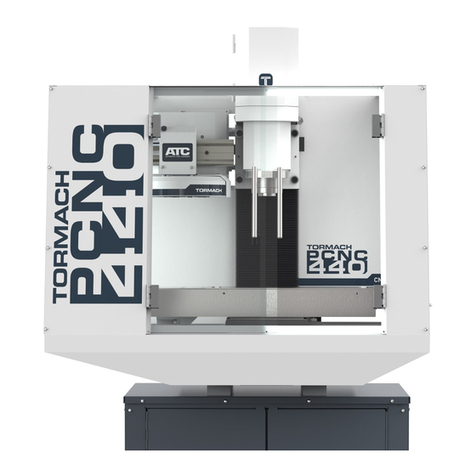

Tormach Automatic Tool Changer User manual

TECHNICAL DOCUMENT Version 1220A

OWNER'S GUIDE

MMACHINE AUTOMATIC TOOL CHANGER

(ATC) RETROFIT FOR PCNC 770 SERIES 3

Page 1

TECHNICAL DOCUMENT

IMPORTANT! Please read this section before you begin installing your Automatic Tool Changer (ATC).

lPower Drawbar Install the Power Drawbar on your machine before installing the ATC. If you have a

Power Drawbar button, don't install it: the button's functionality is replaced by the ATC.

lPathPilot You must update your controller to the latest version of PathPilot before installing and

operating the ATC. If you don't, there's a risk that the ATC could become inoperable. Follow the

instructions detailed in "Before You Begin" (on the next page).

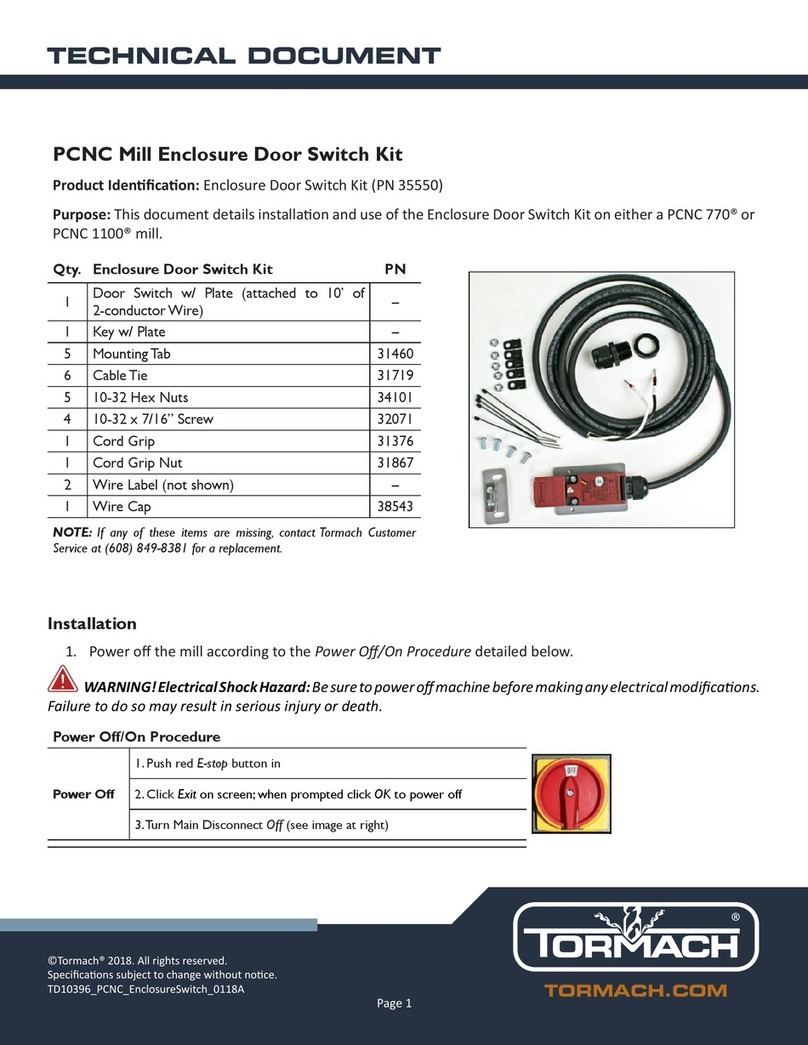

PURPOSE

This document gives instructions on installing and using an Automatic Tool Changer (ATC)for PCNC 1100 Series 3.

PRODUCT INFORMATION

Product: Automatic Tool Changer (ATC)for PCNC 1100 Series 3 (PN39009)

The Automatic Tool Changer (ATC) holds up to 10 tools in a single tray. If your program requires more tools, the

ATC changes tools automatically for all tools assigned to the tray, and pauses for a manual tool change for all tools

not assigned to the tray.

Automatic Tool Changer (ATC)for 770M

Quantity Description

1 ATCAssembly

3 Fixed Standoff Assembly (PN35832)

10 Plastic Screw (PN32173)

1 Tilt Standoff Assembly (PN35911)

MMachine ATC Retrofit for PCNC 770 Series 3 (PN39006)

Quantity Description

3 5/16-18 × 3/4 Socket Head Cap Screw (PN39010)

3 M8 × 1.25 - 20 Socket Head Cap Screw (PN39307)

1 ATCLegacy Adapter Cable (PN38661)

1Coolant Hose Bracket Kit for PCNC 770 (PN 37259)

1 MMachine ATC Carousel Plate Spacer (PN39005)

Note: If any items are missing, we can help. Email support@tormach.com to contact Tormach Technical

Support for guidance on how to proceed.

Page 2

©Tormach® 2020

Specifications subject to change without notice.

tormach.com

TD10560: Owner's Guide: M ATC Retrofit for PCNC 770 Series 3 (1220A)

TECHNICAL DOCUMENT

BEFORE YOU BEGIN

1. If there's a tool holder in the spindle, remove it.

2. Remove any accessories or fixtures from the machine table.

3. Center the machine table: from the PathPilot interface, in the MDILine DRO field, type G20 G53 G1 X7

Y-3.75 Z0 F20. Then select the Enter key.

IMPORTANT! You must update your controller to the latest version of PathPilot before installing and

operating the Automatic Tool Changer. If you don't, there's a risk that the ATC could become

inoperable.

4. Update your controller:From the Status tab, select Update. Then, follow the on-screen instructions. Once

the controller is updated to the latest version of PathPilot, go to Step 5.

WARNING! Electrical Shock Hazard: You must power off the machine before making any electrical

connections. If you don't, there's a risk of electrocution or shock.

5. Power off the machine and the PathPilot controller.

a. Push in the Emergency Stop button on the operator panel, which removes power to motion control.

b. From the PathPilot interface, select Exit.

c. Turn the Main Disconnect switch to OFF on the side of the electrical cabinet.

Page 3

©Tormach® 2020

Specifications subject to change without notice.

tormach.com

TD10560: Owner's Guide: M ATC Retrofit for PCNC 770 Series 3 (1220A)

TECHNICAL DOCUMENT

SETUP

Complete the following steps in the order listed:

Required Tools 4

Air Requirements 4

Install the Automatic Tool Changer (ATC) 4

Make Final Alignments to the Automatic Tool Changer (ATC) 32

Required Tools

This procedure requires the following tools. Collect them before you begin.

Required Tools for Installation

l1-1/2 in. adjustable wrench

lMarker

lMetric hex wrench set

lPhillips screwdriver

lSmall, flat-head screwdriver

lSnips

lSocket wrench, and a 13 mm socket

Required Tools for Verification

lMachinist's square, between 6 in. and 9 in. (152 mm and 229 mm)

lStraight rod (for Tormach Tooling System (TTS) tool holder), between 8 in. and 12 in. (203 mm and 305 mm)

lTormach Tooling System (TTS) tool holder (for alignment rod)

Air Requirements

You must verify that the site conforms to the following air supply requirements.

lAir Pressure Between 90 psi and 120 psi (620 kPa to 825 kPa).

If the air supply is more than 120 psi (825 kPa), you must use a regulator.

lAir Volume At least 6 CFM at 90 PSI. Check with your plasma source manufacturer in case your model

requires more volume.

lDry Air We recommend using a compressed air dryer, desiccator, or filter between the air compressor and

the machine.

lLubricated Air You must lubricate the air with air tool oil.

Use the FRLFilter-Regulator-Lubricator (PN 32457) or similar for this purpose.

Install the Automatic Tool Changer (ATC)

Complete the following steps in the order listed:

Page 4

©Tormach® 2020

Specifications subject to change without notice.

tormach.com

TD10560: Owner's Guide: M ATC Retrofit for PCNC 770 Series 3 (1220A)

TECHNICAL DOCUMENT

Install the Air Cylinder 5

Mount the Automatic Tool Changer (ATC) Bracket 6

Install the Main Assembly 8

Level the Automatic Tool Changer (ATC) 8

Prepare the Machine 9

Examine Perpendicularity in the Y Direction 10

Examine Perpendicularity in the X Direction 11

Examine the Alignment of the Carousel Door Opening 12

Make Air Connections 14

Make Electrical Connections 15

Rewire the Power Drawbar Board 15

Connect the ATCLegacy Adapter Cable 17

Rewire the ATC Board 25

Verify the Installation 26

Adjust the Power Drawbar 28

Adjust the Drawbar Tension 28

Adjust the Initial Setup 29

Install the Air Cylinder

1. Attach the air cylinder on to the ATC main assembly.

Figure 1: Putting the air cylinder into the ATC main assembly.

Page 5

©Tormach® 2020

Specifications subject to change without notice.

tormach.com

TD10560: Owner's Guide: M ATC Retrofit for PCNC 770 Series 3 (1220A)

TECHNICAL DOCUMENT

2. Secure the air cylinder to the ATC main assembly with a 12 mm hex wrench (provided) and two M14 × 20

mm socket head cap screws.

Figure 2: Putting the air cylinder hardware into the air cylinder.

3. Connect the air lines from the ATC main assembly to the air cylinder as follows:

lConnect the short air line to the front of the cylinder.

lConnect the long air line to the back of the cylinder.

Mount the Automatic Tool Changer (ATC) Bracket

1. Identify the four provided standoffs that are used to mount the ATC to the Z-column:

lThree fixed standoffs

lOne tilt standoff

2. Remove the flange nuts and the washers from the standoffs, and then set them aside.

3. Identify and remove the four set screws on the Z-column with a flat-blade screwdriver.

Page 6

©Tormach® 2020

Specifications subject to change without notice.

tormach.com

TD10560: Owner's Guide: M ATC Retrofit for PCNC 770 Series 3 (1220A)

TECHNICAL DOCUMENT

4. Install the four standoffs on the Z-column as shown in the following image.

Figure 3: Four standoffs installed on the Z-column.

5. Securely tighten the standoffs on the Z-column with a 1-1/2 in. adjustable wrench.

6. Put the ATC mounting bracket on the standoff's threaded studs as shown in the following image.

Figure 4: ATC mounting bracket moving on to the four standoffs.

Note: Verify that the tilt standoff's eccentric cam fits into the large slot on the ATC mounting

bracket.

Page 7

©Tormach® 2020

Specifications subject to change without notice.

tormach.com

TD10560: Owner's Guide: M ATC Retrofit for PCNC 770 Series 3 (1220A)

TECHNICAL DOCUMENT

7. Secure the bracket by reinstalling the washers and flange nuts that you removed in Step 2 with a 13 mm

socket.

8. Pull the bracket toward the front of the machine. You'll make adjustments to the location of the bracket

later in this procedure, but we recommend starting with it moved forward.

Install the Main Assembly

1. Remove the four preinstalled M8 × 1.25 - 16 mm socket head cap screws and washers from the bottom of

the ATC electrical cabinet. Then, set all aside for later use.

CAUTION! Team Lift Required:You must have the aid of more than one person to lift and move the

object. The object is heavy, and lifting it by yourself can cause serious injury.

2. Lift the ATC main assembly on to the mounting bracket.

Figure 5: ATC main assembly positioned above the mounting bracket.

3. Align the locating pin on the ATC main assembly with the matching hole in the mounting bracket.

4. Secure the ATC main assembly to the mounting bracket with the four M8 × 1.25 - 16 mm socket head cap

screws and washers that you set aside in Step 1.

Level the Automatic Tool Changer (ATC)

This section gives instructions to roughly level the ATC on the machine by using a long, straight rod. More

adjustments are made later in the installation procedure.

NOTICE! After the initial installation, you must level the ATC. If you don't, there's a risk of machine damage.

Complete the following steps in the order listed:

Prepare the Machine 9

Page 8

©Tormach® 2020

Specifications subject to change without notice.

tormach.com

TD10560: Owner's Guide: M ATC Retrofit for PCNC 770 Series 3 (1220A)

TECHNICAL DOCUMENT

Examine Perpendicularity in the Y Direction 10

Examine Perpendicularity in the X Direction 11

Examine the Alignment of the Carousel Door Opening 12

Prepare the Machine

1. Push the tool tray toward the spindle.

Figure 6: Tool tray moved in toward the spindle.

2. Verify that the linear bearing on the ATC is flush with the ATC main assembly.

Figure 7: Linear bearing flush with the ATC main assembly.

Page 9

©Tormach® 2020

Specifications subject to change without notice.

tormach.com

TD10560: Owner's Guide: M ATC Retrofit for PCNC 770 Series 3 (1220A)

TECHNICAL DOCUMENT

3. Find a straight rod between 8 in. and 12 in. (203 mm and 305 mm) long. Verify that it's straight: roll it on a

known flat surface (like a granite surface plate).

Note: You'll use the rod to verify that the ATC is correctly installed on the mill, so it must be

straight.

4. Put the alignment rod into a tool holder.

5. Put the tool holder into the fork so that the groove in the tool holder slides into the fork. Don't rest the tool

holder on top of the fork.

Figure 8: Groove on a Tormach Tooling System (TTS) aligned with the shoulder of an ATC fork.

6. Put a machinist's square on the machine table.

Examine Perpendicularity in the Y Direction

1. Verify that the rod is perpendicular to the machine table in the Y direction: compare the rod's position to the

vertical edge of the machinist's square.

lIf the rod is perpendicular to the vertical edge of the machinist's square, go to "Examine

Perpendicularity in the X Direction" (on the next page).

lIf the rod must be adjusted, go to Step 2.

2. Loosen the flange nuts on the standoffs.

Page 10

©Tormach® 2020

Specifications subject to change without notice.

tormach.com

TD10560: Owner's Guide: M ATC Retrofit for PCNC 770 Series 3 (1220A)

TECHNICAL DOCUMENT

3. Turn the tilt standoff with an adjustable wrench, and slowly pivot the ATC until the rod is perpendicular to

the vertical edge of the machinist's square.

Figure 9: Tilt standoff.

4. Tighten the flange nuts with a 13 mm socket.

5. Reexamine the alignment of the ATC in the Y direction. If the rod isn't perpendicular to the vertical edge of

the machinist's square, repeat Steps 2 through 5.

Examine Perpendicularity in the X Direction

1. Verify that the rod is perpendicular to the machine table in the X direction: compare the rod's position to the

vertical edge of the machinist's square.

lIf the rod is perpendicular to the vertical edge of the machinist's square, go to "Examine the

Alignment of the Carousel Door Opening" (on the next page).

lIf the rod must be adjusted, go to Step 2.

Page 11

©Tormach® 2020

Specifications subject to change without notice.

tormach.com

TD10560: Owner's Guide: M ATC Retrofit for PCNC 770 Series 3 (1220A)

TECHNICAL DOCUMENT

2. Loosen the two socket head cap screws on the linear rails.

Figure 10: Socket head cap screws on the linear rails.

3. Slowly pivot the linear rails up or down until the rod is perpendicular to the vertical edge of the machinist's

square.

4. Tighten the socket head cap screws.

5. Reexamine the alignment of the ATC in the X direction. If the rod isn't perpendicular to the vertical edge of

the machinist's square, repeat Steps 2 through 5.

Examine the Alignment of the Carousel Door Opening

1. Remove the tool holder from the fork, and set it aside.

Note: You'll need this tool later in the installation procedure to make further alignments.

2. Power on the machine and the PathPilot controller.

a. Turn the Main Disconnect switch to ONon the side of the electrical cabinet.

b. Twist out the Emergency Stop button on the operator panel, which enables movement to the machine

axes and the spindle.

c. Press the Reset button on the operator panel.

d. Bring the machine out of reset and reference it.

3. Verify that the ATC is all the way forward (toward the spindle), and then slowly move the Z-axis down (-Z) to

examine the clearance of the carousel door opening.

Page 12

©Tormach® 2020

Specifications subject to change without notice.

tormach.com

TD10560: Owner's Guide: M ATC Retrofit for PCNC 770 Series 3 (1220A)

TECHNICAL DOCUMENT

4. Verify that the carousel door opening is approximately equal to the front back and left of the spindle

mounting flange:

lIf the carousel door opening is approximately equal, go to Step 8.

Figure 11: Distance between the carousel door opening and the spindle mounting flange.

lIf the carousel door opening must be adjusted, go to Step 5.

5. Loosen the four socket head cap screws that secure the ATC main assembly to the mounting bracket with a 6

mm hex wrench.

Figure 12: Socket head cap screws securing the ATC main assembly to the mounting bracket.

Page 13

©Tormach® 2020

Specifications subject to change without notice.

tormach.com

TD10560: Owner's Guide: M ATC Retrofit for PCNC 770 Series 3 (1220A)

TECHNICAL DOCUMENT

6. Adjust the carousel door opening as required:

lIf the Carousel Door Opening is Contacting the Front Pivot the ATC around the locating pin on

the bottom of the mounting bracket toward the front of the machine (closer to you).

lIf the Carousel Door Opening is Contacting the Back Pivot the ATC around the locating pin on

the bottom of the mounting bracket toward the back of the machine (closer to the machine column).

lIf the Carousel Door Opening is Contacting the Left Loosen the four flange nuts that attach the

mounting bracket to the column to move the bracket forward or backward.

Note: Moving the ATC mounting bracket could change the position of the tilt standoff (on the

Z-column). If you move it, you must verify that the ATC is still correctly installed; go to

"Examine Perpendicularity in the Y Direction" (page10).

Repeat this step as needed.

7. Tighten the socket head cap screws and the flange nuts (if you loosened them in Step 5).

8. Move the tool tray to its retracted position.

9. Center the machine table: from the PathPilot interface, in the MDILine DRO field, type G20 G53 G1 X7

Y-3.75 Z0 F20. Then select the Enter key.

10. Power off the machine and the PathPilot controller.

a. Push in the Emergency Stop button on the operator panel, which removes power to motion control.

b. From the PathPilot interface, select Exit.

c. Turn the Main Disconnect switch to OFF on the side of the electrical cabinet.

Make Air Connections

1. Cut the cable tie that secures the ATC cables and plastic tubes together with snips.

2. Route the loose ends of the two 1/4 in. plastic tubes connected to the ATC main assembly through the

enclosure knockout, up the energy chain, and toward the Power Drawbar.

WARNING! Crush Hazard: If the ATC isn't completely retracted, it could move once the air is

reconnected. When you reconnect the air, you must keep your hands away from the ATC.

Page 14

©Tormach® 2020

Specifications subject to change without notice.

tormach.com

TD10560: Owner's Guide: M ATC Retrofit for PCNC 770 Series 3 (1220A)

TECHNICAL DOCUMENT

3. Connect the loose ends of the 1/4 in. plastic tubes in the following order:

a. Connect the Retract (PDBBottom) airline to the bottom push-to-connect elbow on the Power Drawbar.

b. Connect the Advance (PDBTop) airline to the top push-to-connect elbow on the Power Drawbar

c. Connect the air supply line from the FRL to the air in port in the ATC main assembly, as shown in the

following image.

Figure 13: Air in port in the ATC main assembly.

d. If you haven't already done so, connect your shop's air supply to the FRL.

Make Electrical Connections

Complete the following steps in the order listed:

Rewire the Power Drawbar Board 15

Connect the ATCLegacy Adapter Cable 17

Rewire the ATC Board 25

Rewire the Power Drawbar Board

If you previously installed the Power Drawbar board, you must rewire it.

To rewire the Power Drawbar board:

WARNING! Electrical Shock Hazard: You must power off the machine before making any electrical

connections. If you don't, there's a risk of electrocution or shock.

1. Power off the machine and the PathPilot controller.

Page 15

©Tormach® 2020

Specifications subject to change without notice.

tormach.com

TD10560: Owner's Guide: M ATC Retrofit for PCNC 770 Series 3 (1220A)

TECHNICAL DOCUMENT

a. Push in the Emergency Stop button on the operator panel, which removes power to motion control.

b. From the PathPilot interface, select Exit.

c. Turn the Main Disconnect switch to OFF on the side of the electrical cabinet.

2. Open the electrical cabinet door.

3. Locate blue wires 105 and 105A on the terminal block in the electrical cabinet.

Figure 14: Current wire configuration on the terminal block.

4. Remove blue wires 105 and 105A.

5. Locate red wire 105A on the terminal block. Then, remove it.

Note: During the original procedure to install the Power Drawbar, wire 105 was given a new label,

making it wire 105A.

6. Connect red wire 105A to the slot opposite red wire 105 on the terminal block.

Figure 15: New wire configuration on the terminal block.

Page 16

©Tormach® 2020

Specifications subject to change without notice.

tormach.com

TD10560: Owner's Guide: M ATC Retrofit for PCNC 770 Series 3 (1220A)

TECHNICAL DOCUMENT

7. In the Power Drawbar control assembly box, locate the blue spindle door interlock wires on the Power

Drawbar board. Then, unplug them.

Figure 16: Current wire configuration on the Power Drawbar board.

8. Pull the loose blue spindle door interlock wires from the Power Drawbar control assembly box, through the Z

column, and out of the machine. Then, discard them.

9. In the Power Drawbar control assembly box, locate the power wire connector on the Power Drawbar board.

Then, unplug it.

10. Pull the loose power wire from the Power Drawbar control assembly box and out of the machine. Then,

discard it.

11. In the Power Drawbar control assembly box, locate the VFD interconnect cable (from DB1) on the Power

Drawbar board. Then, unplug it.

Connect the ATCLegacy Adapter Cable

1. Connect the ATCLegacy Adapter Cable to the ATC power cable on the main assembly.

2. Route the loose wires from the ATCLegacy Adapter Cable out of the enclosure and toward the electrical

cabinet on the back of the machine.

Page 17

©Tormach® 2020

Specifications subject to change without notice.

tormach.com

TD10560: Owner's Guide: M ATC Retrofit for PCNC 770 Series 3 (1220A)

TECHNICAL DOCUMENT

3. Use any open access hole in the bottom of the electrical cabinet to route the loose wires into the electrical

cabinet.

Figure 17: Access hole in the bottom of the electrical cabinet.

4. Remove the wire trough covers in the electrical cabinet.

Page 18

©Tormach® 2020

Specifications subject to change without notice.

tormach.com

TD10560: Owner's Guide: M ATC Retrofit for PCNC 770 Series 3 (1220A)

TECHNICAL DOCUMENT

5. Identify wires T1 and B5 on the ATCLegacy Adapter Cable. Then, route them through the wire troughs

toward the variable frequency drive (VFD).

Figure 18: VFD in the electrical cabinet.

Page 19

©Tormach® 2020

Specifications subject to change without notice.

tormach.com

TD10560: Owner's Guide: M ATC Retrofit for PCNC 770 Series 3 (1220A)

TECHNICAL DOCUMENT

6. Use a Phillips screwdriver to remove the cross-head screw on the VFD, and then remove the VFD faceplate.

Figure 19: Removing the faceplate from the VFD.

7. If you previously installed the Power Drawbar board, you must remove the VFDinterconnect cable. Identify

it on the VFD and remove it. Then, pull the loose cable out of the machine, and discard it.

Figure 20: VFDinterconnect cable connected to the VFD.

Page 20

©Tormach® 2020

Specifications subject to change without notice.

tormach.com

TD10560: Owner's Guide: M ATC Retrofit for PCNC 770 Series 3 (1220A)

This manual suits for next models

2

Table of contents

Other Tormach Industrial Equipment manuals

Tormach

Tormach 1100MX User manual

Tormach

Tormach PCNC 440 Technical manual

Tormach

Tormach 24R User manual

Tormach

Tormach CNC Scanner User manual

Tormach

Tormach 770M User manual

Tormach

Tormach PCNC 770 User manual

Tormach

Tormach ATC User manual

Tormach

Tormach Slant-PRO 15L User manual

Tormach

Tormach 35550 Technical manual

Tormach

Tormach 51136 User manual