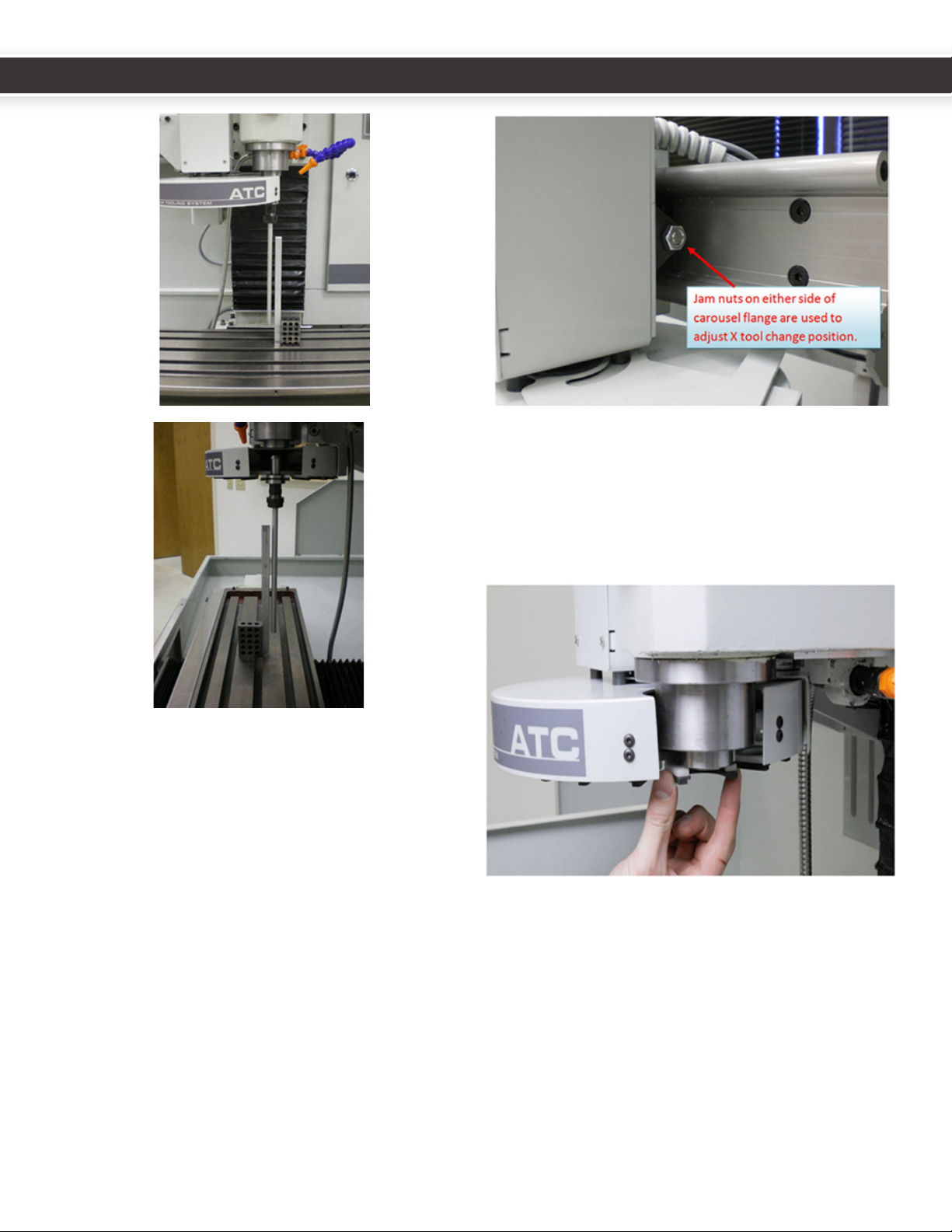

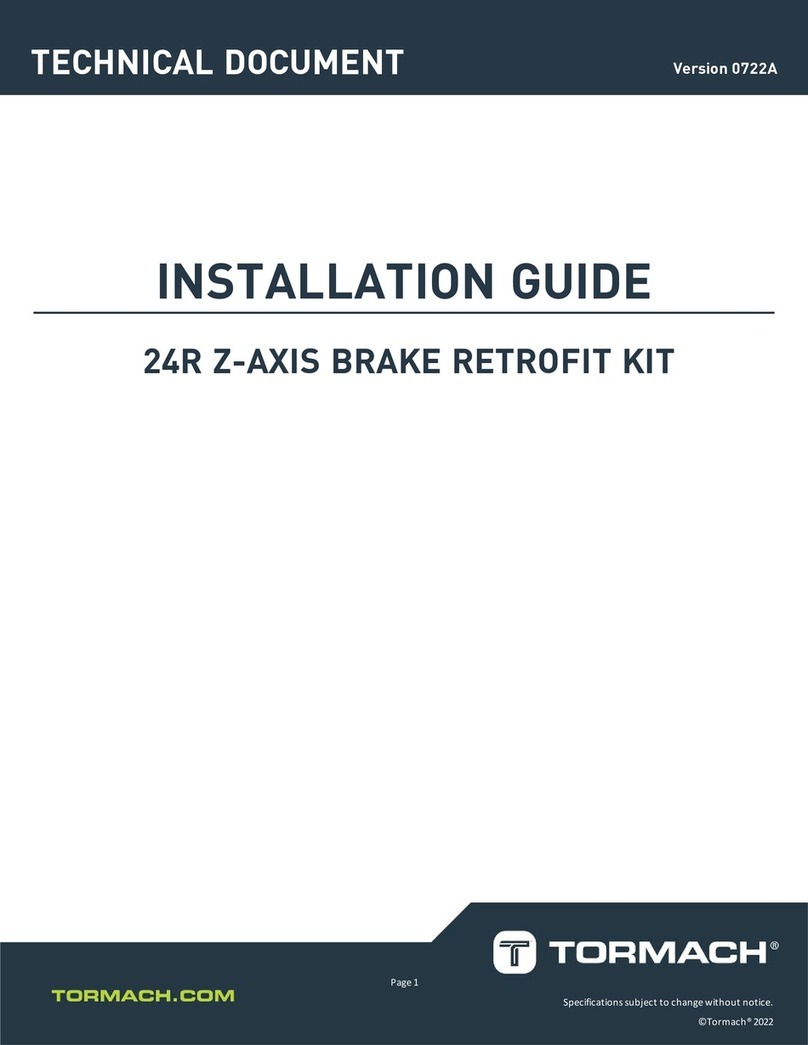

2.3 Mounting the ATC

MounngandaligningtheATCtothemillisajobthatis

bestdonewithtwopeople.TheATCcarouselassembly,

whichweighsapproximately50pounds,iscumbersometo

liandposionaccuratelyespeciallywhenworkingover

themill’schiptray.Installaongoessmoothlywhenone

personholdstheATCinposionwhileanassistantghtens

thefastenersthatconnectittothesquaretubemount.

Initial Hardware Installation

WARNING! SHUT THE COMPUTER

DOWN, THEN POWER DOWN THE MILL

USING THE ROTARY SHUTOFF SWITCH

ON THE RIGHT HAND SIDE OF THE

CONTROL CABINET.

Youmayndinstallaoneasiestifyourstpullthemill

awayfromthewall.

Ifed,removethecoolanthoseandmountfromthe

spindle head.

Ifed,removethelehandmachinearmfromthemill

column.

45

UM10081_TTS_ATC_PCNC1100_1013A UM10081_TTS_ATC_PCNC1100_1013A

Ifed,removetheuppercoolantsplashguards

(backsplash)fromtheleandrighthandchiptrays.

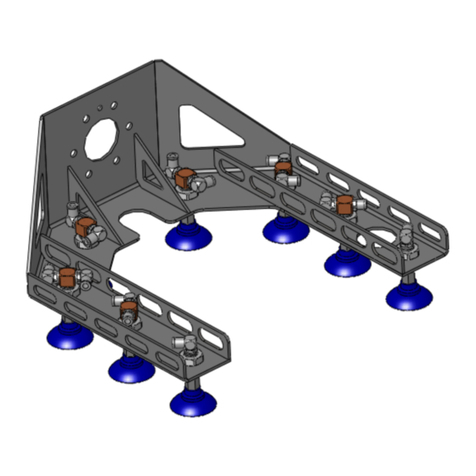

1. ThreadtheM8sideofhexstandosintomillcolumn

andghtensecurelywithawrench.

2. HangthetoolchangersquaretubemountontheM10

studs.Securewithangenutsandwashers.Theslots

arewiderthanthestudtoallowforminordeviaons

inholelocaons,andtofacilitateasmalldegreeoflt.

3. Withtheassistanceofanotherperson,fastentheATC

tothemountusingthe4M10socketheadcapscrews

andangenuts.

4. Duetostackupofparttolerances,exibility,and

backlashinthelinearbearings,thechangermight

seleslightly,orsagfromhorizontalonitsmounng

system.Thisisnormal.Compensateforminorsagby

lngthemountslightlysothetooltrayappearslevel

usingabubblelevel.

Note: Be sure to adjust the mount so that the mill

spindle cover sheet metal clears the ATC linear rail.

5. Reroutethecoolanthosebymounngthecoolant

hoseclamptotheincludedcoolantplate.Aachthe

platetotheundersideofthespindleheadusingthe

twothreadedholesontheundersideofthespindle

headcasng.

67

UM10081_TTS_ATC_PCNC1100_1013A UM10081_TTS_ATC_PCNC1100_1013A

3. ELECTRICAL INSTALLATION

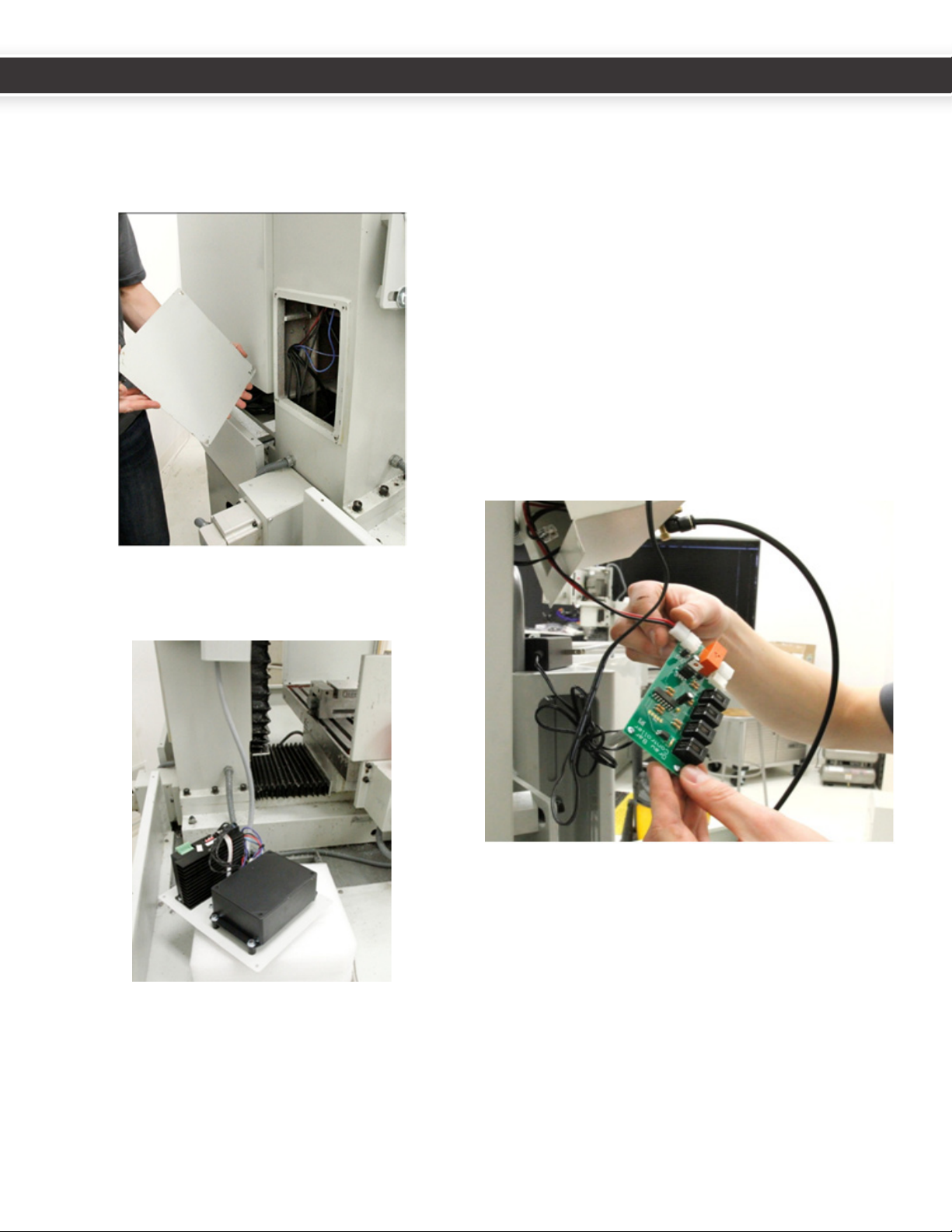

1. Removethefourcolumncoverplatescrewsfrombase

ofcolumnatthebackofthemill.TheZcolumncover

platewillbereplacedwiththeATCcontrolmodule.

Save the screws.

2. LaytheATCcontrolmoduleplatewithsolenoid

sidedownonthechiptrayortheYaxisbearingbox

temporarily.

3. Removethepowerdrawbarelectricalhousing(Zaxis

motorconneconboxcoverplate).

Bar control circuit board.

CircuitboardslabeledRev1.2willneedtobereplaced.In

thiscaseTormachshouldhaveincludedtheupdatedcircuit

boardwithyourATC.

• Toreplaceanold(Rev1.2orearlier)circuitboard,

disconnectandremovetheoldcircuitboard,taking

noteofthelocaonsoftheconnectors.Whilenot

necessary,youmaynditeasiertoremovetheair

linesandthecablecarrieraswell.

• Replacetheolddrawbarboardwiththenewone.

Itiseasiesttoreplacethesolenoidleads(redand

blackwire)beforere-mounngthecircuitboard.The

solenoidleadsgototheoppositesideofboardfrom

otherconnectors.Thisistheonlyconnectoronthat

side(2pinnylon).

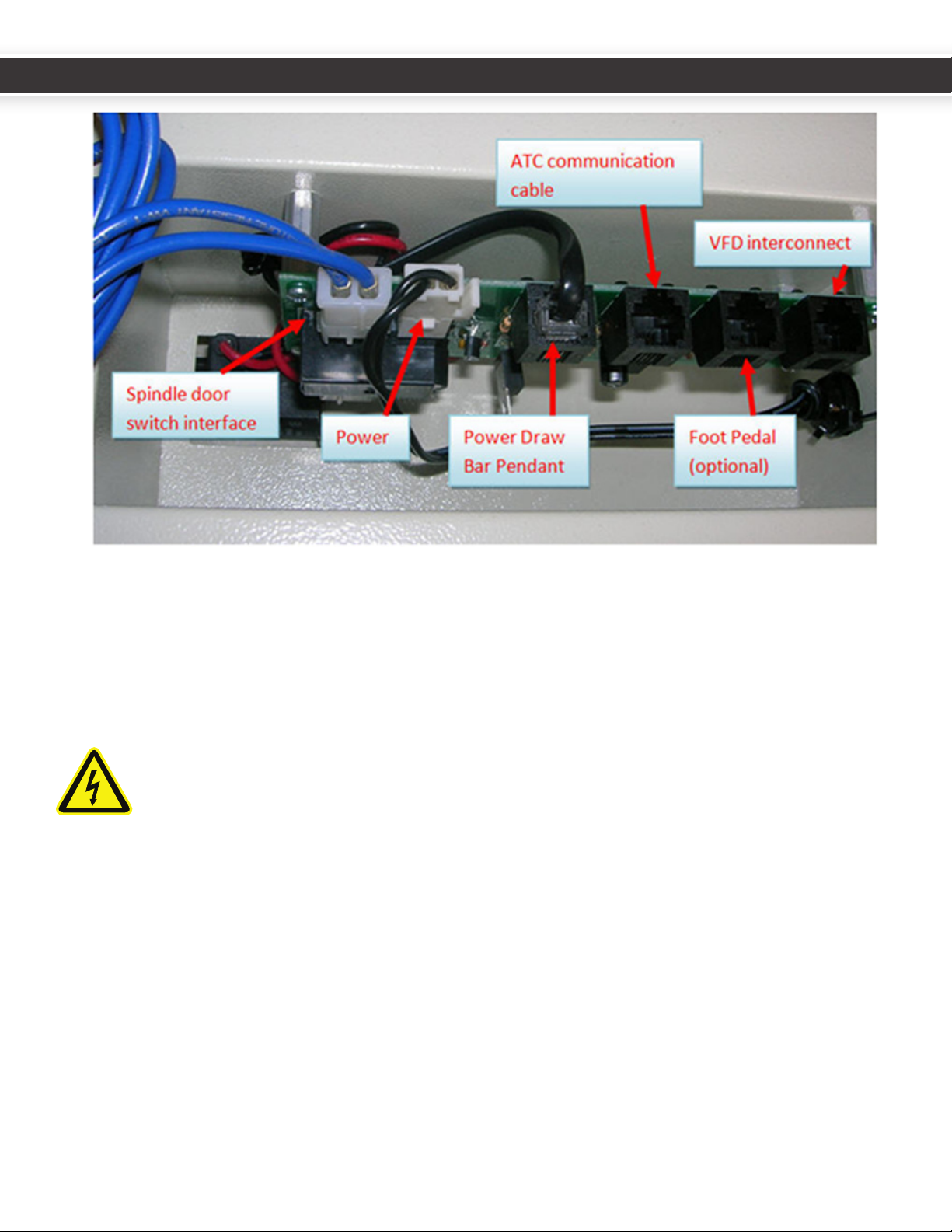

ConnecttheblackVFDinterconnectRJ11cable(withthe

spadeterminalends)totheDB1connectoronthepower

drawbarcontrolboard,andtheATCcommunicaonRJ11

cabletotheDB3connectorasshowninthefollowing

gure.

67

UM10081_TTS_ATC_PCNC1100_1013A UM10081_TTS_ATC_PCNC1100_1013A

4. Removetheold“wallwart”powerconnectorandreplaceitwithwires501,502.Thesewireswillberoutedtothe

newDCBusBoard,andyouwillbeabletothrowoutthewallwartpowersupply.

supply.

5. Routeallwires(thetwoRJ11cables,thebluespindledoorswitchinterfacewires,andthepowerwires503,504)

throughthemillcolumn.

COLUMN. THESE WIRES CARRY 110V AC AND IN RARE CASES CAN CAUSE EMF THAT

DISTURBS USB SIGNAL TRANSMISSION WHEN THEY ARE NOT TWISTED. TWISTING THE

WIRES CANCELS THIS EMF.

89

UM10081_TTS_ATC_PCNC1100_1013A UM10081_TTS_ATC_PCNC1100_1013A

6. Re-securethedrawbarelectricalhousingtotheZaxis

motorconneconboxcoverplate).

7. ConnecttheATCcommunicaonRJ11cable(fromthe

DB3connectoronthepowerdrawbarcircuitboard)

andtheUSBcabletotheATCcontrolboard.

8. DropanyslackwiresfromtheATCcontrolmoduleinto

theZcolumn,andsecuretheATCcontrolmoduleto

thebackofthemillusingthesavedM5screwsand

intoexisngcolumnholes.Besurethatextrawire

slackdoesnotcontacttheYaxisballscrew.

9. RoutetheUSBcablethroughtheboomholeofthe

electriccabinetintoanyPCUSBport.

CAUTION! DO NOT CONNECT THE USB

CABLE TO THE COMPUTER UNTIL AFTER

THE SOFTWARE INSTALLATION IS

COMPLETE.

your electrical cabinet to route the USB cable to your

control computer.

10.RuntheblueATCcontrolboardpowerleads(503,504)

andthepowerdrawbarcircuitboardpowerleads

(501,502)throughthewirechannelsfromtheholeto

thebusboardatthetopofthecabinet.

11.Series31100machinescomewiththecorrectDCBus

BoardforusewiththeATC.Series3ownerscanskip

steps12-13.Domakesuretoinstallthe5x20mmfuses

intheDCBusBoardATCandPDBfuseholders.This

appliestoallmodelmachines.

89

UM10081_TTS_ATC_PCNC1100_1013A UM10081_TTS_ATC_PCNC1100_1013A

12. PCNC 1100 MACHINES SERIAL NUMBERS 1999 AND

LOWER: ReplacetheoldDCbusboard(PN30661)with

thenewbusboard(PN32005).Ensureallfusesare

presentontheDCBusBoardbeforeinstallaon(there

shouldbenoemptyfuses).WhenremovingtheoldDC

busboard,catchthestandosandsavethescrews.

Replacewiththenewboardonthesamestandos.

Itisextremelyhelpfultotackgluethestandosin

placebeforemounngtheboard.Aneasywaytodo

thisistoputadabofhotglueonthefastenersbefore

inserngthemthroughtheboardholesandstandos.

13.Double-checkthepolarityofthecapacitor,stepper

driver,andATCconneconsbeforepoweringupthe

machine.Reversingpolaritywilldestroythestepper

driversandATCcontrolboard.

14.Installthepowerdrawbardaughterboardpower

supply(PN31980)byslidingitontothespade

connectorsonthenewDCbusboard(PN32005).This

boardsuppliesthe12Vneededbythepowerdrawbar,

andwillallowyoutothrowawaythewallwartpower

supplythatcamewiththepowerdrawbar.

15.RoutetheRJ11VFDinterconnectcablealongthe

boomwiretraytotheVFD.RemovetheVFDcover

byunscrewingthePhillipsfasteneronthefaceofthe

coverplate.

10 11

UM10081_TTS_ATC_PCNC1100_1013A UM10081_TTS_ATC_PCNC1100_1013A

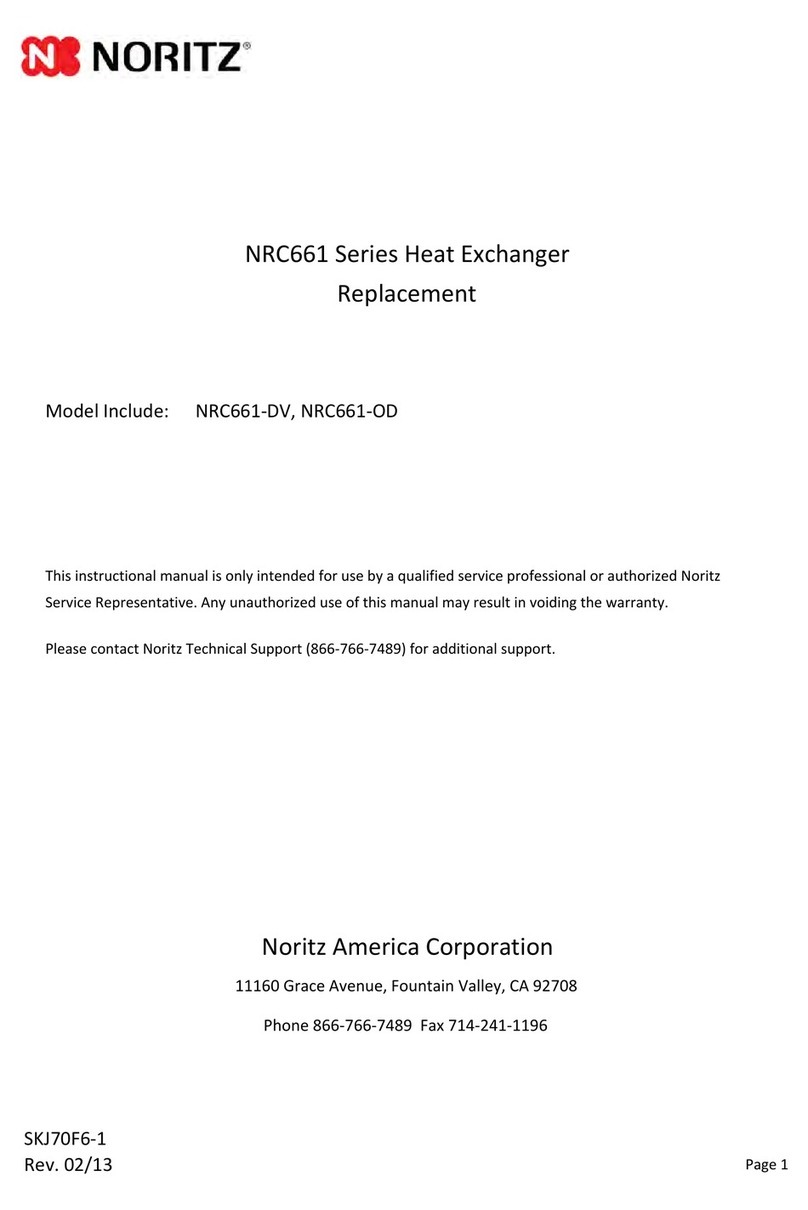

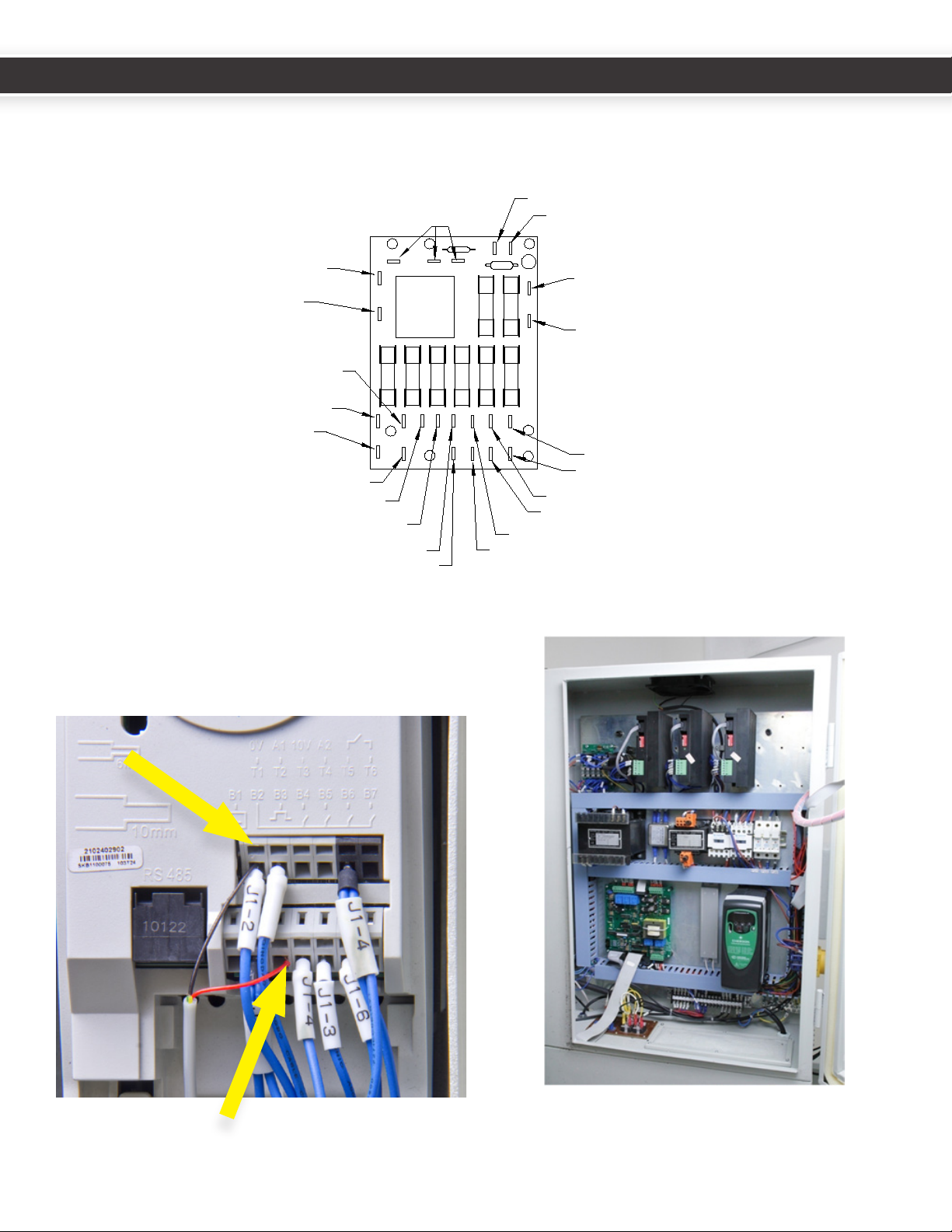

32005 DC BUS

Lables and wire numbers

X+ 302

X- 303

Y+ 304

Y- 305

Z+ 306

Z- 307A+ 324

A- 325

BRAKE RLY+ 328

BRK- 327

BRAKE RLY- 329

BRK+ 326

J2-48VAC L15

J1-48VAC L25 CAP- 300

CAP+ 301

8 A

8 A

8 A

8 A

2 A

8 A

15 A

8 A

503 Optional ATC +

504 Optional ATC -

501 Optional PDB -

502 Optional PDB +

DAUGHTERBOARD

FOR OPTIONAL PDB

F1 = X AXIS

F2 = Y AXIS

F3 = Z AXI

F4 = A AXIS

F5 = DC BRAKE

F6 = MAIN

F7 = PDB

F8 = ATC

F7

F6

F1

F2

F3

F4

F5

F8

S

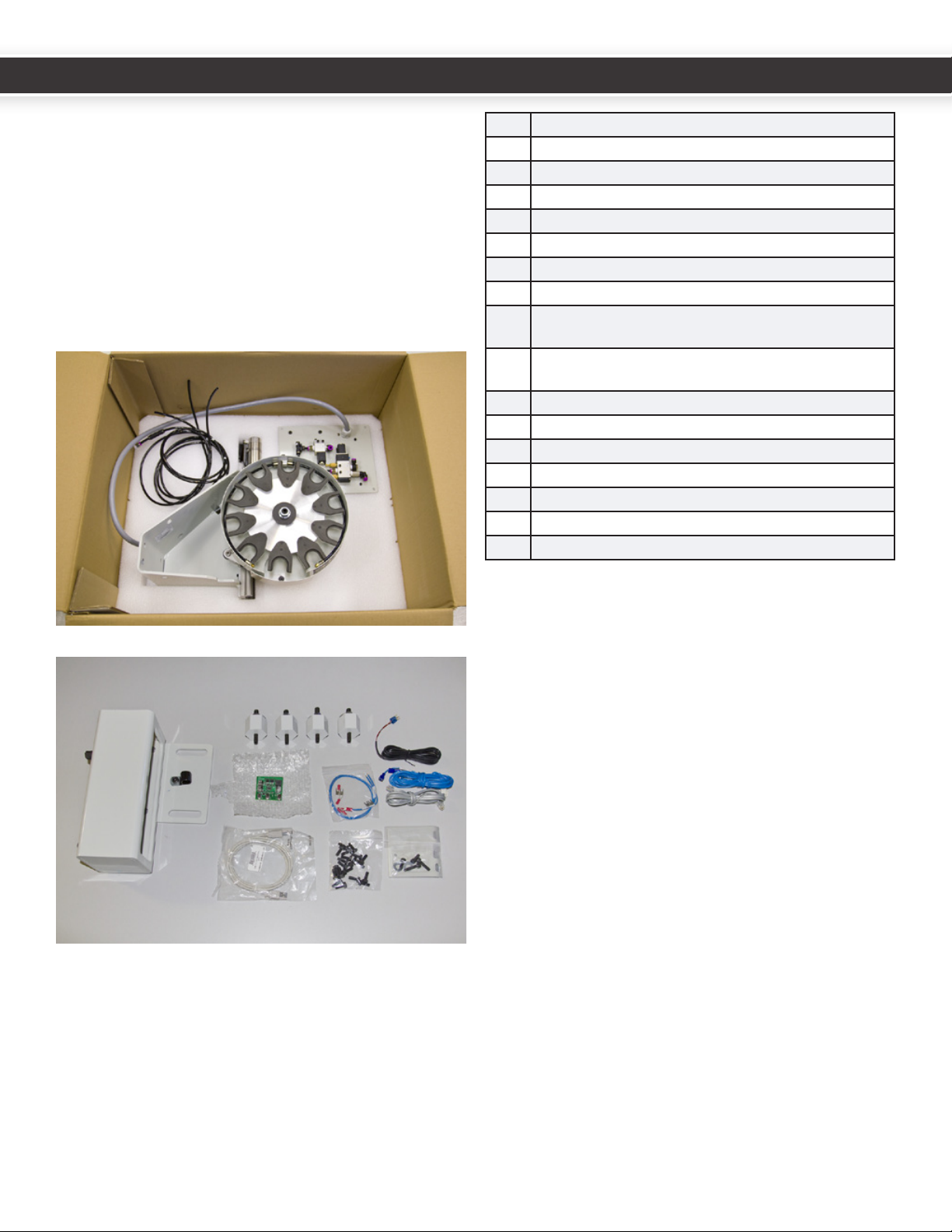

16.InserttheblackandredwiresoftheRJ-11cableinto

posionsT1andB3ontheVFDfor1100machines.To

maketheseconnecons,insertasmallatheadscrew

driverintheholejustabovethewireterminaltoopen

the terminal.

Tidyupthewiresandreplacethecabletraycovers.

Red Wire

to B3

Black Wire

to T1

10 11

UM10081_TTS_ATC_PCNC1100_1013A UM10081_TTS_ATC_PCNC1100_1013A

4. AIR LINES

4.1 Air Line Connection and

Requirements

Itisrecommendedtousealter/dryer/lubricatoronthe

airlineusedtosupplytheATC.Airsupplyrequirements

dependonfrequencyoftoolchanges.Forsuccessful

operaon,yourcompressorwillneedtobeableto

maintain95PSItotheATC.Typicallyconsumponfor

frequenttoolchangesislessthan4CFMat95PSI.

Pleasenotethatnotallregulatorsarecreatedequal.

Inexpensiveregulatorstendtoconstrictairow,which

makesforlongermake-upmesasthepowerdrawbar

res.Whilethisisnotaproblemforthepowerdrawbar

whenoperatedbyhand(theuserjustwaitstheextra

secondortwoforthecylindertofullypressurize),itcan

causeproblemswhenusingtheATC,whichonlypauses

500msbetweenthedrawbarringandthezaxismoving.

Beerregulatorsdonotrestricttheowwhileregulang

pressure.

Connecting the Air Lines

1. Manuallypullthetooltraytotheretractedposion

bypullingonthemotorenclosureoritwillretract

suddenlywhenyoupressurizetheairlines.

2. Routetheairlines.Thelinesarelabeledateachend-

connectthemtothesolenoids/ngswiththesame

labels.

3. Connecttheairlinefromyourcompressortothele

sideinputconnectorlabeled“AIR-IN”.Youcanremove

thepushnganduseaquickconnectagainstthe

rstteeifdesired,butwe’vefounditeasiertorun

tubingtoaquickconnectnginaneasier-to-reach

locaon.

4. Threadthe¼NPTpushngintotheairinputport

ofthepowerdrawbar.Connectthepowerdrawbar

airlinelabeled“D”(withtheaachedcheckvalve)

betweenthe“DRAWBAR”pushngontheright

sideoftheATCsolenoidpanelandthedrawbarinput

pushngonthedrawbarsolenoid.Thecheckvalve

allowsairtopassinonedirecononly–ifyouinstallit

backwardsthepowerdrawbarwillnotoperate.

5. Ifyouhavepurchasedtheoponalpressuresensor(PN

32329),spliceitintoairlineDandinserttheelectrical

connectorintothejackonthecolumncoverplateas

showninthisphoto:

6. UsetheP-clamptosecurethegreyATCcontrolcable

totheboxbeam,allowingenoughslackforthe

carousel’srangeofmoon:

12 13

UM10081_TTS_ATC_PCNC1100_1013A UM10081_TTS_ATC_PCNC1100_1013A

Thetraysolenoidshaveadjustmentscrewsthatallowyou

toadjusttrayinandtrayoutspeeds.Thesolenoidshave

beenpre-adjustedbeforeshipping.Aircushionpinvalves

ateitherendoftheaircylindercanbeadjustedtocontrol

dampingatextremeendsofcylindertravel.Thesearealso

pre-adjusted.Toolchangemeshouldnotbeadjustedto

lessthan8seconds.Conversely,movingtooslowlywill

triggeranerrorcondion.

Tray Solenoids

12 13

UM10081_TTS_ATC_PCNC1100_1013A UM10081_TTS_ATC_PCNC1100_1013A

5. SOFTWARE INSTALLATION

Youmaynowreapplypowertothemillandpoweron

yourcomputer.MakesurethattheUSBcabletotheATC

controllerisunpluggedforthenextsteps.

TheATCsowareinstallaonwilldeletethecontentsof

thePCNC3folderonyourCdrivebeforeinstallingthenew

soware.IfyouhavesavedpersonallesinthePCNC3

folder,copytheselestoafolderonyourdesktopbefore

youinstallthenewsoware.

TobegintheATCsowareinstallaon,makesure

thatMach3isshutdown,andinserttheCDintothe

computer’sCDdrive.Amenuwilldisplaychoicesfor1100

SeriesIIand1100Series3millingmachines.Choosethe

appropriatesowareforyourmachine.Thesoware

installaonshouldpreserveyourtooltable,xture

osets,andMachlicensele.Itwill,however,deleteany

changesyouhavemade(probepolarity,jogincrements,

NewFangledWizardlicensele).Ifyoupreviously

customizedyourversionofMach3usingPCNCCongyou

willneedtorepeatthesecustomizaonsaerinstallingthe

newsoware.

standard Tormach screens. Flash screens are no

14 15

UM10081_TTS_ATC_PCNC1100_1013A UM10081_TTS_ATC_PCNC1100_1013A

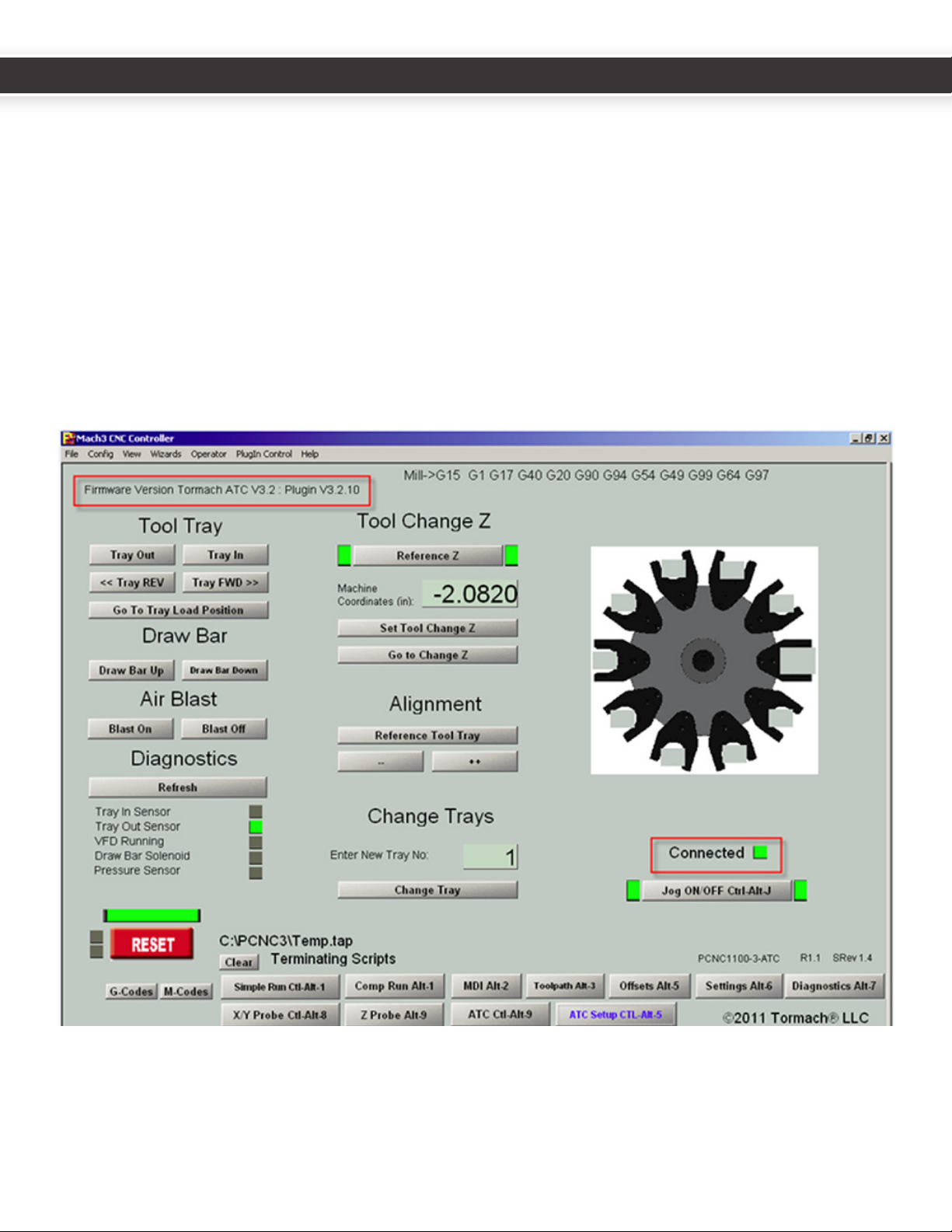

6. SYSTEM VALIDATION

ConnecttheUSBcablefromtheATCcontrollertothemill’scontrolcomputer.Startthecontrolsowareusingthe

PCNC1100-ATCicononthedesktop.Whenthesystemcomesup,itshouldndtheATCautomacallyontheUSBports

andcongureitself.YoushouldseeaconrmaonmessageonthemainMachscreenmessagelinethatdisplaysthe

sowareversion:

“ATCStartup–inialized”

AnswerYEStoscreenpromptsrequesngit’s“okaytoresetandreferencez”.WhenusingtheATC,thesepromptsalways

occuratstartup.Ingeneral,youshouldalwaysreferenceZimmediately.Thetoolchangerwillpromptduringexecuonif

youskipitnow.

ClickontheATCSetupbuononthelowerporonofthescreen.Notethattheupperlecornerdisplaysthermware

andpluginversions.ThegreenCONNECTEDlightshouldbeglowingtoindicateUSBcommunicaonisestablished.This

veriesthesowareinstallaonandtheUSBconnecon.

14 15

UM10081_TTS_ATC_PCNC1100_1013A UM10081_TTS_ATC_PCNC1100_1013A

WiththeZaxisinthehomed(highest)posion,perform

thefollowingteststoverifytheoperaonofthetool

changer:

1. ApplyathinlmofwayoiltothelinearrailsoftheATC

slideassembly.Somechaerisexpectedunltheoil

haslubricatedthelinearbearings.

2. OntheATCSetupscreen,click“TrayIn”,“TrayOut”

buonstoverifythatthetrayairlinesarecorrectand

thatthemagnecaircylindersensorsareproperly

working.Message“ATCbuonexecuted”aereach

buonpressveriesoperaoncompleon.

3. Withthetrayinthe“in”posion,clickthe“Refresh”

buonunder“Diagnoscs”ontheATCSetupscreen.

VerifythattheTrayInSensorLEDisilluminatedwhen

the tray is in.

4. RepeatStep3forTrayOutposion.Youwillneedto

clickthe“Refresh”buontoreadthesensors.

• IfeithertheTrayInorTrayOutsensorfailstorespond

asexpected,refertothe“SensorIssue”seconin

Maintenance and Troubleshoong.

5. WiththetrayoutjogtheZaxisdownacoupleof

inches.

square tube mount.

Clickthe“GotoTrayLoadPosion”.Thisshouldmove

theZaxisupandbringthetrayin.

6. Clickthe“ReferenceToolTray”buonontheATC

Setupscreen-itshouldndandcenteronitshome

switch.Itwillturnunlitndsoneendofthesensor,

thenreverseandndtheotherendofthesensor,and

thencenterbetweenthesetwospots.

7. Testthedrawbarpendant.

8. OntheATCSetupscreen,clicktheDrawBarUp,Draw

BarDownbuons.Thedrawbarshouldoperate

accordingly.

9. ClickDrawBarDownbuonontheATCsetupscreen.

Itshouldreandlatch.Nowhitthetop(Lock)buon

onthependant.Itshouldunlatch.

10.ClickBlaston,BlastoontheATCSetupscreen.You

shouldheartheairstartandstopatthenozzlesinthe

tooltray.

11.Withatoolinthespindleandthetrayintheout

posion,startthespindleatlowspeedinmanual

mode.Clickthe“Refresh”buonontheATCSetup

screen,andverifythattheVFDRunningLEDis

illuminated.

12.Oponalpressuresensorvericaon:Ifyouhave

installedthepressuresensoraccessory(PN32329)

youmayverifythatthePressureSensorLEDonthe

ATCSetupscreenisilluminatedunderlowpressure

condionsanddarkundernormalpressurecondions.

Youwillhavetoclickthe“Refresh”buontoseethe

LEDchangecorrespondingtoachangeinstate.

6.1 Align Tool Tray and

Slots

Accuratealignmentofthetooltrayandslots,andthe

drawbarthrow,arethemostimportantfactorsinassur-

ingreliableandrepeatabletoolchangeroperaon.Take

yourme,andtakecaretodothisaccurately.Avideoof

thealignmentprocedurecanbewatchedonourwebsite:

hp://www.tormach.com/upgrades_s_atc.html

1. ItishelpfultogettheATCassemblyapproximately

levelusingabubblelevelbeforebeginningthe

alignmentprocedure.

16 17

UM10081_TTS_ATC_PCNC1100_1013A UM10081_TTS_ATC_PCNC1100_1013A

2. Makesurethespindleisiniallyempty.Thereshould

benotoolholderinthespindleatthispoint.

3. Clickthe“GoToTrayLoadPosion”buonontheATC

Setupscreen.TheZaxiswilljogupandthetraywill

actuatein,openingthetoolaccessdoor,andthedraw

barwillactuate.

4. Verifythatthespindleisroughlyinthecenterofthe

carouseldooropening.Ifnecessary,movetheATC

forwardorbackwardbylooseningthefourangenuts

thatholdthesquaretubemounttothecolumn.

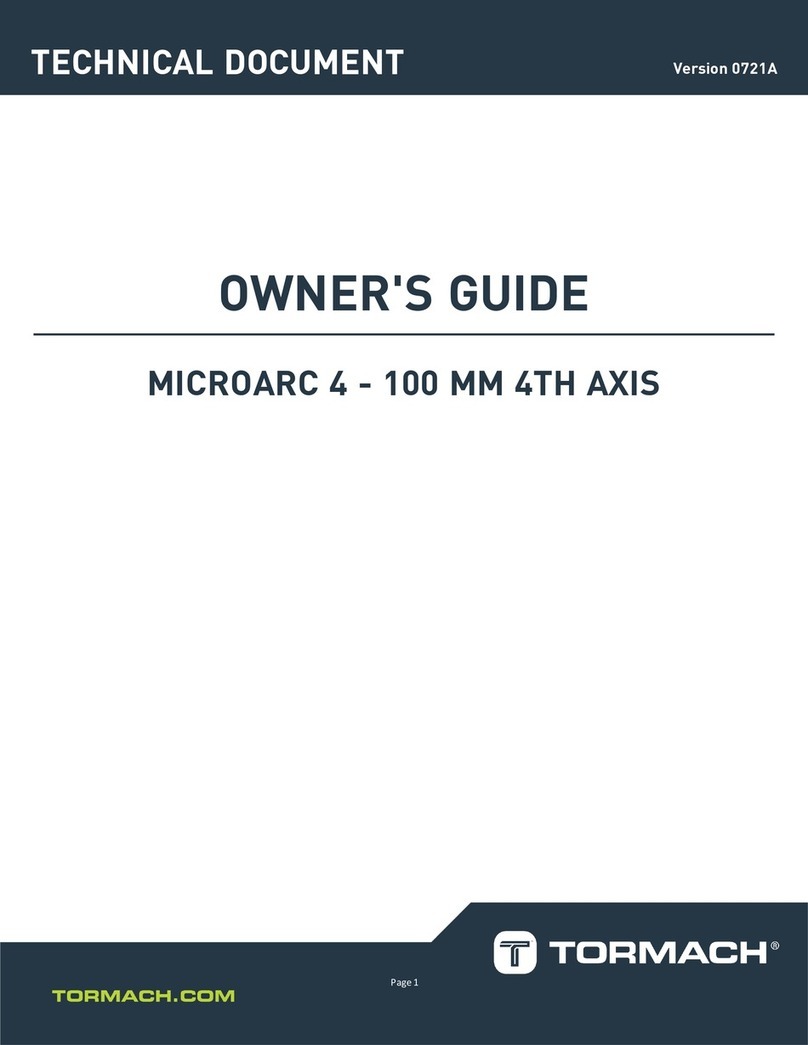

5. Insertalong(12-14”)dowelorpieceofroundstock

intoaTTStoolholder.Insertthetoolholderintothe

forkoftheexposedtrayslot.Usingothervercallines

(edgeofmilcolumn,Tslotsintable)sightalongthe

dowelandcheckwhetherthedowelandthespindle

axisareparallelinbothXandYplanes.

6. Ifthedowelandthespindleaxisarenotparallel,

adjusttheltoftheATCinbothXandYdirecons

unltheyare.

• TiltintheYdireconisfacilitatedbylooseningthe

angenutsthatholdthesquaretubemounttothe

column,thengentlytappingtheATCtrapezoidmount

with a mallet.

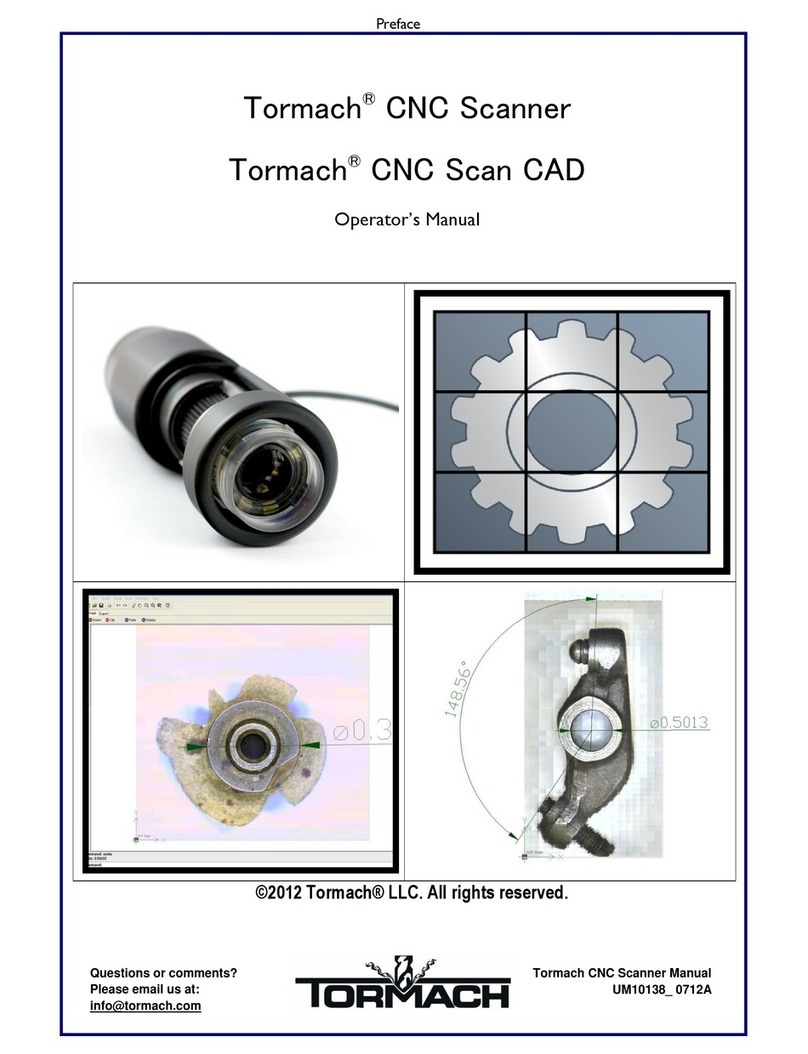

• TiltintheXdireconcanbeadjustedbyloosening

thesocketheadcapscrewsthatmounttheATCtothe

squaretube,thenturningtheeccentricadjustment

screws.ThisisbestdonewiththeATCinthe“Tray

In”posion,asthecenterofgravityoftheunitin

the“TrayIn”posionwillallowyoutouseboth

adjustmentscrewstolttheATC.

• Verifythatthetoolholdershankisparalleltothe

spindleaxisinbothXandYbyusinganangleblockor

1-2-3blockwithastraightedge:

16 17

UM10081_TTS_ATC_PCNC1100_1013A UM10081_TTS_ATC_PCNC1100_1013A

7. Onceyouaresasedthattheaxisofthedowelis

paralleltothespindleaxisinbothXandY,jogthe

spindledowntothetopoftheTormachtoolholder

shank.Donotgoallthewaydowntotheshoulderyet.

Verifybyeyethatitisroughlycenteredonthecollet

centeropening.

• Toadjustthealignmentofthetoolholdertothecollet

intheXdirecon,loosenthejamnutattheendofthe

traycylinderrodandmoveittoaroughlycentered

posion.Press“TrayIn”toverifytheadjustment.You

willlikelyhavetorepeatthisprocedureseveralmes

togetthelocaoncorrect.

• Toadjustthealignmentofthetoolholdertothecollet

intheYdirecon,usethe“--“or“++”-buonsonthe

ATCSetupscreenAlignmentsecon.Itisbesttowiggle

theforkwithyourthumbandindexngertofeelthe

extremesofthecarouselbacklashagainstthespindle

withyourngerstoseethatitisroughlycenteredle

andrightofforkwhilemakingthisadjustment.

18 19

UM10081_TTS_ATC_PCNC1100_1013A UM10081_TTS_ATC_PCNC1100_1013A

Other manuals for ATC

2

Table of contents

Other Tormach Industrial Equipment manuals

Tormach

Tormach PCNC 770 User manual

Tormach

Tormach Automatic Tool Changer User manual

Tormach

Tormach 770M User manual

Tormach

Tormach CNC Scanner User manual

Tormach

Tormach MICROARC 4 User manual

Tormach

Tormach 1100MX User manual

Tormach

Tormach 770MX User manual

Tormach

Tormach 51136 User manual

Tormach

Tormach 33318 Technical manual

Tormach

Tormach ATC User manual

Tormach

Tormach Slant-PRO 15L User manual

Tormach

Tormach PCNC 440 Technical manual

Tormach

Tormach 37335 User manual

Tormach

Tormach 24R User manual

Tormach

Tormach Slant-PRO 15L User manual

Tormach

Tormach 1100MX User manual

Tormach

Tormach 35550 Technical manual

Tormach

Tormach PCNC 1100 Deluxe Stand User manual